Mahadevan krishnan coaxial energetic deposition of thin films

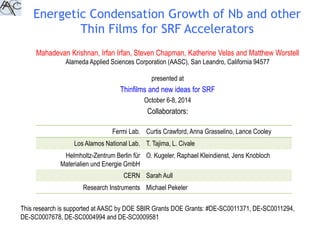

- 1. Energetic Condensation Growth of Nb and other Thin Films for SRF Accelerators Mahadevan Krishnan, Irfan Irfan, Steven Chapman, Katherine Velas and Matthew Worstell Alameda Applied Sciences Corporation (AASC), San Leandro, California 94577 presented at Thinfilms and new ideas for SRF October 6-8, 2014 Collaborators: Fermi Lab. Curtis Crawford, Anna Grasselino, Lance Cooley Los Alamos National Lab. T. Tajima, L. Civale Helmholtz-Zentrum Berlin für Materialien und Energie GmbH O. Kugeler, Raphael Kleindienst, Jens Knobloch CERN Sarah Aull Research Instruments Michael Pekeler This research is supported at AASC by DOE SBIR Grants DOE Grants: #DE-SC0011371, DE-SC0011294, DE-SC0007678, DE-SC0004994 and DE-SC0009581

- 2. Outline Motivation for thin films in SRF cavities History of thin film development Energetic Condensation Nb-on-Cu for SRF cavities Nb-on-stainless steel bellows for SRF accelerators Cu-on-stainless steel for RF Couplers Nb-on-Al for SRF cavities 2

- 3. Motivation for AASC’s SRF program The accelerator technology R&D research area of DOE (NP & HEP) develops the next generation of particle accelerators and related technologies for discovery science; and also for possible applications in industry, medicine and other fields SRF accelerators are a key part of this future development, as they can significantly reduce costs SRF technology also has many commercial applications: More than 1000 particle accelerators worldwide; most use normal cavities Superconducting RF (SRF) cavities offer a ~10x improvement in energy efficiency over normal cavities, even accounting for cryogenic costs at 2K Operating at higher temperatures (~10K) would further improve accelerator energy efficiency as the cryogenic cooling becomes less demanding and moves away from liquid He and towards off the shelf cryo-coolers such as those used in cryo-pumps Replacing bulk Nb with Nb coated Cu cavities would also reduce costs The ultimate payoff would be from cast Al SRF cavities coated with higher temperature superconductors (Nb3Sn, MoRe, MgB2, Oxipnictides) Our thin film superconductor development is aimed at these broad goals 3

- 4. Challenges for thin film SRF: path to success Cu and/or Al cavity substrates might be of two different forms Amorphous Polycrystalline How do we grow low-defect Nb films on such substrates? Understand adhesion, thickness, smoothness, RRR, stability at the coupon level Proceed to RF cavity level and measure Q at high fields Install 9-cell Nb coated Cu modules in SRF accelerator and validate the thin film solution Spur acceptance of thin film Nb by accelerator community Continue R&D towards higher Tc films and Al cavities Where we are Where we are headed 4

- 5. Outline Motivation for thin films in SRF cavities History of thin film development Energetic Condensation Nb-on-Cu for SRF cavities Nb-on-stainless steel bellows for SRF accelerators Cu-on-stainless steel for RF Couplers Nb-on-Al for SRF cavities 5

- 6. Examples of early SRF thin film development LEP at CERN tested Magnetron sputter coated Cu cavities with Nb thin films (1980s) C. Benvenuti, N. Circelli, M. Hauer, Appl. Phys. Lett. 45, 1984. 583; C. Benvenuti, Part. Accel. 40 1992. 43; C. Benvenuti, S. Calatroni, G. Orlandi in: 20th International conference on Low Temperature Physics, Eugene 1993, to be published in Physica B; C. Benvenuti, S. Calatroni, I.E. Campisi, P. Darriulat , M.A. Peck, R. Russo, A.-M. Valente, Physica C316, 1999, 153–188, (Elsevier): Study of the surface resistance of superconducting niobium films at 1.5 GHz RRR=11.5 on oxide coated Cu, 29 on oxide-free Cu coated at 150C G. Arnolds, Doktorarbeit, University of Wuppertal, WUB 79-14 (1979) Wuppertal studied 8, 3 and 1 GHz Nb cells vapor deposition coated with Nb3Sn E. Palmieri et al in Italy: Quarter-wave resonators that were sputter coated So why have thin film cavities not taken off? 6

