Real-time PID control of an inverted pendulum

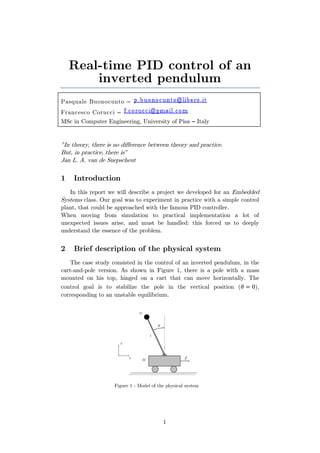

- 1. 1 Real-time PID control of an inverted pendulum Pasquale Buonocunto – Francesco Corucci – MSc in Computer Engineering, University of Pisa – Italy "In theory, there is no difference between theory and practice. But, in practice, there is" Jan L. A. van de Snepscheut 1 Introduction In this report we will describe a project we developed for an Embedded Systems class. Our goal was to experiment in practice with a simple control plant, that could be approached with the famous PID controller. When moving from simulation to practical implementation a lot of unexpected issues arise, and must be handled: this forced us to deeply understand the essence of the problem. 2 Brief description of the physical system The case study consisted in the control of an inverted pendulum, in the cart-and-pole version. As shown in Figure 1, there is a pole with a mass mounted on his top, hinged on a cart that can move horizontally. The control goal is to stabilize the pole in the vertical position ( ), corresponding to an unstable equilibrium. Figure 1 - Model of the physical system

- 2. 2 3 Testbed 3.1 Plant Figure 2 shows the real plant on which we worked. The cart is actuated with a DC motor through a belt: the motor also provides an encoder, that we used to deduce the horizontal position of the cart. The inclination of the pole is measured with a potentiometer placed at its bottom. Figure 2 – The plant The motor (Figure 3) is a ESCAP DC MOTOR/ENCODER 22V E9-0500-2.0-1: it is a little bit underutilized since the board Belt Potentiometer DC Motor Motor encoder Figure 3 - The DC motor used to control the plant

- 3. 3 provides it less voltage/current than expected, but we used it anyway since we had just demonstration purposes (otherwise a dedicated power circuit should have been necessary). Other limitations of the plant will be discussed later in this paper. 3.2 Control electronics Figure 4 shows the control electronics. Figure 4 - Control electronics We used an Evidence1 FLEX motion board equipped with the DC Motor plug-in. The board mounts a microcontroller of the dsPIC33 serie. We also realized a simple circuit with three potentiometers, in order to be able to regulate online the control parameters. The wiring is realized as follows (refer to the appendix for the nomenclature): 1 http://www.evidence.eu.com CON23 PIN NO. 4 3 2 1 CONNECTED TO B A + - CON22 PIN NO. 2 CONNECTED TO ENC_STDBY CON24 PIN NO. 4 3 CONNECTED TO Vmotor+ Vmotor-

- 4. 4 CON8 PIN NO. 20 19 12 10 2 1 CONNECTED TO - + Ki_POT Kd_POT POLE_POT Kp_POT DC Motor + encoder B, A, +, - Vmotor+, Vmotor- ENC_STDBY EncoderDC motor Kp Ki Kd + Bar potentiometer - Figure 5 - Wiring scheme

- 5. 5 4 Angle control: the first PID controller For what concerns the stabilization of the pole, we implemented a speed control of the DC motor using a PID controller. Below the digital implementation of the PID controller (simplified code): float PID(float setpoint,float actual_position) { static float pre_error = 0.0; static float integral = 0.0; static EE_UINT8 count = 0; static float errors[I_WINDOW_SIZE]; float error; float derivative; float output; EE_UINT8 i; ... // Calculate error error = setpoint - actual_position; // Integral component if(Ki > 0.0 && WINDOWED_INTEGR) { // Windowed integration mode integral = 0.0; // The truncated integration is realized with // a cyclic array // Insert new value in the window errors[count] = error; // Update counter count = (count+1) % I_WINDOW_SIZE; // Accumulation for(i = 0; i < I_WINDOW_SIZE; i++) integral += errors[i]*dt; } else if(Ki > 0.0) // Non-windowed integration mode integral += error*dt; // // Anti-windup saturation of integral component // float Ki_integral = Ki*integral; if(Ki_integral> ANTI_WINDUP_THR) Ki_integral = ANTI_WINDUP_THR;

- 6. 6 else if(Ki_integral < -ANTI_WINDUP_THR) Ki_integral = -ANTI_WINDUP_THR; // Derivative component derivative = (error - pre_error)/dt; // Calculate output output = Kp*error + Ki_integral + Kd*derivative; ... //Saturation Filter if(output > MAX_PID) { output = MAX_PID; } else if(output < MIN_PID) { output = MIN_PID; } //Update error pre_error = error; return output; } Figure 6 - Digital implementation of the PID controller Some comments about the code: - It is possible to choose two different modes of integration: windowed and not windowed - Our PID provides an anti-windup saturation of the integral component - The control output is (obviously) saturated 5 Position control: the second PID A PID is sufficient to stabilize the pole in a vertical position, but since the rail is bounded it is important to make the controller aware of the fact that it could end up hitting the physical bounds of the rail (this is possible in practice using an encoder placed on the DC motor, whose angular information is translated into a linear one). A software strategy that tries to manually manage this condition preserving the stability of the pole is quite difficult to think. We thought that the better thing to do was to try to keep the cart away from the bounds (ideally in the center of the rail)

