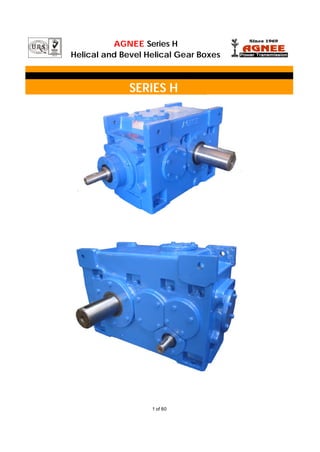

Agnee h series helical gearbox-bevel helical gear box

- 1. AGNEE Series H Helical and Bevel Helical Gear Boxes SERIES H 1 of 80

- 2. AGNEE Series H Helical and Bevel Helical Gear Boxes AGNEE H series helical parallel shaft and bevel helical right angle drive industrial gearboxes have been introduced to meet the requirements of today's demanding applications in the medium and heavy- duty sector of the power transmission market. AGNEE gear units are fully metric and are suitable for most applications horizontal drives and vertical drives. Based on a modular design and construction, the high degree of interchangeability of parts and sub- assemblies among all variants effects considerable economies of production, whilst maintaining the highest standard of component and unit elements. A wide choice of ratio is available based on recommendations laid down in AGMA standards with additional half ratio steps. Profile ground helical gears together with spiral bevel gears lapped in pairs, ensure high standards of accuracy, surface finish and quiet running characteristics. Helical gears are fitted in parallel shaft units whilst units with shaft at right angle incorporate spiral bevel and helical gears. High quality alloy case hardening material provide long life wear resistance and fatigue strength. The high power to weight ratio of all units combines with volume to enable installation in the most difficult situations, Each of the two variants contains unique features suited to their own operating conditions. Horizontal units feature optional right or left and shaft arrangements from the same sub- assemblies and are available as foot mounted, shaft mounted or foot/shaft mounted types 2 of 80

- 3. AGNEE Series H Helical and Bevel Helical Gear Boxes CONTENTS Sr. No. 1. 2. 3. Particulars Page No. MARKETING DATA a. Index b. Design Feature 3 4 SELECTION- Procedure and Example a. Horizontal 5 RATINGS - Mechanical & Thermal Ratings (Kw) Type Shaft H1 H2 H3 H4 B2 B3 B4 4. Reduction Single Double Triple Quadruple Double Tripe Quadruple Parallel Parallel Parallel Parallel Right Angle Right Angle Right Angle 8 11 13 15 17 19 21 DIMENSIONS – Principal, shafts & Keyways (mm) A. Horizontal Units Type Shaft Mounting H1 H2 H2 SF H3 H3SF H4 H4SF B2 B2 SF B3 B3 SF B4 B4 SF 5. Reduction Single Double Double Tripe Tripe Quadruple Quadruple Double Double Tripe Tripe Quadruple Quadruple Parallel Parallel Parallel Parallel Parallel Parallel Parallel Right Angle Right Angle Right Angle Right Angle Right Angle Right Angle Foot Foot Foot/ Shaft Foot Foot/ Shaft Foot Foot/ Shaft Foot Foot/ Shaft Foot Foot/ Shaft Foot Foot/ Shaft Engineering Data 23 26 30 33 37 40 43 45 48 51 54 57 60 62 3 of 80

- 4. AGNEE Series H Helical and Bevel Helical Gear Boxes DESIGN FEATURES GEARS : High quality alloy case hardening materials provide long life wear resistance and fatigue strength. Profile ground single helical gears and spiral bevel gears lapped in pairs ensure high standards of accuracy, surface finish and quiet running characteristics. Helical gears are fitted in parallel shaft units whilst units with shafts at right angles incorporate spiral bevel and helical gears. BEARINGS : Taper Roller bearings are used throughout. GEAR CASES : Gear cases are of rigid cast iron construction with modern styling. MS Fabricated gear cases are available as optional. Inspection covers are provided for viewing gear contacts. Oil level dipsticks, ventilators and drain plugs are fitted. Cases are split in horizontal plain for horizontal gearboxes and in the vertical plain for vertical gearboxes. Gearcase Finish : Internal and external semi-gloss blue painted with linear epoxy primer. External surfaces are finished with alkyde semi-gloss blue paint. These paints are resistant to dilute acids and alkalis, oils and solvents, 0 sea water and temperatures upto 140 C. External Dimensions : Centre distances are chosen from ISO preferred number series. Shaft extensions and hollow wheelshaft bores are to ISO metric standards. Fastners are metric. Lubrication : In horizontal units, lubrication in most instances is by transfer of oil by gears dipping in the sumps of gear unit bases. Where high pitch line speeds could cause churning of the lubricant, case baffles are fitted as indicated on rating tables. Forced lubrication is necessary where shown and complete systems can be supplied when required. In vertical units, lubrication in most instances is provided by a pump driven from the bottom of the high speed or second motion shaft. The low speed gears dip in the oil bath. In some cases, it is necessary to use a forced lubrication system with a separate oil tank. These are marked in the ratings tables. All units are provided with combined dipsticks and ventilators and drain plugs. COOLING : Depending on the application, standard gear units are cooled by : Normal heat dissipation by convection from external surfaces.Fans fitted to high speed shafts. Cooling water coil fitted in gear unit base. Fan and cooling coil.Separate oil cooler incorporated in forced lubrication systems. SHAFT MOUNTED UNITS : Shaft mounted units are of two designs, the first of which is mounted on the driven machine shaft extension and connected to the foundation by torque arm. Additionally foot/shaft design is available for mounting on a base plate with motor and coupling, the complete assembly being mounted on the driven machine shaft extension connected to the foundation by a torque arm. MOTORISED GEAR UNITS : Gear units of double and triple reduction types are available as standard assemblies with flanged motors directly mounted on gear case input shaft housing by adaptors. Mo tor and gear unit shafts are connected by flexible coupling. HOLD BACKS : Hold backs can be fitted to all horizontal, two and three stage gear units, where required to operate in nonreversing drives. They are located on horizontal pinion shaft and have ad equate capacities to deal with full rated torque. Lubrication is provided automatically from the oil in the gear unit. Changing the direction of locking rotation is a simple operation. PRESERVATION/PROTECTION : AGNEE helical gear units are despatched without oil. Prior to despatch they are test run with a rust preventative oil giving adequate protection to internal parts for a period of 6 months, covering normal transport and covered storage. NOTE : Where gear units are to operate in abnormal condition or where they are to stand for long period without running for e.g. in plant installation, AGNEE must be notified so that suitable protective arrangements can be made. As improvements in design are being made, this specification is not to be regarded as binding in detail and drawings and capacities are subject to alterations without notice. Certified drawings would be sent on request. 4 of 80

- 5. AGNEE Series H Helical and Bevel Helical Gear Boxes SELECTION PROCEDURE Gearbox Selection for Horizontal Units Table 1: Mechanical Service Factors (Horizontal & Vertical) Duration of service Hrs. Per Day 1. Select Gearbox Type 1.1 Parallel Shafts (helical) or right angle drive (bevel/helical), foot mount, shaft mount with or without foot. Prime Mover 1.2 Calculate gearbox ratio = Input Speed/ Output speed ELECTRIC MOTOR, Steam Turbines 2. Select Gearbox Size from Mechanical Capacity 2.1 Determine type of load from table 3 on page 10 (uniform, moderate shock or heavy shock). Multi-Cylinder Internal Combustion Engine Single Cylinder Internal Combustion Engine 2.2 Determine mechanical service factor from table 1. 2.3 Calculate the required mechanical power capacity (Pm ) (Pm ) = absorbed power (kW) x mechanical service factor 2.4 Select gearbox size from rating tables. Pm must be equal to or less than the mechanical rating of the gearbox. 3. Thermal Rating Check 3.1 Thermal ratings are given for the following four cases : Gearbox without additional cooling. Gearbox fitted with fan. Gearbox fitted with cooling water coil. Gearbox fitted with fan and coil. 3.2 Determine the thermal service factor from table 2. Pt must be equal to or less than the thermal capacity of the gearbox 0.80 1.00 1.25 1.00 1.25 1.50 1.50 1.75 2.00 Under 3 3 to 10 Over 10 1.00 1.25 1.50 1.25 1.50 1.75 1.75 2.00 2.25 Under 3 3 to 10 Over 10 1.25 1.50 1.75 1.50 1.75 2.00 2.00 2.25 2.50 Table 2 : Thermal Service Factors (Horizontal & Vertical) for ambient temperature and duration of operation. Type Of Cooling Ambient Temperature o C 100% 805 60% 40% 20% Gear 10 1.12 1.34 1.57 1.79 2.05 Running Time in Hour Boxes 20 1.00 1.20 1.40 1.60 1.80 without 30 0.88 1.06 1.23 1.41 1.58 additional 40 0.75 0.9 1.05 1.20 1.35 Cooling 50 0.63 0.76 0.88 1.01 1.13 3.3 Calculate the required thermal power capacity (Pt) (Pt ) = absorbed power (kW) ÷ thermal service factor. 3.4 Specify the type of cooling required by referring to thermal rating tables. Under 3 3 to 10 Over 10 Load Classifications-Driven Machine Uniform Moderate Heavy Shock Shock 10 1.15 1.38 1.61 1.84 2.07 Gear 20 1.00 1.20 1.40 1.60 1.80 Boxes 30 0.09 1.08 1.26 1.44 1.62 with Fan 40 0.80 1.96 1.12 1.29 1.44 50 0.70 0.84 0.98 1.12 1.26 . Additional Catalogue Information 1. Gearbox overload capacity at start. 2.5 x mechanical rating, 5 times per day or, 2 x mechanical rating, 5 times per hour. Gear 10 1.10 1.32 1.54 1.76 1.98 Boxes 20 1.00 1.20 1.40 1.60 1.80 2. Intermittent duty. Higher power than catalogue mechanical ratings can be transmitted on very intermittent operation within the finite life of the gears. Consult us with specific application details. with 30 0.09 1.08 1.26 1.44 1.62 Cooling 40 0.85 1.02 1.19 1.36 1.53 Coil (1) 50 0.80 0.96 1.12 1.29 1.44 Gear 10 1.12 1.34 1.57 1.79 2.05 Boxes 20 1.00 1.20 1.40 1.60 1.80 with Fan 30 0.92 1.10 1.29 1.47 1.66 & Cooling 40 0.83 1.0 1.16 1.33 1.50 Coil (1) 50 0.78 0.94 1.09 1.25 1.40 (1) Based on Cooling -Water Temperature 20 C. 5 of 80

- 6. AGNEE Series H Helical and Bevel Helical Gear Boxes HOW TO ORDER, Selection Example How to order-Information required when ordering standard gear units Prime Mover 1. Type - electric motor or engine, for example 4 cylinder internal combustion engine 2. Power rating in kW 3. Output speed. If variable, indicate speed range and frequency of variable. 4. Dimensions of prime mover. 3.Ratio 4.Shaft handling. Refer to dimension pages and quote reference. 5.Direction of rotation (for units with right angle shafts refer to handling diag rams on dimension pages). If holdback arrangement is to be fitted, please indicate the direction of rotation of low speed shaft looking towards it. Driven Machine 1. Type, for example, kiln, conveyor, etc. 2. Power rating in kW 3. Speed 4. Service - hours per day, running time in any hour, details of reversals if applicable, type of loading, ambient temperature, etc. Shaft Connections 1. Couplings Quote shaft diameters with tolerances or coupling bores. 2. Details of overhung loads, including diameter and type of sheave, sprocket or pinion and any thrust loads. Gear Unit 1. Type, for example, H2. 2. Size, for example, 315. Example 1 A foot mounted parallel shaft speed reducer is to be directly coupled to a 750 kW, 1500 rpm motor. The output shaft is to rotate at 365 rpm and is coupled to a large industrial fan absorbs 725 kW on 24 hours/day 0 service. The maximum ambient temperature is 30 C. Selection 1. Gearbox Type 1.1 Parallel shaft type is specified - type H. 1.2 Ratio =1500÷365 =4.11, type H1 (single reduction) 2. Mechanical Capacity 2.1 From table 3 on previous page the application is moderate shock. 2.2 From table 1 on page 3 the service factor is 1.5. 2.3 The required mechanical capacity = 1.5 x 725 = 1088 kW 2.4 Under mechanical ratings a unit size 315, nominal ratio 4.13, has a capacity of 1293 kW 3. Thermal Rating Check 3.1 From table 2 on previous page the thermal 0 service factor for 30 C ambient temperature and 100% running time is 0.9 for a unit with fan cooling (reference to the thermal ratings shows that at least fan cooling is required.) 3.2 The required thermal capacity = 725 - 0.9 = 806. 3.3 Under thermal ratings, fan cooled, a size 315 has a capacity of 918 kW at 1500 rpm, ratio 4.15 4. Check that the exact ratio. 5. Order a gearbox type H1 - 315 exact ratio 4.15 with cooling fans fitted. Shaft mounted units for High Inertia Drive When used on Traverse drives with inertia driven loads, e.g. crane drives (slewing, long travel and cross travel) bogie drives and selected high inertia load roller table drives, it is recommended that shaft mounted units should be fitted with shock absorbing Torque Arms. Consult us with specific application details. Example 2 A shaft mounted gear unit right angle shafts is required to drive a belt conveyor running 24 hours/day at 80 rpm. The unit must have feet for the attachment of a motor mounting baseplate. The motor is 500 kW at 1500 rpm and the absorbed power at the conveyor headshaft is 465 kW. The ambient temperature on 0 site is 20 C. Selection 1. Gearbox Type 1.1 Foot shaft mounted unit with right angle shafts. 1.2 Ratio = 1500÷80 = 18.8, type B2SF could be used 2. Mechanical Capacity 2.1 From table 3 on page 10 the application is uniform load. 2.2 From table 1 on page 3 the service factor is 1.25 2.3 The required mechanical capacity = 1.25 x 465 = 581 kW 2.4 Under mechanical ratings a unit size B3SF - 400, nominal ratio 18.9, has a capacity of 620 kW. The double reduction type B2SF - 400 ratio 18.9 has insufficient mechanical capacity. 3. Thermal Rating Check 3.1 From table 2 on previous page the thermal service factor 0 for 20 C. ambient temperature and 100% running time is 1.0 3.2 The required thermal capacity = 465÷1.0 = 465 kW. 3.3 Under thermal ratings, fan cooled, a size 400 at 1500 rpm has a capacity of 484kW 4. Check that the exact ratio. 5. Order a gearbox type B3SF - 400, exact ratio with cooling fans fitted. 6 of 80

