Lecture+2+MB+and+degrees+of+freedom++calculations (5).pdf

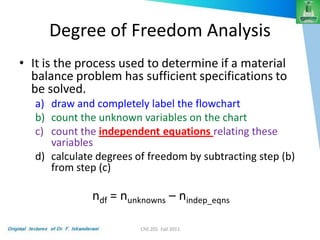

- 1. Degree of Freedom Analysis • It is the process used to determine if a material balance problem has sufficient specifications to be solved. a) draw and completely label the flowchart b) count the unknown variables on the chart c) count the independent equations relating these variables d) calculate degrees of freedom by subtracting step (b) from step (c) ndf = nunknowns – nindep_eqns 1 ChE 201 Fall 2011

- 2. Degree of Freedom Analysis ndf = nunknowns – nindep_eqns • If ndf = 0, problem can be solved (in principle). • if ndf > 0, problem is underspecified and at least ndf additional variables must be specified before the remaining variable values can be determined. • if ndf < 0, the problem is overspecified with redundant and possibly inconsistent relations. 2 ChE 201 Fall 2011

- 3. Degree of Freedom Analysis • Sources of equations relating unknown process stream variables include: – Material balances. For a nonreactive process, no more than nms (number of molecular species or components ) independent material balances may be written. – Energy balance. An energy balance provides a relationship between inlet and outlet material flows and temperatures. (We will see this in ChE 301) – Process specifications. – Physical properties and laws. – Physical constraints. – Stoichiometric relations. (for reacting systems) 3 ChE 201 Fall 2011

- 4. • A stream of humid air enters a condenser in which 95% of the water vapor in the air is condensed. • The flow rate of the condensate (liquid leaving the condenser) is measured and found to be 225 L/h. • Calculate the flow rate of the gas stream leaving the condenser and the mole fractions of O2, N2, and H2O. 4 ChE 201 Fall 2011 Degree of Freedom Analysis Example 1 condenser

- 5. • 6 unknowns – 3 material balances (1 each for O2, N2, H2O) – condensate volumetric to molar flow relation (MW and ρ) – process specification: 95% of the water is condensed • ndf = 6 – (3 + 1 + 1) = 1 Underspecified cannot solve 5 ChE 201 Fall 2011 Degree of Freedom Analysis Example 1 condenser

- 6. Degree of Freedom Analysis • 5 unknowns – 3 material balances (1 each for O2, N2, H2O) – condensate volumetric to molar flow relation (MW and ρ) – process specification: 95% of the water is condensed • ndf = 5 – (3 + 1 + 1) = 0 Solvable 6 ChE 201 Fall 2011 Example 2 condenser

- 7. • Density relationship • 95% condensation specification • O2 Balance • N2 Balance • H2O Balance • outlet gas composition • total outlet gas flow rate 5 4 3 total total 5 O H total 4 N total 3 O 5 2 1 4 1 3 1 1 2 kg 10 0 . 18 O H ol m 1 L O H kg h O H L 2 n n n n n n y ; n n y ; n n y n n 100 . 0 n n 79 . 0 900 . 0 n n 21 . 0 900 . 0 n n 100 . 0 95 . 0 n 00 . 1 225 n 2 2 2 3 2 ) l ( 2 ) l ( 2 7 ChE 201 Fall 2011 Degree of Freedom Analysis condenser

- 8. 20% CB CC CD 100% CA CC 100% CA CB CC 100% CA CB 30% CC CD 100% F1 =10 mole/hr F3 F2 F4 Find the number of degrees of freedom Let us count unknown variables Degree of Freedom Analysis Example 3

- 9. 20% CB CC CD 100% CA CC 100% CA CB CC 100% CA CB 30% CC CD 100% F1 =10 mole/hr F3 F2 F4 1 2 3 4 5 6 7 8 9 Find the number of degrees of freedom Degree of Freedom Analysis Example 3

- 10. • 9 unknowns – 4 material balances (1 each for C1, C2, C3, C4) • ndf = 9 – (4) = 5 Degree of Freedom Analysis Example 3

- 11. Material Balance General Procedure – Single Unit operation 1. Choose as a basis of calculation an amount or flow rate of one of the process streams. – If an amount or flow of a stream is given, it is usually convenient to use it as the basis of calculation. Subsequently calculated quantities will be correctly scaled. – If several stream amounts or flows are given, always use them collectively as the basis. – If no stream amount or flow rate is specified, take as a basis an arbitrariy amount or flow rate of a stream with a known composition. 11 ChE 201 Fall 2011

- 12. General Procedure – Single Unit Op 2. Draw flowchart and fill in all variable values, including the basis. Label unknown stream variables. – Flowchart is completely labeled if you can express the mass / mass flow rate (moles / molar flow rate) of each component of each stream in terms of labeled quantities. – Labeled variables for each stream should include 1 of: a. total mass (or flow), and mass fractions of all stream components b. total moles (or flow), and mole fractions of all stream components c. mass, moles (or flow) of each component in each stream • use (c) if no steam information is known – incorporate given relationships into flowchart – label volumetric quantities only if necessary 12 ChE 201 Fall 2011

- 13. General Procedure – Single Unit Op 3. Express what the problem statement ask you to do in terms of the labeled variables. 4. If given mixed mass and mole units, convert. 5. Do a degree-of-freedom analysis. 6. If ndf = 0, write equations relating unknowns. 7. Solve the equations in (6). 8. Calculate requested quantities. 9. Scale results if necessary. 13 ChE 201 Fall 2011

