3.tension members

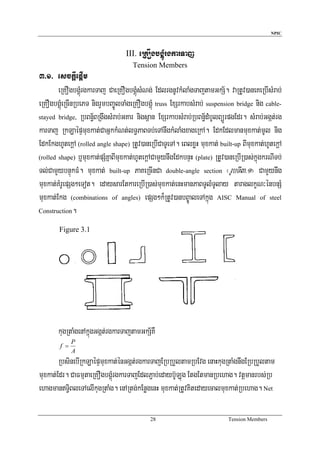

- 1. NPIC III. eRKOgbgÁúMrgkarTaj Tension Members 3>1> esckþIepþIm eRKOgbgÁúMrgkarTaj CaeRKOgbgÁúMsMNg; EdlrgnUvkMlaMgTajtamGkS½. vaRtUv)aneKeRbIsMrab; eRKOgbgÁúMeRcInRbePT nigrYmbBa©ÚlTaMgeRKOgbgÁúM truss ExSrkabsMrab; suspension bridge nig cable- stayed bridge, RbBn§½BRgwgsMrab;GKar nigs<an ExSrkabsMrab;RbBn§½dMbUlBüÜrpgEdr. sMrab;Ggát;rg karTaj RkLaépÞmuxkat;CaGñkkMNt;lT§PaBTb;eTAnwgkMlaMgxageRkA. EdkEdlmanmuxkat;mUl nig EdkEkghUtekþA (rolled angle shape) RtUv)aneRbICaTUeTA. eBlxøH muxkat; built-up BImuxkat;hUtekþA (rolled shape) b¤muxkat;pSMKñaBImuxkat;hUtekþACamYynwgEdkbnÞH (plate) RtUv)aneRbIR)as;kñúgkrNITb; Tl;CamYybnÞúkFM. muxkat; built-up PaKeRcInCa double-angle section ¬rUbTI3>1¦ CamYynwg muxkat;KMrUepSg²eTot. edaysarEtkareRbIR)as;muxkat;enHmanPaBTUlMTUlay taraglkçN³énbnSM muxkat;Ekg (combinations of angles) epSg²k¾RtUv)anbB©ÚaleTAkñúg AISC Manual of steel Construction. Figure 3.1 kugRtaMgenAkñúgGgát;rgkarTajtamGkS½KW P f = A RbsinebIRkLaépÞmuxkat;énGgát;rgkarTajERbRbYltamRbEvg enaHkugRtaMgnwgERbRbYltam muxkat;Edr. CaFmμtaeRKOgbgÁúMrgkarTajEdlP¢ab;edayb‘ULúg EtgEtmanRbehag. vtþmanrbs;Rb ehagmanT§iBleTAelIkugRtaMg. enARtg;kEnøgenH muxkat;RtUvKitedayecalmuxkat;Rbehag. Net 28 Tension Members

- 2. T.chhay area b¤ net section Camuxkat;suT§EdlminKitmuxkat;Rbehag É gross area Camuxkat;eBjEdlKitrYm TaMgmuxkat;Rbehag. CaerOy² Ggát;rgkarTajEtgRtUvP¢ab;edayb‘ULúgenAxagcug ¬rUbTI3>2¦. Figure 3.2 karKNnaeRKOgbgÁúMrgkarTaj CakareRCIserIsGgát;Edlmanmuxkat;RKb;RKan; edIm,ITb;nwgkug RtaMgEdl)anBIbnÞúkemKuN. kñúgkrNIEdlsÁal;muxkat;Ggát; ersIusþg;KNna (design strength) RtUv)anKNna nigeFVIkareRbobeFobCamYybnÞúkemKuN. CaTUeTA analysis CadMeNIrkarKNnaviPaK ÉcMENk design CadMeNIrkarKNnasarcuHsareLIg ehIyRtUvkarkarsakl,g nigmankMhusecos minput. 3>2> ersIusþg;KNna Design strength eRKOgbgÁúMrgkarTajGacminCab;edaysßanPaBkMNt; (limit state) BIr³ - kMhUcRTg;RTayelIslb; (excessive deformation). edIm,IkarBarsßanPaBenH bnÞúkenAelI gross section RtUvEtmantMéltUcRKb;RKan; EdlnaMeGaykugRtaMgenAelI gross section man tMéltUcCagkugRtaMgyal (yield stress) F . y Pn < Fy Ag Edl Pn = nominal strength in yielding Fy = yield strength Ag = gross section area 29 eRKOgbgÁúMrgkarTaj

- 3. NPIC - kardac; (fracture). edIm,IkarBarsßanPaBenH kugRtaMgenAelI net section RtUvEtmantMéltUc CagersuIsþg;dac; (tensile strength) F . u Pn < Fu Ae Edl Pn = nominal strength in yielding Fu = tensile strength Ae = effective net area . kñúgkrNIxøH A mantMélesμI net section A EtkñúgkrNI e n xøHvamantMéltUcCag A . n eTaHbICaenAelI net section ekItmanyalmunk¾eday EtkMhUcRTg;RTayenAelIRbEvg éntMN mantMéltUcCagkMhUcRTg;RTayenAelIEpñkrgkarTajEdlenAsl;. mUlehtu KWsac;lUt srub (total elongation) EdlCaplKuNRbEvgedIm nigsac;lUteFob (strain) ¬GnuKmn¾eTAnwgkug RtaMg¦. sßanPaBkMNt; (limit state) sMerceGay gross section rgkugRtaMgyal (yield stress) KWedaysarEtsac;lUtsrubmantMélFMCag minedaysarkaryalmuneT. emKuNersIusþg; φ = 0.9 sMrab;karyal yielding t emKuNersIusþg; φ = 0.75 sMrab;kardac; fracture t BIsmIkar !># eyIgGacsresr ∑γ Q i i ≤ φt Pn b¤ P ≤ φ P u t n Edl P CabnSMbnÞúkemKuNEdlmantMélFMCageK. u edaysareKman limit state BIr dUcenHsßanPaBTaMgBIrRtUvbMeBjlkçxNÐxageRkam³ uP ≤ 0.9 F A y sMrab;; gross section g uP ≤ 0.75F A sMrab;; net section u e tMéltUcCagkñúgcMeNamtMélTaMgBIrCa ersIusþg;KNnarbs;eRKOgbgÁúM. RkLaépÞBitR)akdEdlRtUv)andkecjBI gross area edayvtþmanRbehagKWGaRs½yeTA nwgdMeNIrkarplit. sMrab;karGnuvtþn_CaTUeTA rn§EdlecaHedaylkçN³bTdæan drill or punch oversized holes eKRtUvbUkbEnßm 2mm eTAelIGgát;p©itrbs;b‘ULúg. sMrab; drill or punch standard holes eKRtUvbUkbEnßm 4mm eTAelIGgát;p©itrbs;b‘ULúg EdleKeRbIR)as;. sMrab;rn§RTEvg slotted 30 Tension Members

- 4. T.chhay holes 2mm RtUv)aneKbUkbEnßmeTAelIGgát;p©itrbs;b‘ULúg. xageRkamCataragbgðajBIGgát;p©itb‘ULúg nigGgát;p©itrn§. Nominal Hole Dimensions, mm Ggát;p©itb‘ULúg xñatRbehag Hole Dimensions Bolt Diameter Standard Oversize Short-Slot Long-Slot (Dia.) (Dia.) (Width × Length) (Width × Length) M16 18 20 18×22 18 ×40 M20 22 24 22×26 22×50 M22 24 28 24×30 24×55 M24 27 [a] 30 27×32 27×60 M27 30 35 30×37 30×67 M30 33 38 33×40 33×75 ≥ M36 d+3 d+8 (d + 3)×(d + 10) (d + 3)× 2.5d RtUvKña 25mm ) [a]Clearance provided allows the use of a 1-in. bolt if desirable. ( ]TahrN_3>1³ r)aEdkm:ak A36 Edlmanmuxkat; 125 × 12.5mm RtUv)aneRbICaGgát;rgkarTaj. 2 vaRtUv)antP¢ab;eTAnwg gusset plate CamYynwgb‘ULúg M16 cMnYn 4 RKab; ¬rUbTI3>3¦. edaysnμt;fa effective net area A esμInwg net area cUrkMNt;ersIusþg;KNna (design strength). e Figure 3.3 dMeNaHRsay³ EdkEdlmanm:ak A36 man F = 250MPa nig F y u = 400MPa sMrab; yielding én gross section 31 eRKOgbgÁúMrgkarTaj

