Global HSE Newsletter March 2014

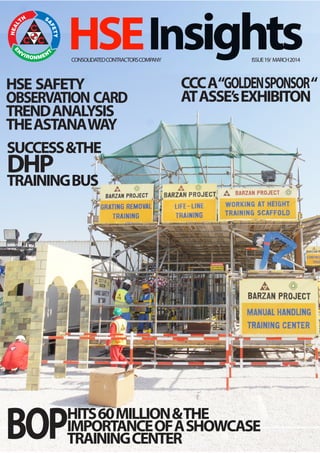

- 1. ISSUE19/ MARCH2014CONSOLIDATEDCONTRACTORSCOMPANY HSEInsights HSE SAFETY OBSERVATION CARD TRENDANALYSIS THEASTANAWAY HITS60MILLION&THE IMPORTANCEOFASHOWCASE TRAININGCENTER SUCCESS&THE DHP TRAININGBUS BOP CCCA“GOLDENSPONSOR“ ATASSE’sEXHIBITON

- 2. ACKNOWLEDGEMENT HSE Group would like to acknowledge and thank everyone that contributed in writing articles for this month’s edition of HSE Insights Global newsletter. The Project management and construction staff contribution reflects a good healthy image, commitment and will send the right message regarding HSE throughout CCC as a company. If you are interested in contributing in future editions, please send your input to hsegroup@ccc.ae before the 12th of each month.

- 3. HSEInsights CONTENTS 19 11 13 04 Quote of the Month 05 HSE Performance Measuring & Monitoring 06 Achieving 60 Million Lost Time Injury Man-Hours 07 BOP Training Center 10 HSE Safety Observation Card Trend Analysis 11 CCC Clean & Green - Lusail Multi-Purpose Hall 13 PPE Free Zone 15 Health Corner- Do You Have Sitting Disease? 17 600,000 Safety Observation Cards 18 Work Safely with Concerete and Cement 18 HSE Group Initiatives 19 HSE Projects News 20 Project HSE Major Awards and Achievements Newsletter Contributors Contents Newsletter Team Robert Davies - Group HSE Director Charles McDaniel - Corporate HSE Training Manager Hazem Faraj - Corporate Sr. HSE Coordinator Newsletter Editor Mohamad Ghadban - Corporate HSE Training Coordinator Dr. Victor Karam- Corporate Health/Medical Manager Hasan Hasanain - Corporate HSE Manager Anan Al Amad - Project Manager Trevor Jones - HSE Manager Buks Beukes - HSE Manager Abdullatef Tanerah - HSE Manager Irvine Watson - Security Manager Rickie Morgan - Superintendent Ricky Carreon - Sr. HSE Officer/Trainer Shadi Alhejazeen - Sr. HSE Supervisor 07

- 4. Quote of the Month “In the middle of every difficulty lies opportunity.” Albert Einstein 4

- 5. HSE PERFORMANCEMEASURING & MONITORING The CCC HSE management system is established, documented and maintained in line with the OHSAS 18001:2007 standard requirements. The company HSE policy statement, procedures, legislative compliances, performance monitoring and continual improvement are core elements of the HSE management system. Model of OHSAS 18001:2007 The CCC HSE management system aims to provide the framework and tools to manage evolving HSE issues quickly and easily whilst meeting the high standard of HSE performance and expectation of both the client and regulatory authority. It also serves to ensure that a safe and healthy working condition is provided to our em- ployees, avoidance of injury to any person, damage to equipment or property, or any harm to the environment as a result of the activities for which the company has responsibility. The primary purpose of measuring HSE performance is to provide information on the progress and current status of activities carried out by the company to control risks to health and safety which has effective benefits in planning and decision making. It is defined in the CCC HSE management system that HSE performance must be measured and monitored using qualitative and quantitative measures. Both proactive and reactive measures of performance are used for HSE performance monitoring and evaluation. The HSE performance is continuously monitored at all levels of the organization from day to day monitoring by Project HSE staff, the Projects Management, Line Man- agers and Supervisors to periodic audits of management systems by Project Management and also by Corporate HSE group through corporate HSE Audits, Cold Eye Reviews, Project Incident Register, Project Safety Obser- vation Register, Project KPI’s, periodic examination of documents and monthly project reports. This monitoring aims to assess how effectively risks are controlled, and how well a positive health and safety culture is developed at the project level. The following techniques are used for measuring the Performance in CCC projects: •Reactive Monitoring which is looking at events that have passed, arguably monitoring failure. Thus, by count- ing the number of unwanted events such as accidents or incidents (near misses), ill health, losses from property damages, dangerous occurrences, environment accidents and chemical, gas and/or oil releases. The projects HSE department and the Corporate HSE Group are monitoring the project performance over a pe- riod of time and the trend analysis is developed to make comparison with similar performance data for different time periods for the same project or with other CCC projects. The Incident Register and the trend analysis are being used to find out the causes of these failures, to learn from these mistakes to prevent reoccurrences of injuries and work-related ill health in future and to improve the health and safety management system and risk control. •Active / Proactive Monitoring which measures the effectiveness of the management systems, the extent of compliance with standards and the HSE management system requirements. Also, the achievement of plans and the goal which is ‘Zero’ fatalities or serious injuries. The projects HSE department and Corporate HSE Group use different tools and techniques to monitor the perfor- mance of the projects, namely, observation safety register and the trend analysis, the HSE site inspection reports, HSE Audits (internal or external), HSE management week- ly walkthroughs, Safety Observation Card records by all projects staff, the Job Safety Task Instruction (JSTI) - Pre- task talk records, Stop cards (for unsafe conditions / acts) to name a few. This type of monitoring provides a firm basis for making decisions regarding improvement in risk control and the health and safety management system. As well it measures success and reinforces positive achievement by rewarding good work, rather than pe- nalizing failure after the event. Such reinforcement can increase motivation to achieve continued improvement. The performance measurement is a key step in any management process and forms the basis of continuous improvement. If measurement is not carried out correctly, the effectiveness of the health and safety management system is undermined and there is no reliable information to inform managers how well the health and safety risks are controlled. “You can’t manage what you can’t measure” – Peter Drucker. 5 Hasan Hasanain|HSE Manager| HSE Group