- 7. 7 with some additional control, in order to decrease the probability of hitting the bounds. Theoretically speaking it should be necessary a much more complex modellization in order to simultaneously control the angle of the pole and the position of the cart, since the two variables are not independent. However, trying to keep things easy, we tried an alternative way to realize something similar to the ideal behavior. We programmed two independent PID controllers, one for the angle stabilization, one for the position stabilization, and we tuned the parameters in order to give more priority to the angle stabilization: this way we are able to obtain a quite stable system, that tries to converge to the center of the rail when this does not disturb the pole stabilization. This corresponds to a simplification of the model, that can be mitigated with an appropriate tuning of the parameters2 . We like to think this simplified modellization as if the second PID (the position control) acts like a disturbance on the first PID (the angle stabilization controller). Figure 7 shows the block description of the system. The code below illustrates how this was implemented (pseudocode): float current_position = <get pole inclination>; float current_ticks = <get cart displacement from center>; float angle_control = PID1(ANGLE_SETPOINT, current_position); float position_control = PID2(POSITION_SETPOINT, current_ticks); float control = angle_control + position_control; <saturation of the resulting control variable> Figure 8 - Control variable calculation 2 This is the interpretation we gave to our idea, that seems to be confirmed by some works found in literature, like [1] Ref angle PID1 PID2 Ref pos + PLANT + - + - pole_angle cart_position angle_control pos_control control Figure 7 - Complete control system

- 8. 8 For what concerns the output control variable (controlling the speed of the DC motor), it was saturated from -100 to +100, using the sign as discriminator for the direction. The amplitude is from 0 to 100 because the control is a PWM duty creating a linear voltage for the DC motor. However, due to practical limitations caused by the cart friction on the rail, the minimum PWM duty cycle usefull to really move the cart is quite high (about 30% with good lubrification), so we limitated it in a shorter range defined by two thresholds (±[MIN_PID, MAX_PID]). 6 PID tuning Given the control system architecture, the proper way to tune the whole system is the following: 1. Keeping the second PID disabled, tune the parameters of the first PID (the angle stabilization one) as if it is the only controller in the system; 2. Once the angle stability is reached, enable and tune the second PID (the position control one) with “light” parameters, in order to preserve the angle stabilization previously obtained. The single PID can be tuned with any of the classical methods, such Ziegler-Nichols: we followed an heuristic methodology inspired to the latter, also driven by the practical interpretation we gave to every parameter. 7 Software organization The application is composed of 5 tasks: - TASK_HOMING [aperiodic]: activated only one time at the startup, it manages the necessary homing steps in order to make system aware of the control set points (rail center, and pole equilibrium position). It requires the user intervention. - TASK_POSITION_CONTROL [period: 150ms, priority: 53 ]: reads the position of the cart and calculates the PID for the position control. The computed value is used from the the angle control task, that performs the real actuation merging the two control variables. - TASK_ANGLE_CONTROL [period: 50ms, priority: 6]: reads the inclination of the bar, calculates the PID for the stabilization of the bar, combines this value with the one from the position control task, then actuates the motor. 3 Task priority in OSEK is specified by a number from 1 to 10. Higher values represents higher priorities

- 9. 9 - TASK_READ_POT [period: 200ms, priority: 3]: this task acquires values from the three external potentiometer, and updates the control parameters accordingly. - TASK_SERIAL_PRINT [period: 500ms, priority: 2]: feedsback some useful information via UART. Figure 9 shows the execution flow of the application: 8 Running demonstration A running demonstration of the implemented system can be viewed in the following videos: http://www.youtube.com/watch?v=zEF6a_m0kdQ http://www.youtube.com/watch?v=9Mg-y6TDef4 9 Limitations The physical system we worked on presented considerable non-idealities, that made quite hard the task of making things work properly. The main limitation of the plant relies in the friction between the rail and the cart, that remains considerable also with appropriate lubrification. Also the traction offered by the belt is asymmetric in the two direction and causes some extra friction. Another issue relies in the motor, its poor precision and its underutilization (since the board provides it less voltage/current than 1. Maintain the bar, press the button, and let the cart scan the rail to identify the center 2. Once the cart have reached the center of the rail, put the pole in the steady state and press again the button main init TASK_HOMING button pressed / activate task TASK_POSITION_ CONTROL TASK_ANGLE_ CONTROL button pressed / activate task TASK_SERIAL_ PRINT TASK_READ_ POT Figure 9 - Execution flow

- 10. 10 expected). The final effect of these limitation is that the movements of the cart are inevitably jerky, making quite difficult to obtain a smooth control and, as a consequence, a good stabilization of the system. 10 Future work The potentiometer used to read the inclination of the pole is quite noisy: with a rough strategy, we just truncated the measures after the second decimal digit, because all we got beyond that was nothing but noise. This was enough for our purposes, but it should be interesting, instead, to implement some filtering strategy to gain accuracy in the angle measurement. For example it could be usefull to oversample the value with a higher frequency in respect to the control frequency (i.e. the frequency with which the measure is consumed), and then apply some filtering (es: low pass, median, …). Another filter that is commonly used in this context is the Kalman filter, used to estimate the measure ensuring a good immunity to noise. 11 References [1] “Simulation and Robustness Studies on an Inverted Pendulum”, HUANG Chun-E, LI Dong-Hai, SU Yong, Proceedings of the 30th Chinese Control Conference, July 22-24, 2011, Yantai, China

- 11. 11 12 Appendices

- 12. 12