- 7. Q-slope is the problem with thin films Qo E, MV/m E, MV/m Qo Bulk Nb has increased in cost by more than 3x over the past few years. Large systems such as the ILC cannot afford to ignore the materials costs. Nb coated Cu becomes more attractive The key milestone for thin film SRF cavities is to show Qo vs. E that approaches that of bulk Nb (high Qo and no Q-slope) 7

- 8. Prior UHV Arc Nb thin films: Tor Vergata, Rome/IPJ, Poland R. Russo, A. Cianchi, Y.H. Akhmadeev, L. Catani, J. Langner, J. Lorkiewicz, R. Polini, B. Ruggiero, M.J. Sadowski, S. Tazzari, N.N. Koval, Surface & Coatings Technology 201 (2006) 3987–3992 RRR up to 80 was reported with substrate heated to 200oC J. Langner, R. Mirowski, M.J. Sadowski, P. Strzyzewski, J. Witkowski, S. Tazzari, L. Catani, A. Cianchi, J. Lorkiewicz, R. Russo, Vacuum 80 (2006) 1288–1293 The INFN/Poland CARE program made good progress Examples of filter efficiency Less than 100 particles / mm2 About 6000 particles / mm2 Nb macro-droplets were studied; a magnetic filter was Roberto Russo - INFN 28 JLab 17-18/7/2005 developed to reduce macros AASC has picked up UHV arc coatings where CARE left off 8

- 9. Outline Motivation for thin films in SRF cavities History of thin film development Energetic Condensation Nb-on-Cu for SRF cavities Nb-on-stainless steel bellows for SRF accelerators Cu-on-stainless steel for RF Couplers Nb-on-Al for SRF cavities 9

- 10. Energetic Condensation In Energetic Condensation, the ions deposit energy in a sub-surface layer (≈3-5 atomic layers deep for ~100eV Nb ions), shaking up the lattice, causing adatom mobility and promoting epitaxial crystal growth Energetic Condensation, when combined with substrate heating, promotes lower-defect crystal growth J.A. Thornton, "Influence of substrate temperature and deposition rate on the structure of thick sputtered Cu coatings”, J. Vac. Sci. Technol. Vol. 12, 4 Jul/Aug 1975 Andre Anders, A structure zone diagram including plasma-based deposition and ion etching, Thin Solid Films 518 (2010) 4087–4090 10

- 11. Coaxial Energetic Deposition (CED) Coaxial Energetic Deposition (CEDTM) CED coater uses “welding torch” technology Arc source is scalable to high throughputs for large scale cavity coatings Present version deposits ~1 monolayer/pulse ~0.2 ms UHV and clean walls are important 11

- 12. Outline Motivation for thin films in SRF cavities History of thin film development Energetic Condensation Nb-on-Cu for SRF cavities Nb-on-stainless steel bellows for SRF accelerators Cu-on-stainless steel for RF Couplers Nb-on-Al for SRF cavities 12

- 13. KEK06 hydro-formed Cu cavity cell from T. Tajima This cavity used 12500 shots at 350-360C to produce a fully covered coating KEK-06 Cu cavity before Nb coating KEK-06 Cu cavity after Nb coating The Nb film survived repeated cycles of HPWR at up to 80Bar Cell was RF tested at LANL 13

- 14. KEK06 hydro-formed copper cavity, CBP at FNAL (Cooper), coated at AASC, tested at LANL (Tajima, Haynes) 1.E+09 1.E+08 1.E+07 1.E+06 1.E+05 4 K <2 K 0 2 4 6 8 10 Q0 The difference between 4K and 2K is smaller than expected: BCS resistance should be about 40x less if all the surfaces are Nb. This suggests that there are areas that are not coated well and lossy, which is causing the lower than expected Q0 Eacc (MV/m) 14

- 15. The Macroparticle Problem As Russo et al had pointed out, macroparticles must be filtered out of the plasma stream for higher quality SRF films Vane filter No filter Passive vane filter We are presently testing a dynamic macro-particle filter 15

- 16. Outline Motivation for thin films in SRF cavities History of thin film development Energetic Condensation Nb-on-Cu for SRF cavities Nb-on-stainless steel bellows for SRF accelerators Cu-on-stainless steel for RF Couplers Nb-on-Al for SRF cavities 16

