Lean Supply Chain Management--by JULIAN KALAC

- 1. Prepared by Julian Kalac, P.Eng Lean Six Sigma Master Black Belt 1

- 2. 2

- 4. 4 Shipped on time and customer happy We Made $$$$ ProductionMaterial Ship order CUSTOMER • No Wasted Time • No Wasted Money • No Wasted Resources • No Wasted Material ? ? 99% Customer Quality

- 5. The truth 5 The Hidden Factory $5000-material scrap costs $35,000 REPRINTS cost Lost order Wrong order shipped ProductionMaterial Ship order CUSTOMER Hidden Factory

- 6. 6 INSANITY --“Doing the same thing over and over again and expecting different results” Albert Einstein

- 7. 7

- 8. 8

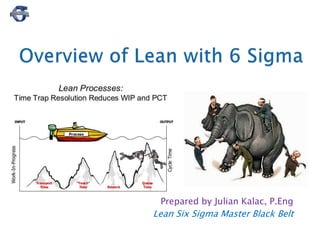

- 9. “Lean” is a Japanese methodology that focuses on producing high quality products FASTER, better and at lowest cost. Lean is about reducing NVA steps and waste (scrap, rework,) focusing on the Value Add work what the customer is paying for Lean is NOT ELIMINATING JOBS! The goal is that “you don’t work harder, but rather smarter” 9

- 10. | | 10 Customers demand shorter lead times, improved quality & reduced prices Increase through-put and quality and reduce time wasted and frustration by working on non-value add activities. Gain new business

- 11. Identification and systemic elimination of non- value add costs and re-alignment of resources to deliver value to the customer faster, better, & more consistently Lean in Manufacturing: ◦ Focus: Eliminate waste, non-value add steps, process constraints and bottle necks that cause problems in work throughput ◦ Approach: Intuitive and broad - “inch-deep, mile wide” 11 Leading to Leading toEliminate Waste Reduced Cycle Times Increased Capacity

- 12. 12 Lean Manufacturing = SPEED focusses on reducing waste/Non-Value Add activity and “Speeding” up the Process cycle Times. Six Sigma = QUALITY 3.4 PPM focusses on reducing defects and process variation Six Sigma “Quality”+ Lean “Speed" = PERFORMANCE

- 13. Value Added Typically 95% of all lead time is non-value added 1. Overproduction 2. Waiting 3. Transportation 4. Non-Value Added Processing 5. Excess Inventory/Material 6. Defects 7. Excess Motion 8. Underutilized People Non-Value Added 5%

- 14. | | 14 Lack of cross-functional training Over relying on a select few while others are Inadequately trained Operators are unable to rotate and help each other out to balance the work- load High overtime, increased pressure stress

- 15. 1

- 16. 1

- 18. 1

- 19. Cycle Time is dictated by the slowest (bottleneck) operation in the cell. 40 min 20 min 25 min 15 min 30 min 1 54 3 2 •What operation controls the cycle? •How can you relieve the bottleneck?

- 20. Bottleneck Management: •Maintain buffer in front of bottleneck – (never starve the bottleneck !) •Improve bottleneck operation •Cross train on bottleneck – Creates a visual work place – Continuous Improvement – Cell Support – Balance activities / operations 20

- 21. Pull Systems Production scheduling method used to link downstream activities to upstream activities Work begins based upon a demand signal (kanban) from a downstream customer, either internal or external Avoids overproduction, work backlog, and disconnects within a process Nothing is produced until the downstream customer signals a need

- 22. KANBAN ◦ A signal to produce ◦ Signal can be an empty square, bin, shelf, cart, or kanban card ◦ Kanban qty is safety stock used while new order is delivered ◦ Kanban qty is calculated based on usage, lead time, delivery time ◦ Can be setup manually or automated ◦ Can extend through electronic notification to suppliers using automatic messaging and triggers

- 23. 2

- 24. SETUP TIME ◦ Starts when last piece of previous job is complete; ends when first good piece of next job is complete INTERNAL SET-UP: While machine is shut-down Goal is to reduce Internal setup time, less= better EXTERNAL SET-UP: While machine is working ◦ Goal is to transfer internal setup activities and increase external setup time, more= better

- 25. Poke yoke = Error Proofing Eliminate/minimize chance for human error to avoid mistakes ◦ Prevention Poke Yoke Stops the process before failures occur Does not allow defects to pass through the process

- 26. High-Level Process Map Suppliers, Departments, Customers Mid-Level Process Map Specific Area ex Production Detail-Level Process Map Specific process/operation (most commonly used) Stop Start Stop Start Start Stop Stop 26