- 5. NPIC Ag = 125 × 12.5 = 1562.5mm 2 ersIusþg; nominal Pn = Fy Ag = 250 × 1562.5 = 390kN ersIusþg;KNna (design strength) φt Pn = 0.9 × 390 = 351kN sMrab; fracture én net section An = Ag − Aholes = 1562.5 − 2 × (12.5 × 20) = 1062.5mm 2 Ae = An = 1062.5mm 2 ¬sMrab;Et]TahrN_enH¦ ersIusþg; nominal Pn = Fu Ae = 400 × 1062.5 = 425kN ersIusþg;KNna (design strength) φt Pn = 0.75 × 425 = 348.75kN dUcenH ersIusþg;KNna (design strength) φ P t n = 348.75kN ¬tMéltUcCag CacMelIy¦ T§iBlénkugRtaMgpþúM (stress concentration) minRtUv)aneKBicarNakñúgkrNIenHeT EtFatuBit kugRtaMgenARtg;rn§mantMélRbEhlbIdgkugRtaMgmFümEdlekItmanenAelI net area ehIykugRtaMgenA Rtg; fillet énmuxkat;hUtekþA mantMélFMCagkugRtaMgmFümelIsBIrdg. edaysarEtPaBsVit b¤PaB hUtlYs (ductile) rbs;EdkEdlTItaMgEdlman overstress RtUv)anecalsMrab;karKNnaTUeTA. eRkam lkçxNÐCak;Esþg EdkGac)at;bg;PaBsVitrbs;va ehIy stress concentration GaceFVIeGayr)adac; Pøam². sßanPaBenHrYmman fatigue loading nigeRkamsIutuNðPaBTabEmnETn. Figure 3.4 ]TahrN_3>2³ r)argkarTajmuxkat;EkgeTal L89 × 89 × 9.5 Rtv)anP¢ab;eTAnwg gusset plate CamYynwgb‘ULúg M22 cMnYn 3 RKab; ¬rUbTI3>4¦. r)aEdkenH manm:ak A36 . bnÞúkefr DL = 155kN 32 Tension Members

- 6. T.chhay nigbnÞúk LL = 67kN . viPaKmuxkat;enH edaysnμt; effective net area A esμIeTAnwg 85% rbs; net e area . dMeNaHRsay³ bnSMbnÞúk (load combination) (A4-1): 1.4 DL = 1.4 × 155 = 217 kN (A4-2): 1.2 DL + 1.6 LL = 1.2 × 155 + 1.6 × 67 = 293.2kN > 217 kN ⇒ Pu = 293.2kN ersIusþg;KNna (design strength) gross section: Ag = 1610mm 2 φt Pn = φt Fy Ag = 0.9 × 250 × 1610 = 362.25kN net section: An = 1610 − (9.5 × 26) = 1363mm 2 Ae = 0.85 × 1363 = 1158.55mm 2 φt Pn = φt F y u Ae = 0.75 × 400 × 1158.55 = 347.57kN < 362.25kN eday P < φ P u t n (293.2kN < 347.57kN ) dUcenH r)armansuvtßiPaBedaybMeBjlkçxNÐ. enAkñúg]TahrN_xagelIenH eyIgeXIjfa bnSMMbnÞúk (A4-2) RtUv)anykmkeFVIkarKNna. enA eBlmanEtbnÞúkefr nigbnÞúkGefreFVIGMeBIelIeRKOgbgÁúM enaHbnSMbnÞúk (A4-2) RtUv)anykmkeFVIkar KNna enAeBlEdlbnÞúkefr tUcCagbnÞúkGefr *dg. sMrab;]TahrN_xagmux eyIgnwgmineFVIkarepÞóg pÞat;bnSMbnÞúk 1.4D (A4-1) eT edaysarEtvaminGacFMCagbnSMbnÞúk (A4-2). 3>3> RkLaépÞmuxkat;RbsiT§PaBsuT§ Effective net area kñúgcMeNamktþaCaeRcInEdlmanT§iBleTAelIkarRbRBwtþeTArbs;r)arrgkarTaj rebobénkart Pa¢b;CaktþamYyEdlsMxan;CageK. tMNPaKeRcInEtgEteFVIeGayr)arcuHexSay karKNnanUvT§iBl rbs;vaRtUv)aneKehAfa Joint efficiency . ktþaenHCaGnuKmn_eTAnwgPaBsVitrbs;sMPar³ (ductility of material) KMlatrbs;eRKOgP¢ab; (fastener spacing) kugRtaMgpþúMenARtg;Rbehag (stress concentration) TMrg;énkarplit rYmTaMg)atuPUtEdleKsÁal;fa shear leg. ktþaTaMgenHnaMeGaymankar kat;bnßyRbsiT§PaBrbs;r)ar b:uEnþ shear lag CaktþamYyEdlsMxan;CageK. Shear lag ekItmanenAeBlEdlmuxkat;r)arTaMgmUlminRtUv)antP¢ab; dUcCaenAeBlEdleCIg mçagrbs;EdkEkgRtUv)anP¢ab;edaysarb‘ULúgeTAnwg gusset plate ¬rUbTI3>5¦. sar³sMxan;rbs;kart 33 eRKOgbgÁúMrgkarTaj

- 7. NPIC P¢ab;edayEpñk eFVIeGayEpñkrbs;r)arEdltP©ab;rgbnÞúkFM (overload) ehIyEpñkEdlmintP¢ab;minman rgkugRtaMgeBjelj. karbnøayRbEvgtMbn;tP¢ab;CYykat;bnßyT§iBlenH. karRsavRCavEdleFVIeLIg eday Munse nig Chesson (1963) )ansMNUmBreGayKit shear lag kñúgkarkat;bnßy net area. edaysarEt Shear lag manT§iBleTAelITaMgkartP¢ab;edayb‘ULúg nigkarpSar enaH effective net area RtUv)anGnuvtþcMeBaHtMNTaMgBIrRbePTenH. Figure 3.5 Effective net area sMrab;tMNb‘ULúg Ae = UAn Effective net area sMrab;tMNpSar Ae = UAg U CaemKuNkat;bnßyRbsiT§PaB (reduction factor) x U = 1− ≤ 0.9 (AISC Equation B3-2) L x CacMgayBITIRbCMuTMgn;rbs;muxkat;eTAbøg;énkartP¢ab;. L CaRbEvgénkartP¢ab;. RbsinebIr)artP¢ab;edaymanlkçN³sIuemRTI x RtUveRCIserIsyktMéltUcCageK ¬rUbTI3>6¦. Figure 3.6 34 Tension Members

- 8. T.chhay L CaRbEvgtP¢ab;tamTisedAbnÞúkeFVIGMeBI ¬rUbTI3>7¦. sMrab;tMNb‘ULúg L RtUv)anvas;BIcug mçagrbs;GkS½b‘ULúg eTAcugmçageTotrbs;GkS½b‘ULúg. sMrab;tMNpSar L RtUv)anvas;BIcugtMNmçageTA tMNmçag. RbsinebI kMNat;EdlpSarmanRbEvgtamTisedAkMlaMg RbEvgkMNat;EdlmanRbEvgEvgCag RtUv)anykmkKNna. Figure 3.7 35 eRKOgbgÁúMrgkarTaj