- 6. “Achieving 60 Million Lost Time Injury Man-hours” On the 10th March 2014 the Barzan Onshore Project, CCCT/JV achieved a milestone achievement of 60,000,000. Lost time Free Man hours. So how has the project man- aged this remarkable figure? Firstly it must be recognized that this is no single person’s efforts, but rather a continu- ous team effort and Partner- ship between the Client (JGC), The Company (Ras Gas) and CCCT/JV (Who together with other Sub-Contractors have achieved over 155 million LTI free Man hours) The Project Manager Mr. Anan Al Amad, has stated clearly, his intent that Safety is the leading priority on the project, and he has demon- strated this physically by his personal drive, energy and support, at all times, he has allocated resources, both project and budget to drive the SHE’S program to ensure it’s, momentum and success. And he continues to demand from his Construction team their involvement and support for the continual high levels of compliance to the program that he and Client expect. The Construction Manage- ment team have embraced the SHE’s program requirements have each in their turn shown and demonstrated their indi- vidual support, to the require- ment. This public demonstration of support and involvement by the Senior Management Team to the High levels of compli- ance has been instrumental, in cascading down wards to the work force the expectations and demands that are re- quired to succeed in imple- menting the highest standards in the work place. The SHE’s training that is delivered to the Project work Management and Workforce, is of the highest quality that can be delivered. The environ- ment that the training is con- ducted in has to be and is of the highest possible standard. The Training where possi- ble is delivered in the native language of the workers, and the supporting documents are translated so as information absorption is maximized, this is then reinforced by practi- cal training in the specially developed and built SHE’s training area (this provides physical reinforcement of the class room sessions, and introduces the students to real world visual acclimatization in a controlled environment that replicates what they will see and what they are expected to do, on site. SHE’s programs that are par- ticularly important to achiev- ing the land mark have been, the Total Safety Task Instruc- tion (TSTI), the Behavioral Observation and Interventions (BO&I), and the Step back 5 x5, also the JSA’s these four programs effect the workers awareness of their immediate work place and clearly identify the hazards that are present and the preventative measures that need to be taken to pro- tect the worker, this get the away from the traditional reli- ance on PPE as the only rather than the last line of defense. There has been targeted encouragement and develop- ment of the line Supervision by providing additional Safety Leadership Training, which clearly outlines their responsi- bilities, to their workers and to the project. This supplements the required training as per the Project Training Needs Matrix. Together this maxi- mizes and develops the site supervisions knowledge and confidence to manage Safety in his area of responsibility. Higher than normal project ratio’s for SHE’s Staff also impact positively on reducing incidents and accident, the long term benefits to the proj- ect are, improved quality and progress achieved through less stoppage time (as a result of injuries and investigations) and financial benefits due to saving on medical bills and higher insurance costs. Incidents that do occur are thoroughly investigated and action plans developed to address lessons learnt, that are addressed and closed out completely and on time. To give a more scientific approach to the manner in which incidents are dealt with number crunching in the form of analysis of JSA’s, TSTI’s and BO&I’s give a clear percent- age of quality of the docu- ments and their findings , this when over laid with the inci- dent frequency indicates if the tools are having an adequate effect on reducing accidents, (Data: would indicate that when the quality of TSTI’s falls below 80% the incidents of accidents increases) A SHE’s officer work program has been developed complete with check sheets that focus and energize the site SHE’s team, to address the issue of complacency, this also pro- duce data that indicates devel- oping trends in area’s that can be addressed proactively. Identified trends are specific Tool Box Talks and Safety Booths that are constructed on site to High light to the worker’s and reinforces the requirements at their place of work. Additionally the use of a Mobile Training Class (Battle Bus) that takes training di- rectly to the site reduces time away from site and provides specific training where it is most needed. Finally the Safety Incentive award scheme cannot and should not be forgotten, here on BOP the investment has been generous and huge, but it has paid dividends the workers see the quality of the awards and are enthused to actively get involved in the SHE’S program, an example is a worker who wrote a song praising the quality of the projects PPE and how it helps and protects him through the day, this song (and his voice) was received with great enthusiasm by the workers to the point where he toured the whole site and performed his song, He also performed for other Sub Contractors (Hence advertising CCCT’S Safety Credo and Reinforcing the Companies Reputation as a Leading Light on The Project) So Quality Safety Perfor- mance can be achieved and maintained on Projects, but it takes hard work, diligence and Team work between SHE’s and Construction, and the absolute Support and Leadership of the Project Manager. 6Anan Al Amad|Project Manager| BOP

