Noyaa project REPORT

- 1. Author and Site Manager: Tom Vaughan Intern, summer 2016 Noyaa Project Report 11/8/2016 – 15/8/2016

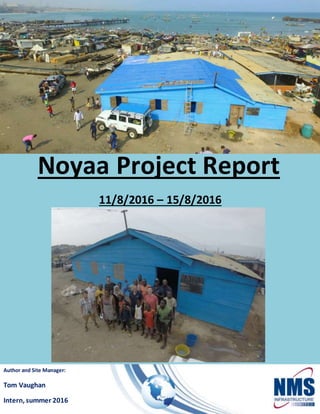

- 2. Background In the autumn of 2012 Noyaa School in Jamestown, Accra (meaning “moving forward” in Ga) was constructed as a temporary building to teach underprivileged children. However this structure has now become the permanent building for the school due to governmental intervention in 2015 preventing the development of a permanent structure. This resulted in the decay of the building because the initial design was never meant to last so long, therefore it was in need of a new roof for 55% of the building (last year some work was carried out to replace 45% of the roof). NMS has been supporting this school for a number of years so agreed to carry out somemaintenance work to stop water inflow into the building and to make it a better learning environment for the pupils. Top left: The school a few years ago. Bottom left: The school in the rain, you can see how heavily the rain comes down! Right: The old roof, notice all of the holes!

- 3. Summary of the project The pupils now have a much more suitable learning environment. Project was completed with only 52.21% of the original budgeted funds! The project was completed one day after planned finish due to unforeseen reworking. All volunteers added an immeasurable physical and spiritual element to the success of the project. Introduction The main aim of this CSR projectas requested by Rachel, the headmistress, was to make Noyaa school watertight. Being a temporary and cheaply build structure, rain water could enter the building through a variety of means – holes in the roof, holes in the wall or leaking through the bottom of the wall. These problems were solved by replacing 55% of the roof (as 45% was replaced last year), adding a gutter and constructing a concrete apron along the right hand side of the building to encourage water to flow away from the building instead of resting against the foundations and leaking in. Although the aforementioned activities made up the primary scope of works, NMS endeavored to achieve more than just water proofing. We made a partition wall using recycled materials from the Dodowa site in order to separate one big classroom into two to allow for an extra classroom for the oldest students in year 4. We also repainted nearly the entire inside of the school and 3 out of the 4 external walls so the school really stands out in Jamestown and the indoor class rooms are now a lot brighter and inviting making a more suitable environment in which to learn. Mc Carthy and Isaac, the carpenters hard at work building the wall.

- 4. Starting Phase The starting phase consisted of: The initial site visit Conducting the site survey Drawing of the designs Putting together a work plan and a cost plan The initial site visit was made by Tom Vaughan on the 12/7/2016 to receive a full brief by Rachel of what needed to be done. She stated that the priority was to replace the roof because whenever it rained, water would come gushing through the holes in the roof and would prevent the teachers from carrying out their classes. The main area of the roof to attend to was a part where the roof divided into two separate structures on different levels. This meant that there was a large gap between the two levels which had received a poor attempt at being covered up by rusty corrugated metal sheets and therefore let in a lot of water (see images below).

- 5. The initial visit also allowed for Tom to meet most of the 97 children who attend the school as they still had 4 weeks until the end of term. The site survey was carried out on the 14/7/2016 by Tom who was assisted by Peter, his driver. Between them they measured all of the dimensions of the school and in particular, the dimensions of the section of roof to be replaced. They also measured the cubic meterage of the concrete apron (0.59m³) and the dimensions for the partition wall which had an area of 11.54m².Bird’s-eye view of the building. Note the green area to be reroofed and the orange area that was replaced a year ago. The total area of roof to be replaced was 123.88 m² or 54.68% of the whole roof.