- 9. NPIC tMélmFüm L sMrab;karP¢ab;edayb‘ULúgsMrab;Ggát;rgkarTajepSg² Commentary to AISC x B3 eGaytMél U CMnYseGaykarKNna 1 − . tMélmFüm U sMrab;tMNb‘ULúgmanBIrRbePT³ sM x L rab;karP¢ab;eday fastener BIrkñúgmYyCYrtamTisedAbnÞúkeFVIkar nigsMrab;karP¢ab;eday fastener bIb¤ eRcInkñúgmYyCYr. eKeGaytMél U bIepSgKña EdleKaeBtamlkçxNÐxageRkam³ !> sMrab;EdkEdlmanmuxkat; W, M, S EdlmanpleFobTTwgelIkMBs;y:agtic ¬nigsMrab; 2 3 muxkat; T Edlkat;ecjBImuxkat;TaMgbIxagelI¦ ehIyRtUv)anP¢ab;enAnwgsøabCamYynwg fastener y:ag ticbIkúñgmYyCYrtamTisedAbnÞúkeFVIGMeBI U = 0 .9 @> sMrab;RKb;TMrg;muxkat;epSgeTot ¬rYmTaMgmuxkat; built-up¦ CamYynwg fastener y:agticbI kúñgmYyCYr U = 0.85 #> sMrab;RKb;Ggát;TaMgGs; CamYynwg fastener y:agticBIrkúñgmYyCYr U = 0.75 rUbxageRkamnwgbgðajnUv bMerIbMras;c,ab;TaMgenH ¬rUbTI3>8¦. eKk¾GaceRbIR)as;tMél U mFümsMrab;tMNpSarEdr. ebIeTaHCamin)anbriyaykñúg Commentary k¾eday EtvaCaectnarbs; ¬AISC, 1989b¦. c,ab;enHdUcKña EtelIkElgsMrab;karpþl; eGayEdleqøIytbeTAnwg fastener BIrminRtUv)anGnuvtþ. tMélmFüm U sMrab;tMNpSarmandUcxag eRkam³ !> sMrab;EdkEdlmanmuxkat; W, M, S EdlmanpleFobTTwgelIkMBs;y:agtic ¬nigsMrab; 2 3 muxkat; T Edlkat;ecjBImuxkat;TaMgbIxagelI¦ ehIyRtUv)anP¢ab;enAnwgsøab U = 0 .9 @> sMrab;RKb;TMrg;muxkat;epSgeTot U = 0.85 36 Tension Members

- 10. T.chhay Figure 3.8 krNIBiesssMrab;kartedaykarpSar Ae mantMéltUcCag A enAeBlEdlmuxkat;rbs;Ggát;xøHb:ueNÑaHminRtUv)antP¢ab;. sMrab;Ggát; n rgkarTajdUcCa bnÞHEdk b¤r)ar ¬dUcbgðajkñúg]TahrN_3>1¦ effective net area RtUv)anykeBj dUckarKNna net area. EteTaHCay:agNa vamankrNIelIkElgsMrab;c,ab;enH³ sMrab;bnÞHEdk b¤Edk r)arEdltP¢ab;edaykarpSartambeNþay (longitudinal weld) Epñkxagcugrbs;va ¬rUbTI3>9¦ . 37 eRKOgbgÁúMrgkarTaj

- 11. NPIC Figure 3.9 Ae = UAn Edl U =1 sMrab; l ≥ 2w U = 0.87 sMrab; 1.5w ≤ l < 2w U = 0.75 sMrab; w ≤ l < 1.5w l = RbEvgkarpSar > w w = cMgaycenøaHkarpSar ¬EdlGacykTTwgrbs; plate b¤ bar¦ AISC B3 k¾eGaynUvkrNIBiessmYysMrab;Ggát;edaykarpSarEt transverse weld b:ueNÑaH A = RkLaépÞmuxkat;EdlpSar e ¬rUbTI3>10¦ bgðajBIPaBxusKñarvagkarpSartambeNþay (longitudinal weld) nigtamTTwg (transverse weld). karEdlpSarEt transverse weld CakarxusFmμta EdleKmineRbIkñúgplitkmμeT. Figure 3.10 ]TahrN_TI3>3³ kMNt; effective net area sMrab;Ggát;rgkarTaj ¬rUbTI3>11¦ 38 Tension Members

- 12. T.chhay Figure 3.11 dMeNaHRsay³ A n = Ag − Aholes An = 3.72 × 10 −3 − (12.7 × 20) × 2 × 10 −6 = 3.212 × 10 −3 m 2 eCIgEtmçagb:ueNÑaHrbs;muxkat;RtUv)anP¢ab; dUcenH net area RtUvEtkat;bnßy. BItaraglkçN³ kñúgEpñkTI1 rbs; Manual cMgayBITIRbCMuTMgn;eTAépÞxageRkAéneCIgrbs; L152 × 152 × 12.7 KW x = 4.25 × 10 −2 m RbEvgtP¢ab;KW L = 75 × 2 = 150mm 42.5 U = 1− = 0.717 < 0.9 150 Ae = UAn = 0.717 × 3.212 ⋅ 10 −3 = 2.3 ⋅ 10 −3 m 2 eKGaceRbItMélmFüm U BI Commentary . edaysarEtmuxkat;minEmn W, M, S b¤ GkSr T ehIymanb‘ULúgeRcInCagBIrkñúgmYyCYrtamTisbnÞúkeFVIGMeBI U = 0.85 Ae = 0.85 × 3.212 ⋅ 10 −3 = 2.73 ⋅ 10 −3 m 2 tMél U TaMgBIrGacTTYlyk)anTaMgBIr EttMél U Edl)anBIkarKNnatam AISC Equation B3-2 mantMélsuRkitCag. EteTaHCay:agNak¾eday k¾tMélmFüm U manRbeyaCn_sMrab;karKNna dMbUg (preliminary design) enAeBlEdlmuxkat;BitR)akd nigB½t’manlMGitGMBIkarpSarminTan;RtUv)an dwgenaH. ]TahrN_TI3>4³ RbsinebIGgát;kñúg]TahrN_TI3 RtUv)anpSardUcbgðajkñúgrUbTI3>12 cUrkMNt; effective net area 39 eRKOgbgÁúMrgkarTaj

- 13. NPIC Figure 3.12 dMeNaHRsay³ dUckñúg]TahrN_TI3>3 manEtEpñkmuxkat;tP¢ab; nig reduced effective net area RtUv)aneRbI. karP¢ab;RtUv)aneFIVeLIgCamYynwgkarpSartambeNþay nigtamTTwg dUcenHvaminEmnCa krNIBiesssMrab;Ggát;pSareT. ⎛x⎞ ⎛ 42.5 ⎞ U = 1− ⎜ ⎟ = 1− ⎜ ⎟ = 0.7 < 0.9 ⎝L⎠ ⎝ 140 ⎠ cMeLIy³ A e = UAg = 0.7 × 3.72 ⋅ 10 −3 = 2.604 ⋅ 10 −3 m 2 3>4> kartMerobtamEbbqøas; Staggered fasteners RbsinebIkartP¢ab;Ggát;eFIVeLIgCamYynwgb‘ULúg net area nwgmantMélGtibrmakñúgkrNIEdl eRKOgP¢ab; (fastener) RtUv)andak;EtmYyCYr. eBlxøH edaysarEtKMlatRtUv)ankMNt; dUcCaTMhM a enA kñúgrUbTI3>13 (a) caM)ac;eFVIeGayeKRtUvEteRbIeRKOgP¢ab;eRcInCagmYyCYr. RbsinebIdUcenH karkat; bnßyRkLaépÞmuxkat;RtUv)ankat;bnßy RbsinebIeRKOgP¢ab;RtUv)antMerobtamEbbqøas; staggered pattern dUcbgðaj. eBlxøH Staggered fasteners RtUv)antMrUveGayerobtamlkçN³FrNImaRtdUc bgðajkñúgrUbTI13 (b). kñúgkrNIepSgeTot muxkat;xøHEdlkat;tamrn§nwgkat;tamrn§EdlmancMnYntic CagRbsinebIeRKOgP¢ab;minRtUv)antMerobtamEbbqøas;eTenaH. RbsinebIcMnYnén stagger mancMnYnticlμm enaHkarP¢ab;Gacdac;tamExSKenøag abcd dUckñúgrUbTI 3>13 (c). kñúgkrNIEbbenH eKminGacGnuvtþTMnak;TMng f = P A )aneT ehIykugRtaMgenAkñúgmuxkat; tamExSeRTt bc KWCabnSMénkugRtaMgTaj nigkugRtaMgkMlaMgkat;. viFIsaRsþ approximate CaeRcIn RtUv)anesñIeLIgedIm,IBnül;GMBIRbsiT§PaBrbs; staggered hole. elak Cochran (1922) )anesñInUvkar 40 Tension Members