- 7. BOPTRAINING CENTER Safety Training in Qatar has been ongoing for many years. Each projects trains thousand of workers annually in a bid to ensure we all go home incident injury free. Safety awareness training is essential for the work- ers, allowing them to gain a full and better under- standing of safe working practices. The training area’s are constructed to replicate actual site condi- tions, making it as realistic as possible The lessons learned over many years has been built into the training programs which is now regarded as being very professional by our client. Barzan Project has put all this knowledge, exer- pertese and training into one location. A working heights scaffold and the surrounding area has been fully utilized to cover all aspects related to site safe- ty awareness. The Working @ Heights training has taken this training to a whole new level. The lifelines that are commonly used in the Middle East and other parts of the world was originally developed by CCC in Qatar shortly after the 2005 Working @ Heights Regulations was introduced. The introduction of this changed the traditional ways in which tradesmen carried out there work at heights. This new HSE guidelines for working @ heights drove the need to develop lifelines allowing the workers a safer working envi- ronment. Further training programs were required and devel- oped to teach workers how to use them safely. Lifeline training is taught on every project in Qatar. Training scaffolds have been designed to cover all aspects related to Working @ Heights activities, which has now been standard- ized and taught on every project in Qatar. The designs for these training scaffolds will be made available for other proj- ects outside Qatar which will include the design and quantities of materials required to construct them. This article will show pictures located on and around the training center demonstrating how a great deal of thought has been put into the overall design and layout. Over head protection fan lifts hoisting and lifiting gin wheels and ropes 7

- 8. PPE Hand protection and pinch points Practical Training area for Manual Handling lifting Techniques safety barricade identification color codes related. Eye Wash Station Welding cutting flame control Harness inspection General Information vitally important for the users,EN Standards Related to Fall Arrest Equipment • Fall arrest Harness must comply to EN 361 • Fall arrest Connectors must comply to 362 • Fall arrest Lanyards must comply to EN 354 • Fall arrest energy absorbers must comply to EN 355 Care and Attention • All harnesses and lanyards to be stored in a dry well ventilated store. • If a harness or lanyard comes in to con- tact with salt water or chemical it must be washed in warm soapy water then rinsed in clean water to remove the soap • A wet harness and lanyards should be hung to dry in a dry well ventilated build- ing. • Any defects found the harness or lan- yard must be removed from circulation and reported and destroyed if necessary. • Do not paint a harness or lanyards. • Never leave the harness or lanyard where it will become subject to weather condi- tions. • Never expose a harness or lanyards to extreme heat. • Harnesses and lanyards must be inspect- ed before use. Inspection Fault Finding • Check all stitching and webbing for signs of • Fraying • Splitting • Scorch marks • Undue wear and tear • Decay. • All belts, buckles, straps or any other type of connecting device must be in good • Working order. • Karabiners/ Scaff & Snap Hooks or any other type of connecting device to be self closing self locking. • All Metal Devices to be free of Decay Twists Bends and Fractures • Must be free of excessive grease oil or paint. • Impact shock absorbers must be tightly packed as per the original manufacturers packing. Access and Egress Freestanding ladders: Every sloping ladder should stand on firm level base and be supported only by the stiles. Where practicable, it should be set at an angle of 4 vertical to 1 horizontal. The stiles should be securely fixed at the top by lashings, or by other means. ladders longer than 3m should be either footed or lashed near the top to prevent the bottom from slipping. Footing a ladder is only effective up to 6m. All ladders regardless of height it is preferred that they be lashed to prevent slippage. 1.0m 4.0m 75 Degrees Access the higher elevations on the training scaffold has been made by means of staircases constructed out of scaffolding. 8

- 9. Grating removal training which is built into the training scaffold Over head view of the grating, which is safely secured and safety associated access below and above controlled By means of safety barricades View from below and the con- trol measure in place View from above and control measures in place HSE Guidance Avoid working @Heights Prevent falls from Heights Mitigate the consequences of any potential fall from Heights Suspension trauma is a killer and occurs when a person is hanging vertically and motionless in a full body harness and cannot or does not move their legs. Hanging vertically and motionless restricts the flow of blood around the body which builds up in the legs and is known as pooling. The heart beats faster due to the restricted blood flow caused by the pooling in the legs and results in a person be- coming unconscious in as little as 5 minutes and can result in death within 30 minutes. People Working @ Heights and exposed to potential falls are at serious risk of suspension trauma if they are required to wear and use a fall protection equipment such as a full body harnesses and associated equipment. If a person was to fall and hang vertically and motionless in a full body harness they are immediate- ly subject to potential suspension trauma. The rescue of a fallen worker must be immediate and rapid. A rescue plan must be in place before any work is allowed to start and all involved are aware of the plan and what measures and means of rescue are in place. HSE Requirement Method Statement Job Safety Analyses Rescue Plan Tool box talk Pre task talk agreeing who will be doing what, when and how, con- sidering the progressive changes during the task. Suspension trauma awareness training is essential for all those who work at heights and required to wear personal fall protection equipment. Horizontal life lines Training: All candidates are taught how to use the horizontal lifelines safely and all have to do participate in walking the beam. Safe means of access along the beam using the lifelines and associated fall protection equipment being demonstrated by CCCC Scaffolding Superintendent Mr Dean Smith. Confined Space Training The Training area includes Confined space training. On a mechanical project this is essential training. An old false work column shutter has been used to rep- licate a vessel, making it a realistic as possible. 9 Trevor Jones|HSE Manager| BOP

