Gp 2012 part 2

•Transferir como PPTX, PDF•

6 gostaram•1,453 visualizações

Denunciar

Compartilhar

Denunciar

Compartilhar

Recomendados

Recomendados

Mais conteúdo relacionado

Mais procurados

Mais procurados (20)

Destaque

Destaque (17)

Fundamentals of mechanical engineering experiments for graduate study

Fundamentals of mechanical engineering experiments for graduate study

TALAT Lecture 2102.04: A Compressed Air Tank for a Lorry, Special Studies: Ro...

TALAT Lecture 2102.04: A Compressed Air Tank for a Lorry, Special Studies: Ro...

SIMULATION OF DEEP DRAWING DIE FOR OPTIMIZED DIE RADIUS USING FEM TECHNIQUE

SIMULATION OF DEEP DRAWING DIE FOR OPTIMIZED DIE RADIUS USING FEM TECHNIQUE

Semelhante a Gp 2012 part 2

Semelhante a Gp 2012 part 2 (20)

Mais de VJTI Production

Mais de VJTI Production (20)

Final account trading account pl acc balance sheet

Final account trading account pl acc balance sheet

Último

VIP Call Girls Napur Anamika Call Now: 8617697112 Napur Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Napur Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Napur understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(Anamika) VIP Call Girls Napur Call Now 8617697112 Napur Escorts 24x7

(Anamika) VIP Call Girls Napur Call Now 8617697112 Napur Escorts 24x7Call Girls in Nagpur High Profile Call Girls

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS Live

Booking Contact Details :-

WhatsApp Chat :- [+91-9999965857 ]

The Best Call Girls Delhi At Your Service

Russian Call Girls Delhi Doing anything intimate with can be a wonderful way to unwind from life's stresses, while having some fun. These girls specialize in providing sexual pleasure that will satisfy your fetishes; from tease and seduce their clients to keeping it all confidential - these services are also available both install and outcall, making them great additions for parties or business events alike. Their expert sex skills include deep penetration, oral sex, cum eating and cum eating - always respecting your wishes as part of the experience

(07-May-2024(PSS)VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...Call Girls In Delhi Whatsup 9873940964 Enjoy Unlimited Pleasure

Último (20)

Value Proposition canvas- Customer needs and pains

Value Proposition canvas- Customer needs and pains

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

Call Girls In Noida 959961⊹3876 Independent Escort Service Noida

Call Girls In Noida 959961⊹3876 Independent Escort Service Noida

The Path to Product Excellence: Avoiding Common Pitfalls and Enhancing Commun...

The Path to Product Excellence: Avoiding Common Pitfalls and Enhancing Commun...

Uneak White's Personal Brand Exploration Presentation

Uneak White's Personal Brand Exploration Presentation

👉Chandigarh Call Girls 👉9878799926👉Just Call👉Chandigarh Call Girl In Chandiga...

👉Chandigarh Call Girls 👉9878799926👉Just Call👉Chandigarh Call Girl In Chandiga...

Call Girls Service In Old Town Dubai ((0551707352)) Old Town Dubai Call Girl ...

Call Girls Service In Old Town Dubai ((0551707352)) Old Town Dubai Call Girl ...

(Anamika) VIP Call Girls Napur Call Now 8617697112 Napur Escorts 24x7

(Anamika) VIP Call Girls Napur Call Now 8617697112 Napur Escorts 24x7

Call Girls In Panjim North Goa 9971646499 Genuine Service

Call Girls In Panjim North Goa 9971646499 Genuine Service

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Insurers' journeys to build a mastery in the IoT usage

Insurers' journeys to build a mastery in the IoT usage

Mysore Call Girls 8617370543 WhatsApp Number 24x7 Best Services

Mysore Call Girls 8617370543 WhatsApp Number 24x7 Best Services

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

Enhancing and Restoring Safety & Quality Cultures - Dave Litwiller - May 2024...

Enhancing and Restoring Safety & Quality Cultures - Dave Litwiller - May 2024...