- 14. T.chhay eRbIR)as;RkLaépÞsuT§ net area EdlesμInwgplKuNrvagkMras;bnÞH nigTTwgsuT§ net width. karKNna RkLaépÞRtUv)aneFVIeLIgdUcteTA³ kMNt;nUvExSdac;EdlGacekIteLIg)anedIm,IeFVIkarGegát nigeGay TTwgsuT§ net width esμInwgTTwgdkeGay s2 d'= d − (2-1) 4g sMrab;muxkat;dac;tam staggered hole b¤dk d sMrab;muxkat;dac;tam unstaggered hole. d CaGgát; p©itRbehag s (pitch) CaRbEvgKMlatrvagrn§BIr CitKñatamTisedARsbnwgbnÞúk nig g (gage) CaRbEvgKM latRbehagtamTTwg. AISC specification k¾eRbInUvnUvviFIsaRsþdUcKñaenHEdr b:uEnþkñúgTMrg;xusKñabnþic. Epñk B2 tMrUvfa TTwgsuT§RtUv)anKNnaeday dkplbUkGgát;p©itRbehagBITTwg ehIybUkbEnßmExSeRTt 2 tamCYrmYy²EdlmantMél 4 g . s Figure 3.13 s2 wn = w g − ∑ d + ∑ 4g enAeBlEdlkardac;GacekIteLIgCaTMrg;eRcIn eKRtUveFVIkarGegátRKb;lT§PaBénkardac;TaMgGs; ehIy net width EdlmantMéltUcCageKbMputRtUv)anykmkeRbI. cMNaMfa viFIsaRsþenHmin)anpþl;nUv TMrg;nwgkardac;CamYyExSRsbeTAnwgTisedAbnÞúkeFVIGMeBIenaHeT. 41 eRKOgbgÁúMrgkarTaj

- 15. NPIC ]TahrN_TI3>5³ KNna net area EdltUcbMputsMrab;bnÞHEdlbgðajkñúgrUbTI3>14 . RbehagTaMg Gs;sMrab;b‘ULúgGgát;p©it 25mm . Figure 3.14 dMeNaHRsay³ Ggát;p©itRbehagRbsiT§PaB effective hole diameter KW 30mm sMrab;ExSbnÞat; abcd wn = 410 − 2(30) = 350mm sMrab;ExSbnÞat; abcde 2(75) 2 wn = 410 − 3(30) + = 341.6mm < 350mm 4(130) cMeLIy³ A n = twn = 20 × 341.6 = 6832mm 2 edaysarEteRKOgP¢ab; (fastener) nImYy²Tb;Tl;nUvkMlaMgesμI²Kña ¬karsnμt;EdleRbIenAkñúg karKNnatMNsamBaØ kñúgCMBUkTI 7¦ sñamExSdac;EdlmanlkçN³epSgKña GaceFVIeGaymuxkat;Rtg; kEnøgdac;rgnUvkMlaMgepSgKña. ]TahrN_ ExS abcde kñúgrUbTI3>14 muxkat;rbs;Ggát;Rtg;kEnøgdac;rg nUvkMlaMgeBj 100% EdlExS ijfh eFVIeGaymuxkat;rbs;Ggát;Rtg;kEnøgdac;Tb;Tl;Et 8 / 11 énkMlaMg EdlGnuvtþ. mUlehtuKW kMlaMg 3 / 11 EdlbBa¢ÚnBIGgát;RtUv)anTb;edayeRKOgP¢ab; munnwg ijfh TTYlnUv bnÞúk. enAeBlEdl eRKOgP¢ab; (fastener) RtUv)anP¢ab;CaCUrenAelIeCIgTaMgBIrrbs;EdkEkg ehIykar P¢ab;manlkçN³qøas; staggered KñaeTAvijTAmk enaHedIm,ITTYl)anRkLaépÞ net area dMbUgeKRtUvBnøat 42 Tension Members

- 16. T.chhay EdkEkgedIm,ITTYl)anbnÞHEdksmmUl. bnÞHEdkenHRtUv)anviPaKdUcbnÞHEdkdéTeTotEdr. karBnøat RtUv)aneFVIeLIgtamRTnugEdkEkg Edlpþl;eGaynUvTTwgEdkbnÞHesμIeTAnwgplbUkRbEvgeCIgrbs;vadk nwgkMras;EdkEkg. AISC B2 kMnt;faRbEvg g Edlkat;tamRTnugEkgrbs;EdkEkg RtUv)andkedaykM ras;EdkEkg. dUcenH RbEvg g enAkñúgrUbTI3>15 EdlRtUv)anykeTAeRbIkñúgtY s 2 / 4 g nwgmantMél esμInwg 75 + 50 − 12 = 113mm . Figure 3.15 ]TahrN_TI3>6³ cUrrkPaBFn; design tensile strength rbs;EdkEkgdUcbgðajkñúgrUbTI 3>16. Edk A36 RtUv)aneKykmkeRbIEdlmanRbehagsMrab;b‘ULúg 22mm. dMeNaHRsay³ KNna net width wg = 203 + 152 − 12.7 = 342.3mm Ggát;p©itRbehagRbsiT§PaB effective hole diameter esμI 28mm sMrab;ExSbnÞat; abdf w = 342.3 − (2 × 28) = 286.3mm n 2 sMrab;ExSbnÞat; abceg w = 342.3 − (3 × 28) + 4(× 63.5 = 263.98mm n 38) Figure 3.16 43 eRKOgbgÁúMrgkarTaj

- 17. NPIC edaysarEt bnÞúk 1 / 10 RtUv)anepÞrBIGgát;edayeRKOgP¢ab;enAcMnuc d enaHExSrdac; potential failure line enHRtUvEtTb;nwgbnÞúkEt 9 / 10 . dUcenH net width 263.98mm RtUvEtKuNnwg 10 / 9 edIm,ITTYl)an net width EdlGaceRbobeFobCamYynwgExSbnÞat;EdlTb;nwgbnÞúkeBj 100% . dUcenHExSbnÞat; abceg man w = 263.98 ×10 / 9 = 293.31mm n sMrab;ExSbnÞat; abcdeg g cd = 76 + 57 − 12.7 = 120.3mm (38) 2 (38) 2 (38) 2 wn = 342.3 − (4 × 28) + + + = 243.74mm 4 × 63.5 4 × 120 4 × 76 eday net width Edldac;tamExS abcdeg mantMéltUcCageK dUcenHkrNIenHRtUv)anykmk KNna net area An = 12.7 × 243.74 = 3095.5mm 2 edaysarEteCIgTaMgBIrrbs;EdkEkgRtUv)anP¢ab; dUcenH Ae = An = 3095.5mm 2 ersIusþg;KNnaKW φt Pn = 0.75Fu Ae = 0.75 × 400 × 3095.5 = 928.65kN φt Pn = 0.5Fy An = 0.9 × 250 × 4390 = 987.75kN cMeLIy³ ersIusþg;KNnaKW 928.65kN cMNaMfa plKuNrvag gross width nwgkMras;EdkEkgKWCa gross area krNIRtwmRtUvRbsinebI eCIgrbs; EdkEkgmanragctuekaNEkg. mUlehtuKWfa eKGacTTYl)anragctuekaNEkgeday dképÞ enARtg;rbt;Ekg nigbUkbEnßmépÞenARtg;cugEdkEkg. AISC Specification min)anpþl;nUvkarENnaMsMrab;karerobeRKOgP¢ab;tamEbbqøas;enAelI rolled shape eRkABI EdkEkg. bnÞHEdksmmUlmanPaBsμúKsμajedaysarkMras;Ggát;manPaBxusKña dUckrNIEdk channel nig wide flange . enAkñúgkrNIEbbenH eKesñIeGayeRbIRkLaépÞ ¬RbesIrCag TTWg¦ nigdkGgát;p©itrn§ EdleGayedaysmIkar (2-1). enAkñúg]TahrN_TI3>7 RKb;rn§RbehagTaMgGs;sßitenAEtmYyEpñkénmuxkat;. 44 Tension Members