- 7. AGNEE Series H Helical and Bevel Helical Gear Boxes OVERHUNG LOADS / AXIAL THRUST LOADS - HORIZONTAL UNITS Whenever a sprocket, gear, sheave or pulley is mounted on the shaft, a calculation should be made to determine the overhung load in kN on the shaft, using the formula : p Where P = = kW x 9545 x K ÷ N x R equivalent overhung load in kN, power carried by the shaft, rpm of the shaft pitch radius of sprocket, pinion, sheave or pulley (mm). Table 4 : Permissible Overhung Load on Low Speed Shaft (kN) (Horizontal Units) Direction Output of Speed Load (rpm) Types H2-H3-B2-B3 Unit Sizw Overhung member Sprocket for chain Spur gear V belt sheave Flat belt pulley Notes : 1. Values are calculated for the most unfavourable direction of rotation. Consult us with specific application details. 2. Overhung loaad values are for loads applied midway along shaft extension. 3. For overhung load and axial thrust values for large sizes consult us. 100 100 172 40 48 57 68 87 118 126 190 125 48 55 62 85 103 132 150 228 52 68 78 97 130 162 190 280 52 68 90 126 148 182 228 320 52 68 90 126 148 182 230 320 315 3 78 31.5> 2 56 80 K Factor 1 1.25 1.5 3.0 47 200 1 42 35 42 47 56 78 100 109 172 200 40 48 62 85 87 118 126 190 125> = = = 450 35 50 kW N R 200 225 250 280 315 355 400 315 41 48 62 85 99 120 150 215 315> 18 23 30 42 49 61 107 78 Table 5 : Permissible Overhung Load High Speed Shaft at 1500 rpm(kN) (Horizontal Units) Type of Unit Unit Size 200 225 250 H2-H2SH2SF 8.45 10.5 13.0 19.5 26.5 32.2 38.7 45.8 280 315 355 400 450 H3-H3SH3SF 3.03 4.58 6.45 B2-B2SB2SF 12.0 15.6 19.6 25.4 30.6 36.0 41.3 49.8 B3-B3SB3SF 3.03 7.12 8.90 12.0 15.6 19.6 25.4 30.6 8.4 10.5 13.0 20.0 28.9 Table 6 : Permissible Axial Thrust on Low Speed Shaft (kN) (Horizontal Units) Output Speed rpm Type H2-H3-B2-B3 400 450 315 12.0 12.5 13.4 11.8 18.3 30.3 28.8 53.4 200 13.4 14.2 15.2 13.3 20.8 34.3 32.6 60.5 125 17.1 17.3 18.0 18.4 25.3 40.0 40.9 70.8 80 18.2 20.5 21.8 23.8 35.6 63.6 55.4 80.85 50 19.4 25.8 25.3 32.1 43.5 66.3 68.5 94.3 31.5 and below 19.4 25.8 25.3 34.3 55.6 66.3 88.6 94.3 7 of 80 200 225 250 280 315 355

- 8. AGNEE Series H Helical and Bevel Helical Gear Boxes LOAD CLASSIFICATION BY APPLICATION 8 of 80

- 9. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H1 SINGLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (kW) Nominal Ratio Input Speed rpm Nominal Output Speed rpm 1.22 1500 1000 750 1.35 Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 1230 820 615 294 194 150 424 284 216 512 340 257 921 615 460 1107 739 577 4852 1229 924 2266 1510 1138 3145 2094 1572 3807* 2667 2172 5514* 3427 2793 5510 4490 5765 4354 1500 1000 750 1111 740 556 276 187 142 407 278 211 512 340 257 921 615 460 1097 732 563 1831 1219 916 2245 1500 1128 3114 2073 1562 3776 2594 2121 5472* 3420 2731 5365 4376 5765 4354 1.50 1500 1000 750 1000 667 500 259 180 136 380 271 204 491 350 260 866 611 458 1086 726 547 1707 1208 905 2224 1490 1117 3093 2063 1541 3745 2500 2007 5431* 3390 2710 5219 4262 5765 4354 1.66 1500 1000 750 904 602 452 251 178 141 343 242 193 455 324 259 810 588 441 1076 716 537 1603 1188 894 2193 1469 1097 3052 2042 1531 3703 2469 1893 5234 3360 2679 4979 4003 5765 4354 1.84 1500 1000 750 815 543 408 236 185 152 333 236 186 436 309 244 754 550 413 997 704 529 1552 1156 870 2059 1448 1086 2969 2010 1510 3414 2448 1841 4883 3300 2648 4927 3755 5765 4354 2.03 1500 1000 750 739 493 369 220 173 142 313 217 175 416 287 234 724 534 401 927 695 521 1448 1094 838 1934 1375 1034 2752 1900 1440 3300 2417 1810 4728 3220 2617 4865 3652 5503 4522 2.25 1500 1000 750 667 444 333 204 141 113 300 208 165 394 270 217 670 495 370 866 679 510 1334 1009 775 1810 1271 962 2534 1750 1320 3072 2313 1779 4366 3120 2472 4781 3579 5143 4226 2.49 1500 1000 750 602 402 301 191 133 104 277 192 150 378 261 207 616 465 379 815 672 506 1231 903 681 1676 1167 881 2200 1520 1150 2845 2146 1748 4003 3021 2320 4625 3507 4709 3896 Nominal ratios are shown. Interpolate for other input speeds. A case baffle is fitted where rating is shown in color. * forced lubrication is necessary. THERMAL CAPACITIES (KW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 1.22 to 1.84 1500 1000 750 48.5 49.8 50.9 64.7 65.8 67.8 82.8 84.7 86.7 197 202 208 304 316 328 2.03 to 3.05 1500 1000 750 37.5 41.7 43.8 50.3 55.6 58.7 64.2 71.4 75.6 152 170 180 3.38 to 5.06 1500 1000 750 35.7 37.8 39.8 48.5 51.8 53.8 62.3 67.6 69.8 130 158 158 1.22 to 1.84 1500 1000 750 185 134 110 252 183 150 330 239 196 490 411 371 770 645 584 2.03 to 3.05 1500 1000 750 134 99.0 82.6 182 135 113 239 176 148 331 278 252 3.38 to 5.06 1500 1000 750 99.0 81.4 72.9 135 111 99.0 177 145 130 277 233 210 225 250 280 315 355 400 450 500 376 397 414 571 601 632 702 808 777 1190 1277 1197 1453 1610 1587 2175 2357 1470 1440 235 250 254 309 325 325 494 486 482 634 616 612 988 925 922 1259 1214 1187 1937 1822 1280 1200 193 213 220 229 244 252 324 329 331 442 437 427 670 663 641 914 896 868 1236 1202 830 800 928 779 704 1351 1133 1024 1616 1357 1226 2520 2116 1912 3203 2687 2430 2250 2070 2810 2630 520 437 394 627 526 475 913 766 692 1093 917 829 1703 1430 1292 2202 1816 1641 1970 1710 2460 2150 437 367 332 526 442 399 766 643 581 918 771 696 1431 1201 1086 1849 1525 1379 1320 1100 1690 1410 Units without Fan Units with Fan Cooling Full Load Efficiency - 98.5% (approx.) 9 of 80

- 10. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H1 SINGLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (kW) Nominal Ratio Input Speed rpm Nominal Output Speed rpm 2.76 1500 1000 750 3.05 Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 543 362 272 173 122 96.0 250 176 140 358 247 197 587 443 348 764 578 436 1076 723 545 1521 1027 774 1976 1333 1007 2617 1979 1614 3838 2800 2160 4250 3217 4332 3559 1500 1000 750 492 328 246 164 112 89.0 232 161 127 301 207 161 532 400 304 719 544 414 880 670 500 1334 896 674 1800 1180 900 2390 1802 1469 3466 2550 1980 4031 3041 4014 3298 3.38 1500 1000 750 444 296 222 145 103 78.0 213 151 114 286 203 155 502 324 246 620 468 356 740 615 468 1200 876 660 1552 1042 785 2276 1719 1314 3300 2300 1750 3625 2731 3720 3057 3.73 1500 1000 750 402 268 201 128 91.0 69.2 187 131 101 275 192 147 391 254 193 530 386 294 720 543 413 1080 743 564 1400 1083 701 2048 1500 1138 2928 1979 1531 3094 2328 3517 2889 4.13 1500 1000 750 363 242 182 108 75.6 56.8 167 117 88.1 237 164 124 338 219 167 442 286 217 636 411 313 969 626 476 1293 833 633 1934 1281 972 2762 1781 1355 2740 2079 3310 2785 4.57 1500 1000 750 328 219 164 98.3 75.6 53.2 147 102 79.6 214 149 115 269 175 130 437 282 215 511 335 251 767 501 377 1055 690 515 1583 1022 776 2234 1448 1097 2281 1728 3026 2487 5.06 1500 1000 750 296 198 148 82.8 57.9 43.1 129 89.5 67.6 177 122 91.7 229 148 113 318 205 156 433 283 213 590 389 290 870 563 427 1221 798 598 1893 1219 926 1698 1283 2763 2270 Nominal ratios are shown.Interpolate for other input speeds. A case baffle is fitted where rating is shown in color. THERMAL CAPACITIES (kW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 1.22 to 1.84 1500 1000 750 201 187 179 250 232 223 304 282 270 365 335 322 486 443 430 1680 1540 1470 2.03 to 3.05 1500 1000 750 146 140 132 182 172 166 220 208 200 262 248 238 347 332 316 3.38 to 5.06 1500 1000 750 113 114 115 140 142 143 169 171 173 202 204 206 245 240 241 1.22 to 1.84 1500 1000 750 401 314 270 497 390 336 601 472 408 714 560 483 995 770 665 2310 1990 1790 2680 2450 2250 2.03 to 3.05 1500 1000 750 288 232 196 359 284 244 434 343 295 515 408 351 710 565 484 1790 1510 1340 3.38 to 5.06 1500 1000 750 207 172 159 257 213 198 311 258 239 370 308 285 487 386 344 1175 975 861 225 250 280 315 355 400 450 500 1920 1860 1800 3120 3200 3190 3530 3610 3600 4370 4500 4520 5050 5140 5700 5620 1270 1180 1110 1530 1400 1330 2820 2690 2530 3120 3080 3010 3880 3950 3940 4500 4510 5010 5010 840 763 709 985 900 840 2025 1840 1710 2410 2210 2080 3340 3170 2980 3460 3290 3900 3710 3970 3800 3670 4620 4390 4200 5580 5370 5200 6190 6040 6980 6810 2220 1860 1650 3580 3240 2960 4060 3760 3550 4900 4690 4530 5450 5240 6150 5910 1415 1190 1040 2600 2230 1980 3210 2740 2460 4280 3850 3480 4250 3900 4800 4400 Units with Cooling Coils + Units with Fan Cooling and Cooling Coils + Full Load Efficiency - 98.5% (approx.) + Based on cooling water temperature 20 degree Celsius. 10 of 80

