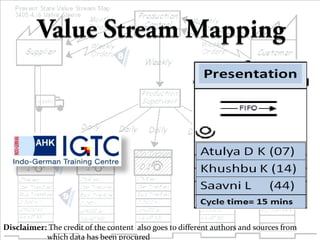

Value Stream Mapping (VSM)

•Transferir como PPTX, PDF•

2 gostaram•4,534 visualizações

Its a perfect little presentation on the precise steps followed under value stream mapping(VSM) done to apply and implement LEAN system in an organization in the most effective and efficient manner

Denunciar

Compartilhar

Denunciar

Compartilhar

Recomendados

Recomendados

Value stream mapping is a practical and highly effective way to learn to see and resolve disconnects, redundancies, and gaps in how work gets done.

This VSM project template helps you and your project team to put together a "storyboard" for effective presentation to your key stakeholders. It includes four key phases:

1) Define and pick product/service family

2) Create a current state map

3) Develop a future state map

4) Develop an implementation plan

This document consists of a VSM project template in Powerpoint format and a set of Excel templates comprising VSM charter, Results table, Implementation Plan and common VSM icons.Value Stream Mapping Project Template by Operational Excellence Consulting

Value Stream Mapping Project Template by Operational Excellence ConsultingOperational Excellence Consulting

Mais conteúdo relacionado

Mais procurados

Value stream mapping is a practical and highly effective way to learn to see and resolve disconnects, redundancies, and gaps in how work gets done.

This VSM project template helps you and your project team to put together a "storyboard" for effective presentation to your key stakeholders. It includes four key phases:

1) Define and pick product/service family

2) Create a current state map

3) Develop a future state map

4) Develop an implementation plan

This document consists of a VSM project template in Powerpoint format and a set of Excel templates comprising VSM charter, Results table, Implementation Plan and common VSM icons.Value Stream Mapping Project Template by Operational Excellence Consulting

Value Stream Mapping Project Template by Operational Excellence ConsultingOperational Excellence Consulting

Mais procurados (20)

Value Stream Mapping Project Template by Operational Excellence Consulting

Value Stream Mapping Project Template by Operational Excellence Consulting

Value Stream Transformation: Achieving Excellence through Leadership Alignmen...

Value Stream Transformation: Achieving Excellence through Leadership Alignmen...

Destaque

Destaque (20)

Value Stream Mapping in Office & Service Setttings

Value Stream Mapping in Office & Service Setttings

Managing Marketing Processes_Marketing Plan Assignment

Managing Marketing Processes_Marketing Plan Assignment

Intro to User Journey Mapping for Building Better Websites - WordCamp Ottawa...

Intro to User Journey Mapping for Building Better Websites - WordCamp Ottawa...

Applying Design Thinking Principles in Product Management

Applying Design Thinking Principles in Product Management

Kanban 101 - 1 - Perfection, Waste and Value Stream Mapping

Kanban 101 - 1 - Perfection, Waste and Value Stream Mapping

Value stream mapping for non manufacturing environments

Value stream mapping for non manufacturing environments

Operational Excellence Management Systems: 10 things you must get right!

Operational Excellence Management Systems: 10 things you must get right!

Semelhante a Value Stream Mapping (VSM)

Semelhante a Value Stream Mapping (VSM) (20)

Introduction to Business Process Analysis and Redesign

Introduction to Business Process Analysis and Redesign

Formatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrma...

Formatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrmatrma...

Application of value stream mapping tool to reduce wastes in bearing industry

Application of value stream mapping tool to reduce wastes in bearing industry

Process choice and layout decisions in manufacturing and services

Process choice and layout decisions in manufacturing and services

Process choice and layout decisions in manufacturing and services

Process choice and layout decisions in manufacturing and services

Have you tried to lean your IT Service Management? by Daniel Breston

Have you tried to lean your IT Service Management? by Daniel Breston

Último

Your voice, smiling, facial expressions, body language, and genuine Hospitality are tightly connected. Always strive to be a Hospitality service professional.