- 6. From these measurements the drawing of the designs could begin. Tom does not claim to have any architectural flare whatsoever however he drew up 6 designs in total to demonstrate to others how he visualised the lay out of the roof (see above), concrete apron and partition wall. He then went over the designs with Francis Yore (site manager in Kumawu and Abetiffi) to ensure that what he was planning to construct would in fact be the correct way to fulfill the brief given to him by Rachel. The final step of the first phase was to put together a work plan and a cost plan based upon the data and measurements Tom had made over the previous few days. The work plan changed quite a bit throughout the project as learning curves and unforeseen events meant that slight adjustments had to be made to the programme of works, scope of works and materials and tool lists along the way. This included the idea of repainting the school, installing a gutter and changing construction materials from screws to nails just to mention a few examples. Safia Wahab worked with Ebenezer Anum to put together a cost plan upon which the budget for the project was based. We had a few issues with this due to the fact that we had planned to recycle some materials from the Dodowa site such as the corrugated metal roofing sheets, plywood boards, 4”x2” beams and the roof caps. However a miscommunication error led to of all the above materials being included in the cost plan which added an extra GH¢5449.90 to the budget. Unfortunately the recycled roofing sheets were deemed unsuitable for roofing and were too few in number so we did in fact end up purchasing all of the roofing sheets albeit at under half of their original budgeted cost! However this miscommunication error led to us having a large contingency budget which led to the decision to carry out further work to the school. This was the origin of the idea to repaint the school and to install guttering as we had more than enough money left over for this. Tom still tried his hardestto keep costs as low as possible as all of the funds for this project did come out of a charity kitty. He achieved this with the help of his purchasing colleagues in the market. Safia, Ebenezer and Frank Asiedu bartered hard and succeeded in making significant savings! We made savings of GH¢ 3,466.89 from the original budget!

- 7. Middle Phase The middle phase consisted of: Sourcing recycled materials from Dodowa Procurement On the 14/7/2016 Tom headed up to the now complete Dodowa site to source the recycled materials we used for the Noyaa project. Tom and Ben Darko walked around the site and selected the 4”x2” beams, roof caps, plywood boards and corrugated metal sheets that were planned to be used in the renovation of the school. The metal sheets, beams and roof caps were then transported to the Tema warehouse for storage until we collected them on Friday the 12/8/2016. The plywood was transported at a later date. Left: The roof caps were left over from the Dodowa hospital Top right: the corrugated metals sheets were previously used for fencing around the Dodowa site.

- 8. As mentioned above, unfortunately we ended up not using the Dodowa metal sheets as after a second inspection by Frank Asdiedu at the Tema warehouse they were deemed unsuitable for roofing material due to the holes and dents made in them when they were used as fencing. This was a shame as it then meant that we had to purchase all of the roofing sheets which increased the cost of the project. However as stated before, we still saved huge amounts and actually ended up buying a better quality roofing sheet than what the recycled sheets would have provided with an approximate life span of 30 years. The procurement stage was not the smoothest part of the project as unfortunately it was a bit of a last minute rush given that Tom was not around in Accra for the weeks running up to the project and Safia had fallen ill the week before hand. However thankfully Ebenezer was at hand to save the day and finalised the cost plan in time to go purchasing the materials on Wednesday the 10/8/2016. We had a few issues with purchasing the sheets as a miscommunication error between Ebenezer and Domod roofing Ltd. meant that the quote Domod had given us was only for 60m² of sheets instead of the 160m² we required. The next quote they gave us for 160m² was way over our budget so we headed to the timber market in Accra and managed to buy all of the sheets we needed for GH¢ 1920.00 instead of the GH¢ 4,136 we originally budgeted for. We sourced many more of our materials from the timber market and went back their a few times during the construction phase for a few extra materials and tools as the market is situated very close to the Noyaa site. Despite these setbacks we encountered during procurementwe had all of the materials on time and came in significantly under budget as mentioned previously, largely due to the bartering skills employed by all members of the procurement team.

- 9. Final Phase The final stage consists of: Construction Unforeseen issues The construction phase was the greatest success during this project. Safia and Tom were joined by three labourers (two carpenters and a mason) from Dodowa kindly recommended to them by Francis Yore to start construction on Thursday 11/8/2016. Theconcrete apron was the first part of the scope of works to be constructed and was all done before lunch despite a burst water pipe (see “unforeseen issues”). Having finished the concrete works before anticipated, we started work on the partition wall and were able to complete the frame for it before we packed up and finished at 4pm. On Friday we completed the wall by nailing the plywood boards to the frame. Top left: Laying the concrete for the apron. Bottomleft:Puttingthe plywoodboardson the frame for the partition wall. Right:Partitionwall completeandawaitingalick of paint.

- 10. Soon after the wall was complete we made a start on removing the old roof. Again this was done in no time at all as the carpenters were very fast and knew exactly what they were doing. There was a bit of mild chaos when it came to disposing of the old roofing sheets as they were in very high demand from the locals who wanted to reuse them. We simply put the sheets outside of the building and let the locals take what they wanted or rather, could carry! Top left: Starting to remove the old sheets. Bottom left: Nearly all removed! Top right: Tom inspecting the work from above. Bottom right: New roof on half of the building! By the end of play on Friday half of the new roof was already on!