- 11. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H2-H2S-H2SF DOUBLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (kW) Nominal Ratio Input Nominal Speed Output rpm Speed 140 160 180 200 rpm Unit Size 225 250 280 315 355 400 450 500 560 630 710 6290 5450 5.6 1500 1000 750 268 179 134 82.1 124 156 213 55.1 82.7 104 142 41.3 62.1 78.1 107 310 207 156 383 677 274 452 223 339 905 605 455 1148 1428 2328* 766 1073 1635 575 872 1334 3630 2050 1890 4630 3290 2720 4290 3290 6.2 1500 1000 750 242 161 121 76.6 117 148 199 51.0 78.0 98.6 132 38.3 58.6 74.0 99.4 283 190 142 420 618 314 413 235 310 822 550 422 1055 1314 2131* 722 993 1479 589 810 1210 2970 1880 1740 4420 3000 2490 3980 3050 6.86 1500 1000 750 219 146 109 76.6 117 148 199 51.0 78.0 98.6 132 38.3 58.6 74.0 99.4 273 182 140 400 592 300 395 224 299 785 525 422 991 1314 2007* 722 993 1479 589 810 1210 2700 1860 1700 4010 2720 2180 3770 2860 7.59 1500 1000 750 198 132 98.8 76.6 108 143 189 51.0 74.8 99.1 126 38.3 53.8 71.4 94.7 248 166 127 381 539 270 360 204 272 730 498 407 896 1241 1831* 652 933 1385 533 762 108626 2640 1800 1650 3700 2520 2120 3720 2820 8.4 1500 1000 750 179 119 89.3 66.3 97.6 131 177 44.2 65.1 87.6 120 33.1 48.8 65.7 97.4 247 181 140 333 498 260 365 202 287 622 468 380 913 1138 1676* 667 871 1323 544 714 1107 2610 1760 1610 3680 2550 2180 3080 2450 9.3 1500 1000 750 161 108 80.7 62.2 91.4 119 162 41.5 60.9 79.3 113 31.0 45.7 59.5 89.9 226 155 127 323 458 247 333 187 261 601 439 350 834 1045 621 799 503 669 1609 1198 1010 2600 1740 1460 3620 2470 2130 3060 2440 10.3 1500 1000 750 146 97.1 72.8 53.9 83.1 113 151 35.9 55.4 75.2 101 27.0 41.6 56.4 80.0 212 149 117 293 394 235 307 180 231 529 420 321 707 917 531 719 400 604 1379 1083 910 2450 1700 1360 3120 2350 2020 3140 2450 11.4 1500 1000 750 132 87.7 65.8 50.6 73.2 105 137 33.8 48.9 69.7 97.4 25.3 36.6 52.2 76.1 187 133 101 280 408 204 283 155 212 519 376 282 684 881 524 694 407 579 1376 1063 860 2200 1480 1140 2870 REFER 2040 TO 1700 AGNEE For capacities higher than above - refer to AGNEE. Nominal ratios are shown. Interpolate for other input speeds. A case baffle is fitted where rating is shown in color. * Forced lubrication system required for Vertical Units. THERMAL CAPACITIES (kW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 Units without Fan Cooling (Horizontal) 5.60 to 11.4 1500 1000 750 28.8 27.2 27.0 35.8 45.7 34.2 44.2 33.1 43.1 82 82 76 102 125 160 220 300 388 480 100 121 156 220 300 388 480 96 115 150 203 278 359 444 495 490 480 615 610 600 760 750 990 970 12.6 to 25.6 1500 1000 750 27.8 27.1 26.1 33.8 43.6 32.2 42.2 31.1 41.1 77 81 76 97 120 156 196 250 324 382 97 115 151 193 250 324 382 82 111 148 185 232 299 353 475 470 460 595 590 580 730 720 960 950 Units with Fan Cooling (Horizontal) 5.60 to 11.4 1500 1000 750 76.5 65.1 57.7 95.7 127 153 81.2 108 130 72.0 96.2 116 186 254 352 460 699 986 1323 1080 169 205 284 370 563 795 1245 860 149 197 272 355 540 762 1043 740 1350 1070 920 1650 1450 1980 1820 12.6 to 25.6 1500 1000 750 71.7 60.9 52.0 95.7 119 143 75.1 102 122 64.2 85.7 104 180 217 280 365 555 782 1017 1040 150 186 247 319 447 630 956 830 131 171 219 279 427 605 800 720 1300 1040 900 1250 1090 1470 1300 Full Load Efficiency - 98% (approx.) 11 of 80

- 12. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H2-H2S-H2SF DOUBLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAP ACITIES (kW) Input Nominal Nominal Speed Output Ratio Speed rpm rpm Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 560 12.6 1500 1000 750 119 79.4 59.5 43.5 29.1 21.8 64.5 43.0 32.8 92.5 123 171 264 367 468 61.5 86.9 125 177 253 339 46.1 64.7 94.0 137 188 256 639 496 379 804 632 527 1252 950 756 1900 1255 980 1500 1000 750 107 71.4 53.6 40.2 26.9 20.2 52.7 35.1 26.4 84.0 112 160 243 322 443 56.0 79.0 116 171 229 311 42.0 61.9 90.4 130 175 246 598 400 301 734 572 473 1097 861 723 1800 1250 935 2520 1770 1330 15.4 1500 1000 750 97.4 64.9 48.7 35.1 23.8 17.6 51.3 34.5 25.7 77.7 92.9 140 200 265 393 51.7 61.1 82.7 129 175 264 38.9 45.7 69.2 98.6 130 198 511 335 251 692 501 372 1045 690 515 1600 1060 830 2260 1540 1240 17.1 1500 1000 750 87.7 58.5 39.7 32.2 21.5 16.1 47.5 31.7 23.8 68.3 91.7 133 200 266 395 45.5 61.1 82.7 129 175 264 34.1 45.7 66.8 98.6 130 198 487 326 245 628 494 372 968 691 513 1480 980 760 2080 1390 1060 18.9 1500 1000 750 79.4 52.9 39.7 28.7 19.1 14.4 42.8 28.5 21.4 61.5 72.2 108 152 218 310 41.0 47.6 70.6 100 144 204 30.7 35.5 53.0 74.5 107 152 433 283 213 590 389 290 870 563 427 1340 900 730 1900 1280 1020 20.9 1500 1000 750 71.8 47.8 35.9 24.8 16.6 12.4 39.8 26.6 19.9 54.1 65.2 87.8 126 186 253 36.0 46.5 61.0 87.5 132 181 27.0 36.1 45.8 65.7 103 142 357 252 189 501 334 252 739 540 422 1230 830 700 1840 1230 970 23.2 1500 1000 750 64.7 43.1 32.3 22.3 14.9 11.2 33.0 22.0 16.5 48.7 59.7 80.2 114 170 235 32.5 42.5 54.7 77.0 121 167 24.4 32.6 41.1 57.8 94.8 130 328 227 171 452 303 228 700 499 391 25.6 1500 1000 750 58.6 39.1 29.3 17.4 11.6 8.7 26.6 17.4 13.0 37.1 49.0 69.7 95.4 132 185 24.8 34.9 49.7 67.9 94.2 132 20.4 27.3 38.9 53.2 73.8 103 271 193 151 397 282 221 710 2680 1810 1615 14.0 630 565 402 314 For capacities higher than above - refer to AGNEE. Nominal ratios are shown. Interpolate for other input speeds. THERMAL CAPACITIES (kW) Nominal Ratio Input Speed rpm Unit Size 140 160 5.60 to 11.4 1500 1000 750 130 129 127 139 139 136 157 170 192 435 490 1040 1210 1770 2010 2320 3040 155 168 188 403 447 940 1110 1620 1860 2190 2860 3320 4070 152 165 185 385 422 877 1030 1510 1740 2040 2680 3070 3740 12.6 to 25.6 1500 1000 750 116 116 113 123 122 120 140 150 177 323 358 701 138 147 174 325 353 647 135 145 170 326 354 627 5.60 to 11.4 1500 1000 750 222 207 200 238 221 213 265 286 318 592 695 1330 1610 2280 2660 3080 3990 246 266 295 500 573 1120 1360 1940 2280 2790 3610 4470 5460 224 257 282 453 510 1000 1200 1740 2030 2560 3330 4080 5010 12.6 to 25.6 1500 1000 750 191 182 172 204 194 184 228 246 271 417 484 882 1070 1540 1750 2320 3180 216 233 259 388 435 760 900 1290 1450 2060 2870 3310 4130 205 222 251 374 415 705 813 1140 1290 1910 2640 3000 3760 180 200 225 250 280 315 355 400 450 500 560 630 710 Units with Cooling coils (Horizontal) 824 1200 1340 1590 2270 749 1080 1210 1480 2140 2430 3100 705 1000 1110 1400 2010 2240 2850 Units with Fan and cooling coils (Horizontal) Full Load Efficiency - 98% (approx.) + Based on cooling water temperature 20 degree Celsius. Cooling coil not available for vertical units. 12 of 80

- 13. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H3-H3S-H3SF TRIPLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Unit Size Input Nominal Nominal Speed Output Ratio Speed 140 160 180 200 225 250 280 315 355 400 rpm rpm 20.9 1500 1000 750 71.8 47.8 35.9 23.2 1500 1000 750 64.7 43.1 32.4 25.6 1500 1000 750 58.6 39.1 29.3 22.1 34.1 49.8 63.8 86.9 125 192 260 336 513 14.8 22.8 33.2 48.1 63.0 93.5 128 174 248 368 11.1 17.1 24.9 37.8 47.3 76.2 96.3 130 186 276 28.4 1500 1000 750 52.8 35.2 26.4 31.4 1500 1000 750 34.7 450 500 560 630 710 1080 810 660 1420 1910 1070 1390 890 1130 1090 820 650 1570 2060 1140 1430 860 1240 707 513 386 1076 782 589 1417 1914 1035 1354 780 1127 20.9 29.8 45.4 62.3 84.0 123 173 229 330 482 14.0 19.9 30.3 44.5 58.2 85.0 116 152 221 330 10.5 14.9 22.8 33.8 43.7 69.3 86.9 115 166 248 702 471 354 1055 705 530 1407 1800 940 1208 708 910 47.8 31.8 23.9 17.1 26.5 41.2 53.1 74.5 109 157 210 295 426 11.5 17.7 27.5 40.0 51.5 82.2 105 141 203 297 8.60 13.2 20.6 30.4 38.6 64.8 78.6 106 152 223 611 415 311 966 648 488 1272 1655 852 1114 641 838 1500 1000 750 43.2 28.8 21.6 16.7 24.5 38.1 49.4 69.7 102 140 189 278 406 11.1 16.4 25.4 35.3 46.6 71.6 93.4 126 186 272 8.30 12.2 19.0 27.7 35.0 56.2 70.0 95.0 140 204 568 383 288 852 571 429 1127 1479 756 989 569 745 38.4 1500 1000 750 39.1 26.0 19.5 14.8 22.4 33.5 48.5 63.0 93..9 128 170 245 367 9.91 14.9 22.3 33.4 42.0 69.7 85.6 114 164 246 7.42 11.2 16.8 25.1 31.6 52.2 64.2 85.0 123 185 509 341 256 793 531 399 1034 1345 697 900 524 677 42.5 1500 1000 750 35.3 23.5 17.6 13.2 20.0 30.8 41.2 57.0 85.4 114 153 228 329 8.89 13.3 20.6 29.4 38.0 60.9 76.3 102 152 220 6.66 10.0 15.4 22.4 28.6 47.1 57.2 76.7 115 166 462 309 233 705 472 355 928 1210 622 812 467 611 47.1 1500 1000 750 31.8 21.2 15.9 12.5 18.4 26.7 36.9 58.0 84.1 111 153 200 283 8.35 13.3 20.6 24.6 39.0 58.0 73.5 102 133 190 6.26 9.21 13.3 18.4 29.3 43.6 55.1 76.7 100 142 423 283 213 649 434 327 905 606 455 52.1 1500 1000 750 28.8 19.2 14.4 11.0 16.7 23.8 33.3 54.3 76.3 99.8 139 178 256 7.38 11.1 15.9 22.2 36.3 51.9 66.6 92.3 119 171 5.51 8.33 11.9 16.7 27.2 38.9 50.0 69.2 89.1 128 393 264 198 579 387 291 822 551 414 TYPES H2-H2S-H3SF REFER TO AGNEE THERMAL CAPACITIES (kW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 Units without Fan (Horizontal) 25.6 to 42.5 1500 1000 750 25.2 23.2 21.2 33.3 30.3 28.2 42.3 38.4 36.2 50 46 43 63 59 56 75 69 67 95 91 88 121 116 112 151 145 141 188 180 173 238 229 224 340 330 320 425 415 405 550 535 520 685 665 650 47.1 to 130 1500 1000 750 22.2 20.2 19.1 29.0 27.2 25.2 37.2 34.3 32.2 31 22 18 38 27 22 48 35 28 59 42 34 77 56 44 95 67 54 121 87 70 151 108 87 320 315 310 405 400 395 530 520 510 670 660 645 Units with Fan Cooling (Horizontal) 25.6 to 42.5 1500 1000 750 - - - 72 66 60 90 84 80 108 99 96 136 130 126 174 166 160 215 207 201 268 257 248 340 328 320 720 650 590 930 850 800 1200 1100 1010 1520 1410 1300 47.1 to 70.6 1500 1000 750 - - - 51 40 35 57 44 38 74 57 50 89 70 60 114 89 77 145 114 98 186 146 126 260 204 175 720 650 590 930 850 800 1200 1100 1010 1520 1410 1300 13 of 80