- 18. T.chhay ]TahrN_TI3>7³ kMNt;RkLaépÞmuxkat;suT§Gb,brma (smallest net area) sMrab;Edk American Standard Channel dUcbgðajenAkñúgrUbTI3>17. RbehagsMrab;b‘ULúgEdlmanGgát;p©it 16mm. dMeNaHRsay³ A n = Ag − ∑ t w × (d b¤ d') d = 20mm ExSbnÞat; abc An = Ag − t w d = 2460 − 11.1 × 20 = 2238mm 2 ExSbnÞat; abcd An = Ag − t w (d sMrab;RbehagRtg; b) − t w (d ' sMrab;RbehagRtg; c) ⎡ 50 2 ⎤ = 2460 − 11.1 × 22 − 11.1 × ⎢22 − ⎥ = 2064.1mm 2 ⎢ ⎣ 4 × 75 ⎥ ⎦ cMelIy³ RkLaépÞmuxkat;Gb,brma (smallest net area) KW 2064.1mm 2 Figure 3.18 45 eRKOgbgÁúMrgkarTaj

- 19. NPIC enAeBlEdlEpñkCaeRcInrbs;muxkat;manRbehag eKeRbIviFIsaRsþedaHRsayxusKñabnþic. eTaH bICaEdkEdlmanrUbragepSgBIEdkEkgminGacBnøattamviFIEdlEdkEkgBnøatk¾eday k¾eKmanviFIsaRsþ epSgeTotkñúgkarBnøatrUbragEdkTaMgenaHEdr. viFIsaRsþkñúgkarBnøatEdkTaMgenaHRtUv)anbgðajkñúgrUbTI 3>18 nigkñúg]TahrN_TI3>8. ]TahrN_TI3>8³ kMNt;ersIusþg;KNnarbs;Edk S-Shape dUcbgðajkñúgrUbTI3>19. RbehagKWsMrab;b‘U LúgEdlmanGgát;p©it 20mm . eRbIEdk A36 . Figure 3.19 dMeNaHRsay³ KNnaRkLaépÞ net area A = A − ∑ (t × Ggát;p©itRbehag ) n g Ggát;p©itRbehagRbsiT§PaB = 24mm sMrab;ExS ad An = 9470 − 4 × 24 × 15.8 = 7953.2mm 2 2 sMrab;ExS abcd RbEvg g sMrab;eRbIenAkñúgtY 4 g KW s g t 89 14 + g1 − w = + 70 − = 107.5mm 2 2 2 2 edayKitRbehagRtg; b nigRtg; c CaRbehagEdlerobqøas; eKTTYl)an ⎛ 382 ⎞ An = 9470 − 4 × 15.8 × 24 − 2 × 14 × ⎜ 24 − ⎟ = 7375.23mm 2 ⎜ 4 × 107.5 ⎟ ⎝ ⎠ kardac;tamExS abcd mantMéltUcCageK. edaysarRKb;EpñkTaMgGs;rbs;muxkat;RtUv)anP¢ab; dUcenH Ae = An = 7375.23mm 2 sMrab; net section 46 Tension Members

- 20. T.chhay φt Pn = 0.75Fu Ae = 0.75 × 400 × 7375.23 = 2212.57kN φt Pn = 0.5Fy An = 0.9 × 250 × 9470 = 2130.75kN cMeLIy³ ersIusþg;KNnaKW 2130.75kN 3>5> Block shear sMrab;rUbsNæanénkartP¢ab;xøH kMNat; b¤bøúkénsMPar³enAxagcugénGgát;GacrEhk. ]TahrN_ kartP¢ab;rbs;Ggát;ragEkgeTalrgkarTaj dUcbgðajkñúgrUbTI3>20 gayrgnUv)atuPUtEbenH EdleK eGayeQμaHfa block shear ¬kardac;TaMgbøúk¦. sMrab;krNIEdl)anbgðajkñúgrUb épÞEdlqUtGacdac; edaykMlaMgkat;TTwg (shear) tammuxkat;beNþay ab nigkMlaMgTaj (tension) tammuxkat;TTwg bc. RbFanbT enHmin)anbgðajy:agc,as;kñúg AISC Chapter D (“Tension Members”) eT b:uEnþkfaxN½Ð epþImdMbUg )anENnaMeyIgeTAkan; Chapter J (“Connections, Joints, and Fasteners”), Section J4.3 (“Block Shear Rupture Strength”). nitiviFIKWQrenAelIkarsnμt;fa muxkat;dac;mYyKWdac;eday fractures nigmYyeTotdac;eday yielding. enaHmann½yfa muxkat;EdlrgkugRtaMgTaj yield naMeGaymuxkat;EdlrgkugRtaMgkMlaMg kat;TTwg fracture b¤pÞúymkvij. muxkat;TaMgBIrenH naMmknUvPaBFn;srub ehIyersIusþg;rbs; block shear KWCaplbUkénPaBFn;énmuxkat;TaMgBIr. Figure 3.20 PaBFn;Fmμta (nominal strength) enAkñúgGgát;rgkarTajKW Fu Ant sMrab; fracture nig Fy Agt sMrab; yield Edl Ant KWCa net area nig Agt KWCa gross area tambeNþaymuxkat;rgkarTaj ¬ bc enAkñúgrUbTI3>20¦. edayykkugRtaMg yield kMlaMgkat; nigkugRtaMg ultimate kMlaMgkat;esμI 60% 47 eRKOgbgÁúMrgkarTaj

- 21. NPIC énkugRtaMgkMlaMgTaj enaHersIusþg;Fmμta (nominal strength) sMrab;kMlaMgkat; fracture KW 0.6Fu Anv nigersIusþg;sMrab;kMlaMgkat; yield KW 0.6Fy Agv Edl Anv KWCa net area nig Agv KWCa gross area tambeNþaymuxkat;rgkMlaMgkat; ¬ ab enAkñúgrUbTI20¦. eKGacmanTMrg;énkardac;Ca2rebob. sMrab;kMlaMgkat; yield nigkMlaMgTaj fracture ersIusþg;KNnaKW φRn = φ[0.6 Fy Agv + Fu Ant ] (AISC Equation J4-3a) sMrab;kMlaMgTaj yield nigkMlaMgkat; fracture ersIusþg;KNnaKW φRn = φ[0.6 Fu Anv + Fy Agt ] (AISC Equation J4-3a) sMrab;krNITaMgBIr φ = 0.75 . BIeRBaH sßanPaBkNt; limit state KW fracture smIkarEdlman lub KWsmIkarNaEdlmantY fracture FMCag. ]TahrN_TI3>9³ kMNt;ersIusþg; block shear rbs;Ggát;rgkarTajdUcbgðajenAkñúgrUbTI3>21. rn§RbehagRtUv)aneRbIsMrab;Ggát;p©it 22mm nigEdkRbePT A36RtUv)aneRbI. Figure 3.21 dMeNaHRsay³ RkLaépÞkMlaMgkat;KW Agv = 9.5 × 190 = 1805mm 2 edaysarEtman 2.5 Ggát;p©itrn§ Anv = 9.5 × [190 − 2.5 × 28] = 1140mm 2 RkLaépÞmuxkat;kMlaMgTaj Agt = 9.5 × 39 = 370.5mm 2 Ant = 9.5 × [39 − 0.5 × 28] = 237.5mm 2 edayeRbI AISC Equation J4-3a eKTTYl)an 48 Tension Members