- 10. HSE SAFETY OBSERVATION CARD TREND ANALYSISWhen we are young our parents tell us to learn from our mistakes and not to make the same mistake twice, as Lessons Learned from thepreviousProjects,theHSES.O.C.TrendAnalysiswasproventobeavaluabletool toreducetheriskandimprovethesafetyculture. The purpose of the HSE S.O.C. Trend Analysis • Hazards and unsafe acts prevention is everyone’s Job and is an essential part of our safety program. • It is a simple technique to plan safety into the workplace. • If everyone is involved in the process, then we can help elimi- nate the hazards before we start work so no one gets hurt in the workplace. • This program will help you learn how to identify hazards and unsafe. acts and how to use the Safety Observation Card (SOC) to help eliminate hazards from our jobsite, thus minimizing poten- tial incidents and injuries. What Are Safety Observations? • A way of identifying safe/unsafe acts, conditions and near misses. • A way to recognize and encourage good performance. • A mechanism for eliminating unsafe acts and condi- tions. The HSE Department utilizes the information gathered from the Observation Cards the information from the (SOC) is bro- 1. Body Positioning 2. Body Usage 3. Office/Other Ergonomic Behav- iors 4. Work Area Maintained 5. Tools & Equipment Operation 6. Procedures 7. Plant, Equipment, Vehicle Op- eration 8. Environmental Behaviors 9. PPE Use 10. Other Behaviors Those 10 categories are broken down into sub-categories for a total of 52 items that gives us a good cross section of the project as a whole to base our analysis off. Observations can be both positive and negative In the case of negative observations this gives us an idea of where need to focus our attention, and how to tailor our training programs to meet the needs of the project more effectively And for positive observations we can look at what is working and help emphasize that point more to the project Examples: • Working in an excavation that is 1.5m or deeper that has not been properly shored. • Intentionally removing protective guards or safety mechanisms from tools. • Materials or tools left lying on elevated positions so that they could potentially fall. As the O&I Cards are turned in the information on them is entered into the matrix which in turn generates our charts Proactive Analysis The SOC Trend analysis provides a firm basis and clear indication on the risks and workers behavior on site which helps to avoid incidents, and it facilitate making decisions regarding improvement in risk control and HSE manage- ment System. Benchmarking The SOC and Trend analysis is a good benchmarking tool, it provides continuous learning from different project sites activities, conditions and workers behaviors , learning more about the project and different sites strengths and weak- nesses, and then acting on the lessons learned. Which leads to real improvement in the safety culture and HSE management system. Changing safety behaviors through the observation card The SOC and Trend analysis measures success and reinforces positive achieve- ment by rewarding good work, rather than penalizing failure after the event. Such reinforcement can increase mo- tivation between workers and improve the safety environment and culture which will change positively the safety behaviors in the project and in CCC company as all. The HSE Department utilizes the results of the Trend Anal- ysis to establish if and where an audit may be required as well what type of training either classroom or Site training needs to be conducted. The area of concern will be contin- uously monitored until the issue is resolved and all items are closed outIn Conclusion, Working safely,It Is Better to Be Safe than Sorry!. 10 Abdullatef M.A | HSE&S Manager| ADP

- 11. •Owner : QATAR OLYMPIC COMMITTEE (QOC) •Client’s Representative: ASTAD •Consultant : KEO •Designer: DAR •Construct an Olympic multipurpose hall for three sports (Handball, Basketball and Volley ball comply with local and international standards for the federation of the three sports; designed to achieve at least three stars under the Qatar sustainability assessment system (QSAS). •The total plot site area is approximately 387,123.4 m2; The Project Consist of three main constructs/buildings with soft and hard landscaping and vehicle passages and parking’s; the building are distributed as follows: •Building No.1: referred to as the“Multi-Purpose Hall“, is the main Arena hall with footprint coverage area around 49,315 m2. It contains the main arena and two training halls with other rooms and facilities for the athletics, operator and spectators. The hall also contains a VIP areas and VVIP lounge. •Building No.2: referred to as the“Cooling Tower Building” (utility Building #01), is the cooling tower room, it is under- ground spaces opened to sky and surrounded by a steel mesh fence. The total plot area is around 910 m2. •Building No.3: is the Microwave Tower CCC Clean & Green - Lusail PROJECT DESCRIPTION “Package I“Substructure works”commenced on 6th Nov. 2012 and completed on 30th Sept. 2013. Package II commenced on 28th Jan. 2013 with 58 % overall progress status“as of 21st mar. 2014”and targeted to be completed by end Dec. 2014. Package III“Envelope works”was novated to CCC/TCC JV on 9th Oct. 2013 and targeted to be completed on 11th July 2014”. The overall structure geometry was done by keeping in view of storms, high winds and number of people occupies the stadium. Civil construction is a great challenge in Qatar due to the adverse and extreme weather conditions. Hence HSE plays a major role to take care of the health, safety and welfare of the workforce in LMH project. LMH safety team has strong commitment and endeavor towards safety. The team comprises with a Senior HSE Manager, Deputy HSE manager, Safety supervisor and 81 Safety Officers (including subcontractors). PROJECT NOTES Commitment to HSE is very important to LMH Project Management Team. We strive to maintain Health, Safety and Welfare of our employees continuously by placing the best HSE practices and standards by implementing good HSE procedures in the workplace, as welfare of our em-ployees is our main construction asset on site. COMMITMENT TO HSE The LMH project team is creating a positive safety culture by displaying safety posters, posting warning signs and giving handouts. To encourage and recognize the workforce LMH team is running an incentive scheme under the name of “safety awards”every month. We established a safety com- mittee in collaboration with construction team for periodical inspections. ESTABLISHING SAFETY CULTURE A Risk assessment will protect workers and construction business as well as complying with Law. Hence LMH team made a rule, that for all the activities prior to the beginning of the job, Method statements and JHA’s must be submitted and approved by the HSE Department. Apart from this, a task risk assessment by the supervisor and area safety officer must be done and discussed with the workforce in the everyday JSTI (Job safety task instructions) talk. RISK ASSESSMENT A MUST FOR ALL ACTIVITIES Provision of HSE Training to employees increases safety awareness and improves the safety records of the com- pany. Therefore, our HSE Training Department conducts many spe¬cial trainings, like Working at heights,(including practical) Confined Space, Emergen¬cy Evacuation etc., for all employees as part of standard procedure. HSE training passports are provided to all the employees after the com- ple¬tion of the training. TRAINING SKILLS AND DEVELOPMENT 11