- 14. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H3-H3S-H3SF TRIPLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Nominal Ratio Input Speed rpm Nominal Output Speed rpm 57.7 1500 1000 750 63.8 Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 560 26.0 17.3 13.0 9.91 6.59 4.95 15.7 10.5 7.93 21.2 14.2 10.6 30.9 20.6 15.5 49.4 32.9 24.7 70.6 47.2 35.4 92.1 61.5 46.0 129 85.9 64.4 159 106 80.0 240 160 120 347 231 174 538 359 270 751 503 377 1500 1000 750 23.5 15.7 11.8 8.31 5.61 4.19 13.6 9.03 6.78 17.7 11.8 8.83 27.6 18.4 13.9 44.7 29.8 22.3 63.9 42.6 32.0 82.0 54.7 41.1 116 77.4 58.0 149 99.2 74.4 215 144 108 314 210 158 478 320 240 670 448 337 70.6 1500 1000 750 21.2 14.2 10.6 7.75 5.16 3.87 12.3 8.21 6.16 17.4 11.6 8.69 22.0 14.7 11.0 34.2 23.3 17.6 45.6 31.4 23.5 67.3 47.7 36.3 91.8 61.1 45.9 130 92.2 71.0 194 130 97.9 272 182 137 438 294 220 613 410 308 78.2 1500 1000 750 19.2 12.8 9.59 6.85 4.56 3.42 10.8 7.17 5.38 16.5 10.9 8.22 22.7 15.1 11.4 31.9 22.7 17.8 50.3 33.5 25.8 65.2 45.7 34.2 94.6 65.1 48.8 119 79.1 59.3 177 118 88.6 252 171 128 388 259 194 549 368 276 86.5 1500 1000 750 17.3 11.6 8.67 6.40 4.27 3.21 9.61 6.41 4.81 14.8 9.86 7.40 17.7 11.8 8.86 28.2 18.9 14.2 38.3 25.5 19.1 55.9 38.9 29.2 72.7 48.5 36.4 112 79.3 59.5 155 103 77.6 228 152 114 316 211 158 468 313 235 95.7 1500 1000 750 15.7 10.4 7.84 5.78 3.86 2.90 8.26 5.51 4.14 12.1 8.05 6.13 16.1 10.7 8.07 26.1 17.4 13.0 35.6 23.8 17.8 52.3 36.0 27.0 69.5 46.4 34.8 101 70.2 52.7 143 95.6 71.7 202 134 101 279 186 139 420 281 211 106 1500 1000 750 14.2 9.43 7.08 5.24 3.49 2.63 7.70 5.13 3.86 10.77 7.18 5.38 14.6 9.70 7.27 23.3 15.5 11.6 32.1 21.4 16.0 47.9 32.5 24.4 61.1 40.7 30.6 92.4 63.2 47.4 127 85.0 63.7 185 124 92.8 257 172 129 386 258 193 117 1500 1000 750 12.8 8.55 6.41 4.71 3.14 2.37 6.73 4.48 3.37 9.86 6.58 4.93 13.1 8.74 6.55 20.9 14.0 10.4 28.2 18.9 14.1 43.9 29.3 21.9 54.4 36.3 27.2 85.9 58.1 43.6 115 76.6 57.4 169 113 84.6 130 1500 1000 750 11.5 7.69 5.77 3.74 2.49 1.89 6.01 4.01 3.01 8.28 5.52 4.14 12.7 8.54 6.40 16.8 11.1 8.39 24.5 16.4 12.3 31.6 21.0 15.7 45.5 30.3 22.8 61.8 41.1 30.9 99.0 66.0 49.6 130 86.9 65.2 630 710 REFER TO AGNEE For higher SIZES - refer to AGNEE. Nominal ratios are shown.Interpolate for other input speeds. THERMAL RATINGS (KW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 Units with Cooling Coils + 25.6 to 42.5 1500 1000 750 42 42 41 54 53 53 60 60 59 79 70 78 91 90 89 228 229 230 244 245 246 439 430 426 490 474 466 722 674 653 782 720 685 1240 1230 1220 1380 1370 1360 1630 1620 1610 2150 2130 2110 47.1 to 130 1500 1000 750 39 39 39 50 49 48 55 55 54 74 74 73 90 89 88 218 219 219 229 230 231 420 422 422 427 425 426 608 592 587 626 611 599 1090 1080 1070 1260 1250 1240 1520 1510 1500 2030 2020 2010 25.6 to 42.5 1500 1000 750 760 696 668 830 745 703 1240 1230 1220 1750 1740 1730 2130 2120 2110 2750 2730 2710 Units with Fan and Cooling Coils + 93 94 96 121 123 126 240 238 236 260 255 253 Full Load Efficiency - 97.5% (approx.) + Based on cooling water temperature 20 degree Celsius. Cooling coils not available for vertical units. 14 of 80 459 442 435 518 490 478

- 15. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H4-H4SF QUADRUPLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Input Nominal Nominal Speed Output Ratio Speed 140 160 180 200 225 rpm rpm Unit Size 250 280 315 355 400 450 500 560 630 710 106 1500 1000 750 14.15 9.43 7.08 5.3 8.5 12.6 15 20.0 3.5 5.6 8.4 10 13.3 2.65 4.25 6.3 7.5 10 35.6 23.7 17.8 44.6 62.7 75.3 95.0 153 267 378 505 29.7 41.8 50.2 63.3 102 178 252 337 22.3 31.35 37.7 47.5 76.5 134 189 253 117 1500 1000 750 12.82 8.55 6.41 4.8 7.7 11.3 13.3 18.5 3.2 5.1 7.5 8.9 12.3 2.4 3.85 5.65 6.65 9.25 31.0 20.6 15.5 40.8 27.2 20.4 53.9 70.8 88.3 141 243 336 449 35.9 47.2 58.9 94 162 224 299 26.9 35.4 44.2 70.5 122 168 225 130 1500 1000 750 11.54 7.69 5.77 4.3 6.9 10.1 12.2 16.5 2.8 4.6 6.7 8.13 11.0 2.15 3.45 5.05 6.1 8.25 28.0 18.6 14.0 36.9 24.6 18.5 49.0 60.8 78.6 127 218 308 400 32.6 40.5 52.4 84.7 145 205 267 24.5 30.4 39.3 63.5 109 154 200 144 1500 1000 750 10.42 6.94 5.21 3.9 6.2 2.6 4.1 1.95 3.1 26.1 17.4 13.0 33.4 22.3 16.7 46.1 58.0 71.1 112 196 279 376 30.7 38.7 47.4 74.7 131 186 251 23.0 29 35.6 56 98 140 188 159 1500 1000 750 9.43 6.29 4.72 3.5 5.6 8.1 10.3 14.2 23.7 31.0 2.3 3.7 5.4 6.9 9.5 15.8 20.7 1.75 2.8 4.05 5.15 7.1 11.85 15.5 176 1500 1000 750 8.52 5.68 4.26 3.2 2.1 1.6 9.3 13.2 6.2 8.8 4.7 6.6 21.4 14.2 10.7 41.8 53.9 66.1 105 182 257 342 27.8 35.9 44.1 70 121 171 228 20.9 27 33.1 52.5 91 129 171 REFER TO 28.1 37.7 48.1 61.6 98 163 229 300 AGNEE 18.7 25.1 32.1 41.1 65.3 109 153 200 14.1 18.85 24.1 30.8 49 82 115 150 195 1500 1000 750 7.69 5.13 3.85 2.8 4.5 6.5 8.6 11.9 1.8 3.0 4.3 5.7 7.9 1.4 2.25 3.25 4.3 6.0 19.3 12.8 9.65 25.5 17 12.8 215 1500 1000 750 6.97 4.65 3.48 2.5 4.0 1.6 2.6 1.25 2.0 7.7 10.9 5.1 7.3 3.9 5.5 17.3 11.5 8.65 23.1 30.7 39.1 50.5 80 135 192 249 15.4 20.4 26.1 33.7 53.3 90 128 166 11.6 15.35 19.6 25.3 40 68 96 125 238 1500 1000 750 6.30 4.20 3.15 2.3 3.7 5.2 1.5 2.4 3.4 1.15 1.85 2.6 6.8 4.5 3.4 9.8 6.5 4.9 15.8 20.7 27.9 35.6 44.2 72.3 121 173 225 10.5 13.8 18.6 23.7 29.5 48.2 81 115 150 7.9 10.35 13.95 17.8 22.1 36.1 61 87 113 264 1500 1000 750 5.68 3.78 2.84 2.09 3.3 4.6 1.39 2.2 3.0 1.04 1.65 2.3 6.3 4.2 3.1 8.8 5.8 4.4 14.3 9.5 7.15 5.0 3.3 2.5 9.0 11.0 15.2 6.0 7.3 10.1 4.5 5.5 7.6 7.2 4.8 3.6 5.8 3.8 2.9 18.9 12.6 9.4 34.1 43.0 54.9 88 148 210 276 22.7 28.7 36.6 58.7 99 140 184 17.0 21.5 27.5 44 74 105 138 25.3 31.8 40.7 64.8 104 152 200 16.8 21.2 27.1 43.2 69 101 133 12.6 15.9 20.3 32.4 52 76 100 For higher SIZES - refer to AGNEE. Nominal ratios are shown.Interpolate for other input speeds. THERMAL RATINGS (KW) Nominal Input Speed Ratio rpm Unit Size 140 160 180 200 225 15.2 14.1 13.1 20.3 18.2 17.1 25.3 23.2 21.2 32.0 32.3 26.4 39.6 32.3 250 280 315 355 400 450 500 560 630 710 98.4 79.3 127.8 102.9 22.19 158.7 127.8 246 242 238 311 308 304 407 515 400 507 392 496 Units without Fan 106 to 657 1500 1000 750 51.4 41.1 86.7 61.7 49.9 Full Load Efficiency - 97.5% (approx.) 15 of 80 82.3 64.6

- 16. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE H4-H4SF QUADRUPLE REDUCTION UNITS - PARALLEL SHAFTS MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Nominal Nominal Input Speed Output Ratio Speed rpm rpm Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 292 1500 1000 750 5.13 3.42 2.56 1.88 1.25 0.94 2.98 4.18 1.98 2.78 1.49 2.09 5.7 3.8 2.8 8.0 5.3 4.0 13.0 17.3 22.9 29.8 37.0 59.2 8.6 11.5 15.2 19.8 24.6 39.4 6.5 8.65 11.45 14.9 18.5 29.6 96 64 48 139 179 93 119 70 90 323 1500 1000 750 4.64 3.09 2.32 1.69 1.12 0.84 2.68 3.70 1.78 2.46 1.34 1.35 5.2 3.4 2.6 7.3 4.8 3.65 9.0 6.0 4.5 15.8 10.5 7.9 21.1 14.1 10.5 27.1 33.6 54.1 18.0 22.4 36.0 13.5 16.8 27.0 90 60 45 126 170 84 113 63 85 358 1500 1000 750 4.19 2.79 2.09 1.52 1.01 0.76 2.41 3.35 4.7 1.60 2.23 3.1 1.20 1.67 2.35 6.6 4.4 3.3 8.2 14.3 5.46 9.5 4.1 7.15 19.2 12.7 9.6 24.5 30.6 48.8 16.3 20.4 32.5 12.2 15.3 24.4 83 55 42 107 148 71 99 54 74 396 1500 1000 750 3.78 2.52 1.89 1.37 2.17 3.0 4.3 5.9 7.4 12.8 0.9 1.4 2.0 2.8 3.9 4.92 8.5 0.685 1.08 1.50 2.15 3.95 3.69 6.4 17.4 11.5 8.7 22.1 27.5 44.2 14.7 18.3 29.4 11.0 13.7 22.1 72 48 36 101 136 67 91 51 68 438 1500 1000 750 3.42 2.28 1.71 1.23 0.82 0.61 1.95 2.69 2.3 1.30 1.79 1.5 0.97 1.34 1.15 3.8 2.5 2.9 4.50 3.00 2.25 7.6 5.0 3.8 10.5 7.0 5.25 13.3 18.5 25.6 8.8 12.3 17.0 6.6 9.2 12.8 67 45 34 95 63 48 485 1500 1000 750 3.09 2.06 1.54 1.10 0.73 0.55 1.76 2.41 2.1 1.17 1.60 1.4 0.88 1.20 1.05 3.6 2.4 1.8 4.23 2.82 2.11 7.0 4.6 3.5 9.7 6.4 4.85 11.7 16.9 23.1 7.8 11.2 15.4 5.8 8.4 11.5 60 40 30 85 57 43 536 1500 1000 750 2.79 1.86 1.39 1.0 0.6 0.5 1.58 2.15 1.05 1.43 0.52 1.07 2.5 1.6 1.2 3.1 4.0 2.0 2.66 1.55 2.0 6.3 4.2 3.1 8.4 5.6 4.2 10.9 15.1 21.0 7.2 10.0 14 5.4 7.5 10.5 51 77 34 51.3 26 39 594 1500 1000 750 2.52 1.68 1.26 0.9 0.6 0.45 1.42 1.93 0.94 1.28 0.71 0.96 2.2 1.4 1.1 2.5 3.9 5.7 1.6 2.6 3.8 1.25 1.95 2.85 7.6 5.0 3.8 9.9 6.6 4.9 13.6 19.0 9.0 12.6 6.8 9.5 48 68 32 45.3 24 34 657 1500 1000 750 2.28 1.52 1.14 0.8 0.5 0.4 1.28 1.72 0.85 1.14 0.64 0.86 1.8 1.3 0.9 2.4 1.6 1.2 7.1 4.7 3.55 9.2 6.1 4.6 12.8 17.8 8.5 11.8 6.4 8.9 47 31 24 3.7 2.4 1.85 5.4 3.6 2.7 For higher SIZES - refer to AGNEE. Full Load Efficiency - 96.5% (approx.) 16 of 80 67 45 34 122 81 61 REFER TO AGNEE

