Denunciar

Compartilhar

Baixar para ler offline

Recomendados

Testing results of a multi-cavity mold for injection molding of MIM 4140 alloy are presented in the article. Recommendations for manufacturing of forming parts of the mold were given. Based on an implemented technological process of casting and subsequent laboratory researches an information was obtained about the condition of a casting (hardness on Super-Rockwell, shrinkage and quality of a surface layer of material before and after heat treatment). Calculated overall dimensions of the forming parts of the project mold will allow making forecast of shrinkage of MIM 4140 alloy after injection molding.Properties of MIM 4140 Alloy After Injection Molding and Sintering

Properties of MIM 4140 Alloy After Injection Molding and SinteringInternational Journal of Innovation Engineering and Science Research

Recomendados

Testing results of a multi-cavity mold for injection molding of MIM 4140 alloy are presented in the article. Recommendations for manufacturing of forming parts of the mold were given. Based on an implemented technological process of casting and subsequent laboratory researches an information was obtained about the condition of a casting (hardness on Super-Rockwell, shrinkage and quality of a surface layer of material before and after heat treatment). Calculated overall dimensions of the forming parts of the project mold will allow making forecast of shrinkage of MIM 4140 alloy after injection molding.Properties of MIM 4140 Alloy After Injection Molding and Sintering

Properties of MIM 4140 Alloy After Injection Molding and SinteringInternational Journal of Innovation Engineering and Science Research

Mais conteúdo relacionado

Mais procurados

Mais procurados (20)

Characterization of al sic metal matrix by stir-casting

Characterization of al sic metal matrix by stir-casting

IRJET-Fabrication And Testing Of Aluminium Metal Matrix Composites Through St...

IRJET-Fabrication And Testing Of Aluminium Metal Matrix Composites Through St...

ALUMINIUM METAL MATRIX COMPOSITE BY STIR CASTING METHODS

ALUMINIUM METAL MATRIX COMPOSITE BY STIR CASTING METHODS

A Review on Friction Stir Welding of Similar and Dissimilar Aluminium Alloys

A Review on Friction Stir Welding of Similar and Dissimilar Aluminium Alloys

Effect of Milling Time on Al-Fe-Cr-20 Wt. % Al2O3composite Prepared Through B...

Effect of Milling Time on Al-Fe-Cr-20 Wt. % Al2O3composite Prepared Through B...

Machining Of an Aluminum Metal Matrix Composite Using Tungsten Carbide Inserts

Machining Of an Aluminum Metal Matrix Composite Using Tungsten Carbide Inserts

IRJET- Evaluation of Mechanical and Wear Properties of Aluminium-Al2O3 Compos...

IRJET- Evaluation of Mechanical and Wear Properties of Aluminium-Al2O3 Compos...

REVIEW ON MECHANICAL PROPERTIES OF NON-ASBESTOS COMPOSITE MATERIAL USED IN BR...

REVIEW ON MECHANICAL PROPERTIES OF NON-ASBESTOS COMPOSITE MATERIAL USED IN BR...

HEAT TREATMENT EFFECT ON MECHANICAL PROPERTIES AND SEM ANALYSIS OF AL6061/WC/...

HEAT TREATMENT EFFECT ON MECHANICAL PROPERTIES AND SEM ANALYSIS OF AL6061/WC/...

Characterization and mechanical behaviour of similar and dissimilar parts joi...

Characterization and mechanical behaviour of similar and dissimilar parts joi...

Classification of Metals used in the Sand Casting Process

Classification of Metals used in the Sand Casting Process

Investigation of Mechanical Behavior of Aluminium Alloys Before and After Wor...

Investigation of Mechanical Behavior of Aluminium Alloys Before and After Wor...

Behaviour Aspects of Copper Slag and Steel Fibers in Concrete Subjected to De...

Behaviour Aspects of Copper Slag and Steel Fibers in Concrete Subjected to De...

WEAR STUDIES ON THE HEAT TREATED AL6061-μSIC AND AL6061-NSIC METAL MATRIX COM...

WEAR STUDIES ON THE HEAT TREATED AL6061-μSIC AND AL6061-NSIC METAL MATRIX COM...

A comparative investigation on physical and mechanical properties of mmc rein...

A comparative investigation on physical and mechanical properties of mmc rein...

Investigation of Mechanical Properties and Wear rate of Aluminium A356 -SiC M...