- 27. VA/NVA Ratio= 46% DPU = ____ RTYield = _____ SCORE CARD: I’m going to have coffee Fill c. maker with water Scoop Coffee into c. maker Get & place Filter in c. maker Drink coffee Is taste OK Brew coffee Pour c. into cup Add cream & sugar Water Supply Process Shopping Process Electricity Supply Process Eating Equipment Supply Process Tasting Process Housekeeping Processes Transactional& SupportProcesses ProcessData &Information NVA = Non-value Added Time VA = Value Added Time VA Time NVA Time Temp of Water= ___ Quality of Water= ___ Pressure of Water= ___ Amount of Coffee= ___ Quality of Coffee= ___ Type of Coffee= ___ Defective Coffee= ___ 60 sec 30 sec 60 sec 360 sec 10 sec 60 sec 10 sec 10 sec 5 sec 600 sec 30 sec

- 28. SCOR (Supply Chain Operations Reference) Model: Structured around Five CORE Process Types SCOR Model Customer’s Customer Supplier’s Supplier Supplier Internal or External Customer Internal or External Your Company Plan Make DeliverSource Make / Repair DeliverMakeSourceDeliver SourceDeliverSource Return Return Return Return Return Return Return Return Plan Plan Provides Framework for your Transformation / Improvement Projects. • Defining the boundaries / scope of the supply chain . • Evaluate the supply chain’s strengths and weaknesses. • Industry benchmarks, standardized terms, metrics, Enables a total enterprise view of a supply chain 2

- 29. Product/ServiceValueStream Processes Processes Process Start Process Finish Process Steps Processes Processes Organization Customers End-use Customers Suppliers Sub- Suppliers Process Steps TransactionalProcessSteps Return Return Plan Make DeliverSource Make/Repai r DeliverMakeSourceDeliver SourceDeliverSource Return Return Return Return Return Return SCOR Supply Chain Model 29

- 30. Customer Batch WIP 1 Test failures Batch WIP 2 Production Defects detected Customer Defects Late Orders QC I Rework Test Rejects QC I2REWORK1 Sub-Assy Riveting Shipping Supplier Sub-Assy2 WIP2 Final-Assy Test 2 Hurry Need To ship!!! NVA = 38% Cost = 32% DLV+Scrap VA= 62% 30

- 31. 15 coils/shift 8 20 26 39 31 10 20 4 13 19 20 8 40 20 20 20 20 20 20 20 Start Loop coils 180 deg twist & prep Skin Electric Press Coil form Model check M/C tapePre-tape Final Tape Apply Mylar Micalast Load Micalastic Impregnation Final Press & Cure Remove Mylar Final gauge ECP Tape ECP oven cure Strand & Final testPack & Ship Stop Rotation schedule: Based on the cycle times above every 2Hrs, Rotate Final Taping operators with operators from “Skinning”, Electric Pressing. Coil forming & Model- checking. This will increase productivity from 28 Coils/Day to 40 Coils/Day and ensure max exposure to F/T not more then 2hrs/day. Needed: Cross-functional training and ~ 1 week learning curve to achieve 85% operator efficiency 3

- 32. Increased Coil Productivity by 30% from 28 to 40 Coils/day = $420K/Year Increased direct labour utilization by 26% =$240K/Year Reduced in-process scrap from 20% to under 4% OEE improvement of 24% (from 62% to 84%) Flexible work Cells & cross functionally trained workers able to help manage bottleneck efficiently MOL order on Final Tape exposure complied with Total Operational Savings = $ 800K 3

- 33. The Five Principles of “Lean Thinking” 1. Define Customer demand TAKT TIME) 2. Map out the Current process (value stream) identify Value and Non Value Add steps 3. Get the product to “flow” faster by eliminating NVA steps and bottlenecks 4. Eliminate WIP, implement continuous flow 5. Implement POKE YOKE systems to error proof to improvements 33

- 34. 34 Lost managemant time cost Maintenance cost Lost opportunity Lost assets cost Rerun cost Lost business, goodwill cost Lost credibility cost Prevention cost appraisal cost Project rework cost Litigation SS Titanic Management Waste Costs: Costs driven by problems and process steps that add no value to products & services delivered to customers Appraisal Costs: Costs incurred to determine the degree of conformance to customer needs Prevention Costs: Costs incurred to keep failure and appraisal costs to a minimum Failure Costs: Costs directly incurred due to defects internal to the system or after delivery to the customer

