Multiphase weaving

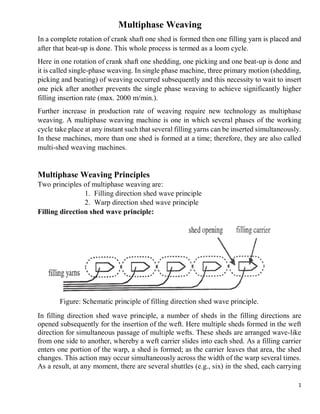

- 1. 1 Multiphase Weaving In a complete rotation of crank shaft one shed is formed then one filling yarn is placed and after that beat-up is done. This whole process is termed as a loom cycle. Here in one rotation of crank shaft one shedding, one picking and one beat-up is done and it is called single-phase weaving. In single phase machine, three primary motion (shedding, picking and beating) of weaving occurred subsequently and this necessity to wait to insert one pick after another prevents the single phase weaving to achieve significantly higher filling insertion rate (max. 2000 m/min.). Further increase in production rate of weaving require new technology as multiphase weaving. A multiphase weaving machine is one in which several phases of the working cycle take place at any instant such that several filling yarns can be inserted simultaneously. In these machines, more than one shed is formed at a time; therefore, they are also called multi-shed weaving machines. Multiphase Weaving Principles Two principles of multiphase weaving are: 1. Filling direction shed wave principle 2. Warp direction shed wave principle Filling direction shed wave principle: In filling direction shed wave principle, a number of sheds in the filling directions are opened subsequently for the insertion of the weft. Here multiple sheds formed in the weft direction for simultaneous passage of multiple wefts. These sheds are arranged wave-like from one side to another, whereby a weft carrier slides into each shed. As a filling carrier enters one portion of the warp, a shed is formed; as the carrier leaves that area, the shed changes. This action may occur simultaneously across the width of the warp several times. As a result, at any moment, there are several shuttles (e.g., six) in the shed, each carrying Figure: Schematic principle of filling direction shed wave principle.

- 2. 2 a different filling yarn. This principle is also called the wave-shed principle. The machine may be rectilinear (flat) or circular. Warp direction shed wave principle: In warp direction shed wave principle, a number of sheds in the warp directions are opened at the same time for the insertion of the weft. These sheds are opened one after another in the warp direction; however, there are several sheds that are open at any given time. Each shed extends across the full width of the warp and moves in the warp direction. Multiple wefts are inserted into a waving warp sheet with multiple sheds along the warp direction. In this system, the weft yarn can be inserted in a manner similar to that of conventional weaving systems. This concept is also called sequential-shed principle or multi-linear shed principle. The M8300 machine uses this concept. Features of weft wave multiphase: A number of sheds in the filling direction are opened subsequently for weft insertion. Sheds are arranged wave-like from one side to another, a weft carrier slides into each shed. As a result, at any moment there are several shuttles in the shed, each carrying a different filling yarn. Machine may rectilinear or circular. The filling yarn is beaten up by a rotating reed. Features of warp wave multiphase: A number of sheds in the warp directions are opened at the same time for the insertion of the weft. Each shed extends across the full width of the warp and moves in the warp direction. The weft yarn can be inserted in a manner similar to that of conventional weaving systems. This concept is also called sequential-shed principle or multi-linear shed principle. Figure: Schematic principle of warp direction shed wave principle.

- 3. 3 Machine had moving filling yarn feeder units with a rotating package frame and a discontinuous yarn pull-off gripper needles. The main reasons of the failure of multiphase loom are: The impossibility of repairing miss-picks. The warp and weft yarns did not lay perfectly perpendicular. In circular machine, narrow range of option and lack of flexibility in the fabric width. Problems in fancy design creation. Usually only plain and twill weave are possible. Different filling yarn tensions, as a result of several filling yarn carriers being activated at the same time. Weft beat-up mechanism do not allow heavy fabrics to be woven. Dispensing with direct unwinding from the cross-wound package, with the disadvantage of an additional rewinding process, necessitated by the special making- up of the filling carrier. Restriction of purely mechanical filling yarn carrier systems with the disadvantage of output limitation. Impossibility to realize the required filling yarn beat-up to obtain uniform filling insertion across the entire weaving width. The M8300 Multiphase Weaving Machine: SulzerTextil has developed a new multiphase weaving machine called M8300 Multi-Linear Shed Weaving Machine. M8300 is a multiphase air-jet weaving machine in which 4 picks are inserted simultaneously. It has a filling insertion rate of over 5000 m/min compared to 2000 m/min of single phase air-jet weaving machines. At ITMA’99 in Paris, SulzerTextil exhibited a show speed of 3230 ppm, which corresponds to 6088 m/min of filling insertion rate. Currently, the commercial speed is around 2800 ppm. The highest output among single phase machines is provided by air-jet. Unlike the other single phase machines, air-jet production rates have continued to increase at a very high rate in recent years. Today, a single phase air-jet weaving machine of 190 cm width typically weaves 23 meter per machine hour. For the same width, the M8300 technology produces 69 meter of fabric per hour. As the weft is inserted continuously without interruption and at an even pull off speed of around 20–25 m/s (72–90 km/h), the stress on the yarn is significantly reduced. The modern single phase weaving machines did not completely eliminate the use of heavy reciprocating parts. The M8300 offers the potential to achieve the advantages of almost completely rotary motion and consequently high productivity. The M8300 produces standard fabrics that amount to 65% of all fabrics produced worldwide. The M8300 technology eliminates the insertion faults and utilizes the basic requirements for uniform fabric appearance.