Investigation of Mechanical Properties and Wear rate of Aluminium A356 -SiC M...

Destaque

Destaque (19)

Applying supervised and un supervised learning approaches for movie recommend...

Applying supervised and un supervised learning approaches for movie recommend...

Steady state mathematical modeling of solid oxide fuel cell for hybrid system...

Steady state mathematical modeling of solid oxide fuel cell for hybrid system...

Fuel emissions correlation assessment of indoor pollutants from different hou...

Fuel emissions correlation assessment of indoor pollutants from different hou...

Semelhante a Ijmet 06 07_009

The main objective of this paper is to

determine casting defects generally happening in an

aluminium die casting process and efforts have been

taken to identify the tools which eliminate the casting

defects. In global prospective this study briefs the

application of the various tools that are used in the

industries for improvement of quality in foundry

industry. In our national prospective these tools are not

so popular, hence this study will help us to utilise the

available technology through which the productivity is

enhanced with safe and economical means. The QC

tools were used to analyse the casting condition of the

given pattern with three dimensional simulations for the

result preparation. This work has been carried out to

improve the quality of the pattern which is made with

gravity die casting process and this was achieved

through continuous quality control operation with QC

tools, then it was taken to test in some simulation

software. The latest trend available in casting and

foundry shops are the scientific approach in

optimization of all kind of fields including optimization

of defects in castings. These trends are incorporated in

the analysis of aluminium die casting.

Analysis of Gravity Die Casted Aluminium parts using MAGMA

Analysis of Gravity Die Casted Aluminium parts using MAGMAIJTRET-International Journal of Trendy Research in Engineering and Technology

Micro Structural Features Induced by Sheet Hydroforming of Non- Ferrous Metals and Alloys by Forouhandeh F in Research & Development in Material ScienceCrimson Publishers-Micro Structural Features Induced by Sheet Hydroforming of...

Crimson Publishers-Micro Structural Features Induced by Sheet Hydroforming of...CrimsonPublishersRDMS

Semelhante a Ijmet 06 07_009 (20)

Regression analysis of shot peening process for performance characteristics o...

Regression analysis of shot peening process for performance characteristics o...

A STUDY AND DESIGN ANALYSIS FOR INJECTION MOULD FOR PLASTIC BEARING

A STUDY AND DESIGN ANALYSIS FOR INJECTION MOULD FOR PLASTIC BEARING

Analysis of Gravity Die Casted Aluminium parts using MAGMA

Analysis of Gravity Die Casted Aluminium parts using MAGMA

Experimental Analysis on Wire Arc Additive Manufacturing

Experimental Analysis on Wire Arc Additive Manufacturing

Design of Experiment Machinability Evaluation of Dry Drilling Machinability o...

Design of Experiment Machinability Evaluation of Dry Drilling Machinability o...

Preparation and Characterization of Aluminium Foam Prepared through Melt Rout...

Preparation and Characterization of Aluminium Foam Prepared through Melt Rout...

Crimson Publishers-Micro Structural Features Induced by Sheet Hydroforming of...

Crimson Publishers-Micro Structural Features Induced by Sheet Hydroforming of...

DESIGN AND ANALYSIS OF AXIAL CROSSING OF WORK ROLLS IN ROLLING MILL WORK ROLL...

DESIGN AND ANALYSIS OF AXIAL CROSSING OF WORK ROLLS IN ROLLING MILL WORK ROLL...

Experimental Investigation for Mechanical Properties of Aluminium Alloy Al 60...

Experimental Investigation for Mechanical Properties of Aluminium Alloy Al 60...

Energy Absorption Characteristics of Thin Walled Metallic and Foam Filled Tub...

Energy Absorption Characteristics of Thin Walled Metallic and Foam Filled Tub...

IRJET- Improving the Performance of M42 Twist Drill Tool

IRJET- Improving the Performance of M42 Twist Drill Tool

IRJET- An Intelligent In -Vehicle Wireless Multilingual Over-Speed Announcer ...

IRJET- An Intelligent In -Vehicle Wireless Multilingual Over-Speed Announcer ...

EXPERIMENTAL INVESTIGATION ON MECHANICAL TESTING OF AL7085/ALUMINA NANO COMPO...

EXPERIMENTAL INVESTIGATION ON MECHANICAL TESTING OF AL7085/ALUMINA NANO COMPO...