- 12. We have approximately 65 numbers of subcontractors are working under CCC in LMH project. As they come from a different environment and safety culture, LMH team give utmost importance for team work, in coordinating with sub-con by conducting regular and periodical meetings for dealing various safety aspects in the project. SUBCONTRACTORS TEAM WORK Environmental Protection takes one of main part in deliv- ering safe work environment for our employees; therefore, LMH Team takes diligent care of various environmental pro- tection activities, like separate wastage areas with adequate waste skips, implementation of segregation method, spill kits, drip pans and bounded walls for liquid storage areas at site office & camp areas in order to maintain auspicious conditions near work & rest places in spite of hard desert ENVIRONMENTAL PROTECTION Fitness of the workforce is given top priority, hence LMH team is established a well-equipped clinic with qualified doc- tors and male nurses. Periodical health checks and constant monitoring of the health condition of the workforce are a regular practice in LMH project. HEALTH SURVEILLANCE Transportation:-Traveling takes time, costs money, involves risks and generates greenhouse gas. Each kilometer of car travel avoided saves up to half a kilogram of greenhouse gas. Hence all the trips are planned and site visits are scheduled. Electronics:- Computer and laptops with screen savers don’t save energy. As a energy saving measure LCD panel mon- itors are used in LMH project. Periodical maintenance to the Air conditioners, kitchen and canteen Fridges and Copy Machines and other appliances are in progress. ENERGY SAVING MEASURES The LUSAIL MULTI- PURPOSE HALL project (LMH) has re- vamped our Environmental outlook to encompass the three R’s (Reduce, Reuse, and Recycle) in our endeavor to“promote sustainability”and“protect the environment”The project’s goals are to move toward Zero Waste to Landfill across the site through innovative ideas and technologies that will eliminate waste pile up. LMH’s focus will be on reduction and re-usage since there are limited means of recycling in the State of Qatar. Where ever possible, CCC and Contractors are expected to limit their sus- ceptibility to waste pile up, through efficient procurement and inventive ideas for material reuse. REDUCE, REUSE, RECYCLE Project free LTI Performance Total Man-hours -16,537,458-as of (19th March 2014) Total Current Man Power -8094- as of (19th March 2014) LMH PROJECT STATISTICS 100% TIE OFF TRAINING REGULAR WASTE REMOVAL JSTI TALKS MESS HALL BLOOD DONATION HOUSEKEEPING & NEWSLETTER 12 Buks Beuks|HSE Manager| LMH

- 13. Currently CCIC are in the third year (final year) of Phase 1 for Qatar Petroleum’s Multi Purpose Administration Complex (MPAC) Flagship Headquarters, just outside Ras Laffan Industrial City (RLIC) in the State of Qatar. The MPAC project is one of the highest profile construction sites currently in RLIC and Qatar, it has received many prestigious visits in recent months including a visit from The European Network for Construction Companies for Research and Development (ENCORD), a group made up of Global HSE Managers from various high profile international companies from around the world, such as Balfour Beattie, Bam, Bilfinger Berger, Skanska, just to name a few, who after their visit praised the MPAC site and the management for the outstanding effort in creating a safe working environment and safety culture for all involved on the site. Civil Construction projects in Qatar bring their own unique challenges, due to the harsh climate and environment, dangerous indigenous species, which are found here and of course, the high temperatures and humidity throughout the summer months, which here in Qa- tar can last up to 7 months of the year. From the onset of the MPAC Project all the workforce have been exposed to all of these elements in one way or an- other, so in an effort to deliver break- through solutions to address these safety challenges, especially when it comes to the Summer months (Heat Stress Season), a visual site survey of the workforce personnel, their activi- ties and their rest facilities was carried out to determine if any improvements could be implemented. Observations identified from, Daily Safe- ty Walkthroughs and Weekly Manage- ment Walkthroughs, Safety Reports, plus the aforementioned Site Survey was that the general work force were starting to display sign’s of fatigue and looked to be struggling with the exposure to the heat and sun, this was primarily identified due to the lack of adequately designed shaded areas during the initial construction phase of MPAC project. Observations included:- Workers were removing there PPE (cov eralls, hard hats) on site in order to try to cool down. Drinking water stations, toilet facilities, rest shelters and smoking shelters were sporadically placed around the work site. Design of the shelters was uniform but did not include ade quate shading, lighting or ventilation. Shelters were located near ongoing work activities such as excavations and concreting operations, therefore ex- posing the workforce to the hazards associated with these activities examples being dust, noise, chemicals etc. During the summer months (Heat Stress Season), another concern that had been raised, was for the Muslim employee’s on the site, especially during the Holy Month of Ramadan, as Ramadan during the life of the project has fallen at the Peak of the summer months (Heat Stress Season). We found that these em- ployees’s were going to the rest shelters at prayer time and removing there PPE, in order to pray. The introduction of dedicated site based Mosque’s became part of the PPE Free Zone. After assessment and evaluation of all the observations an idea was formed in conjunction with all Safety personnel, CCIC construction managers involved on the MPAC Project, to introduce specific self contained PPE free rest ar- eas of a standard design and adequate dimensions (approximately 25 meters by 15 meters), which would be located at a safe distance from the construc tion activities. Therefore providing rest, smoking, eating, ablution, waste man- agement, HSE information and prayer facilities for the MPAC employee’s on- site, within a Secure and Safe Environ- ment. PPE Free Zone’s: Standard designed amenities will include:- •Rest Shelters with seating capacity for 60 to 100 personnel with a mini- mum 4 industrial fans for cooling and air flow, •Smoking Shelter Facility with indus- trial fan for air flow, •Mosque with AC Units, •Toilet Block, •Washing Facilities, •Refrigerated Drinking Water Stations as well as additional water Igloo’s. •HSE Information Boards (PPE Require- ments, Safety Alerts, TBT etc in the various languages), •Heat Stress Index Board, •Heat Stress colour coded Flags (Green, Yellow, Orange & Red). •Wind Sock, •Waste Management Facilities compris- ing of the colour coded waste skips with dedicated cleaning crews. As the buildings increased in height, CCIC introduced smaller rest areas at elevated points within each of the buildings; this offered employee’s somewhere to cool down relax and take refreshment without removing their PPE. PPE FREE ZONE 13 PPE FREE ZONE MPAC