The importance of Smiling is vital in the hospitality industry. People who were or are being raised and educated on digital devices have not had the opportunity to learn and use the necessary and multiple communication skills the way previous generations did. It's a lost art that needs to be presented to the generations that followed the Baby Boomers. These are the generations alive today: Generation X, Generation Y (Millennials), Generation Z, and Generation Alpha.W.H.Bender Quote 62 - Always strive to be a Hospitality Service professional

W.H.Bender Quote 62 - Always strive to be a Hospitality Service professionalWilliam (Bill) H. Bender, FCSI

Saudi Arabia [ Abortion pills) Jeddah/riaydh/dammam/+966572737505☎️] cytotec tablets uses abortion pills 💊💊

How effective is the abortion pill? 💊💊 +966572737505) "Abortion pills in Jeddah" how to get cytotec tablets in Riyadh " Abortion pills in dammam*💊💊

The abortion pill is very effective. If you’re taking mifepristone and misoprostol, it depends on how far along the pregnancy is, and how many doses of medicine you take:💊💊 +966572737505) how to buy cytotec pills

At 8 weeks pregnant or less, it works about 94-98% of the time. +966572737505[ 💊💊💊

At 8-9 weeks pregnant, it works about 94-96% of the time. +966572737505)

At 9-10 weeks pregnant, it works about 91-93% of the time. +966572737505)💊💊

If you take an extra dose of misoprostol, it works about 99% of the time.

At 10-11 weeks pregnant, it works about 87% of the time. +966572737505)

If you take an extra dose of misoprostol, it works about 98% of the time.

In general, taking both mifepristone and+966572737505 misoprostol works a bit better than taking misoprostol only.

+966572737505

Taking misoprostol alone works to end the+966572737505 pregnancy about 85-95% of the time — depending on how far along the+966572737505 pregnancy is and how you take the medicine.

+966572737505

The abortion pill usually works, but if it doesn’t, you can take more medicine or have an in-clinic abortion.

+966572737505

When can I take the abortion pill?+966572737505

In general, you can have a medication abortion up to 77 days (11 weeks)+966572737505 after the first day of your last period. If it’s been 78 days or more since the first day of your last+966572737505 period, you can have an in-clinic abortion to end your pregnancy.+966572737505

Why do people choose the abortion pill?

Which kind of abortion you choose all depends on your personal+966572737505 preference and situation. With+966572737505 medication+966572737505 abortion, some people like that you don’t need to have a procedure in a doctor’s office. You can have your medication abortion on your own+966572737505 schedule, at home or in another comfortable place that you choose.+966572737505 You get to decide who you want to be with during your abortion, or you can go it alone. Because+966572737505 medication abortion is similar to a miscarriage, many people feel like it’s more “natural” and less invasive. And some+966572737505 people may not have an in-clinic abortion provider close by, so abortion pills are more available to+966572737505 them.

+966572737505

Your doctor, nurse, or health center staff can help you decide which kind of abortion is best for you.

+966572737505

More questions from patients:

Saudi Arabia+966572737505

CYTOTEC Misoprostol Tablets. Misoprostol is a medication that can prevent stomach ulcers if you also take NSAID medications. It reduces the amount of acid in your stomach, which protects your stomach lining. The brand name of this medication is Cytotec®.+966573737505)

Unwanted Kit is a combination of two medicines, whiAbortion pills in Jeddah |• +966572737505 ] GET CYTOTEC![Abortion pills in Jeddah |• +966572737505 ] GET CYTOTEC](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Abortion pills in Jeddah |• +966572737505 ] GET CYTOTEC](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Abortion pills in Jeddah |• +966572737505 ] GET CYTOTECAbortion pills in Riyadh +966572737505 get cytotec

Último (16)

Marketing Management 16th edition by Philip Kotler test bank.docx

Marketing Management 16th edition by Philip Kotler test bank.docx

How Software Developers Destroy Business Value.pptx

How Software Developers Destroy Business Value.pptx

Reviewing and summarization of university ranking system to.pptx

Reviewing and summarization of university ranking system to.pptx

W.H.Bender Quote 62 - Always strive to be a Hospitality Service professional

W.H.Bender Quote 62 - Always strive to be a Hospitality Service professional

digital Human resource management presentation.pdf

digital Human resource management presentation.pdf

internship thesis pakistan aeronautical complex kamra

internship thesis pakistan aeronautical complex kamra

Abortion pills in Jeddah |• +966572737505 ] GET CYTOTEC![Abortion pills in Jeddah |• +966572737505 ] GET CYTOTEC](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Abortion pills in Jeddah |• +966572737505 ] GET CYTOTEC](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Abortion pills in Jeddah |• +966572737505 ] GET CYTOTEC

Leaders enhance communication by actively listening, providing constructive f...

Leaders enhance communication by actively listening, providing constructive f...