- 36. 3 σ Methodology that Focuses on Reducing Process Variation, using data-driven, measurement-based, statistical methods to Solve problems, improve performance σ Focus: Surgical “inch-wide, mile-deep” investigation and resolution σ Approach: σ Data driven solves problems at the system and root cause level σ Implement robust control plans for sustained improvements What is “Six Sigma”? An Analytical Methodology that Focuses on Reducing Process Variation

- 37. 1 )( 2 n xxi Sigma = = Deviation ( Square root of variance ) -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 Axis graduated in Sigma 68.27 % 95.45 % 99.73 % 99.9937 % 99.999943 % 99.9999998 % result: 317300 ppm outside (deviation) 45500 ppm 2700 ppm 63 ppm 0.57 ppm 0.002 ppm between + / - 1 between + / - 2 between + / - 3 between + / - 4 between + / - 5 between + / - 6 =

- 38. 38 •Identify customer metrics •Select performances standards •Select objectives •Map the process •Validate measurement System (MSA) •RESULT: Process maps and good quality data collected by listening to the process •Identify sources of variation & failure points •Redefine and Re-prioritize •Establish process capability •Identify improvement opportunities •RESULT: The critical sources of variation identified root causes determined •Monitor processes to prevent recurrence of variation, defects and non-value work •Maintain performance levels •find more creative ways to improve •fix root causes •Find/Implement Preventive Fixes •Deploy changes organization •RESULT: Performance is more predictable ; culture changing •Plan and apply Improve Tools to fix problems and reduce variation •Implement improvement opportunities •RESULT: Improve tools applied, changes implemented and performance improvement in place DMAIC Improvement Model A Road Map for guiding Improvement Projects •Identify customer problems •Identify performances standards •Identify improvement objectives •Link problem to the key performance metrics •Find the right problems •RESULT: Problem Statement & Project Charter Define Measure AnalyzeImprove Control Results Define Measure AnalyzeImprove Control Results

- 39. 39 Define Measure AnalyzeImprove Control Results Define Measure AnalyzeImprove Control Results Applied Learning Theory Practice Coached Projects Training typically occurs over a 4-6 month period using a Learn Apply; Learn Apply; … format. Projects that solve real performance problems in your organization are part of the certification and learning process Recognize: •Find problems •Link to organization's needs •Form teams, define resources •Understand program req’ts Deploy: •Validate improved performance that stays in place •Spread improvements across the enterprise •Harvest the performance improvements •Change the culture

- 41. To understand where you want to be, you need to know how to get there.v Map the Process Measure the Process Identify the variables - ‘x’ Understand the Problem - ’Y’ = function of variables -’x’ Y=f(x)

- 42. 4 2) Clearly Define your Problem and the Impact Example: Too many mistakes in purchase request specifications are causing rework rates of 34%, high costs and late deliveries (less than 50% on time) to our customers 1) Find • Customer Issues • Performance Reviews • Meetings • New Projects • Failures, Re-work • Projects • Continuous improvement activities • Champions • Stakeholders • Employees • SCOR Maps • Research • Brainstorm • Wait until the crisis hits you • Value Stream Maps 3) Clearly State the Initial Scope for your project (Set targets and timelines!) Example: This first phase of this project – by 3Q 2004 - will identify problems and root causes in the purchase request process, increase first pass yield rates to 95%, reduce the cost of poor quality by 50% and increase on-time deliveries to our customers to greater than 90% 4) Link improvement targets to customer needs and organizational objectives 5) Project Plan – Charter, Resources, Milestones

- 43. 4 3 Process Flow for Measure Phase Data Storage and Archiving Foundations for Wisdom and good decision making start with Good Data What data do we need? Can we use “old” historical data? Is old data (still) usable? How was it collected? Wisdom Knowledge Data Information Wisdom Knowledge Data Information Wisdom Knowledge Data Information Data Selection Data Integrity Analysis Data Collection Measurement System Analysis Process Mapping

- 44. Is your error in the process or in the way you measure it? Could it be that you actually are “good” but the error in the measurement system shows that you are not “good”? Overall Variation Occurrence-to- Occurrence ( or Piece- to-Piece) Variation Measurement System Variation Repeatability: Variation due to gage or measurement tool Reproducibility: Variation due to people or operators who are measuring 2 Total = 2 Part-Part + 2 R&R

- 45. Accurate but not precise - On average, the shots are in the center of the target but there is a lot of variability Precise but not accurate - The average is not on the center, but the variability is small Source: iSixSigma

- 46. 46 Organize & Understand your data Statistical Analysis Determine significant factors Sort, Collate, Investigate your data Wisdom Knowledge Data Information Wisdom Knowledge Data Information Wisdom Knowledge Data Information