- 4. 4 Major characteristics of M8300 multiphase weaving machine: Characteristics of M8300 are: Filling insertion rate is up to 5400 m/min, 2800 picks/min. Weft is inserted by means of low pressure air. Compressed air pressure is 3 bar. Weaving width of 190 cm. Warp density up to 32 ends/cm. Filling density adapted to warp density. Yarn count range from 10 Ne to 40 Ne. Standard leno selvedge. Warp change duration is 45 minutes. Warp beam diameter up to 1600 mm Fabric beam diameter up to 2000 mm. Generally weave is plain. Functional principle of M8300: Shed Formation in M8300: The M8300 is based on the multilinear shed principle. Several sheds, arranged in warp direction, one behind the other and in parallel, are opened across the entire weaving width. A filling yarn is inserted into each of these open sheds simultaneously; as a result, four picks are inserted, at the same time. If each filling is inserted at a speed of 1250 m/min, the filling insertion rate is 5000 m/min. Figure: Multilinear shedding of M8300 The warp ends pass over the rotating weaving rotor; the sheds are formed consecutively on its circumference by shed forming elements (Figure (Shed-1)). The curvature and motion of the rotor causes the shed forming elements to open the sheds one after another. By minimal movements of the warp positioners (only a few millimeters) the warp ends are positioned such that they are either picked up by the shed forming elements and form the upper shed or remain in the lower shed position (Figure (Shed-2)). Figure (Shed-2): Warp yarn positioning.

- 5. 5 Each warp yarn is inserted individually into the eye of a warp positioner. The warp positioners are located close to the rotor and axially parallel to it. The number of warp positioners needed depends on the warp density; due to their extremely low mass and short stroke, they can move at very high speed. This is a key precondition for the performance potential of the M8300. Because the motion sequence of the warp positioners is controllable, the M8300 is capable of producing a variety of simple standard fabrics. Filling insertion in M8300: The second function of the shed forming elements on the weaving rotor is to form a filling channel (Figure Filling-1). The filling is inserted into this channel by low pressure compressed air over the full width of the fabric. Relay nozzles are integrated in the shed- forming elements at regular intervals. The four filling yarns are drawn from stationary bobbins by metering rollers, simultaneously and at a constant speed. The simultaneous insertion of four fillings onto a moving rotor necessitates several technical innovations. The yarn feeder subunit is concentrically fitted to the rotor and takes on the function of yarn distribution for the constantly fed filling yarns. The filling processing unit (Figure Filling-2) consists of two concentrically arranged disks that include a multichannel system. The yarns being transported with air leave the guiding channels in a synchronized sequence in order to enter the corresponding filling channel. The filling yarn controller also serves as the main nozzle. Figure (Shed-1): Shed forming elements on the M8300.

- 6. 6 Filling Beat-up and selvage motion: Beat-up combs located on the weaving rotor between the rows of shed forming elements perform the function of the conventional reed (Figure B-1). The lower shed, which rises after insertion of the filling, lifts the filling out of the filling channel over the entire weaving width. The beat-up comb behind the filling then catches up with it and beats it up. The selvages are critical for further processing of a fabric. Figure (Filling-1): Filling insertion elements. The yarn clamp and the cutter are located between filling processing and the filling channels. The clamp stops the yarn and the rotating main cutter cuts every inserted filling yarn. During filling insertion, each yarn tip performs a screw motion as a result of longitudinal movement of the yarn and the constant rotation of the weaving rotor. On the receiving side, arrival of the filling yarn is detected by an electronically controlled filling yarn detector. If a weft yarn is not inserted completely, the machine stops to facilitate the removal of the residual weft yarn. Figure (Filling-2): Filling processing unit.

- 7. 7 At present, the selvages formed on the M8300 are of standard leno type. No auxiliary selvages are required, neither at the insertion nor at the receiving side. Advantages of the M8300 multiphase weaving machine: Advantages of the M8300 multiphase weaving machine compared to high speed single phase weaving machines are following: Output in production of simple standard fabrics almost three times as high. Lower power consumption (approximately half). Smaller space requirement (up to 60% depending on installation). Lower dynamic stress on building (less expensive floor construction). Less air conditioning needed and lower dust content in air due to air conditioning of working area. Easier to operate. Substantially lower noise level [sound pressure level reduced by approximately 10 dB] Depending on fabric type and location, over 30% reduction in weaving costs. Figure (Beat-up): The filling is beaten up at the fell by the specially shaped beat-up combs.