Beyond the Codes_Repositioning towards sustainable development

Beyond the Codes_Repositioning towards sustainable development

Gautam Buddh Nagar Call Girls 🥰 8617370543 Service Offer VIP Hot Model

Gautam Buddh Nagar Call Girls 🥰 8617370543 Service Offer VIP Hot Model

Siliguri Escorts Service Girl ^ 9332606886, WhatsApp Anytime Siliguri

Siliguri Escorts Service Girl ^ 9332606886, WhatsApp Anytime Siliguri

Value Stream Mapping (VSM)

- 1. Disclaimer: The credit of the content also goes to different authors and sources from which data has been procured

- 2. Value • "Value" is what the customer is buying • A capability provided to a customer of the highest quality, at the right time, at an appropriate price, as defined by the customer.

- 3. • Planning tool to optimize results by eliminating waste • Removes wasted steps and improves productivity • Non value adding activities: Scrapping, Sorting, Storing, Counting, Moving, Documentation etc. • Value adding activities :Machining, Processing, Painting, Assembling Value Stream Mapping

- 4. Why ? Provide optimum value to the customer through a complete value creation process with minimum waste in: Design (concept of customer needs) Build (order to delivery) Sustain (in-use through life cycle to service)

- 5. • Flowchart • Depicts and improves the flow and processing of inventory • Usage of symbols (the language of lean). • Usually includes People, Tools and technologies, Physical facilities, Communication channels How ?

- 6. What flows? “ITEMS” flow in a value stream In manufacturing, materials are the items In service, external customer needs are the items

- 7. Symbols used in VSM

- 8. Generally VSM has four major steps as given by Rother and Shook (1996): • Lean production means continuous improvement, we must keep on changing future state into current state

- 10. Lean Production uses Takt Time as the time in which we get a finished product or assembly. If you have a Takt Time of two minutes that means every two minutes a complete product or assembly is produced off the line. Takt Time Takt Time = Available time/ customer demand

- 11. Welding process: Takt Time = Available time/ customer demand = 27 *1320 *60/50000 = 42.7 sec. Complete cycle time of welding (CT+LT): Number of working days - 27 Net working time per day - 1320 min. Demand for month - 50000 Welding Cycle time - 43 sec Lead time - 8 sec Welding Production per day - 1320*60 / (43+8) =1550 parts per day (should be 1854) Example of one of the improvements It is found that cycle time of complete welding process exceeds the takt time so there is need to improve the process capability of welding process to meet the demand of customer within the time. We are improving the cycle time of welding process by introducing a new welding machine and by improving layout of weld shop. Cycle time before improvement = 43sec. Cycle time after improvement = 22 sec. % improvement in production = (2600 – 1550)/1550 There is near about 67% improvement by improvement in value adding activities.

- 13. Some wastes of LEAN eliminated by VSM: Overproduction Defects Motion Waiting Long Transportation Routes Underutilized people Extra Processing Inventory

- 14. It helps to visualize the station cycle times, inventory at each stage, manpower and information flow across the supply chain. Enables a company to ‘see’ the entire process in both its current and desired future state Bridges the gap between the current state and the future state. Gives a better value to the customer Conclusion

- 15. Danke!!

Notas do Editor

- -give an example of dell server to server communication.-

- Build:Assemble to orderMake to orderEngineer to orderSustain: after sales services

- Internal and External CustomersEvery organisation has internal and external customers and The Hanley is no exception.External customers: who are they?- The needs of these people may be:- To receive good quality customer service.- To receive useful and professional advice.- To be kept up-to-date on their accounts/mortgages.Internal customers: who are they?- People who work for The organization.To members of staff, their colleagues, sometimes in different departments, are also their customers.The needs of these people may be:- To have a good environment to work in.- To have the correct resources to work with.- To be trained to correct standard to be able to do their job

- To withdraw from a previous processLoad level- intermediate steps at a constant rate so that further also constantPhysical pull- from supermarkets the materials have to be pulled physically into kittings.

- Source: International Journal of Innovative Technology and Exploring Engineering (IJITEE) ISSN: 2278-3075, Volume-1, Issue-2, July 2012

- -3 shifts a day of total 22 hrs. (1320 mins)

- -Daily schedule was not needed-inventory was held only for 7 days rather than 15 days.-SAP communication directly with planning department, made easy the task of keeping track of the process and the time taken by then in the complete process.-the time for inventory being held between intermediary quality check and welding has been reduced to 1 day from 3 days-Inventory has been under control (RM and finished goods both) by communication with SAP-we are improving the cycle time of welding process by introducing a new welding machine and by improving layout of weld shop.