IRJET - Characteristics of Butt Joint Produced by Friction Stir Welding Process

IRJET - Characteristics of Butt Joint Produced by Friction Stir Welding Process

Comparative study of tensile properties of forged hybrid alloys of aa6061 si...

Comparative study of tensile properties of forged hybrid alloys of aa6061 si...

IRJET- Tribological Evaluation of LM26 Aluminum Metal Matrix Composites.

IRJET- Tribological Evaluation of LM26 Aluminum Metal Matrix Composites.

Mais de IAEME Publication

Mais de IAEME Publication (20)

IAEME_Publication_Call_for_Paper_September_2022.pdf

IAEME_Publication_Call_for_Paper_September_2022.pdf

MODELING AND ANALYSIS OF SURFACE ROUGHNESS AND WHITE LATER THICKNESS IN WIRE-...

MODELING AND ANALYSIS OF SURFACE ROUGHNESS AND WHITE LATER THICKNESS IN WIRE-...

A STUDY ON THE REASONS FOR TRANSGENDER TO BECOME ENTREPRENEURS

A STUDY ON THE REASONS FOR TRANSGENDER TO BECOME ENTREPRENEURS

BROAD UNEXPOSED SKILLS OF TRANSGENDER ENTREPRENEURS

BROAD UNEXPOSED SKILLS OF TRANSGENDER ENTREPRENEURS

DETERMINANTS AFFECTING THE USER'S INTENTION TO USE MOBILE BANKING APPLICATIONS

DETERMINANTS AFFECTING THE USER'S INTENTION TO USE MOBILE BANKING APPLICATIONS

ANALYSE THE USER PREDILECTION ON GPAY AND PHONEPE FOR DIGITAL TRANSACTIONS

ANALYSE THE USER PREDILECTION ON GPAY AND PHONEPE FOR DIGITAL TRANSACTIONS

VOICE BASED ATM FOR VISUALLY IMPAIRED USING ARDUINO

VOICE BASED ATM FOR VISUALLY IMPAIRED USING ARDUINO

IMPACT OF EMOTIONAL INTELLIGENCE ON HUMAN RESOURCE MANAGEMENT PRACTICES AMONG...

IMPACT OF EMOTIONAL INTELLIGENCE ON HUMAN RESOURCE MANAGEMENT PRACTICES AMONG...

VISUALISING AGING PARENTS & THEIR CLOSE CARERS LIFE JOURNEY IN AGING ECONOMY

VISUALISING AGING PARENTS & THEIR CLOSE CARERS LIFE JOURNEY IN AGING ECONOMY

A STUDY ON THE IMPACT OF ORGANIZATIONAL CULTURE ON THE EFFECTIVENESS OF PERFO...

A STUDY ON THE IMPACT OF ORGANIZATIONAL CULTURE ON THE EFFECTIVENESS OF PERFO...

A STUDY ON TALENT MANAGEMENT AND ITS IMPACT ON EMPLOYEE RETENTION IN SELECTED...

A STUDY ON TALENT MANAGEMENT AND ITS IMPACT ON EMPLOYEE RETENTION IN SELECTED...

ATTRITION IN THE IT INDUSTRY DURING COVID-19 PANDEMIC: LINKING EMOTIONAL INTE...

ATTRITION IN THE IT INDUSTRY DURING COVID-19 PANDEMIC: LINKING EMOTIONAL INTE...

INFLUENCE OF TALENT MANAGEMENT PRACTICES ON ORGANIZATIONAL PERFORMANCE A STUD...

INFLUENCE OF TALENT MANAGEMENT PRACTICES ON ORGANIZATIONAL PERFORMANCE A STUD...

A STUDY OF VARIOUS TYPES OF LOANS OF SELECTED PUBLIC AND PRIVATE SECTOR BANKS...

A STUDY OF VARIOUS TYPES OF LOANS OF SELECTED PUBLIC AND PRIVATE SECTOR BANKS...

EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POL...

EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POL...

ROLE OF SOCIAL ENTREPRENEURSHIP IN RURAL DEVELOPMENT OF INDIA - PROBLEMS AND ...

ROLE OF SOCIAL ENTREPRENEURSHIP IN RURAL DEVELOPMENT OF INDIA - PROBLEMS AND ...

OPTIMAL RECONFIGURATION OF POWER DISTRIBUTION RADIAL NETWORK USING HYBRID MET...

OPTIMAL RECONFIGURATION OF POWER DISTRIBUTION RADIAL NETWORK USING HYBRID MET...