- 17. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE B2-B2SF DOUBLE REDUCTION UNITS - RIGHT ANGLE SHAFTS - MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Nominal Ratio Input Speed rpm Nominal Output Speed rpm 5.06 1500 1000 750 5.60 Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 296 198 148 75.9 50.6 38.0 114 75.6 56.7 150 111 84.7 224 150 113 322 215 161 450 300 224 618 411 308 830* 553 415 1117* 744 558 1666* 1135 854 2048* 1542 1179 1500 1000 750 268 179 134 72.5 50.4 38.0 112 75.4 56.7 148 108 84.3 224 150 113 306 215 161 450 300 224 618 411 308 830 553 415 1117* 744 558 1614* 1135 854 2048* 1542 1179 6.20 1500 1000 750 242 161 121 71.6 50.3 38.0 107 75.0 56.7 143 105 82.6 224 150 113 288 215 161 450 300 224 618 411 308 830 553 415 1117* 744 558 1479* 1115 854 2048* 1542 1179 6.86 1500 1000 750 219 146 109 67.4 49.4 37.9 100 73.7 56.6 137 100 78.3 212 145 111 277 190 143 415 282 215 618 411 308 830 553 415 1066* 744 558 1417* 1073 834 2048* 1542 1179 7.59 1500 1000 750 198 132 98.8 63.0 46.1 36.0 93.6 68.6 53.4 125 91.4 71.3 181 121 90.5 252 173 129 378 253 190 502 334 250 713 475 357 965 643 482 1314* 939 704 1862* 1313 984 8.40 1500 1000 750 179 119 89.3 55.7 38.4 29.5 85.0 58.7 45.3 118 80.8 62.3 162 108 81.1 231 157 118 320 213 159 440 293 219 606 404 303 848 566 424 1210 821 616 1676 1156 869 9.30 1500 1000 750 161 108 80.6 51.2 35.4 27.1 76.9 53.1 40.6 105 72.1 55.0 139 92.4 69.3 209 140 104 278 185 139 381 254 190 542 361 271 714 476 357 1066 709 532 1490 993 745 10.3 1500 1000 750 146 97.1 72.8 46.8 31.3 23.7 69.9 46.9 35.4 97.2 65.3 49.3 117 83 65.9 169 120 93.1 228 163 126 326 227 171 434 320 240 647 431 324 897 652 489 1345 899 674 For higher SIZES - refer to AGNEE. Nominal ratios are shown. Interpolate for other input speeds.* Forced lubrication is necessary. THERMAL CAPACITIES (KW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 Units Without Fan ( Horizontal) 5.06 to 9.30 1500 1000 750 40 41 42 52 52 53 64 64 65 79 80 81 99 100 106 122 124 125 153 177 189 201 241 258 292 328 318 373 454 443 425 584 581 Refer to AGNEE 10.3 to 18.9 1500 1000 750 39 40 41 51 51 51 62 62 62 71 78 79 96 97 99 116 118 120 146 163 174 193 222 236 269 319 311 343 417 429 503 529 512 Refer to AGNEE Units With Fan Cooling ( Horizontal) 5.06 to 9.30 1500 1000 750 85 73 63 111 95 83 140 120 105 173 149 130 214 191 173 272 238 230 368 320 290 449 389 355 661 575 522 864 751 682 955 1092 976 Refer to AGNEE 10.3 to 18.9 1500 1000 750 84 71 63 109 92 81 137 117 102 171 146 128 212 189 170 275 233 204 331 285 240 389 353 323 548 470 425 701 612 546 860 871 793 Refer to AGNEE 17 of 80 REFER AGNEE

- 18. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE B2 -B2SF DOUBLE REDUCTION UNITS - RIGHT ANGLE SHAFTS - MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Nominal Nominal Input Output Speed Ratio rpm Speed rpm Unit Size 140 160 180 200 225 250 280 315 355 577 385 289 400 450 827 556 418 1169 780 586 11.4 1500 1000 750 132 87.7 65.8 40.1 28.0 21.1 64.5 45.0 33.9 88.6 61.9 46.8 108 71.7 53.8 155 105 78.8 209 144 108 300 200 150 401 276 207 12.6 1500 1000 750 119 79.4 59.5 35.5 24.7 18.5 57.5 40.2 29.9 78.1 54.5 40.5 93.4 62.6 47.0 134 89.6 67.2 187 125 93.5 257 171 128 351 234 176 493 329 246 729 486 364 1009 673 505 14.0 1500 1000 750 107 71.4 53.6 30.9 21.6 16.2 46.7 32.6 24.3 65.2 45.5 33.8 80.7 57.6 38.0 115 82.1 64.3 158 114 88.9 217 115 122 305 219 171 446 319 246 656 468 364 933 66 504 15.4 1500 1000 750 97.4 64.9 48.7 28.6 20.0 14.8 42.9 30.0 22.3 57.2 40.0 29.8 74.3 52.3 39.2 106 75.5 58.4 146 104 80.7 207 143 109 298 200 150 411 283 212 604 413 309 860 573 430 17.1 1500 1000 750 87.8 58.5 43.9 24.0 16.8 12.5 37.9 26.5 19.7 52.0 36.2 27.0 62.4 41.6 31.1 96.4 64.3 48.2 119 79.2 59.4 178 119 88.8 242 161 121 323 215 160 462 308 232 663 443 332 18.9 1500 1000 750 79.4 52.9 39.7 23.4 16.4 12.2 35.2 24.5 18.2 48.6 33.9 25.2 62.4 41.6 31.1 87.5 58.3 43.8 119 116 86.5 170 116 86.5 242 161 121 316 210 157 462 308 232 663 443 332 500 For higher SIZES - refer to AGNEE. Nominal ratios are shown. Interpolate for other input speeds.* Forced lubrication is necessary. . THERMAL CAPACITIES (KW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 225 250 280 315 355 400 450 500 Units with cooling coils* ( Horizontal) 5.06 to 9.30 1500 1000 750 106 106 105 135 135 134 152 151 151 169 169 169 242 238 235 588 533 507 679 1420 611 1270 571 1180 1590 1440 1340 2330 2170 2020 1960 1860 1740 Refer to AGNEE 10.3 to 18.9 1500 1000 750 101 100 100 129 128 127 145 145 144 161 161 160 238 235 233 437 423 414 471 449 440 1110 998 629 1680 1510 1400 1450 1310 1210 Refer to AGNEE 5.06 to 9.30 1500 1000 750 161 148 138 206 189 176 231 213 198 257 236 221 317 286 260 755 636 580 899 1720 751 1470 670 1320 1980 1700 1520 2820 2500 2270 2540 2240 2030 Refer to AGNEE 10.3 to 18.9 1500 1000 750 141 133 124 180 169 159 202 190 115 224 211 199 288 263 242 545 495 468 608 1190 537 1020 505 940 1380 1160 1050 2040 1740 1550 1890 1580 1400 Refer to AGNEE 990 896 849 Units With Fan Cooling and cooling coils *( Horizontal) Full load efficiency -97%, 8 Based on cooling water temperature 20o C 18 of 80 REFER AGNEE

- 19. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE B 3-B3SF TRIPLE REDUCTION UNITS - RIGHT ANGLE SHAFTS - MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Input Nominal Nominal Speed Output Ratio rpm Speed 140 rpm Unit Size 160 180 200 225 250 280 315 355 400 450 500 560 630 710 2165 1448 1086 2958 1968 1479 2541* 1903 14.0 1500 1000 750 107 71.4 53.6 27.6 45.9 69.8 93.7 18.4 34.3 50.0 62.5 13.9 26.1 38.0 46.9 127 84.9 63.7 191 128 106* 256 171 127 332 231 174 529 352 264 688 459 344 965 643 482 2162 987 740 15.4 1500 1000 750 97.4 64.9 48.7 27.6 45.5 68.3 93.7 18.4 34.3 50.0 62.5 13.9 26.1 38.0 46.9 127 84.9 63.7 191 128 106* 256 171 127 332 231 174 515 344 268 643 429 323 955 643 482 1479 2162* 2958* 987 1448* 1968* 2541* 740 1086 1479 1903 17.1 1500 1000 750 87.7 58.5 43.9 27.6 45.5 68.3 75.9 117 18.4 33.3 46.0 50.6 78.1 13.9 25.9 35.0 38.0 69.71 178 78.1 69.7 254 170 127 332 231 174 451 314 236 620 426 320 909 606 455 1479 2162* 2958* 987 1448* 1968* 2541* 740 1086 1479 1903 18.9 1500 1000 750 79.4 52.9 09.7 27.6 45.5 64.3 75.9 18.4 33.3 48.4 50.6 13.9 25.9 37.8 38 116 77.3 69.7 178 120 94.9 251 168 126 332 231 174 437 314 236 620 426 320 852 591 443 1479 2162* 2958* 987 1448* 1968* 2541* 740 1086 1479 1903 20.9 1500 1000 750 71.8 47.8 35.9 27.6 41.3 59.4 65.9 18.4 27.5 39.6 49.5 13.9 20.7 29.7 37.1 95.3 68.6 56.0 148 105 82.8 205 138 103 281 203 151 385 285 200 537 396 276 749 508 381 1241* 1903* 2545* 830 1271 1698* 2250* 623 950 1272 1686 23.2 1500 1000 750 64.7 43.1 32.3 25.7 39.1 54.7 65.9 17.1 26.0 36.5 49.5 12.8 19.5 27.4 37.1 95.3 68.6 56.0 148 105 82.8 205 138 103 281 203 151 385 285 200 537 396 276 749 508 381 1075 754 54 1582 2212 1114 1489* 2145* 843 1127 1613* 25.6 1500 1000 750 58.6 39.1 29.3 23.5 35.9 49.5 60.8 15.6 24.0 32.9 43.0 11.8 18.0 24.7 32.3 86.0 63.3 50.2 131 96.1 72.1 181 121 90.5 252 169 126 339 226 170 459 431 324 647 431 324 980* 699 548 1417 2069* 1008 1479* 1979* 791 1127 1541 28.4 1500 1000 750 52.8 35.2 26.4 20.2 28.9 43.8 55.0 13.4 19.3 29.2 37.1 10.1 14.5 21.8 29.2 79.6 53.1 40.6 131 89.8 67.9 166 114 86.6 236 157 120 305 206 159 450 302 234 620 417 328 901* 643 504 1303* 1903* 926 1354 1823* 726 1018 1386 31.4 1500 1000 750 47.8 31.8 23.9 18.4 26.5 39.5 49.8 12.3 17.6 26.4 34.2 9.21 13.2 19.8 26.9 72.2 48.1 37.3 120 80.5 60.4 151 104 78.5 214 143 111 276 190 145 407 279 212 561 385 302 830* 587 440 1200* 1748* 853 1219 1614 661 911 1386 34.7 1500 1000 750 43.2 28.8 21.6 17.2 23.2 36.3 44.9 11.5 13.4 23.7 29.6 8.60 11.6 18.1 22.1 63.4 42.3 31.8 103 69.7 52.3 151 101 7507 201 134 101 257 182 139 366 245 139 553 384 290 752* 504 378 1127* 1531* 756 1028 1046 569 774 1055 For higher SIZES - refer to AGNEE. Full Load Efficiency - 96.5% (approx.) THERMAL CAPACITIES (KW) Nominal Ratio Input Speed rpm 140 160 180 200 225 Unit Size 14.0 TO 63.8 1500 1000 750 30 29 27 39 37 32 48 46 43 59 55 52 76 71 67 14.0 TO 95. 1500 1000 750 56 53 45 86 71 60 110 91 78 138 114 97 173 147 128 250 280 315 355 400 450 500 560 630 710 185 178 170 225 220 217 279 270 270 355 340 330 440 420 410 580 560 555 720 700 690 424 355 311 536 436 394 712 555 490 720 650 590 930 850 800 1200 1100 1010 1520 1410 1300 Units without Fan 95 89 86 122 112 109 154 148 142 Units with Fan 216 180 158 276 230 200 Full Load Efficiency - 97% (approx.) 19 of 80 347 294 260