Gp 2012 part 2

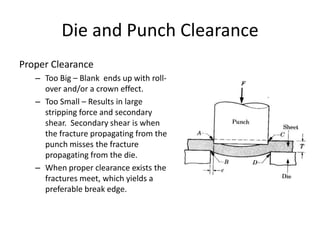

- 1. Die and Punch Clearance Proper Clearance – Too Big – Blank ends up with roll- over and/or a crown effect. – Too Small – Results in large stripping force and secondary shear. Secondary shear is when the fracture propagating from the punch misses the fracture propagating from the die. – When proper clearance exists the fractures meet, which yields a preferable break edge.

- 2. Forces for Cutting For Cutting: • In general ferrous stamping materials, shear strength is 70-80% ultimate tensile strength • Force=Shear Strength*Perimeter of Cut*Thickness • When calculating tonnage required it is recommended that ultimate tensile strength be used instead of shear strength to compensate for die wear. Tonnage=(UTS*Perimeter*Thickness) • Take caution in using value of shear strength. Consideration must be made for prior operations that may affect the material properties. – Work Hardening – Annealing or Tempering – Other processes that affect the mechanical properties of the material

- 3. Shear angle for Punch and die

- 4. Work and Energy • In terms of metal cutting: Energy of cutting =average force*Penetration • Force: Since the force/displacement curve for cutting sheet metal is nearly rectangular use the maximum force prior to fracture as the average force

- 5. Cutting Operations • Blanking – Material removed is the work-piece • Piercing – Material removed is scrap • Lancing – No metal removed, bending and cutting • Cut-off/Parting- Separating parts or reducing scrap strip size • Notching – Removing material from the outer edges of the strip • Shaving – Removing the break edge • Trimming – Removing “Flash” from drawn parts

- 7. Lancing

- 9. Notching

- 17. Progressive Dies • Dies fed directly from steel coil • No need for blanking operation • Scrap get cut away as part gets formed • Restricted to simple parts

- 18. Tool Design • It is a specialized area of manufacturing engineering which comprises the analysis, planning, design, construction and application of tools, methods and procedures necessary to increase manufacturing productivity. • Work holding tools – Jigs and Fixtures • Cutting tools • Sheet metal dies • Forging dies • Extrusion dies • Welding and inspection fixtures • Injection molds

- 20. Drawing

- 27. Bending

- 31. Bending • FIGURE 7.15 (a) Bending terminology. The bend radius is measured to the inner surface of the bend. Note that the length of the bend is the width of the sheet. Also note that the bend angle and the bend radius (sharpness of the bend) are two different variables. (b) Relationship between the ratio of bend radius to sheet thickness and tensile reduction of area for various materials. Note that sheet metal with a reduction of area of about 50% can be bent and flattened over itself without crackling. Source: After J. Datsko and C. T. Yang.

- 32. Methods of Reducing or Eliminating Springback • FIGURE 7.21 Methods of reducing or eliminating springback in bending operations..

- 39. Bending force : Maximum bending force, P = KLSt2 W K – constant ranges from 0.33(wiping die) – 0.66(u-die)-1.32(V-die) S – yield stress L- length of the bend t- thickness of sheet For a V-die Max bending force, P = (UTS)LT 2 W UTS – Ultimate tensile strength

- 42. Beading : • The periphery if the sheet metal is bent into the cavity of a die Fig 16.24 (a) Bead forming with a single die (b) Bead forming with two dies,in a press brake

- 43. Dimpling : • First hole is punched and expanded into a flange • Flanges can be produced by piercing with shaped punch • When bend angle < 90 degrees as in fitting conical ends its called flanging

- 48. Shear Spinning

- 49. Explosive forming : • Explosive energy used s metal forming • Sheet-metal blank is clamped over a die • Assembly is immersed in a tank with water • Rapid conversion of explosive charge into gas generates a shock wave .the pressure of this wave is sufficient to form sheet metals