APPLICATION OF FRUGAL APPROACH FOR PRODUCTIVITY IMPROVEMENT - A CASE STUDY OF...

APPLICATION OF FRUGAL APPROACH FOR PRODUCTIVITY IMPROVEMENT - A CASE STUDY OF...

A MULTIPLE – CHANNEL QUEUING MODELS ON FUZZY ENVIRONMENT

A MULTIPLE – CHANNEL QUEUING MODELS ON FUZZY ENVIRONMENT

Último

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call Girl Aurangabad Indira Call Now: 8617697112 Aurangabad Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Aurangabad Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Aurangabad understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

From customer value engagements to hands-on production support, our Services span across every stage of our customers digital transformation journey, to help ensure that every customer is successful in their adoption of our solutions.

• Implementation, Upgrade, Migration, and Maintenance Services

• On-Premises and On-Cloud

• COTS Training Services; On-Site and Virtual

• Software Support Services; Legacy and 3DEXPERIENCE

• Value Engagement & Blueprinting

• Specialized Consulting and Support Services

• Customized Training Services

• Automation and Configuration Services

• Technical Resource Augmentation Services

• Project Management

• Know-how Training (mentoring) and Resource AugmentationNavigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...Arindam Chakraborty, Ph.D., P.E. (CA, TX)

Welcome to the April edition of WIPAC Monthly, the magazine brought to you by Water Industry Process Automation & Control.

In this month's edition, along with the latest news from the industry we have articles on:

The use of artificial intelligence and self-service platforms to improve water sustainability

A feature article on measuring wastewater spills

An article on the National Underground Asset Register

Have a good month,

OliverWater Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024Water Industry Process Automation & Control

Último (20)

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024

Block diagram reduction techniques in control systems.ppt

Block diagram reduction techniques in control systems.ppt

Ijmet 06 07_009

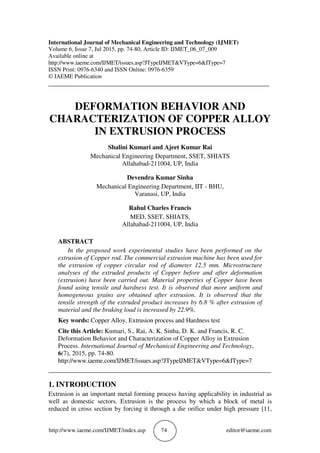

- 1. http://www.iaeme.com/IJMET/index.asp 74 editor@iaeme.com International Journal of Mechanical Engineering and Technology (IJMET) Volume 6, Issue 7, Jul 2015, pp. 74-80, Article ID: IJMET_06_07_009 Available online at http://www.iaeme.com/IJMET/issues.asp?JTypeIJMET&VType=6&IType=7 ISSN Print: 0976-6340 and ISSN Online: 0976-6359 © IAEME Publication ___________________________________________________________________________ DEFORMATION BEHAVIOR AND CHARACTERIZATION OF COPPER ALLOY IN EXTRUSION PROCESS Shalini Kumari and Ajeet Kumar Rai Mechanical Engineering Department, SSET, SHIATS Allahabad-211004, UP, India Devendra Kumar Sinha Mechanical Engineering Department, IIT - BHU, Varanasi, UP, India Rahul Charles Francis MED, SSET, SHIATS, Allahabad-211004, UP, India ABSTRACT In the proposed work experimental studies have been performed on the extrusion of Copper rod. The commercial extrusion machine has been used for the extrusion of copper circular rod of diameter 12.5 mm. Microstructure analyses of the extruded products of Copper before and after deformation (extrusion) have been carried out. Material properties of Copper have been found using tensile and hardness test. It is observed that more uniform and homogeneous grains are obtained after extrusion. It is observed that the tensile strength of the extruded product increases by 6.8 % after extrusion of material and the braking load is increased by 22.9%. Key words: Copper Alloy, Extrusion process and Hardness test Cite this Article: Kumari, S., Rai, A. K. Sinha, D. K. and Francis, R. C. Deformation Behavior and Characterization of Copper Alloy in Extrusion Process. International Journal of Mechanical Engineering and Technology, 6(7), 2015, pp. 74-80. http://www.iaeme.com/IJMET/issues.asp?JTypeIJMET&VType=6&IType=7 _____________________________________________________________________ 1. INTRODUCTION Extrusion is an important metal forming process having applicability in industrial as well as domestic sectors. Extrusion is the process by which a block of metal is reduced in cross section by forcing it through a die orifice under high pressure [11,