- 20. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE B 3-B3SF TRIPLE REDUCTION UNITS - RIGHT ANGLE SHAFTS - MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Input Nominal Nominal Speed Output Ratio rpm Speed 140 rpm Unit Size 160 180 200 225 250 280 315 355 400 450 500 560 630 710 38.4 1500 1000 750 39.1 28.0 19.5 15.3 21.5 32.9 40.2 10.2 14.4 22.0 26.9 7.86 10.8 16.5 20.2 57.6 38.4 28.9 94.2 63.3 47.5 138 91.7 68.8 182 122 91.4 237 168 126 333 223 168 507 350 264 685 458 343 1027* 1396* 687 935 1281 517 703 963 42.5 1500 1000 750 35.3 23.5 17.6 13.7 19.6 28.9 36.6 9.10 13.0 19.3 24.5 6.83 9.77 14.5 18.3 52.6 35.0 26.3 86.5 57.7 43.2 125 83.4 62.6 167 111 83.3 218 153 115 303 203 152 460 320 240 624 418 313 936 627 471 1272* 852 1166 641 878 47.1 1500 1000 750 31.8 21.2 15.9 12.2 17.7 26.1 33.1 8.13 11.8 17.7 22.1 6.10 8.84 13.3 16.6 47.5 31.7 23.8 78.2 52.5 39.1 113 75.4 56.6 150 100 75.3 201 139 104 274 183 138 414 276 207 529 354 266 801 536 402 1028 689 518 1033 777 52.1 1500 1000 750 28.8 19.2 14.4 10.7 15.5 24.0 24.0 7.09 10.3 16.0 16.0 5.31 7.76 7.76 12.0 29.8 19.9 14.9 42.6 28.4 21.3 70.1 46.8 35.1 102 67.7 50.8 134 90.0 67.6 183 125 93.5 247 165 124 351 234 240 724 485 364 931 624 469 935 703 57.7 1500 1000 750 26.0 17.3 13.0 9.36 14.7 21.5 27.0 6.25 9.79 14.4 18.0 4.66 7.34 10.8 13.4 38.6 25.7 19.3 63.5 42.4 31.9 87.4 58.2 43.7 122 81.6 61.1 161 107 80.7 217 145 109 305 203 152 430 287 216 652 435 327 837 561 422 840 632 63.8 1500 1000 750 23.5 15.7 11.8 8.84 13.2 18.5 24.0 5.91 8.82 12.3 15.9 4.43 6.62 9.24 12.0 36.8 25.5 13.1 50.4 35.3 26.5 73.2 51.9 39.2 101 67.5 50.7 141 100 78.1 207 140 103 297 200 150 390 260 195 590 395 297 759 508 382 753 565 70.6 1500 1000 750 21.2 14.2 10.6 8.18 10.2 16.8 22.2 5.46 6.83 11.2 14.8 4.10 5.13 8.38 11.2 31.7 21.1 15.8 41.3 27.6 20.7 65.8 43.9 32.9 96.4 64.3 48.2 122 81.3 60.9 173 116 86.5 242 161 121 359 240 180 543 362 272 676 452 339 701 526 78.2 1500 1000 750 19.2 12.8 9.59 6.69 9.71 14.4 19.7 4.47 6.48 9.58 13.1 3.35 4.86 7.19 9.83 31.1 20.9 15.7 42.5 28.6 21.5 61.9 41.6 31.1 83.1 55.4 41.6 119 79.2 59.4 172 114 85.0 223 149 112 315 210 157 462 308 232 624 418 313 584 438 86.5 1500 1000 750 17.3 11.6 8.67 6.09 9.14 12.4 17.7 4.06 6.09 8.27 11.8 3.05 4.57 6.21 8.87 `28.2 18.9 14.2 38.2 25.5 18.9 56.4 39.5 29.6 74.0 49.4 37.0 111 78.4 58.9 155 103 77.6 223 149 112 95.7 1500 1000 750 15.7 10.4 7.84 5.63 8.15 10.2 16.2 3.75 5.45 6.78 11.5 2.81 4.08 5.08 8.63 22.6 15.1 11.3 31.7 22.1 16.6 42.4 28.3 21.2 62.6 41.4 31.0 83.2 55.5 41.6 131 89.0 66.8 175 117 87.8 REFER TO AGNEE For higher SIZES - refer to AGNEE. * forced Lubrication is necessary THERMAL CAPACITIES (KW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 225 14.0 TO 78.2 1500 1000 750 64 64 63 88 87 85 115 114 111 131 129 127 148 146 145 86.5 TO 95.7 1500 1000 750 58 58 57 78 76 73 103 99 98 117 117 115 131 129 128 270 269 268 273 272 271 506 500 499 524 509 508 14.0 to 63.8 1500 1000 750 72 71 69 102 97 94 133 127 123 151 145 140 193 181 171 322 308 301 360 341 332 669 621 599 764 693 656 250 280 315 355 400 450 500 560 630 710 995 912 866 860 788 749 1240 1230 1220 1380 1370 1360 1630 1620 1810 2150 2130 2110 737 718 699 622 607 596 - - - - 1080 967 905 968 856 795 1540 1530 1520 1750 1740 1730 2130 2120 2750 2730 2110 Units with cooling coils 295 289 287 324 318 314 619 590 576 698 651 627 Units with Fan cooling and cooling coils * Full Load Efficiency - 97% (approx.), Based on cooling water temperature 20o C 20 of 80

- 21. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE B 4-B4SF QUADRAPLE REDUCTION UNITS - RIGHT ANGLE SHAFTS - MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Input Nominal Nominal Speed Output Ratio rpm Speed 140 rpm Unit Size 160 180 200 225 250 280 315 355 400 450 500 560 630 86.5 1500 1000 750 17.34 11.56 8.67 6.85 10.55 15.70 18.34 25.65 42.93 4.43 7.03 10.45 12.22 17.10 28.62 3.32 5.27 7.85 9.17 12.82 21.46 55.22 36.81 27.61 74.73 34.55 119 191 49.82 63.00 79.30 127.3 37.36 47.30 59.50 95.5 330 220 165 445 297 222 608 405 304 95.7 1500 1000 750 15.67 10.45 7.83 5.98 3.98 2.98 9.49 6.32 4.74 14.0 16.75 23.53 39.00 9.33 11.16 15.68 26.00 7.00 8.37 11.76 19.50 50.67 33.78 25.33 68.16 85.75 45.44 57.16 34.80 42.80 108 72 54 174 116 87 303 202 151 414 276 207 562 375 281 106 1500 1000 750 14.15 9.43 7.08 5.39 3.59 2.69 8.54 12.62 15.90 22.05 36.46 5.69 8.41 10.61 14.70 24.31 4.27 6.31 7.95 11.02 18.23 47.80 31.86 23.90 64.23 81.62 42.82 54.40 32.11 40.80 102 68 51 163 109 82 267 178 133 379 253 190 505 337 252 117 1500 1000 750 12.82 8.55 6.41 4.85 3.23 2.42 7.68 11.27 13.57 18.97 31.80 5.12 7.51 9.05 12.65 21.20 3.84 5.63 6.78 9.48 15.90 40.81 27.20 20.40 55.22 69.85 87.50 142 36.81 46.56 58.30 94.6 27.61 34.90 43.70 71 243 162 121 336 224 168 449 300 225 130 1500 1000 750 11.54 7.69 5.77 4.36 2.90 2.18 6.92 10.10 12.40 17.38 28.72 4.61 6.73 8.27 11.58 19.15 3.46 5.05 6.20 8.69 14.36 37.31 24.87 18.65 50.24 63.17 79.60 127 33.50 42.11 53.0 85 25.12 31.50 39.80 63.50 218 145 109 308 205 154 400 267 200 144 1500 1000 750 10.42 6.94 5.21 3.93 2.62 1.96 6.22 4.14 3.11 9.05 11.66 16.22 26.82 6.03 7.77 10.81 17.88 4.52 5.83 8.11 13.41 35.19 23.46 11.73 47.27 31.51 23.63 75.2 50.1 37.6 121 81 605 196 131 98 279 186 140 376 251 188 159 1500 1000 750 9.43 6.29 4.72 3.53 2.35 1.76 5.60 3.73 2.80 8.11 10.57 14.73 24.27 5.40 7.05 9.82 16.18 4.05 5.28 7.36 12.13 31.69 21.12 15.84 42.82 54.38 68.10 28.55 36.00 45.40 21.41 27.19 34.0 109 73 54.5 181 121 91 257 171 128 342 228 171 176 1500 1000 750 8.52 5.68 4.26 3.18 2.12 1.59 5.05 3.36 2.52 7.26 4.84 3.63 9.56 13.25 21.94 6.37 8.83 14.62 4.78 6.62 10.97 28.72 19.15 14.36 38.69 49.08 34.6 25.79 32.72 41.05 19.35 24.54 30.80 98 65 49 163 109 82 229 153 115 300 200 150 195 1500 1000 750 7.69 5.13 3.58 2.86 1.90 1.43 4.54 3.02 2.27 6.49 4.32 3.24 8.61 11.98 19.82 5.74 7.98 13.21 4.30 5.99 9.91 25.86 17.24 12.93 34.98 44.31 23.32 29.5 17.49 22.1 89 59 44.5 148 99 74 209 139 105 710 276 184 138 60 40 30 55.5 37.0 27.7 For higher SIZES - refer to AGNEE. * forced Lubrication is necessary THERMAL CAPACITIES (KW) Nominal Ratio Input Speed rpm Unit Size 140 160 180 200 225 86.5 To 438 1500 1000 750 14 13 12 18 17 15 23 21 19 53 50 47 69 64 61 250 280 315 355 400 450 500 560 630 710 168 162 153 204 200 197 253 241 235 323 309 300 400 382 373 527 509 504 654 636 627 Units without Fans 86 81 18 111 101 99 140 134 129 21 of 80

- 22. AGNEE Series H Helical and Bevel Helical Gear Boxes TYPE B 4-B43SF QUADRAPLE REDUCTION UNITS - RIGHT ANGLE SHAFTS - MECHANICAL AND THERMAL CAPACITIES KW MECHANICAL CAPACITIES (KW) Nominal Nominal Input Output Speed Ratio rpm Speed 140 rpm Unit Size 160 180 200 225 250 280 315 355 400 450 500 560 630 215 1500 1000 750 6.97 4.65 3.48 2.57 1.71 1.28 4.08 2.72 2.04 5.82 7.75 10.81 17.81 3.88 5.16 7.20 11.87 2.91 3.87 5.40 8.90 23.21 15.47 11.60 31.48 40.07 20.98 26.71 15.74 20.03 51.9 54.6 26.0 80 53 40 135 90 67.5 192 128 96 249 166 125 238 1500 1000 750 6.30 4.20 3.15 2.32 1.54 1.16 3.68 2.45 1.84 5.21 7.00 3.47 4.66 2.60 3.50 9.82 6.54 4.91 16.22 10.81 8.11 21.30 14.20 10.65 28.62 36.36 19.08 24.24 14.30 18.18 45.5 30.3 22.3 73 49 36.5 121 81 60.5 173 115 87 225 150 113 264 1500 1000 750 5.68 3.78 2.84 2.09 1.39 1.04 3.31 2.20 1.65 4.66 6.43 3.10 4.28 2.33 3.21 8.92 5.95 4.46 14.73 9.82 7.36 19.29 12.86 9.64 25.97 33.18 17.31 22.12 12.98 16.59 41.5 27.6 20.7 66 44 33 104 69 52 152 101 76 200 133 100 292 1500 1000 750 5.13 3.42 2.56 1.88 1.25 0.94 2.98 1.98 1.49 4.18 5.82 2.78 3.88 2.10 2.91 8.06 5.37 4.03 13.35 8.90 6.67 17.49 11.66 8.74 23.53 15.68 11.76 30 20 15 37.4 60 24.9 40 18.7 30 96 64 48 139 93 70 179 119 90 323 1500 1000 750 4.64 3.09 2.32 1.69 1.12 0.84 2.68 1.78 1.34 3.74 4.70 2.49 3.13 1.87 2.35 5.18 3.45 2.59 6.19 4.12 3.9 10.36 6.90 5.18 14.52 9.68 7.26 18.0 12.0 9.0 24.9 16.6 12.5 34.3 22.8 17.1 90 60 45 126 84 63 358 1500 1000 750 4.19 2.79 209 1.52 1.01 0.76 2.41 1.60 1.20 3.35 4.3 2.23 2.86 1.67 2.15 4.69 3.12 2.35 5.59 3.72 2.35 9.40 6.26 4.70 13.14 16.43 8.76 10.95 6.57 8.21 22.7 15.1 11.3 31.4 21.0 15.7 83 55 41.5 110 73 55 396 1500 1000 750 3.78 2.52 1.89 1.37 0.91 0.68 2.17 1.44 1.08 3.00 3.80 2.00 2.53 1.50 1.90 4.25 2.83 2.12 5.05 3.36 2.52 83.50 5.66 4.25 11.87 14.84 7.91 9.89 5.93 7.41 20.6 13.7 10.3 28.3 18.8 14.1 72 48 36 101 67 51 438 1500 1000 750 63.42 2.28 1.71 1.23 0.82 0.61 1.95 1.30 0.97 2.69 3.5 1.30 2.3 0.97 1.75 3.88 2.58 1.94 4.61 3.07 2.30 7.71 5.14 3.85 18.5 12.3 9.25 25.7 17.1 12.85 60 40 30 92 61 36 For higher SIZES - refer to AGNEE. * forced Lubrication is necessary 22 of 80 10.81 1.20 5.40 13.46 8.97 6.73 710