- 22. T.chhay φRn = φ[0.6 Fy Agv + Fu Ant ] = 0.75 × [0.6(250 )(1805) + 400 × 237.5] = 0.75 × [270750 + 95000] = 274.3kN edayeRbI AISC Equation J4-3b eKTTYl)an φRn = φ[0.6 Fu Anv + Fy Agt ] = 0.75 × [0.6(400 )(1140 ) + 250 × 370.5] = 0.75 × [273600 + 92625] = 274.7 kN smIkarTI 2 mantY fracture FM ¬tYEdlman F ¦ dUcenHsmIkarTI 2 lub. u cMeLIy³ ersIusþg;KNnasMrab; block shearKW 274.7kN 3>6> karKNnaGgát;rgkarTaj Design of tension members karKNnaGgát;rgkarTaj KWkarKNnark gross area nig net area RKb;RKan;sMrab;Ggát;Edlrg karTaj. RbsinebIGgát;enaHRtUv)anP¢ab;edaytMNb‘ULúg enaHeKRtUvkarnUvmuxkat;smRsbsMrab;RkLa épÞEdl)an)at;bg;edaysarrn§tMN. sMrab;Ggát;Edlmanmuxkat;ctuekaNEkg karKNnamanlkçN³ RsYlCag. RbsinebImuxkat; rolled shape RtUv)aneRbImuxkat;EdlRtUvkat;bnßyminGacRtUv)an BüakrN_TukCamun)an BIeRBaHkMras;rbs;muxkat;enARtg;cMnucrn§minRtUv)andwg. karBicarNabnÞab;kñúgkarKNnaGgát;rgkarTajKW PaBrlas; (slenderness). RbsinebIGgát; rbs;eRKagbgÁúMmanmuxkat;tUceFobeTAnwgRbEvgrbs;va enaHGgát;enaHmanlkçN³Rsav (slender). kar KNnaEdlmanlkçN³suRkit KWpleFobrlas; (slenderness ration) R Edl L CaRbEvgrbs;Ggát; L nig r Ca kaMniclPaB (radius of gyration) énRkLaépÞmuxkat;Gb,brma. kaMniclPaB (radius of gyration) Gb,brma KWRtUvKñanwgGkS½ minor principal énmuxkat;. tMélrbs; radius of gyration RtUv)anerobCataragsMrab;muxkat; rolled shape TaMgGs;enAkñúg properties tables enAkñúgEpñkTI1 én Manual. sMrab;Ggát;rgkarsgát; slenderness mansar³sMxan;sMrab;ersIusþg; (strength) b:uEnþ slenderness minsUvCasMxan;sMrab;Ggát;rgkarTajb:unμaneT. eTaHCay:agnwgk¾eday enAkñúgsßanPaBxøH vaCakarRbesI sMrab;karkMNt;nUv slenderness sMrab;Ggát;rgkarTaj. RbsinebIbnÞúkcMGkS½enAkñúg 49 eRKOgbgÁúMrgkarTaj

- 23. NPIC Ggát;rgkarTajRsav (slender tension member) RtUv)anCMnYsedaybnÞúktamTTwg transverse load tUc enaHrMjr½EdleKminR)afñacg;)an b¤PaBdabnwgekItmaneLIg. Ca]TahrN_ krNIenHGacekIteLIg sMrab;EdkBRgwg (bracing rod) EdlmanlkçN³mintwgRbQmnwgkMlaMgxül;. sMrab;krNIenH AISC B7 )anesñInUv slenderness ratio GtibrmaesμInwg 300. tMélenHRKan;EtCatMélesñI (commended value) BIeRBaH slanderness minmanPaBsMxan;sMrab;Ggát;rgkarTajeT ehIytMélenHGacRtUv)anykFM CagenHenAeBl Edlkal³eTs³BiessGnuBaØteGay. EdntMélenHminRtUv)anGnuvtþeTAelIExSkabeT ehIy specification k¾)anelIkElgcMeBaHEdksrésEdr. bBaðasMxan;kñúgkarKNnaRKb;muxkat;TaMgGs; rYmbBa©ÚlTaMgkarKNnaGgát;rgkarTaj KWkarrk nUvmuxkat; EdlplbUkbnÞúkemKuNTaMgGs;minRtUvelIsersIusþg;rbs;Ggát;. Edl ∑ γQ ≤ φRn sMrab;Ggát;rgkarTaj smIkarenHmanrag Pu ≤ φt Pn b¤ φt Pn ≥ Pu Edl Pu KWCaplbUkbnÞúkemKuN. edIm,IKNna yielding 0.9 Fy Ag ≥ Pu b¤ Pu Ag ≥ 0.90 F y edIm,IeCosvag fracture 0.75Fu Ae ≥ Pu b¤ Ae ≥ 0.75uFP u Slenderness ratio RtUv)anbMeBjRbsinebI L r≥ 300 Edl r Ca radius of gyration Gb,brma nig L CaRbEvgGgát;. ]TahrN_TI3>10³ Ggát;rgkarTajEdlmanRbEvg 1750mm RtUvTb;nwgbnÞúkefresvakmμ (service dead load) 80kN nigbnÞúkGefresvakmμ (service live load) 233kN . eRCIserIsGgát;Edlmanmux kat;ctuekaNEkg. eRbIEdk A36 nigtMNRtUv)ansnμt;eRbIb‘ULúgEdlmanGgát;p©it 22mm mYyCYr. dMeNaHRsay³ Pu = 1.2 × 80 + 1.6 × 233 = 468.8kN 50 Tension Members

- 24. T.chhay 468.8 ⋅ 103 muxkat;caM)ac; Ag = Pu 0.9 Fy = 0.9 × 250 = 2083.6mm 2 muxkat;caM)ac; A = 0.75F = 468.8×⋅400 = 1562.7mm 3 P u 10 2 e 0.75 u edaysarEt A = A sMrab;Ggát;enH gross area EdlRtUvKñanwg muxkat;caM)ac; net area enHKW e n Ag = An + Ahole = 1562.7 + 28 × t sakl,g t = 25mm Ag = 1562.7 + 28 × 25 = 2262.7mm 2 edaysarEt 2262.7 > 2083.6 dUcenHmuxkat;caM)ac;KW 2262.7mm 2 Ag 2262.7 wg = = = 90.5mm t 25 sakl,gmuxkat; 25 × 92 epÞógpÞat; slenderness ratio 92 × 253 I min = = 119791.7mm 4 12 A = 25 × 92 = 2300 BI I = Ar eyIgTTYl)an 2 I min 119791.7 rmin = = = 7.22mm A 2300 L 1750 = = 242.4 < 300 (OK) r 7.22 cMeLIy³ eRbIEdlEdlmanmuxkat; 25 × 92 . Ggát;enAkñúg]TahrN_TI3>10 manTTwgtUcCag 203mm EdlRtUv)aneKcat;fñak;vaCar)arEdk bar CaCagEdkbnÞH plate. r)arEdkKYrRtUv)ankMNt;edayeGayTTwgrbs;vaERbRbYlmþg 5mm nigkM ras;rbs;vaERbRbYlmþg 2mm ¬RbBn§½cMNat;fñak;Cak;lak;RtUv)anpþl;eGaykñúgEpñkTI1 én Manual eRkamcMNgeCIg “Bars and Plates”. 51 eRKOgbgÁúMrgkarTaj

- 25. NPIC Figure 3.22 KMlatRbehagtamTTWgsMrab;EdkEkg (mm) Leg 203 178 152 127 102 89 76 64 51 44 38 35 32 25 g1 114 102 89 76 64 51 44 35 26 25 22 22 19 16 g2 76 64 57 51 g3 76 76 64 44 (b) RbsinebIEdkEkgRtUv)aneRbICaGgát;rgkarTaj ehIykartP¢ab;RtUv)aneFVIeLIgedayeRbIb‘ULúg enaHvacM)ac;RtUvmanépÞ ¬TMhM¦ RKb;RKan;sMrab;bLúg. vaGacekItmanbBaðaenAeBlEdl eKeRbIb‘ULúgBIr ‘U CYrenAelIeCIgmYy. rn§RbehagRtUv)anecaHenATItaMgdUcbgðajenAkñúgrUbTI3>22 (a) sMrab;karplitTUeTA eday)andkecjBIrUbTI 9-5 enAkñúgEpñkTI9 én Manual (VOL. II). cMgayKMlatRbehagtamTTwg gage g1 RtUv)aneRbIenAeBlEdleKmanb‘ULúgmYyCYr ehIy g 2 nig g 3 RtUv)anenAeBlEdleKmanb‘U LúgBIrCYr. rUbTI3>22 (b)bgðajfaeCIgEdkEkgRtUvmanRbEvgy:agxøIbMput 127mm edIm,IGnuBaØateGay eRbIb‘ULúgBIrCYr)an. ]TahrN_TI3>11³ KNnaGgát;rgkarTajEdlmanmuxkat;EdkEkgeCIgminesμIKña (unequal-leg angle) RbEvg 4.6m Tb;nUv service dead load 155kN nig service live load 310kN . eRbIEdkRbePT A36 . kartRtUv)anbgðajenAkñúgrUbTI23. 52 Tension Members