- 17. Nb on stainless steel bellows: temperature matters Coating of stainless steel with Nb film at 350C and at 550C 350C coating Images of Nb coated coupons (350C coating) after the DeFelsko pull-off tests. The IPA cleaned Nb film was detached at 30Bar while the pickled coating detached at 56 Bar (with no Nb film detachment) 550C coating Image of Nb coated coupon (550C coating with only acetone/IPA cleaning) after the DeFelsko pull-off tests. The Al dolly detached at 56 Bar (with no Nb film detachment) 17

- 18. Nb on stainless steel bellows: LN2 cold shock tests Courtesy of Sergey Belomestnykh & Binping Xiao of BNL Nb on stainless steel bellows before cold test Nb-on-Cu-on stainless steel bellows after cold test: 3 dips (overnight) BNL reports that the Nb films adhered very well to the stainless steel; mechanical flexing tests are in progress, to be followed by RF tests 18

- 19. Outline Motivation for thin films in SRF cavities History of thin film development Energetic Condensation Nb-on-Cu for SRF cavities Nb-on-stainless steel bellows for SRF accelerators Cu-on-stainless steel for RF Couplers Nb-on-Al for SRF cavities 19

- 20. Status of AASC Process: Cu on stainless steel tube Tech. was careless with wrench Copper surface after 86Bar HPWR test (courtesy of Curtis Crawford/FNAL) Stainless steel tube coated with a ~28μm Cu film using the AASC CED process Curtis Crawford/FNAL measured RRR≈52 in our Cu films Temple Univ. measured RRR~42 - 64 20

- 21. Status of AASC Process: bellows coating Stainless steel bellows coated with a ~45μm Cu film using the AASC CED process CED process coats irregular surfaces such as bellows 21

- 22. Bellows received from RI (Michael Pekeler) We plan to coat RF Coupler bellows in December, followed by RF Coupler tubular sections in early 2015 22

- 23. CED4: a dedicated Coating Apparatus for Couplers CED4 will be operational in November 2014 23 Stainless steel tubes (doppelgangers) for RF Coupler tubes CED4 coating apparatus

- 24. Outline Motivation for thin films in SRF cavities History of thin film development Energetic Condensation Nb-on-Cu for SRF cavities Nb-on-stainless steel bellows for SRF accelerators Cu-on-stainless steel for RF Couplers Nb-on-Al for SRF cavities 24

- 25. Nb-on-Al for future SRF cavities: Nb crystals grown on Al6061 at 350C show good adhesion Before LN2 dip After LN2 dip Curtis Crawford/FNAL has recently tested adhesion The Nb-on-Al samples passed the tape-pull test and adhered at up to 92 Bar HPWR (maximum test pressure used) 25 Two Al6061 coupons (350C & 150C), before and after the liquid nitrogen dip

- 26. Nb-on-Al for future SRF cavities: Nb crystals grown on Al6061 at 350C show encouraging results XRD showed ~11nm grain size Nb crystals across the entire film surface; mix of (200), (211), (222) and (311) Nb observed 26 ! 200 211 222 311 SQRT!(counts)! Two-ThTewtao (-dtehge. ta (deg.) SQRT (counts)

- 27. Summary AASC pursues thin film growth for several SRF applications using Energetic Condensation Nb-on-Cu SRF cells (1.3GHz) aim to produce a Qo vs. E graph that approaches bulk Nb performance Nb-on-stainless steel bellows aims to produce “fingerless” bellows for SRF accelerators Cu-on-stainless steel tubes and bellows aims to produce an alternative to electroplated RF Couplers (better adhesion and avoid Ni flash layer) All of this research and development is funded by the US DOE SBIR program 27

- 28. Backup slides • Backup slides 28

- 29. Subplantation Models Y. Lifshitz, S. R. Kasi, J.Rabalais, W. Eckstein, Phy. Rev. B Vol. 41, #15, 15 May 1990-II: Subplantation model for film growth from hyperthermal species D.K. Brice, J.Y. Tsao and S.T. Picraux: PARTITIONING OF ION-INDUCED SURFACE AND BULK DISPLACEMENTS; see also W. D. Wilson, Radiat. Eff. 78, 11 (1983) 50-120eV energy spread in Nb ions from cathodic arc * A. BENDAVID, P. J. MARTIN, R. P. NETTERFIELD, G. J. SLOGGETT, T. J. KINDER, C., ANDRIKIDIS, JOURNAL OF MATERIALS SCIENCE LETTERS 12 (1993) 322-323 29