- 11. On Saturday we had 11 volunteers from the office arrive to give a helping hand! That meant that the pace of work really picked up! The labourers continued with the rest of the roof and completed it by around 3pm. In the meantime the volunteers dusted and sanded the walls in the partitioned rooms, the main assembly room and the front hall way in preparation for repainting. Given the pace of work and extra funds Tom decided to go and purchase more paint so we could also repaint 3 outside walls and the big back room too! In the afternoon Harry Oliver and Peter Marks put on a gutter which Tom and Peter had only gone out to purchase that day as Rachel informed Tom that due to a short overhang on the roof, rain often runs off of the roof and gets blown back into the school by the wind through holes in the wall. Left:Harry Oliveranda local lad paintingthe newly partitioned room. Right:Notice difference betweenpaintedandnon- painted bits!

- 12. On Sunday we only had 5 volunteers as we had worked so quickly over the past few days Tom didn’t see the need for 11 volunteers again. All we needed to do on Sunday was to paint the back room (which Matt Jordan and Emmet Mullan headed up along with some local children) and Harry and Peter carried out some final reparations on the roof (see “unforeseen issues”), while Tom drifted between the two tasks. Derrick Cobinah arrived at lunch time with the NMS drone to take some spectacular aerial shots of the school! However Tom’s estimations on timings proved to be too optimistic. By 4:30pm we had an exhausted work force and about 2 hours of work left to do so we decided to pack up for the day and head back home for a very well deserved BBQ! On Monday Tom headed back to Jamestown for the morning to complete the reworking on the roof and give the school a sweep and general tidy up with the help of Emmanuel and a few other local children.

- 13. There were a few unforeseen issues that needed resolving during the construction phase but there was nothing we couldn’t sort out. As mentioned earlier, on Thursday the mason managed to burst a pipe when digging down for the concrete apron’s foundation. Tomwas out at the warehouse in Tema at the time however Safia was on site and immediately set to buying the necessary items to repair the pipe. An hour later and only GH¢ 14.50 out of pocket, the pipe was fixed and the concrete work continued. Rachel arranged for a plumber to come the next day to do a full repair of the pipe; this was paid for by the landowner. Regrettably as well as the recycled roofing sheets, we didn’t use the roof caps either because when it came to actually fitting them to the roof we discovered that the gap from the purlins of the eaves to the roof cap was too far. Therefore we decided it would simply be easier and more cost effective to cut the roofing sheets into 2 parts lengthwise down the middle and use that as a roof cap instead of going out and purchasing long screws and having to drill through the thick steel of the Dodowa roof caps (see image to the left). However the main issue on Saturday was when we tried a wet test with a bucket of water over a part of the roof wherethe carpenters had only overlapped the sheets by one ridge and most of the water came splashing through. Tom had noticed the light coming through the junctions after just 4 layers of sheets were installed on Friday so from that point onwards the carpenters wereinstructed to double up the overlap. However to save ripping up their previous work Tom decided that putting a second layer of roofing sheets over the first 4 layers would be the best way to resolve this issue. We had to purchase a further 5 sheets but we cut them in half lengthwise and nailed them over the existing junctions in the roofing sheets.

- 14. Conclusion As a result of the work carried out on the Noyaa School for underprivileged children, the pupils can now attend school come rain or shine with the comfort of knowing that they shall no longer be plagued by flooded classrooms and damp notebooks. This in turn means that their education is no longer interrupted so they have a greater chance of learning more and eventually progressing into the official Ghanaian education system. The creation of another classroom makes it a better environment for the 4th and oldest year group to learn in as there will now be less distractions from other year groups. This is vital for them as it is their last year in Noyaa School which is always when the most valuable lessons are learnt. Moreover a repainted school not only makes for a brighter and happier environment in which to learn but also really makes the school stand out in Jamestown! Above: Before Below: After

- 15. As author of this report and site manager Tom Vaughan would personally like to extend a special thank you to Safia Wahab for being and excellent coworker and facilitating many different parts of this project. It wouldn’t have happened without her! Tom would also like to thank Adrian Crowley, Ebenezer Anum, Caroline Young, Harry Oliver and Francis Yore for lending their advice, time and expertise to this project. Of course he is greatly appreciative of all of the hard work that all of the volunteers put in on the weekend. They did not need to help but they deliberately took time out of their weekend in order to make this project happen, Tom and the rest of the Noyaa community will be eternally grateful! Thank you all!!!