- 14. The ground level rest shelters would be classified as PPE Free Zones with- in a boundary fence line, where as the additional at height rest shelters would only be for rest and refreshment at the work location, this avoided the need for employee’s working inside the building from unnecessarily having to travel up or down the 11 floors of the Office Canteen Building (OCB for example), especially during the Heat Stress Season. The management and Safety Depart- ment introduced the following mea- sures:- The Safety Challenge:- •Harsh Climate. •Indigenous Species. •Ramadan. •Multicultural Workforce. •Heat Stress. Heat Stress:- •Introduction of PPE Free Zones & Rest Areas at Height. PPE Free Zones:- There are 4 main locations within the MPAC site firstly the largest construction is the Office Canteen Building (OCB) comprising of two (2) towers North and South, the North tower has 7 floors and South tower has 11 floors. Secondly there is Central Plant & Sub-station (CPB) this comprises of two, 2 storey buildings. Thirdly there is Medical Center and Heli-Pad, this comprises of one 2 storey building. The final construction area is the infra- structure, which is located away from the main buildings work activities. For any staff/engineers, that have to visit the site on a daily basis they are walking from the Temporary Site Facility Offices (TSF) to each location, the current distance is approximately 5 kilometers around the site. There are several disciplines and trades that have to do this walk on a daily basis therefore the PPE Free Zone during the Heat Stress Season was very well received by all on site. In addition a mobile phones policy of “use in the PPE Free Zones” was imple- mented and enforced; this reduced the “temptation” for Mobile phones to be used by the workforce in the high risk construction areas. Information on correct PPE to be worn is displayed on all exits of the PPE free Zones to ensure all employees are fully compliant and wearing their correct PPE before they return to their work area. Thinking behind PPE free zones:- This enabled employees to remove all PPE including coveralls to ensure maxi- mum rest, relaxation, replenishment of water and cooling down periods. The catalyst for introducing these measures came from the site management teams desire to comply and improve upon Qa- tari Labour Law, Qatar Petroleum’s HSE Heat Stress requirements and CCC Heat Stress Policy. Safety Opportunity:- One of the greatest advantages we found was that these PPE free zones offered and provided an excellent opportunity for CCIC HSE department to disseminate HSE information such as Hazard Identification, Hand Safety, Use of Power/Hand Tools, Working at Height, Confined Space, home made / damaged tools display cabinets to mention a few, this was done with the aim to refresh the core safety values held by CCIC to the entire work force in a localised area, with a captured audience, therefore providing the workforce with an onsite information centre. Outcome:- •The PPE Free Zones enabled the MPAC HSE team to identify 11 minor first aid cases (first symptoms of heat stress): nausea/dizziness and provided instant medical treatment therefore ensuring that the identified cases did not develop to a greater level. (7 cases during Rama- dan) •A rested, relaxed and refreshed work- force, therefore reducing fatigue levels. •PPE compliance at an exceptional level. •Enhanced integration of nationalities as PPE free zones encouraged cross nation- ality dialogue. •A great Reduction in the unauthorized use of mobile phones in the construction areas. This has been backed up by the sites current safety statistics:- •Project free LTI performance, to date is currently 19,659,058 (14th March 2014) •Total current Man Power 3,267 as of (14th March 2014) •Direct on-site Man Power 2,971 as of (14th March 2014) •In-Direct Man Power 296 as of (14th March 2014) •TRIR 0.050 14 Stuart Tannahil |HSE Manager| MPAC

- 15. Do You Have Sitting Disease? Too much time sitting down may spell bad news for your health. Here are 11 solutions Chances are you're reading this article sitting down. And if you're like most computer users, you've been in your chair for a while. You're probably inactive for more of your day than you realize. Do you sit in your car while commuting to an eight-hour-a-day desk job and then unwind in front of the television all evening? Do you depend on email, direct-deposit paychecks, and online shopping to accom- plish tasks that 10 or 20 years ago would have required you to run errands? If so, then you may have "sitting disease." That's the new buzzword for a sedentary lifestyle that may put your health at risk. A growing body of research shows that long periods of physical inactivity raise your risk of developing heart disease, diabetes, cancer, and obesity. In January 2010, British experts linked prolonged periods of sitting to a greater likelihood of disease. And that same month Aus- tralian researchers reported that each hour spent watch- ing TV is linked to an 18% increase in the risk of dying from cardiovascular disease, perhaps because that time is spent sitting down. You’re meant to Move “Human beings evolved as a walking entity, exploring the world on our feet,” says James Levine, MD, author of Move a Little, Lose a Lot. “The strangest thing in the world is that people spend all day scrunched in a chair. It’s a form of physical entrap- ment,” “Fight sitting disease by taking steps to become more physically active. But how do you actually do that when you’re locked into a lot of sitting time at work and getting around town”? •Get NEAT. Levine recommends studding your day with non-exercise activity thermogenesis (NEAT). NEAT includes stretching, turning, and bending. Aim for 10 minutes of NEAT each hour. “When I speak to the patient who is battling with a sedentary lifestyle, ‘I can’t afford the gym’ is no longer a barrier,” Levine says. “What I’m asking you to do doesn’t cost anything. You integrate activity into your day, whether pacing around on the telephone, not using email, or taking the kids for a walk in the mall.” 15 HealthCorner