- 2. Deformation Behavior and Characterization of Copper Alloy in Extrusion Process http://www.iaeme.com/IJMET/index.asp 75 editor@iaeme.com 12]. Some of the important products of extrusion are rods of various cross sections, tubes, I-sections, channels etc. Extrusion is a hot-working process, which, like forging, rolling, etc., uses the good deformability of heated metallic materials for shaping them. The most important aspect of this process is that it enables considerable change of shape to be achievable in a single operation. Extrusion process is a means of dealing with metals and alloys whose metallurgical & mechanical properties renders them unsuitable for shaping by other manufacturing methods. With extrusion it is possible to form complex sections that cannot be produced by other methods of manufacturing. One of the current challenges faced by the manufacturing industry is to produce component of high strength, resistance to fatigue, heat corrosion and low production cost. Forming is one of the process, which bears the additional advantage of greater utilization of raw materials and high productivity apart from above advantage. Among the common forming processes extrusion-forging is a process where difficult to produce shapes, can be formed with better mechanical properties and net shape production can be achieved. The experimental works on plastic deformation [12, 14] and metal forming starting in France by Colomb and Tresca. In the early 20th century the research on plastic deformation flourished in German. Towards the 2nd half of the 20th century analysis of the metal forming process was developed and efficiently used in all over the world. Many researchers contributed remarkable findings towards the field of extrusion [16]. 2. EXPERIMENTAL STUDY AND CHARACTERIZATION In the previous chapter literature review on Extrusion process has been carried out so that the probable conditions for the experiments could be made and experiments can be carried out successfully for different metals and alloys and formability knowledge could be generated to help industries involved in continuous extrusion process [2−4, 6−9]. The results so obtained would be required to be validated the process under study so as to ensure the correctness of the theory and practice. In the extrusion process, extrusion ratio, extrusion velocity and pressure by intensifier can be set and calculated and the best condition for extrusion of an alloy or metal is found .It is desired that a defect free part is produced. All the products of different alloys or metals out of the fabricated and commercial extrusion set up have been formed and presented in section 3.2. Material characterization of the product samples such as microstructure analysis, tensile test and hardness test before and after deformation has been carried out in this chapter to predict the material properties of feedstock before and after extrusion. The experiment is done for the Copper feedstock for several extrusion speed and extrusion ratio and formability of Copper has been found very well after the experiments. Figures 1−3 show the extruded product of Copper at different velocity and extrusion ratio. Figure 3 show the commercial setup used for carrying out the experimentation of Copper feedstock at different velocity and extrusion ratio. Table 1 Chemical Composition of the Copper feedstock (C 101) used for extrusion experiments Elements % Composition Copper 99.99 Oxygen 0.0005

- 3. Shalini Kumari, Ajeet Kumar Rai, Devendra Kumar Sinha and Rahul Charles Francis http://www.iaeme.com/IJMET/index.asp 76 editor@iaeme.com Figure 1 Pure Copper rod feedstock before extrusion of 12.5 mm diameter Figure 2 Extruded Copper rod of 8mm diameter, extrusion ratio 3.18 3. CHARACTERIZATION In this section three more studies are introduced such as Microstructure analysis of the extruded products like Copper, Tensile test and Hardness test of the extruded products to examine the material properties and microstructure prior and after the deformation of the feedstock material. 3.1. Microstructure analysis of the raw material and extruded product In this section, the process of microstructure analysis of the extruded products through LOM (Light Optical Microscopy) method is explained .The Extrusion of Copper rod is carried out on the commercially available Extrusion set up TBJ 350. Metallography (Sample Preparation) of Samples The products of Copper extruded out using the commercially available setup are cut to a finite length using hacksaw as shown in Figure 3. Also samples of raw feedstock of Copper are prepared to study the microstructure of the material before and after deformation [13]. The aim of this section is to determine the probable extrusion speed and extrusion ratio at which the best microstructures are obtained. Figure 3 Microstructure samples of Copper rod before and after extrusion For microstructure analysis of any material, the faces of prepared samples on which microstructures is to be obtained are initially rubbed on emery papers of coarse, medium and fine grades in longitudinal and lateral directions so as to avoid any