- 23. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H1 -Foot Mounted Units Single Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS SHAFT HANDING / ROTATION OPPOSITE ROTATION AVAILABLE Unit Size A B D E F F1 G H J K L M N P 140 140 299 160 174 135 180 190 224 335 - 120 425 165 185 160 160 342 180 194 155 200 225 260 375 - 135 475 185 205 180 180 382 200 214 170 220 250 290 425 - 147.5 530 200 225 200 200 408 225 239 180 230 265 310 475 - 165 595 225 235 225 225 465 250 267 203 255 280 340 530 - 185 660 250 260 250 250 515 280 298 215 275 300 370 600 - 210 740 280 280 280 280 570 315 327 235 300 335 410 670 - 240 820 315 305 315 315 651 355 350 256 325 375 450 750 - 270 920 355 330 355 355 711 400 405 286 360 425 500 865 530 305 1055 400 365 400 400 808 450 456 320 400 475 560 1000 600 350 1200 450 405 450 450 908 500 497 360 445 530 640 1120 670 395 1330 500 450 500 500 1015 560 624 410 505 630 720 1250 750 440 1490 560 515 23 of 80

- 24. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H1 -Foot Mounted Units Single Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS Unit Size P1 Q R S T U U1 V V1 V3 W W1 140 140 140 14 4x12 20 100 60 45 70 120 110 140 160 160 160 18 4x16 20 110 70 50 75 125 110 140 180 180 175 18 4x16 25 120 85 55 85 135 110 170 200 200 185 22 4x20 25 125 90 60 90 296 140 170 225 225 205 22 4x20 30 130 95 70 100 320 140 210 250 250 220 26 4x24 30 140 115 80 110 350 170 210 280 280 240 26 4x24 35 160 125 90 125 400 170 210 315 315 260 33 4x30 40 180 130 100 140 440 210 250 355 355 290 33 6x30 50 200 155 110 160 500 210 300 400 400 325 39 6x36 55 220 175 125 180 550 210 300 450 450 365 39 6x36 60 250 195 140 200 606 250 350 500 500 420 45 4x42 65 280 220 160 220 660 300 350 24 of 80

- 25. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H1 -Foot Mounted Units Single Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS INPUT SHAFT Unit Size OUTPUT SHAFT Input Shafts V V4 W2 Y Z V1 110 102 13,982 13,939 39,5 39,3 70,030 70,011 W3 Y1 Z1 140 130 19,978 19,926 62,5 62,3 M24x50 M16x32 110 102 13,982 13,939 44,5 44,3 75,030 75,011 M24x50 140 130 19,978 19,926 67,5 67,3 55,030 55,011 M16x32 110 102 15,982 15,939 49,0 48,8 85,035 85,013 M24x50 170 160 21,978 21,926 76,0 75,8 200 60,030 60,011 M24x50 140 130 17,982 17,939 53,0 52,8 90,035 90,013 M24x50 170 160 24,978 24,926 81,0 80,8 225 70,030 70,011 M24x50 140 130 19,978 19,926 62,5 62,3 100,035 100,013 M24x50 210 200 27,978 27,926 90,0 89,8 250 80,030 80,011 M24x50 170 160 21,978 21,926 71,0 70,8 110,035 110,013 M30x60 210 200 27,978 27,926 100,0 99,8 280 90,035 90,013 M24x50 170 160 24,978 24,926 81,0 80,8 125,040 125,015 M30x60 210 200 31,974 31,912 114,0 113,8 315 100,035 100,013 M24x50 210 200 27,978 27,926 90,0 89,8 140,040 140,015 M30x60 250 240 35,974 35,912 128,0 127,7 355 110,035 110,013 M30x60 210 200 27,978 27,926 100,0 99,8 160,040 160,015 M42x80 300 290 39,974 39,912 147,0 146,7 400 125,040 125,015 M30x60 210 200 31,974 31,912 114,0 113,8 180,040 180,015 M42x80 300 290 44,974 44,912 165,0 164,7 450 140,040 M30x60 140,015 250 240 35,974 35,912 128,0 127,7 200,046 200,017 M42x80 350 340 44,974 44,912 185,0 184,7 500 160,040 M42x80 160,015 300 290 39,974 39,912 147,0 146,7 200,046 220,017 M56x105 350 340 49,974 49,912 203,0 202,7 140 45,018 45,002 M16x32 160 50,018 50,002 180 W Output Shafts 25 of 80 V5 W1

- 26. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H2-Foot Mounted Units DOUBLEReduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS SHAFT HANDING / ROTATION OPPOSITE ROTATION AVAILABLE Unit Size A A1 B D E F F1 G H J K K1 L M N P 140 140 240 364 160 174 135 180 190 224 405 - - 120 495 165 185 160 160 272 406 180 194 155 200 225 260 450 - - 135 550 185 205 180 180 305 449 200 214 173 220 250 290 505 - - 147.5 610 200 225 200 200 340 499 225 239 180 230 265 310 560 - - 165 680 225 235 225 225 385 567 250 267 203 255 280 340 630 - - 185 760 250 260 250 250 430 632 280 298 215 275 300 370 710 - - 210 850 280 280 280 280 480 687 315 327 237 300 335 410 800 - - 240 950 315 305 315 315 540 780 355 350 256 325 375 450 900 - - 270 1070 355 330 355 355 605 870 400 405 286 360 425 500 1005 530 - 305 1195 400 365 400 400 680 972 450 456 320 400 475 560 1160 600 - 350 1360 450 405 450 450 765 1101 500 497 360 445 530 640 1300 670 - 395 1510 500 450 500 500 855 1225 560 624 410 500 630 720 1460 750 - 440 1700 560 510 560 560 960 1375 630 679 435 525 670 770 1650 - 560 505 1900 630 535 630 630 1080 1545 710 754 480 575 750 860 1860 - 630 575 2130 710 585 710 710 1210 1735 800 850 550 650 850 980 2090 - 710 655 2380 800 660 26 of 80

- 27. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H2-Foot Mounted Units DOUBLEReduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS Unit Size P1 Q R S T U U1 V V1 V3 W W1 140 140 140 14 4x12 20 100 60 32 70 105 80 140 160 160 160 18 4x16 20 110 70 35 75 108 80 140 180 175 175 18 4x16 25 120 85 38 85 120 80 170 200 185 185 22 4x20 25 125 90 38 90 130 80 170 225 205 205 22 4x20 30 130 95 45 100 140 110 210 250 220 220 26 4x24 30 140 115 55 110 155 110 210 280 240 240 26 4x24 35 160 125 65 125 170 140 210 315 260 260 33 4x30 40 180 130 75 140 190 140 250 355 290 290 33 6x30 50 200 155 85 160 214 170 300 400 325 325 39 6x36 55 220 175 90 180 245 170 300 450 365 365 39 6x36 60 250 195 100 200 265 210 350 500 420 420 45 8x42 65 280 220 110 220 250 210 350 560 445 445 45 8x42 70 320 240 125 240 275 210 410 630 490 490 52 8x48 75 350 280 140 280 303 250 470 710 560 560 52 8x48 80 370 320 160 320 330 300 470 See Sheet 2 of HD-210 for shaft and keyway details. Ventilators is located on top cover, sizes 500 to 710. E is over ventilator on these sizes, and dipsticks position is as shown Sizes 200 to 315 have 4 facing. U Sizes 355 to 500 have 6 facings and sizes 560 to 710 have 8. 27 of 80

- 28. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H2-Foot Mounted Units Double Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS INPUT SHAFT OUTPUT SHAFT Input Shafts For Ratio 11.4/1 to 26.5/1 Unit Size Output Shafts V V4 W W2 Y Z V1 V5 W1 W3 Y1 Z1 140 32,018 32,002 M8x18 80 73 9,985 9,949 27,0 26,8 70,030 70,011 M24x50 140 130 19,978 19,926 62,5 62,3 160 35,018 35,002 M8x18 80 73 9,985 9,949 30,0 29,8 75,030 75,011 M24x50 140 130 19,978 19,926 67,5 67,3 180 38,018 38,002 M16x32 80 73 9,985 9,949 33,0 32,8 85,035 85,013 M24x50 170 160 21,978 21,926 76,0 75,8 200 38,018 38,002 M16x32 80 73 9,985 9,949 33,0 32,8 90,035 90,013 M24x50 170 160 24,978 24,926 81,0 80,8 225 45,018 45,002 M16x32 110 102 13,982 13,939 39,5 39,3 100,035 100,013 M24x50 210 200 27,978 27,926 90,0 89,8 250 55,030 55,011 M24x50 110 102 15,982 15,939 49,0 48,8 110,035 110,013 M30x60 210 200 27,978 27,926 100,0 99,8 280 65,030 65,011 M24x50 140 130 17,982 17,939 58,0 57,8 125,040 125,015 M30x60 210 200 31,974 31,912 114,0 113,8 315 75,030 75,011 M24x50 140 130 19,978 19,926 67,5 67,3 140,040 140,015 M30x60 250 240 35,974 35,912 128,0 127,7 355 85,035 85,013 M24x50 170 160 21,978 21,926 76,0 75,8 160,040 160,015 M42x80 300 290 39,974 39,912 147,0 146,7 400 90,035 90,013 M24x50 170 160 24,978 24,926 81,0 80,8 180,040 180,015 M42x80 300 290 44,974 44,912 165,0 164,7 450 100,035 100,013 M24x50 210 200 27,978 27,926 90,0 89,8 200,046 200,017 M42x80 350 340 44,974 44,912 185,0 184,7 500 110,035 110,013 M30x60 210 200 27,978 27,926 100,0 99,8 200,046 220,017 M56x105 350 340 49,974 49,912 203,0 202,7 560 125,040 125,015 M30x60 210 200 31,974 31,912 114,0 113,8 240,046 240,017 M56x105 410 400 55,968 55,894 220,0 219,7 630 140,040 140,015 M30x60 250 240 35,974 35,912 128,0 127,7 280,052 280,020 M56x105 470 460 62,968 62,894 260,0 259,7 710 160,040 160,015 M42x80 300 290 39,974 39,912 147,0 146,7 320,057 320,021 M56x105 470 460 69,968 69,894 298,0 297,7 28 of 80

- 29. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H2-Foot Mounted Units Double Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS Unit Size Input Shafts For Ratios 5.6/1 to 10.3/1 V V4 W Output Shafts W2 Y Z V1 V5 27,0 26,8 70,030 70,011 M24x50 W1 W3 Y1 Z1 140 130 19,978 19,926 62,5 62,3 140 32,018 32,002 M8x18 80 73 9,985 9,949 160 38,018 M16x32 38,002 80 73 9,985 9,949 33,0 32,8 75,030 75,011 M24x50 140 130 19,978 19,926 67,5 67,3 180 45,018 M16x32 45,002 110 102 13,982 13,939 39,5 39,3 85,035 85,013 M24x50 170 160 21,978 21,926 76,0 75,8 200 50,018 M16x32 50,002 110 102 13,982 13,939 44,5 44,3 90,035 90,013 M24x50 170 160 24,978 24,926 81,0 80,8 225 55,030 M24x50 55,011 110 102 15,982 15,939 49,0 48,8 100,035 M24x50 100,013 210 200 27,978 27,926 90,0 89,8 250 65,030 M24x50 65,011 140 130 17,982 17,939 58,0 57,8 110,035 M30x60 110,013 210 200 27,978 27,926 100,0 99,8 280 75,030 M24x50 75,011 140 130 19,978 19,926 67,5 67,3 125,040 M30x60 125,015 210 200 31,974 31,912 114,0 113,8 29 of 80

- 30. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H2SF-Foot/Shaft Mounted Units DOUBLE Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS SHAFT HANDING / ROTATION OPPOSITE ROTATION AVAILABLE Unit Size A A1 B D E F F1 G H J K K1 K2 L M N P 140 140 240 364 160 174 135 180 190 224 405 - - - 120 495 165 185 160 160 272 406 180 194 155 200 225 260 450 - - - 135 550 185 205 180 180 305 449 200 214 173 220 250 290 505 - - - 147.5 610 200 225 200 200 340 499 225 239 180 230 265 310 560 - - - 165 680 225 235 225 225 385 567 250 267 203 255 280 340 630 - - - 185 760 250 260 250 250 430 632 280 298 215 275 300 370 710 - - - 210 850 280 280 280 280 480 687 315 327 237 300 335 410 800 - - - 240 950 315 305 315 315 540 780 355 350 256 325 375 450 900 - - - 270 1070 355 330 355 355 605 870 400 405 286 360 425 500 1005 530 - - 305 1195 400 365 400 400 680 972 450 456 320 400 475 560 1160 600 - - 350 1360 450 405 450 450 765 1101 500 497 360 445 530 640 1300 670 - - 395 1510 500 450 500 500 855 1225 560 624 410 500 630 720 1460 750 - - 440 1700 560 510 560 560 960 1375 630 679 435 525 67 770 1650 - 560 530 505 1900 630 535 630 630 1080 1545 710 754 480 575 750 860 1860 - 630 600 575 2130 710 585 710 710 1210 1735 800 850 550 650 850 980 2090 - 710 670 655 2380 800 660 30 of 80

