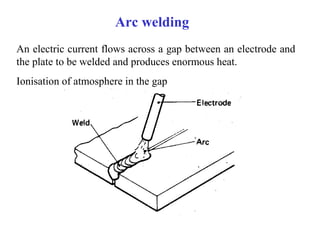

Arc Welding

- 1. An electric current flows across a gap between an electrode and the plate to be welded and produces enormous heat. Ionisation of atmosphere in the gap Arc welding

- 2. Tungsten Inert Gas (TIG) Welding or Gas Tungsten Arc Welding (GTAW) An arc is formed between a pointed tungsten electrode and the workpiece at the joint line. Electrode not consumed during welding. Molten pool and arc shielded by by an inert gas (usually Ar)

- 3. Tungsten Inert Gas (TIG) Welding • Current 10 to 300 A • Heat input 0.2 to 8 kJ / s Typical applications: High-quality welds in metals such as aluminium, stainless steels, nimonic alloys, and copper in chemical plant; sheet work in aircraft engines and structures.

- 4. Manual Metal Arc (MMA) Welding or Shielded Metal Arc Welding (SMAW) or Stick Electrode Welding Arc between a consumable flux coated electrode and the workpiece. Electrode is consumed during welding so has to be moved towards weld pool to maintain arc gap. Flux coating of the electrode disintegrates during welding, giving off vapors that serve as a shielding gas and providing a layer of slag, both of which protect the weld area from atmospheric contamination.

- 5. Manual Metal Arc (MMA) Welding • Current 25 to 350 A • Heat input 0.5 to 11 kJ / s Typical applications: Fabrication of pressure vessels, ships, structural steelwork; joints in pipework and pipelines; construction and repair of machine plant. Versatile process Simple equipment and operation Most widely used arc welding

- 6. Welding electrode for MMA Typically 460 mm long When melted to 50 mm arc is extinguished, solid slag / flux cleaned from the surface and welding is resumed. The choice of electrode for MMAW depends on a number of factors, including the weld material, welding position and the desired weld properties. The electrode is coated in a metal mixture called flux, which gives off gases as it decomposes to prevent weld contamination, introduces deoxidizers to purify the weld, causes weld-protecting slag to form, improves the arc stability, and provides alloying elements to improve the weld quality.

- 7. Metal Inert Gas (MIG) Welding or Gas Metal Arc Welding (GMAW), CO2 welding Arc between a consumable electrode and the parent metal Electrode is fed by at a constant rate by a motor. Power-supply unit controls the arc length; the welder keeps the nozzle at a fixed height (~ 20 mm). Molten pool and arc shielded by by a non-reacting gas (Ar or Ar + 5% O2 / 20% CO2 or pure CO2 (MAG welding)) GMAW torch nozzle cutaway image. (1) Torch handle, (2) Molded phenolic dielectric (shown in white) and threaded metal nut insert (yellow), (3) Shielding gas nozzle, (4) Contact tip, (5) Nozzle output face

- 8. Metal Inert Gas (MIG) Welding • Current 60 to 500 A • Heat input 1 to 25 kJ / s Typical applications: Medium-gauge fabrications such as earth-moving equipment, plate, and box girders; sheet-metal work for car bodies. GMAW Circuit diagram. (1) Welding torch, (2) Workpiece, (3) Power source, (4) Wire feed unit, (5) Electrode source, (6) Shielding gas supply.

- 9. Submerged Arc Welding (SAW) Arc between a bare consumable electrode and the parent metal Motorised feeding of electrode wire into the arc at a rate matched by its melting so that arc length is constant. Molten pool and arc submerged beneath a layer of granulated flux added separately. Flux melts to provide a protective blanket.

- 10. • Current 350 to 2000 A • Heat input 9 to 80 kJ / s Submerged Arc Welding (SAW) Typical applications: Joints in thick plate in pressure vessels, bridges, ships, structural work, welded pipe.

- 11. Resistance Spot Welding The work, which is usually in the form of a lap joint, is gripped between two copper electrodes. A high current at a low voltage flows through the parent metal between the electrodes. At the interface, heat is generated by the resistance offered to the current flow. A spot or slug of metal is melted and bridges the interface. The current flows for only a short time (typically 0.06 to 3 seconds). When the current is switched off (automatically), the weld solidifies under pressure.

- 12. Typical applications: Light fabrications from pressed sheet, such as car bodies and domestic washing machines. Also used for high-quality work in aircraft engines.