- 4. Deformation Behavior and Characterization of Copper Alloy in Extrusion Process http://www.iaeme.com/IJMET/index.asp 77 editor@iaeme.com scratches and obtain mirror like faces before polishing of the samples. Polishing of the samples plays a vital role in the microstructure analysis of different materials. Some materials which are very soft such as Aluminum are very sensitive to pressure, therefore polishing of such kind of materials consumes much time as compared to other materials such as Copper and Brass. Polishing of the prepared samples are carried out till scratch free mirror like finish of the faces of the prepared samples are obtained. Velvet cloth, Brasso and Kerosene have been used while polishing of the prepared samples. During polishing of the prepared samples it has been found that polishing of Copper is easier as compared to the polishing of Aluminum samples. After polishing, the samples are etched using proper etchant. For Aluminum samples, Keller’s reagent (3 ml HCl, 5 ml HNO3, 2 ml HF, 190 ml water) has been used as etchant whereas for Copper samples Ferric chloride in suspension of hydro fluoric acid and water has been used as etchant. Finally, the polished scratch free samples are mounted on the slide and are placed under the microscope with different magnifications for obtaining microstructures of the prepared samples.. 3.2. Microstructure analysis of samples Different samples of Aluminum and Copper at various extrusion wheel velocity and extrusion ratio have been taken to study the microstructure and deformation characteristics. Measurement of grain size and its comparison before and after deformation (extrusion) is possible by using standard length at different places in an image and the equation is given as: d= (Laverage.grain shape factor)/M Where d: grain diameter, and M: magnification and grain shape factor is constant for every material .Therefore its value can be neglected for comparison before and after deformation (extrusion). L(ave)= 1/N∑L/ni N: number of data L: Real visible and measured test length and ni: number of intercept. For all images real magnification has been calculated from the ratio of visible or actual standard length over written length. All the samples are of circular shape cut out of raw feedstocks as well as of extruded products. The samples of Aluminum and Copper are prepared from the extruded product at various extrusion wheel velocity and extrusion ratio. Sample of raw feedstock is also prepared to examine its microstructure before deformation (extrusion) and comparison of microstructure and grain size can be studied at different extrusion wheel velocity and extrusion ratio. LOM (Light Optical Microscope) has been used for getting images of microstructure after proper polishing. Magnification of 50x, 100x and 200x has been used for all the samples. PL-Ink capture and Axiovision Rel 4.8 software have been used for obtaining the images under microscope and for measuring the grain size by making standard length respectively. 4. RESULTS AND DISCUSSION 4.1. Microstructure Analysis In this section the microstructure images of all the samples of Copper alloy (C 101) has been carried out under different extrusion ratio. The microstructure of the

- 5. Shalini Kumari, Ajeet Kumar Rai, Devendra Kumar Sinha and Rahul Charles Francis http://www.iaeme.com/IJMET/index.asp 78 editor@iaeme.com feedstock before extrusion and the final microstructure of the extruded product are shown in Figures 4 and 5. The microstructure images of all the samples show no considerable changes of grain size during before deformation (extrusion) but the shape of grains is changed as they are elongated after deformation (extrusion). The feedstock before extrusion has uniform grains. The average size of the extruded alloy after extrusion ranges from 80 µm to 200 µm. Figure 4 shows the microstructures of Copper samples of raw feedstock of 12.5 mm size at 50x, 100x and 200x respectively. Figure 5 Shows the microstructures of Copper samples of 8 mm size at 50x, 100x and 200x respectively 4.2. Tensile Test Result It can be inferred from the table that maximum load bearing capacity of the extruded product increases by 8%. The tensile strength of the extruded product increases by 6.8 % and the braking load is increased by 22.9% after extrusion of material. Table 2 Tensile Test result of Copper rod S. No. Sample details Max. Displace- ment (mm) Max. Load (kN) Max. Strength (MPa) Breaking Displace- ment (mm) Breaking Load (kN) 0.2% Yield Strength (MPa) Energy Break (J) % Elongation 1 12.5 mm 3.13 3.648 234 7.440 1.458 127.9 22.11 43 2 8 mm 6.300 3.941 250 9.168 1.793 53.2 30.23 52.46