- 31. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H2SF-Foot/Shaft Mounted Units DOUBLE Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS Unit Size P1 Q R S T U U1 V V1 V2 V3 V6 W W1 X X1 X2 Z 140 140 - 14 4x12 20 100 60 32 - - 105 110 80 - 140 76 75 75 160 160 - 18 4x16 20 110 70 35 - - 108 115 80 - 160 86 85 85 180 175 175 18 4x16 25 120 85 38 85 90 120 125 80 65 175 - - - 200 185 185 22 4x20 25 125 90 38 95 100 130 148 80 70 185 - - - 225 205 205 22 4x20 30 130 95 45 115 120 140 160 110 80 205 - - - 250 220 220 26 4x24 30 140 115 55 125 130 155 175 110 90 220 - - - 280 240 240 26 4x24 35 160 125 65 140 145 170 200 140 105 240 - - - 315 260 260 33 4x30 40 180 130 75 160 165 190 220 140 110 260 - - - 355 290 290 33 6x30 50 200 155 85 170 175 214 250 170 130 290 - - - 400 325 325 39 6x36 55 220 175 90 190 200 245 275 170 150 325 - - - 450 365 365 39 6x36 60 250 195 100 220 230 265 303 210 160 365 - - - 500 420 420 45 6x42 65 280 220 110 250 260 250 250 210 185 420 - - - 560 445 445 45 8x42 70 320 240 125 290 300 275 275 210 200 445 - - - 630 490 490 52 8x48 75 350 280 140 330 340 303 303 250 220 490 - - - 710 560 560 52 8x48 80 370 320 160 360 370 330 330 300 230 560 - - - Sizes 140 to 315 have 4 facings. Sizes 355 to 500 have 6 facings and sizes 560 to 710 have 8. Ventilators is located on top cover, sizes 500 to 710. E is over ventilator on these sizes, and dipsticks position is as shown 31 of 80

- 32. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H2SF –Foot/ Shaft Mounted Units Double Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS INPUT SHAFT Unit Size OUTPUT SHAFT Input Shafts Ratios 11.4/1 to 25.6/1 V V4 W2 Y Z 80 73 9,985 9,949 27,0 26,8 X1 X2 Z1 Y1 - 76 75,030 75,011 80,1 79,9 20,026 19,974 - M8x20 80 73 9,985 9,949 30,0 29,8 - - 86 85,071 85,036 90,6 90,4 22,026 21,974 180 38,018 M16x32 38,002 80 73 9,985 9,949 33,0 32,8 85,035 85,000 90,047 90,012 - - - - 200 38,018 M16x32 38,002 80 73 9,985 9,949 33,0 32,8 95,035 95,000 100,047 100,012 - - - - 225 45,018 M16x32 45,002 110 102 13,982 13,939 39,5 39,3 115,035 120,047 115,000 120,012 - - - - 250 55,030 M24x50 55,011 110 102 15,982 15,939 49,0 48,8 125,040 130,054 125,000 130,014 - - - - 280 65,030 M24x50 65,011 140 130 17,982 17,939 58,0 57,8 140,040 145,054 140,000 145,014 - - - - 315 75,030 75,011 M24x50 140 130 19,978 19,926 67,5 67,3 160,040 165,054 160,000 165,014 - - - - 355 85,035 M24x50 85,013 170 160 21,978 21,926 76,0 75,8 170,040 175,054 170,000 175,014 - - - - 400 90,035 90,013 M24x50 170 160 24,978 24,926 81,0 80,8 190,040 200,061 190,000 200,015 - - - - 450 100,035 M24x50 100,013 210 200 27,978 27,926 90,0 89,8 220,046 230,061 220,000 230,015 - - - - 500 110,035 M30x60 110,013 210 200 27,978 27,926 100,0 99,8 250,046 260,069 250,000 260,017 - - - - 560 125,040 M30x60 125,015 210 200 31,974 31,912 114,0 113,8 290,052 300,069 290,000 300,017 - - - - 630 140,040 M30x60 140,015 250 240 35,974 35,912 128,0 127,7 330,057 340,075 330,000 340,018 - - - - 710 160,040 M42x80 160,015 300 290 39,974 39,912 147,0 145,7 360,057 370,075 360,000 370,018 - - - - 140 32,018 32,002 M8x20 160 35,018 35,002 W Output Sleeve Bores V1 32 of 80 V2

- 33. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H3-Foot Mounted Units TRIPLE Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS SHAFT ROTATION 33 of 80

- 34. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H3 -Foot Mounted Units TRIPLE Reduction - Par allel Shafts - Principal Dimensions (mm) DIMENSIONS Unit Size A A1 A2 B D 140 140 240 320 434 160 160 160 272 362 481 180 180 180 305 405 529 200 200 200 296 103 499 225 225 343.8 118 567 250 250 378 130 280 280 419.2 315 315 355 355 400 400 596.7 450 450 500 500 560 D1 E F F1* G H J K K1 L M 174 135 - 190 224 490 - - 120 580 - 194 155 - 225 260 540 - - 135 640 - 214 173 - 250 290 600 - - 147.5 705 225 122 239 180 230 265 310 560 - - 165 680 250 132 267 203 255 280 340 630 - - 185 760 632 280 150 298 215 275 300 370 710 - - 210 850 148 687 315 167 327 237 300 335 410 800 - - 240 950 468 165 780 355 190 350 256 325 375 450 900 - - 270 1070 536.8 188 870 400 212 405 286 360 425 500 1005 530 - 305 1195 209 972 450 241 456 320 400 475 560 1160 600 - 350 1360 679.7 235 1101 500 265 497 360 445 530 640 1300 670 - 395 1510 855 1135 1360 560 - 624 410 495 630 720 1680 - 560 440 1920 560 960 1275 1510 630 - 679 435 520 670 770 1890 - 630 505 2140 630 630 1080 1435 1690 710 - 754 480 570 750 860 2130 - 710 575 2400 710 710 1210 1610 1890 800 - 850 550 655 850 980 2400 - 800 655 2690 Unit Size N P P1 Q R S T U U1 V V1 V3* V4* W W1 140 165 - 140 140 14 4x12 20 100 60 19 70 - - 40 140 160 185 - 160 160 18 4x16 20 110 70 22 75 - - 50 140 180 200 - 175 175 18 4x16 25 120 85 25 85 - - 60 170 200 225 - 185 185 22 4x20 25 125 90 28 90 130 148 60 170 225 250 - 205 205 22 4x20 30 130 95 32 100 140 160 80 210 250 280 - 220 220 26 4x24 30 140 115 38 110 155 175 80 210 280 315 - 240 240 26 4x24 35 160 125 45 125 170 200 110 210 315 355 - 260 260 33 4x30 40 180 130 50 140 190 220 110 250 355 400 - 290 290 33 6x30 50 200 155 55 160 214 250 110 300 400 450 - 325 325 39 6x36 55 220 175 65 180 245 275 140 300 450 500 - 365 365 39 6x36 60 250 195 75 200 265 303 140 350 500 560 505 420 420 45 8x42 65 280 220 90 220 200 200 170 350 560 630 530 445 445 45 8x42 70 320 240 100 240 220 220 210 410 630 710 580 490 490 52 8x48 75 350 280 110 280 250 250 210 470 710 800 665 560 560 52 8x48 80 370 320 125 320 275 275 210 470 *Fan can be fitted for ratios 20.9 to 70.6 only Ventilators is located on top cover, sizes 500 to 710. E is over ventilator on these sizes, and dipsticks position is as shown Sizes 140 to 315 have 4 facings Sizes 355 to 450 have 6 facings and s izes 500 to 710 have 8. 34 of 80

- 35. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H3-Foot Mounted Units Triple Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS INPUT SHAFT OUTPUT SHAFT Input Shafts Ratios 52.1 to 130 Unit Size Output Shafts V V4 W W2 Y Z V1 140 19,009 18,996 M6x16 40 34 5,988 5,958 15,5 15,4 70,030 70,011 19,978 62,5 M24x50 140 130 19,926 62,3 160 22,009 21,996 M6x16 50 43 5,988 5,958 18,5 18,4 75,030 75,011 19,978 67,5 M24x50 140 130 19,926 67,3 180 25,009 24,996 M6x16 60 53 7,985 7,949 21,0 20,8 85,035 85,013 M24x50 170 160 200 28,009 27,996 M8x18 60 53 7,985 7,949 24,0 23,8 90,035 90,013 24,978 81,0 M24x50 170 160 24,926 80,8 225 32,018 32,002 M8x18 80 73 9,985 9,949 27,0 100,035 27,978 90,0 M24x50 210 200 26,8 100,013 27,926 89,8 250 38,018 M16x32 80 73 38,002 9,985 9,949 33,0 110,035 27,978 100,0 M30x60 210 200 32,8 110,013 27,926 99,8 280 45,018 13,982 39,5 125,040 31,974 114,0 M16x32 110 102 M30x60 210 200 45,002 13,939 39,3 125,015 31,912 113,8 315 50,018 13,982 44,5 140,040 35,974 128,0 M16x32 110 102 M30x60 250 240 50,002 13,939 44,3 140,015 35,912 127,7 355 55,030 15,982 49,0 160,040 39,974 147,0 M16x32 110 102 M42x80 300 290 55,011 15,939 48,8 160,015 39,912 146,7 400 65,030 17,982 58,0 180,040 44,974 165,0 M24x50 140 130 M42x80 300 290 65,011 17,939 57,8 180,015 44,912 164,7 450 75,030 19,978 67,5 200,046 44,974 185,0 M24x50 140 160 M42x80 350 340 75,011 19,926 67,3 200,017 44,912 184,7 500 90,035 24,978 81,0 200,046 49,974 203,0 M24x50 170 160 M56x105 350 340 90,013 24,926 80,8 220,017 49,912 202,7 560 100,035 27,978 90,0 240,046 55,968 220,0 M24x50 210 200 M56x105 410 400 100,013 27,926 89,8 240,017 55,894 219,7 630 110,035 27,978 100,0 280,052 62,968 260,0 M30x60 210 200 M56x105 470 460 110,013 27,926 99,8 280,020 62,894 259,7 710 125,040 31,974 114,0 320,057 69,968 298,0 M30x60 210 200 M56x105 470 460 125,015 31,912 113,8 320,021 69,894 297,7 35 of 80 V5 W1 W3 Y1 Z1 21,978 76,0 21,926 75,8

- 36. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H3-Foot Mounted Units Triple Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS Unit Size Input Shafts Ratios 25.6 to 47.1 V V4 W W2 Y Output Shafts Z V1 V5 W1 W3 Y1 Z1 140 19,009 M6x16 18,996 40 34 5,988 15,5 70,030 19,978 62,5 M24x50 140 130 5,958 15,4 70,011 19,926 62,3 160 28,009 M8x18 27,996 60 53 7,985 24,0 75,030 M24x50 140 130 19,978 67,5 7,949 23,8 75,011 19,926 67,3 180 28,009 M8x18 27,996 60 53 7,985 24,0 85,035 M24x 50 170 160 21,978 76,0 7,949 23,8 85,013 21,926 75,8 200 32,018 M8x18 32,002 60 53 9,985 27,0 90,035 M24x50 170 160 24,978 81,0 9,949 26,8 90,013 24,926 80,8 225 38,018 M16x32 80 38,002 73 9,985 33,0 100,035 M24x50 210 200 27,978 90,0 9,949 32,8 100,013 27,926 89,8 250 50,018 13,982 44,5 110,035 27,978 100,0 M16x32 110 102 M30x60 210 200 50,002 13,939 44,3 110,013 27,926 99,8 280 55,030 15,982 49,0 125,040 31,974 114,0 55,011 M16x32 110 102 15,939 48,8 125,015 M30x60 210 200 31,912 113,8 315 55,030 15,982 49,0 140,040 35,974 128,0 M16x32 110 102 M30x60 250 240 55,011 15,939 48,8 140,015 35,912 127,7 355 65,030 17,982 58,0 160,040 39,974 147,0 65,011 M24x50 140 130 17,939 57,8 160,015 M42x80 300 290 39,912 146,7 36 of 80

- 37. AGNEE Series H Helical and Bevel Helical Gear Boxes Type H3SF-Foot/Shaft Mounted Units Triple Reduction - Parallel Shafts - Principal Dimensions (mm) DIMENSIONS SHAFT HANDING / ROTATION 37 of 80