Denunciar

Compartilhar

Baixar para ler offline

Recomendados

Recomendados

Mais conteúdo relacionado

Mais procurados

Mais procurados (20)

Total Productive Maintenance (TPM) for EVERTS 20Aug2018

Total Productive Maintenance (TPM) for EVERTS 20Aug2018

Mini-Training: Using root-cause analysis for problem management

Mini-Training: Using root-cause analysis for problem management

Destaque

Destaque (16)

Continuous Improvement - Kaizen vs Problem Solving

Continuous Improvement - Kaizen vs Problem Solving

Continuous improvement methods summary by the sig rev052914

Continuous improvement methods summary by the sig rev052914

Lean manufacturing concepts and tools and quality management1

Lean manufacturing concepts and tools and quality management1

Semelhante a Problem Solving A3 Approach

Semelhante a Problem Solving A3 Approach (20)

Cusersibrahimdesktopproblemsolvinganddecisionmaking 090321143622 Phpapp01

Cusersibrahimdesktopproblemsolvinganddecisionmaking 090321143622 Phpapp01

8D Problem Solving WorksheetGroup NumberGroup Member Nam.docx

8D Problem Solving WorksheetGroup NumberGroup Member Nam.docx

Module 3.1 PowerPoint Slide Deck - DOWNLOAD for Presentation version April 20...

Module 3.1 PowerPoint Slide Deck - DOWNLOAD for Presentation version April 20...

Kaizen for The Service Sector with Coke Scholars Service Summit Aug2017

Kaizen for The Service Sector with Coke Scholars Service Summit Aug2017

Mais de Nigel Thurlow

Mais de Nigel Thurlow (18)

Problem Solving A3 Approach

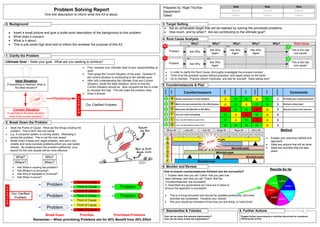

- 1. Dated 0. Background 1. Clarify the Problem Current Situation In contrast to the ideal situation, what is the current situation? Problem Solving Report One line description to inform what this A3 is about. 2. Break Down the Problem Ideal Situation If everything is resolved, what is the ideal situation? Ultimate Goal – State your goal. What are you seeking to achieve? Visualizing · Set an achievable target that will be realized by solving the prioritized problems. · How much, and by when? Are we contributing to the ultimate goal? 3. Target Setting Problem Problem Why? Root CauseWhy? Why? Why?Why? Ask Why Ask Why Again 1.1 1.2 1.3 4. Root Cause Analysis Signed Role Role Role Dated Signed Dated Signed Prepared by: Nigel Thurlow Department: Dated: B A This is the real root cause! Ask Why Ask Why Again 2.1 2.2 Ask Why Again This is the real root cause! Ask Why Again 1 2 5. Countermeasures & Plan 6. Monitor and Review 7. Standardise & Yokoten 8. Further Actions 1 1 1 2 2 2 Cause C/M Countermeasure Effect Practical Cost Business Impact Time Priority Comments Assess measures to solve problems D O O D O 1 Prioritize your countermeasures Make a list and evaluate them for effectiveness D O D O O 3 Do them in that order! Remember 80%Benefit for 20%Effort C O O C D 5 Stay focussed on the outcome You can't solve everything! O D C O D 6 Your countermeasure goes here O D O C D 2 Your countermeasure goes here O O O O D 4 A B C D E F · Explain your planning method and approach. · State key actions that will be done. · State key activities that will take place. Method 1. Explain here how you will ‘Check’ that you plan has been followed, and how you will ‘Check’ that the ‘Countermeasures’ are successful. 2. Described any governance you have put in place to ensure this approach is successful. How to ensure countermeasures followed and are successful? Results So far Suggest further improvements or activities that should be considered following this activity. How can we reuse this process improvement? How can we share across the organization? · Insert a small picture and give a bullet point description of the background to this problem. · What does it concern. · What is it about. · This is juts some high level text to inform the reviewer the purpose of this A3. GAP · First, consider your Ultimate Goal of your responsibilities at work. · Then grasp the Current Situation of the work. Question if the current situation is contributing to the ultimate goal. · After fully understanding the Ultimate Goal and Current Situation, clarify the Ideal Situation, which is how the Current Situation should be. Now compare the two in order to visualize the Gap. This will make the problem clear. · Draw a picture! Problem Problem Point of Cause Problem Our Clarified Problem P R O B L E M · Seek the Points of Cause. What are the things creating the problem. This is NOT the root cause. · e.g. A computer system is running slowly. Rebooting it solves the problem. This is not the root cause! · Break Down a large and vague problem, and sort it into smaller and more concrete problems which you can tackle directly. By breaking down the problem sufficiently, your search for the root causes will be more effective. Point of Cause Point of Cause Point of Cause Point of Cause Point of Cause Point of Cause Our Clarified Problem P R O B L E M What? Who? Where? When? · Ask What is causing the problem? · Ask Where it is occurring? · Ask Who is impacted or involved? · Ask When it occurs? Remember – When prioritizing Problems aim for 80% Benefit from 20% Effort Break Down Prioritize Problem Problem Prioritized Problems B A · In order to clarify the Root Cause, thoroughly investigate the process involved. · Think of all the possible causes without prejudice, and based solely on the facts! · Go to Gember. Practice Genchi Genbutsu, and see for yourself. Keep asking why! M ay-13 Jun-13 Jul-13 A ug-13 Sep-13 Oct-13 05 12 19 25 02 09 16 23 30 07 14 21 28 04 11 18 25 01 08 15 22 29 06 13 20 27 Workstream Workstream Workstream Workstream Workstream Workstream A B C D E F PLAN 14.2857% 14.2857% 14.2857% 14.2857% 14.2857% 14.2857% 14.2857% · This is a living document and should be updated periodically, and when activities are completed. Visualize your results! · Plot your results so reviewers know how you are doing, or have done!