- 26. T.chhay Figure 3.23 dMeNaHRsay³ bnÞúkemKuN (factored load) P = 1.2D + 1.6L = 1.2(155) + 1.6(310) = 682kN u nig muxkat;caM)ac; A = φPF = 0.9682 ) = 3031.1mm g u (250 2 t y ehIy muxkat;caM)ac; A = φPF = 0.75(400) = 2273.3mm e 682 u 2 t u kaMniclPaB (radius of gyration) KYrmantMély:agtUcbMput L 4600 r= = = 15.33mm 300 300 edIm,IrknUvmuxkat;RsalbMputsMrab;bMeBjlkçxNÐTaMgenH eyIgrkEdk (unequal-leg angle) Edlman RkLaépÞeBj (gross area) EdlGacTTYlyk)anmantMélrUcbMput rYcehIyepÞógpÞat; effective net area. kaMniclPaB (radius of gyration) k¾GacRtUv)anepÞógpÞat;edaykarRtYtBinitüpg Edr. eday sarkarteFVIeLIgedaymanb‘ULúgBIrCYr enaHeCIgEdlRtUv)aneFVIkartP¢ab;RtUvmanTTwgtUc bMput 127mm ¬emIlkñúgtaragKMlatRbehagtamTTWgsMrab;EdkEkg rUbTI3>22¦. eyIgcaMepþImBItaraglkçN³sMrab; EdkEkgeTal table of properties for single angle enAkñúgEpñkTI1 én Manual nigerobnUvmuxkat; EdkRsalCageKtamlMdab;BItUceTAFM ¬minEmnlMdab;dUcKñaenAkñúgtarageT¦. muxkat;xageRkamGacRtUv)anerob. L152 × 102 × 12.7 : A = 3060mm nig r = 22.1mm g 2 min L127 × 89 × 15.9 : A = 3180mm nig r = 20mm g 2 min L 203 × 102 × 11.1 : A = 3300mm nig r = 22.1mm g 2 min L178 × 102 × 12.7 : A = 3400mm nig r = 22.15mm g 2 min ¬cMNaMfa sMrab;EdkEkg GkS½ X nig Y Edl)anbgðajenAkñúgtaragminEmnCaGkS½em r(principal axes)eT EtGkS½ Z eTIbCaGkS½em (principle axis) r = r . EtsMrab;EdkEkgDub (double-angle min z shape) GkS½ X nig Y KWCaGkS½em.¦ 53 eRKOgbgÁúMrgkarTaj

- 27. NPIC sakl,g L152 × 102 ×12.7 . muxkat;enHman gross area EdlRtUvKñaBitR)akdeTAnwgRkLaépÞcaM)ac; ¬RbesIrCagmuxkat;bIeTot RkLaépÞrbs;vaRtUv)aneGayenAkñúgtarag¦. An = Ag − Aholes = 3060 − 2(24)(12.7 ) = 2450.4mm 2 edaysarRbEvgtminRtUv)andwg AISC Eq. B3-2 minGacRtUv)aneRbIedIm,IKNna shear lag factor U . dUcenH eyIgeRbI U = 0.85 / tMélmFüm)anBI Commentary. ¬]TahrN_TI8 kñúgCMBUkTI 7 tMNsamBaØ bgðajlMGitGMBItMN nigtMél U mFüm GacRtUv)aneRbIedIm,ITTYl)annUvmuxkat;sakl,g bnÞab;tMél U BI AISC Eq. B3-2 GacRtUv)anKNna¦. A = UA = 0.85 × 2450.4 = 2082.84mm < 2273.3mm e n 2 ¬minl¥ N.G.¦ 2 sakl,g L127 × 89 × 15.9 An = 3180 − 2(24)(15.9 ) = 2416.8mm 2 Ae = 0.85 × 2416.8 = 2054.28mm 2 < 2273.3mm 2 ¬minl¥ N.G.¦ eTaHbICamuxkat;enHman gross area FMCagmuxkat;munk¾eday Etvamin)anbegáIn net area eT. mUlehtu KWRkLaépÞEdlRtUvdksMrab;rn§mantMélFM edaysarEtkMras;eCIg. sakl,g L203 ×102 ×11.1 An = 3300 − 2(24)(11.1) = 2767.2mm 2 Ae = 0.85 × 2767.2 = 2352.12mm 2 > 2273.3mm 2 (OK) cMeLIy³ muxkat;enHbMeBjRKb;lkçxNÐtMrUvkar dUcenHeRbI L203 ×102 ×11.1 ttameCIgEdlmanRbEvg 203mm . enAeBlEdlEdkrag (structural shape) b¤EdkbnÞHRtUv)aneRbIedIm,IpÁúMCa built-up shape vamin RtwmEtRtUv)anpÁúMenAEtxagcugGgát;b:ueNÑaHeT b:uEnþvak¾RtUv)anpÁúMenAcenøaHtamRbEvgbeNþayrbs;vapg Edr. eKminRtUvkarkarpÁúMEdlmanlkçN³Cab;rhUteT. karpÁúMEbbenHRtUv)aneKehAfa stitching ehIy eRKOgP¢ab;rbs;vaRtUv)aneKehAfa stitch bolts. karGnuvtþTUeTAKWkMNt;TItaMg stitching Edl L / r sM rab;EpñkpÁúMnImYy² minelIs L / r sMrab;muxkat; built-up. AISC D2 ENnaMfa Edkrag built-up Edl EpñkpÁúMrbs;vaRtUv)anEckeday filler EdlRtUv)aneRbIsMrab;P¢ab;enAcenøaH filler enaHtMélGtib,rma L / r sMrab;EpñkmYy²minRtUvelIs 300. Edkrag built-up EdlekItelIgedayEdkbnÞH b¤edaykarpÁúM rvagEdkbnÞHnigEdkragRtUv)aneBalenAkñúg AISC Section J3.5 of Chapter J (“Connections joints, 54 Tension Members

- 28. T.chhay and Fasteners”). CaTUeTA KMlatrbs;eRKOgP¢ab; b¤karpSarminKYrelIs 24dg énkMras;EpñkesþIgbMput rbs;bnÞHEdk b¤ 300mm . RbsinebIGgát;CaEdk weathering EdlsßitenAkñúgbriyakasgayrgERcHsIu enaHKMlatGtibrmaKW 24dg énkMras; b¤ 175mm . 3>7> EdksrésEdlmaneFμj nigExSkab Threaded rods and Cables enAeBl slenderness minRtUv)anBicarNa Edksrés rod Edlmanmuxkat;mUl nigExSkab (cable) RtUv)aneRbIR)as; CaTUeTACaGgát;rgkarTaj. Edksrés nigExSkabxusKñaRtg; Edksréstan; EtExSkabekItBIExSlYs kabCaeRcInvNнbBa©ÚlKñaehIymanrUbragdUcExSBYr. Edksrés nigExSkab RtUv)aneKeRbICaerOy²sMrab;RbBn§½dMbUlBüÜr k¾dUcCa hanger nig suspension member sMrab;s<an. Edksrésk¾RtUv)aneRbIenAkñúgRbBn§½ bracing enAkñúgkrNIxøH vaRtUv)aneKeFVIeRbkugRtaMg edIm,IkarBar vaBIPaBrlg; (slack) enAeBlEdlbnÞúkxageRkARtUv)andk. rUbTI3>24 bgðajBIviFItEdksrés nigExS kabKMrU. enAeBlcugmçagrbs;EdksrésRtUv)aneFVIeGaymaneFμj (thread) eBlenaH upset end RtUv)an eRbI. EpñkEdlmaneFμjRtUv)ankat;ecjedIm,IBRgIkmuxkat;. enAkEnøgeFμj muxkat;EdkRtUv)ankat; bnßy EtkareFVI upset end )anbegáInmuxkat;EdkeGayFM. EdkbTdæan upset end EdlmaneFμj CaTUeTA man net area enARtg;kEnøgeFμj eRcInCagRtg;EpñkEdlKμaneFμj. eTaHCa upset end mantMéléføk¾ eday EtvamincaM)ac;eRbIRKb;krNIeT. RkLaépÞmuxkat;RbsiT§PaB (effective cross-sectional area) enARtg;EpñkeFμjRtUv)aneKeGay eQμaHfa stress area ehIyvaCaGnuKmn_eTAnwgGgát;p©it unthreaded nwgcMnYneFμjkñúg 1inch . pleFob rvag stress area nig nominal area ERbRbYlb:uEnþvamantMéltUcbMputRbEhl 0.75 . dUcenHersIusþg;rg karTaj nomial rbs;Edk threaded GacRtUv)ansresrdUcxageRkam³ Pn = As Fu = 0.75 Ab Fu Edl As = stress area Ab = nominal (unthreaded) area smIkarenHpþl;nUv nominal strength EdlRtUv)anbgðajenAkñúgtarag Table J3.2 enAkñúg Section J3.6 én AISC Specification. emKuNersIusþg; resistance factor enAkñúgkrNIenH φt = 0.75 . 55 eRKOgbgÁúMrgkarTaj