- 47. We know we must change X to create a change in Y… But how do we know which Xs to change and how to change them ? 4 Y =f (x1, x2, …) process output key process input factors affecting process output function of

- 49. Statistical Analysis 0.0250.0200.0150.0100.0050.000 7 6 5 4 3 2 1 0 New Machine Frequency 0.0250.0200.0150.0100.0050.000 30 20 10 0 Machine 6 mths Frequency Is the factor really important? Do we understand the impact for the factor? Has our improvement made an impact What is the true impact? Hypothesis Testing Regression Analysis 55453525155 60 50 40 30 20 10 0 X Y R-Sq = 86.0 % Y = 2.19469 + 0.918549X 95% PI Regression Regression Plot Apply statistics to validate actions & improvements P value< 0.5--Significant

- 50. The minimum sample size required to provide exactly 5% overlap (risk). In order to distinguish the Delta. Note: If you are working with Non- normal Data, multiply your calculated sample size by 1.1 50 40 50 60 7040 50 60 70 40 60 7050 Population P value< 0.5--Significant

- 51. 51 PROBLEM FINDING FACT FINDING PROBLEM DEFINITION IDEA FINDING EVAL. & SELECT PLAN ACCEPT -ANCE ACTION 1 2 3 4 6 7 8 5 Select Tool Analyze Data & Information Apply tools & Make Changes Six Sigma Projects 5S PM/TPM TQM Rapid Improve- ment Event Integrated Process Team (IPT) Establish Baselines/Metrics Other CI Tools Kanban DFSS ApplytheTool (1) (2) (3)Implement / Deploy Fixes (0) Identify failure points, bottlenecks and improvement opportunities from Define-Measure-Analyze Phases PM = Preventive Maintenance TPM = Total Productive Maintenance CI = Continuous Improvement DFSS = Design for Six Sigma TQM = Total Quality Management

- 52. Maintaining and Improving Control: Managing Change Quality Management Systems What’s Left? What’s Next? 52 Control Tools: • POKA YOKE • Control Charts • Statistical Process Control (SPC) Document Procedures and Best Practices Create Visual Controls and “Dashboards” Update Deployment Plan Complete Control FMEA Update and Deploy Communication Plan Execute Deployment Plan Document Other Opportunities Prepare and Implement Control Plan Report out, Hand- off and Closure Prepare and Implement Training Plan Process Flow Diagram for Control Phase:

- 53. 53 Key Process Input Variable Key Process Output Variable Process Specification (LSL, USL, Target) Capability (Cp, Cpk, DPMO) and date Measurement Technique Sample Size Sample Frequency Control Element Contigency Remedial Audit Phone Call LSL - NA TGT- 10 sec USL - 30 secs Cpk=.85 05 Dec 03 Call Center Manager Dashboard 30 1/2 hourly CCM to adjust seated agents CCM to reprioritize worload to meet specification Daily report to be examined by Supervisor N New Customer LSL - NA TGT- 15 min USL - 30 min Cpk=. 48 05 Dec 03 New Acct Dept Visual Display 100 Weekly Nacct Mgr to monitor and adjust new Acct Reps Nacct Mgr to reprioritize Monthly report to NAM regional manager Y New Accounts 0 Field defects DPMO = 66289 05 Dec 03 New Acct Dept Visual Display 100 Weekly Nacct Mgr to monitor and adjust new Acct Reps Nacct Mgr to use Pareto Analysis to determine defect category Monthly report to NAM regional manager Y Lead Time LSL - NA TGT- 5 Days USL - 10 Days Cpk = 1.43 05 Dec 03 Operations Dashboard 30 Daily Ops Mgr Review Identify trend root cause Director Review Weekly N Customer Expedite Expedite Order 0 Expedited DPMO = 24721 05 Dec 03 Operations Dashboard 25 Weekly Ops Mgr Review Identify trend root cause Director Review Monthly Y Key Process Input Variable Key Process Output Variable Process Specification or Target Output Value Current Performance Value Sample Size Sample Frequency Control Element Contingency Plans Remedial Plans Is the Performance Audited