- 30. Energetic Condensation: some book-keeping N.A. Marks, Phys. Rev. B 56(5) 1997 (thermal spikes paper) 100eV ion into 8.45x1022 /cc solid ro = 1.5nm 3100 2600 2100 1600 1100 600 t=0 t=0.1ps t=0.2ps t=0.6ps t=0.8ps t=1ps 0 1 2 3 4 Temperature, K Depth, nm thermal spike energy= 0.24 eV thermal speed= 705 m/s Nb lattice spacing= 0.33 nm time to move one spacing= 0.47 ps Observe that spike “quenching time” of ~0.8ps is comparable to the time for atoms to move and rearrange themselves; energetic condensation provides mobility for lattice rearrangement 30

- 31. Energetic Condensation vs. sputtering and PVD (A. Anders) Nb (A. Bendavid, CSIRO) Ion energy, eV f(e) * A. BENDAVID, P. J. MARTIN, R. P. NETTERFIELD, G. J. SLOGGETT, T. J. KINDER, C., ANDRIKIDIS, JOURNAL OF MATERIALS SCIENCE LETTERS 12 (1993) 322-323 (M.M. Bilek) f(e) Ion velocity, m/s Compressive stress Comparison of Stress build-up in low energy deposition, energetic condensation, and energetic condensation plus high voltage bias Relief of compressive stress by pulsed ion impact [*] [*] M. M. Bilek, R N. Tarrant, D. R. McKenzie, S H. N. Lim, and D G. McCulloch “Control of Stress and Microstructure in Cathodic Arc Deposited Films” IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 31, NO. 5, OCTOBER 2003 31

- 32. High RRR on coupons motivates coating accelerator structures RRR-330 measured on a-sapphire RRR-585 measured on 5μm film on MgO Change in crystal RRR orientation from 110 to 200 at higher temperature Polycrystalline Monocrystal with two orientations 110 110 & 200 200 Monocrystal with 100 orientation RRR=7, 150/150 RRR=181, 500/500 RRR=316, 700/700 RRR M Krishnan, E Valderrama, B Bures, K Wilson-Elliott, X Zhao, L Phillips, A-M Valente-Feliciano, J Spradlin, C Reece and K Seo, “Very high residual-resistivity ratios of heteroepitaxial superconducting niobium films on MgO substrates,” Superconductor Science and Technology , vol. 24, p. 115002, November 2011 M. Krishnan, E. Valderrama, C. James, X. Zhao, J. Spradlin, A-M Valente Feliciano, L. Phillips, and C. E. Reece, K. Seo, Z. H. Sung, “Energetic condensation growth of Nb thin films”, PHYSICAL REVIEW SPECIAL TOPICS - ACCELERATORS AND BEAMS 15, 032001 (2012) X. Zhao, L. Philips, C. E. Reece, Kang Seo, M. Krishnan, E. Valderrama, “Twin symmetry texture of energetically condensed niobium thin films on a-plane sapphire substrate”, Journal of Applied Physics, Vol 115, Issue 2, 2011 32

- 33. SIMS with Cs beam of high RRR Nb films: Nb (100) on MgO: Bulk Nb sample: RRR~300 RRR=442 H count (normalized) in thin films is 7x103 times lower than in bulk Nb! 33

- 34. RRR–316 & 7: Cross sectional EBSD and macroparticles Conductor – Mounting material Nb MgO MgO Nb 0.15μm scan step size RRR=316: single crystal growth of Nb BSE image – X-section view Conductor – Mounting material MgO Nb Nb thin film layer 0.1μm Scan step size Lower CI values between Nb matrix and MgO substrate indicate that there could be an amorphous or non-structured layer between them 35nm Scan step size MgO layer RRR=7: textured Nb film Thickness ~ 2.43um Contrast due to FIB milling trace This macro landed on 2.4μm Nb film No Columnar structure; XRD shows (100) single crystal RRR=316: Macro-particle condenses onto Nb film and acquires film’s (100) crystalline structure 34

- 35. Nb on copper coupons Fine grain Cu coupons polished at AASC EBSD image of Nb on mechanically polished Cu showing large (~75 um) grains • Nb/Cu results confirm that Nb film quality improves with both deposition temperature and thickness 35

- 36. Magnetic vortex penetration in Nb/Cu films: Data provided by T. Tajima and L. Civale of LANL Colt James, Mahadevan Krishnan, Brian Bures, Tsuyoshi Tajima, Leonardo Civale, Nestor Haberkorn, Randy Edwards, Josh Spradlin, Hitoshi Inoue, IEEE Trans. Appl. Supercond. 23 36