- 14. Distillation Column example • Ex. 4.3-5 1. basis is given as a volumetric quantity 2a. Flowchart drawn from description 2b. Convert mole to mass fractions 2c. no stream information known write in terms of species flows 14 ChE 201 Fall 2011

- 15. Distillation Column example • Ex. 4.3-5 2d. confirm every component mass flow in every process stream can be expressed in terms of labeled quantities and variables. 2e. process specification 15 ChE 201 Fall 2011

- 16. Distillation Column example • Ex. 4.3-5 3. write expressions for quantities requested in problem statement B T 3 3 B B x 1 x ; m m x 3 T 3 B 3 m m m 3 1 2 m m m 16 ChE 201 Fall 2011

- 17. Distillation Column example • Ex. 4.3-5 4. Convert mixed units in overhead product stream kg T kg 2 T kg B kg 2 B T kmol T kg B kmol B kg 058 . 0 942 . 0 1 y 942 . 0 mixture kg 7881 B kg 7420 y mixture kg 7881 T kg 461 B kg 7420 T kg 461 13 . 92 T kmol 0 . 5 B kg 7420 11 . 78 B kmol 0 . 95 17 ChE 201 Fall 2011

- 18. Distillation Column example • Ex. 4.3-5 5. Perform degree of freedom analysis =0.942 =0.058 4 unknowns -2 material balances -1 density relationship -1 process specification 0 degrees of freedom 18 ChE 201 Fall 2011

- 19. Distillation Column example • Ex. 4.3-5 6. Write system equations 7. Solve h kg L kg h L 1 1744 872 . 0 2000 m i. volumetric flow conversion h B kg 1 3 B 8 . 62 m 45 . 0 08 . 0 m ii. benzene split fraction h B kg 2 3 B 2 B 2 1 766 m m y m m 45 . 0 iii. benzene balance h T kg 3 T 3 T 2 B 2 1 915 m m y 1 m m 55 . 0 iv. toluene balance h kg h kg 3 T 3 B 2 1 1744 1744 m m m m iv. total mass balance (check) 19 ChE 201 Fall 2011

- 20. Distillation Column example • Ex. 4.3-5 8. Calculate additional quantities =0.942 =0.058 =1744 kg/h =915 kg T/h =62.8 kg B/h =766 kg/h h kg h T kg h B kg 3 978 915 8 . 62 m kg T kg 3 T kg B kg h kg h B kg 3 3 B 3 B 936 . 0 064 . 0 1 y 064 . 0 978 8 . 62 m m y 20 ChE 201 Fall 2011

- 21. Balances on Multiple Unit Ops • A system is any portion of a process that can be enclosed within a hypothetical box (boundary). It may be the entire process, a single unit, or a point where streams converge or combine. 21 ChE 201 Fall 2011

- 22. Balances on Multiple Unit Ops • Boundary A encloses the entire process. – inputs: Streams 1, 2, and 3 – products: 1, 2, and 3 – Balances on A would be considered overall balances – internal streams would not be included in balances 22 ChE 201 Fall 2011

- 23. Balances on Multiple Unit Ops • B: an internal mixing point (2 inputs, 1 product) • C: Unit 1 (1 input, 2 products) • D: an internal splitting point (1 input, 2 products) • E: Unit 2 (2 inputs, 1 product) 23 ChE 201 Fall 2011

- 24. Balances on Multiple Unit Ops • The procedure for solving material balances on multi-unit processes is the same as for a single unit; though, it may be necessary to perform balances on several process subsystems to get enough equations to determine all unknown stream variables. 24 ChE 201 Fall 2011

- 25. Two-Unit Process Example • Variables for Streams 1, 2, and 3 are unknown 25 ChE 201 Fall 2011

- 26. Two-Unit Process Example • Variables for Streams 1, 2, and 3 are unknown • Label unknown stream variables 26 ChE 201 Fall 2011

- 27. Two-Unit Process Example • Degree-of-freedom analysis – overall system: 2 unknowns – 2 balances = 0 (find m3, x3) – mixer: 4 unknowns – 2 balances = 2 – Unit 1: 2 unknowns – 2 balances = 0 (find m1, x1) – mixer: 2 unknowns – 2 balances = 0 (find m2, x2) 27 ChE 201 Fall 2011

- 28. Extraction-Distillation Process 28 ChE 201 Fall 2011

- 29. Simultaneously solve total mass and acetone balances to determine m1 and m3. Solve MIBK balance to determine xM1. Extraction-Distillation Process 29 ChE 201 Fall 2011

- 30. Solve acetone, MIBK, and water balances to determine mA4, mM4, and mW4. Extraction-Distillation Process 30 ChE 201 Fall 2011

- 31. For either (just 1) extractor unit, solve acetone, MIBK, and water balances to determine mA2, mM2, and mW2. Extraction-Distillation Process 31 ChE 201 Fall 2011

- 32. ndf = 4 unknowns (mA6, mM6, mW6, and m5) – 3 balances = 1 underspecified Extraction-Distillation Process 32 ChE 201 Fall 2011

- 33. ndf = 4 unknowns (mA6, mM6, mW6, and m5) – 3 balances = 1 underspecified Extraction-Distillation Process 33 ChE 201 Fall 2011