- 54. DPMO / Control Chart 20000 25000 30000 35000 40000 45000 50000 55000 60000 65000 70000 75000 80000 85000 90000 95000 100000 2/5/2001 2/19/2001 3/5/2001 3/19/2001 4/2/2001 4/16/2001 4/30/2001 5/14/2001 5/28/2001 6/11/2001 6/25/2001 7/9/2001 7/23/2001 8/6/2001 8/20/2001 9/3/2001 9/17/2001 10/1/2001 10/15/2001 10/29/2001 11/12/2001 11/26/2001 12/10/2001 12/24/2001 DPMO Baseline DPMO UCL LCL Mean Goal Process Change REGIONAL CONTROL BEGINS PAST BKLOG PAST BKLOG P-DUE PAST UNITS DUE PM DUE LUBE SVC DUE REGION ASSIGN PM DAYS LUBE DAYS GOAL SVC NETWORK 2327 1 0 107 4 93 77 CENTRAL 151 0 0 8 4.8 6 8 F.B.U. 74 0 0 0 0 3 2 MIDWEST 178 2 1 9 4.6 7 3 NORTHEAST 312 0 0 33 9.7 12 18 SOUTHERN 389 0 0 43 10.1 16 36 WESTERN 259 0 0 19 6.7 10 11 TOTAL 3689 3 0 219 5.4 150 155 OFFLINE 203 4 1.8 37 16.8 1 4 NEW ACCOUNT EXCEPTION SUMMARY 12/08/2003 Item No. Problem/Opportunity Benefit Person(s) Responsible Due Date % Complete Comments 1 2 3 4 5 6 7 8 Kaizen Event Newspaper Team: Kaizen Event: Kaizen Newspaper The Control Plan explains how the Dashboard Works and what to do if performance goes out of controlImprovement Actions and Activities Updated: __/__/__ By:________

- 55. 5 DPMO / Control Chart 20000 25000 30000 35000 40000 45000 50000 55000 60000 65000 70000 75000 80000 85000 90000 95000 100000 2/5/2 0012/19/20013/5/2 0013/19/20014/2/2 0014/16/20014/30/20015/14/20015/28/20016/11/20016/25/20017/9/2 0017/23/20018/6/2 0018/20/20019/3/2 0019/17/200110/1/2001 10/15 /2001 10/29 /2001 11/12 /2001 11/26 /2001 12/10 /2001 12/24 /2001 DPMO Baseline DPMO UCL LCL Mean Goal Process Change REGIONAL CONTROL BEGINS

- 56. 5 Control Limits -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 DPMO / Control Chart 20000 25000 30000 35000 40000 45000 50000 55000 60000 65000 70000 75000 80000 85000 90000 95000 100000 2/5/2 0012/19/20013/5/2 0013/19/20014/2/2 0014/16/20014/30/20015/14/20015/28/20016/11/20016/25/20017/9/2 0017/23/20018/6/2 0018/20/20019/3/2 0019/17/200110/1/2001 10/15 /2001 10/29 /2001 11/12 /2001 11/26 /2001 12/10 /2001 12/24 /2001 DPMO Baseline DPMO UCL LCL Mean Goal Process Change REGIONAL CONTROL BEGINS

- 57. Lean Manufacturing Value Stream Mapping Line Balancing Continuous Flow PULL system KANBAN Set Up reduction (SMED) Poke Yoke/Error Proofing 5S Six Sigma DMAIC, SIPOC process Gage R&R FMEA Hypothesis Testing Regression Statistical Analysis Process Capability Cp, Cpk Roll Throughput Yield Design of Experiments Control Charts 57

- 58. “Lean” focuses on: The systematic elimination of waste and re-alignment of resources to deliver value to the customer faster, better, & more consistently Supply Chain Management: Mapping your processes through the entire business enterprise with standard elements “Six Sigma” focuses on: Use of analytical and methodical fact based problem solving methods Drastically reduce variation then control and manage whatever variation is left over Increase predictability, accuracy and precision Product and Services Cash/Funding Information Customer’s Customer Supplier’s Supplier SupplierSupplier CustomerCustomerYour Company PlanPlan Make DeliverSourceSource Make / Repair DeliverMakeSourceDeliver SourceDeliverDeliverSource ReturnReturn ReturnReturn ReturnReturn ReturnReturn ReturnReturn ReturnReturn ReturnReturn ReturnReturn PlanPlan PlanPlan LSL USLẊ Theory of Constraints: Find & eliminate the bottle necks Business Process Re- engineering: Start over VA Time NVA Time FLOW

- 59. Numbers, words, quantities, values stored sitting in piles or queues waiting for future use Charts, summaries, spread sheets, etc. that organize the data Presentations, plans and tools that explain and communicate the information Processes, organizations and team using the information to improve, manage, build systems and develop cultures Push the data “up” to become Wise Always loop back to check the data Wisdom Knowledge Data Information Where are you looking from? The WISDOM TOWER: Changing Perspectives