- 16. •Think beyond your workout. Even if you exercise at lunch, you may still be sitting too much. “Getting one hour of exercise in the middle of the day is ob- viously going to be better than not doing anything, but that still leaves approximately seven hours of predominantly sitting during the workday,” David Dunstan, PhD, says. “We have to have a whole- day approach to physical activity promotion,” says Dunstan, who heads the physical activity laboratory in the division of metabolism and obesity at Baker IDI Heart and Diabetes Institute in Melbourne, Australia. He led the study on TV time and the risk of dying from cardiovascular disease. •Mix standing and sitting. Sitting constantly is unhealthy, but standing still for long stretches of time can cause problems, too, such as a bad back or sore feet. It’s better to frequently shift between sitting and standing, Dunstan notes. •Take regular breaks. “Most people know that if they don’t exercise, they’ll gain weight, but they aren’t motivated to become more active,” says exercise physiologist Fabio Comana, spokesman for the Amer- ican Council on Exercise in San Diego. Get yourself moving more often with small goals, he says. “Stretch out your entire body, all the muscles that are cramped. If you do it five or six times a day, you’ll start to notice a difference.” •Pretend it’s 1985. Have a question for your co-worker down the hall? Don’t shoot him an e-mail; walk to his workplace and ask him face to face. Some companies have instituted email-free Fridays to get employees out of their chairs more often, Levine says. •Adopt new habits. Standing uses more muscles and burns more calories than sitting, so train yourself to stand whenever you talk on the telephone. Pace during staff meetings if your boss will allow it. Ask friends to go for a walk during lunch instead of chatting in the break room. Use the stairs instead of the elevator. •Rearrange the office. Help your company encour- age its employees to be more physically active with- out suggesting that they install treadmills at every workstation, Levine says. Start having walk-and-talk meetings with your co-workers rather than confer- ence room meetings. Move trash cans out of offices to make people walk to throw out garbage. Relocate water coolers by windows, where people will want to congregate. •Embrace new technology. Telecommute from a park on a sunny day, or walk around outside while participating in a conference call. “Instead of tying people to their desks, technology is starting to release people from their desks,” Levine says, noting the widespread use of text messaging, laptops, and cell phones with wireless Inter- net access. “The evolution of technology allows people to be far more mobile.” •End your workday with a bang, not a whimper. Prolonged sitting at work can tire you out, making you zone out as 5 p.m. approaches, Comana says. “But if you take a brisk, 15-min- ute walk in the afternoon, you’ll be far more productive in your last two hours. If you’re worried that you don’t have time for a walk, you may be surprised that you get your work done more quickly afterwards.” •Rethink your commute. It’s dangerous to try to exercise while you’re driving, but if you take a bus or train to work, you can stand, clench, and relax your muscles or get off a stop early and k several blocks. If mass transit isn’t an option, find a distant parking spot so you walk for a few minutes before and after work, Dunstan says. •Watch more television. That is if you vow to be active when you watch. “It is not our objective at all to discourage people from watching TV,” Levine says. Pull your dust-covered treadmill out of retire- ment, place it in front of the television, and only allow yourself to watch when you’re walking. March in place or tidy the room while watching. Research shows that the longer you sit watching television, the greater your waist circumference, and the higher your risk is of dying from cardiovascular disease, Dunstan says. 16 Dr. Victor Karam|Corporate Health/Medical Manager| HSE

- 17. 600,000Safety Observation Cards“A Safety Achievement!” On 28th of February 2014, CCTJV, along with other Contractors in PMP, has reached a Safety Milestone in submitting a 600,000 total of Safety Observation Cards (SOC), thus consid- ered as an achievement in terms of world class safety performance. Qatar Gas PMT Project Manager Mr. Jim Ierubino, TCJV Project Director, CCT Project Manag- er Mr. Oussama EL Jerbi, and other PMP project delegates congratulated the CCT team for the outstanding participa- tion and contribution to this achievement. On the 10th of March 2014, TCJV Construction and HSE Manager , in collaboration of CCT JV Site and HSE Man- agers handed over, to all CCT JV workforce on PMP, QR100 gift vouchers in CCT JV camp, during a “hand-shaking” ceremony, to convey the management appreciation to the workforce’s contribution to the SOC program. On the 20th of March 2014, during the weekly Incident Prevention Committee meet- ing, and in presence of TCJV, Qatar Gas PMT has handed over to CCT JV a memento, as a token of appreciation for CCT JV’s valuable con- tribution in the PMP SOC program, in the occasion achieving the 600,000 SOC’s milestone achievement. SOC is a proactive safety management tool provid- ing leading indicators on site HSE performance and critical areas for management planning and deployment of actions. wherein the Health, Safety & Environment (HSE) group analyses the data on site, to generate reports with recommendations on the control measures to the project management, high- lighting the “weaknesses” and “Strengths” in terms of safety performance based on the rate of occurrence of the observations, and recom- mending actions to be PMP group photo was taken on the 04th of March 2014 at PMP Green field area (above photo) where approx 1000 men from CCT JV participated. 17Rabih Rouwadi|Construction Manager| RGX initiated to avoid reoccurrence of unsafe acts, or take oppor- tunities by re-enforcing observed positive outcomes. SOC’s are filled by each person on the project, thus recording safe or unsafe observations. All employees on the project con- tributed in the SOC program and CCT JV team have made significant contribution to this Milestone and are proud to be part of this significant achievement. Qatar - PMP