- 6. Deformation Behavior and Characterization of Copper Alloy in Extrusion Process http://www.iaeme.com/IJMET/index.asp 79 editor@iaeme.com 4.3. Hardness Test Result Table 3 Hardness test result of Copper rod S. No. Sample detail Average Hardness on Vickers Scale 1 12.5 mm(Raw material) 70.6 2 8 mm(Extruded Product) 82.2 It can be inferred from the table that hardness of the extruded product increases and is more than the material before extrusion. 5. CONCLUSION In the present experimental work commercial Extrusion machine [9] has been used for the extrusion of circular rod of diameter 12.5 mm and the product has been found satisfactory. Characterization of Continuous Extrusion process like microstructure analysis, tensile and hardness test of the copper sample before and after extrusion has been performed in the proposed work. Microstructure analysis of the extruded products of Copper before and after deformation (extrusion) has also been carried out. Material properties of Copper have been found using tensile and hardness test. It can be concluded from the proposed work that • More uniform and homogeneous grains are obtained after extrusion. • Material properties of the material can be enhanced after extrusion of raw material as it is clearly visible from tensile and hardness test result. REFERENCES [1] Cho, J. R., Kim, Y. H., Kim, K. S., Jeong, H. S. and Yoon, S. S. A study of the application of upper bound method to the CONFORM process, Journal of Materials Processing Technology 97, 2000, pp. 153–157. [2] Tonogi, T., Okazato, K. and Tsukada, S. Precise Extrusion Technology by Conform Process for Irregular Sectional Copper. Hitachi Cable Review, 21, 77– 82, 2002. [3] Manninen, T., Katajarinne, T. and Ramsay, P. Analysis of Flash formation in continuous rotary extrusion of copper. Journal of Materials Processing Technology, 177, 2006, pp. 600–603. [4] Manninen, T., Katajarinne, T. and Ramsay, P. Numerical simulation of Flash formation in continuous rotary extrusion of copper, Journal of Materials Processing Technology, 177, 2006, pp. 604–607. [5] Kim, Y. H., Cho, J. R., Kim, K. S., Jeong, H. S. and Yoon, S. S. A study on optimal design for CONFORM process. Journal of Materials Processing Technology, 80–81, 1998, pp. 671–673. [6] Lu, J., Saluja, N., Riviere, A.L. and Zhou, Y. Computer modeling of the continuous forming extrusion process of AA6061 alloy. Journal of Materials Processing Technology, 79, 1998, pp. 200–212. [7] Manninen, T., Ramsay, P. and Korhonen, A. S. Three-Dimensional Numerical Modeling of Continuous Extrusion. Journal of Materials Processing Technology, 177, 2010, pp. 600–603. [8] Khawaja, K. and Seneviratne, L. Sensing & Control of Conform™ Extrusion Gap Between Wheel and Tooling Plates. IEEE/ASME International Conference on Advanced Intelligent Mechatronics Proceedings, 8–12 July 2001, 2001.

- 7. Shalini Kumari, Ajeet Kumar Rai, Devendra Kumar Sinha and Rahul Charles Francis http://www.iaeme.com/IJMET/index.asp 80 editor@iaeme.com [9] Khawaja, K., Clode, M. P., Althoefer, K. and Seneviratne, L. Gap Sensing Benefits in Conform™ Extrusion Machinery. IEEE International Conference on Robotics and Automation Proceedings, April 2004, 2004. [10] Pande, P. P. and Dr. Sambhe, R. U. Exergy Analysis of a Compression Ignition Engine. International Journal of Mechanical Engineering & Technology, 3(2), 2012, pp. 633–642. [11] Green, D. Conform: A new concept for continuous extrusion forming of metals. Journal of Engineering for Industry, Transaction ASME, 96, 1974, pp. 893. [12] Avitzur, B. and Talbert, S. H. Upper Bound Solutions and the Balance of Power Approach. Plasticity and Modern Metal Forming Technology. Blazynski, T. Z. ed., Elsevier, 1989, 17. [13] Bramley, A. N. and Osman, F. H. The Upper Bound Method, Numerical Modeling of Material Deformation Processes – Research. Development and Applications, Hartley, P. et al. ed., Springer-Verlag, 1992, pp. 114. [14] Hill, R. The Mathematical Theory of Plasticity. Clarendon Press, 1950. [15] Johnson, W. and Mellor, P. B. Engineering Plasticity. Von Nostsrand and Reinhold Company, 1973. [16] Kudo, H. Upper Bound Approach to Metal Forming Process to Date and in the Future. Metal Forming and Impact Mechanics, Reid, S. R. ed., Pergamon, 1985.