- 18. WORKSAFELYWITH CONCRETEANDCEMENT Concrete is a common building material that can be used in a variety of ways. It’s generally made by combining cement, sand, aggregate (small stones) and water. When these mate- rials are mixed in the correct amounts and if they’re further strengthened by adding re-bar, fiberglass strands or plas- tic rods, the concrete can be used to build roads, bridges, buildings, septic tanks, floors, concrete blocks, and even countertops for homes. However, anyone who uses or works around concrete and cement should understand the poten- tial health hazards and follow safe handling procedures to prevent harmful exposures. There are some applications of concrete that necessitate the addition of other materials that could adversely affect health if improperly handled. Additions may include alkaline com- pounds (such as lime) that are corrosive to human tissue, small amounts of crystalline silica that are abrasive to skin and causes damage to lungs or small amounts of chromium that can cause allergic reactions. The risk of illness or injury from these additions in the concrete depends on the level and length of exposure and the sensitivity of the individual. Adverse health effects from concrete or cement are general- ly the result of exposure through skin contact, eye contact or inhalation. •Skin Contact – getting cement dust or wet concrete on your skin can cause burns, rashes, and skin irritations. Sometimes workers become allergic if they’ve had skin contact with cement over a long period of time. •Eye Contact – getting concrete or cement dust in your eyes may cause immediate or delayed irritation of the eyes. Depending upon how much and for how long you get the dust in your eyes, effects to your eyes can range from red- ness to painful chemical burns. •Inhalation – inhaling cement dust may occur when workers empty bags of cement to make concrete. When sanding, grinding, cutting, drilling or breaking up concrete, the dust generated has the same hazards as the dust from cement. Exposure to cement or concrete dust can cause nose and throat irritation. Long term exposure to concrete dust con- taining crystalline silica can lead to a disabling lung disease called silicosis.There are ways to prevent or control negative health effects when working with concrete and cement. First of all, dress for protection. Wear alkali resistant gloves, long sleeves and pants to reduce skin exposure to concrete or cement dust, and waterproof boots that are taller than the concrete is deep. Wear safety glasses with side shields to protect the eyes or if it’s very dusty, goggles. Don’t wear contact lenses. When dust can’t be avoided, wear employ- er-approved respiratory protection. And remember to wash your hands and face before eating, drinking, smoking or using the toilet at the end of the day. 18 Shadi AlHijazeen |Sr. HSE Supervisor| DHP HSE Training - MPRC, Algeria MRPC Project, Algeria had a boost in HSE Training with more than 100 employees trained over a 7 day period during the Month of March 2014: The courses were conducted by the Corporate Senior HSE Training Coordi- nator, Mr. Hazem Faraj and included: 1. HSE Managers & Supervisors HSE Management System Induction 2. Risk Assessment 3. Hazards Identification 4. Train the HSE Trainer The attendees displayed great enthu- siasm and potential for improvement. The courses were delivered effectively with the support of Project Manage- ment. HSE Group NEWS ASSE Exhibition CCC contributed as a Golden sponsor, in ASSE’s Exibition that took place on March 17 2014. the American Society of Safety Engineers (ASSE) is the world’s oldest professional safety society. ASSE promotes the expertise, leadership and commitment of its members, while providing them with professional development, advocacy and standards development. It also sets the occupational safety, health and environmental community’s standards for excellence and ethics.

- 19. An essential part of achieving Incident Injury Free working environment is pro- viding effective and adequate training. Effective HSE training given to employees will teach them how to work safely and protect themselves from any injury. To enhance delivery of training, DHP secured a Training Bus in Septem- ber 2012 and is utilized daily for various training requirements. The advantages of the acquisition are: · Reduce employees downtime and cost. · Can conduct training in site. · 4,922 employees have been trained on the bus. · 9,844 training man-hours achieved. · Stand down.. · On The Job training in site With the Training Bus going to site to conduct trainings, we find it beneficial as we can cover the 15km long road- work site area for DHP. It also enables us to sustain our commitment to HSE by delivering needed trainings to our site personnel helping them to work injury free while working for CCC. Dukhan Highway Project (DHP) Training Bus Dukhan Highway Project (DHP) Shahaniya Camp To further provide information for the new residents we are in the process of providing an information booklet ,the contents will be covered by Administra- tion Staff as an information /induction process for all new employees and cover standards for CCC/T residences. These standards set out to reinforce CCC/Ts commitment to improving to quality of life for their employees in DHP Qa- tar and in addition provide a relaxing atmosphere for their workforce, with recreational facilities ,plants, trees, and paintings by our resident Picasso Mr. Inderjit Singh. 19 Ricky Carrepm |Sr. HSE Officer| DHP Barrie Dennis |HSE Manager|DHP Projects HSE NEWS

- 20. Project HSE MajorAwards & Achievements 60 Million MAN-HOURS BOP-QATAR Congratulations! Note: HSE Group has certain Achievement Milestones. Any projects reaching any of these milestones in the month previous to the newsletter being issued will be mentioned in the Project HSE Major Awards and Achievements Page. Milestone Mentioned upon completion of: 1,3,4,5,8,10,15,20,25,30,35,40,45,50,60,70,80,90,100 Million Manhours To the HSE & Project Construction Teams and to all those who contributed towards this outstanding achievement. 30 Million MAN-HOURS AMTB-UAE 20 Million MAN-HOURS MPAC-QATAR 15 Million MAN-HOURS SML-QATAR 5 Million MAN-HOURS WGPP-SAUDI ARABIA 4 Million MAN-HOURS KBZH-MOROCCO 3 Million MAN-HOURS DUAR-NIGERIA 20

- 21. HSEInsights Phone : 00971 2 654 8000 | Fax : 00971 2 5540 675 email: hsegroup@ccc.ae www.ccc.gr Address: HSE Group, EPSO Building #4, Mussafah, Abu Dhabi, United Arab Emirates