- 29. NPIC RbsinebI upset end RtUv)aneRbI enaHlT§PaBrgkarTajenAGgát;eFμjEdlFMRtUvFMCag Fy KuNnwg unthreaded body area (AISC Table J3.2, footnote c). Figure 3.24 ]TahrN_TI3>12³ Edk threaded RtUv)aneKeRbICaGgát;sMrab;BRgwgEdlRtUvEtTb;Tl;nwg service tensile load. EdlbnÞúkefr 9kN nigbnÞúkefr 26.5kN . etIGgát;p©itEdkTMhMb:uNÑaRtUv)aneRbI RbsinebI A36RtUv)aneRbI? dMeNaHRsay³ bnÞúkemKuN (factored load) Pu = 1.2(9) + 1.6(26.5) = 53.2kN Edaysar φ P ≥ P t n u φt (0.75Fu )Ag ≥ Pu muxkat;caM)ac; A g = Pu = 53.2 φt (0.75)Fu 0.75(0.75)400 = 236.44mm 2 BI A = πd 2 g 4 Ggát;p©itcaM)ac; d = 4 × 236.44 = 17.35mm π cMeLIy³ eRbIEdk threaded EdlmanGgát;p©it 18mm (A g = 254.47mm 2 ). 56 Tension Members

- 30. T.chhay edIm,IkarBarkarxUcxatkñúgeBlsagsg; EdksrésminRtUvRsav b¤rlas; (slender) eBkeT. eTaHbIminmankarTamTarBI specification k¾eday EtsMrab;karGnuvtþn_TUeTA Ggát;p©itGb,brmaEdlRtUv eRbI RtUvmantMél 16mm . ExSkabkñúgrUbragCa strands b¤ wire rope RtUv)aneRbIenAkñúgkarGnuvtþn_EdlTamTar high strength EtPaBrwg (rigidity) minmanlkçN³sMxan;eT. bEnßmBIelIkareRbIR)as;vaenAkñúgRbBn§½s<anBüÜr nigdMbUl vak¾RtUv)aneKeRbIenAkñúgeRKOgelIkdak;dUcCa hoist nig derrick EdleKeRbIvadUcCaExSeyag sMrab;GKarx<s;² nigsMrab;BRgwgtambeNþayenAkñúgGKarEdleFVIBIEdk. PaBxusKñarvag strand nig wire rope KWbgðajenAkñúgrUbTI3>25. Strand CakarrYmpSMKñaénsréslYsCaeRcInrMuvN½ÐKña ehIy wire rope CakarrYmpSMKñaén strand CaeRcInrMuvN½ÐKña. kareRCIserIsExSkabEdlRtwmRtUvsMrab;bnÞúkEdleGayCaTUeTAQrenAelIkarBicarNaGMBI ersIu sþg; (strength) nigkMhUcRTg;RTay (deformation). bEnßmBIelIsac;lUteGLasÞicFmμta karlUtdMbUg EdlbNþalmkBI seating b¤ shifting énsréslYsmYy² EdlCalT§plvaeFVIeGayExSkabmankarlUt Gcié®nþy_. sMrab;mUlehtuenH CaTUeTAExSkabRtUv)aneKTajBnøÚtmun (prestretched). Wire rope nig strand RtUv)anpliteLIgBIEdkEdlmanesIusþg;x<s;CagEdksMNg;Fmμta ehIyminmanEcgenAkñúg AISC Specification eT. ersIusþg;dac;rbs;ExSkabnImYy² k¾dUcCakarlMGitBIkarttMNr GacTTYl)anBI manufacturer’s literature. Tinñn½ymanRbeyaCn_sMrab;RbePTenHmanenAkñúg Cable Roof structures (Bethlehem Steel, 1968). 3>8> Ggát;rgkarTajenAkñúgdMbUl Tension members in roof trusses Ggát;rgkarTajCaeRcInEdlvisVkrKNnaCaeRKOgbgÁúM trusses. enAeBleRKOgbgÁúM trusses RtUv)aneRbIR)as;enAkñúgsMNg; CaTUeTAvamannaTIcMbgkñúgkarRTRbBn§½dMbUlEdleKRtUvkarElVgEvg. va RtUv)aneKykmkeRbIenAeBlEdléfø nigTMgn;FñwmmantMélx<s;. ¬eRKOgbgÁúM trusses RtUv)anKitCaFñwmCM 57 eRKOgbgÁúMrgkarTaj

- 31. NPIC erA (deep beam) EdlykecjnUvEpñénRTnugy:ageRcIn¦. dMbUl trusses RtUv)aneRbICaerOy²enAkñúg sMNg;shRKas eTaHbICasMNg;RbePTenHRtUvkareRKagrwg (rigid frame) k¾eday. dMbUl trusses KMrU EdlRTeday load-bearing wallRtUv)anbgðajenAkñúgrUbTI 3>26. sMNg;RbePTenH CaTUeTAcugmçag rbs; trusses EdlP¢ab;eTAnwgCBa¢aMgRtUv)aneKKitCaTMr pinned nigTMrmçageTotRtUv)aneKKitfaCaTMr roller. dUcenH trusses GacRtUv)anviPaKCaeRKOgbgÁúMsþaTickMNt;. CBa¢aMgEdlCaTMrGaceFVIBIebtug BRgwgedayEdk bøúkebtug dæ b¤bnSMénsMPar³TaMgenH. CaFmμta dMbUl trusses EtmanKMlatesμIKñatambeNþayGKar nigcgP¢ab;KñaeTAvijeTAmkeday sarFñwmbeNþayEdleKehAfa édrENg (purlin) nigedayEdkExVg (X-bracing). tYnaTIcMbgrbs;éd rENgKWbBa¢ÚnbnÞúkeTAGgát;xagelI (top chord) rbs; trusses b:uEnþvak¾GaccUlrYmedayEpñkxøHkñúgkar BRgwgRbBn§½. CaTUeTAEdkBRgwg (bracing) RtUv)andak;enAkñúgbøg;énGgát;xagelI nigGgát;xageRkam b:uEnþvamuncaM)ac;enARKb;ElVg (bay)TaMgGs;eT edaysarkMlaMgxag (lateral forces) GacRtUv)anbBa¢ÚnBI ElVgEdlTb;mYyeTAElVgEdlTb;mYyeTot edaysarédrENg. vaCakarRbesIrbMputEdlédrENgRtUv)andak;enAelItMNrbs; trusses. dUenH trusses Gac RtUv)anKitCaeRKOgbgÁúMtMNsnøak; (pin-connected structure)EdlRTbnÞúkEtRtg;tMN. EteBlxøHkM raldMbUlminGaclatsn§WgelIcMgayrvagtMN dUcenHeKRtUvkarédrENgkNþal (intermediate purlin). enAkñμúgkrNIEbbenHGgát;xagelInwgrgnUvm:Um:g;Bt;FM k¾dUcCakMlaMgsgát;Ekg (axial compression)ehIy vaRtUv)anKNnaedayKitCa Fñwm-ssr (beam-column)EdlmanBnül;kñúgCMBUkTI6. Sag rod CaGgát;rgkarTajEdlRtUv)aneRbIedIm,Ipþl;TMrxagsMrab;édrENg. bnÞúkPaKeRcInEdl GnuvtþmkelIédrENgmanTisQr dUcenHvanwgmanbgÁúMkMlaMgRsbeTAnwgmMuCMraldMbUl EdlnwgeFVIeGay édrENgekagenAkñúgTisedAenaH ¬rUbTI 3>27¦. Sag rod GacRtUv)andak;enAcMnuckNþal b¤cMnucmYyPaKbI b¤GacjwkenAtambeNþayédrENg GaRs½yeTAnwgcMnYnTMrEdlRtUvkar. KMlatrbs; sag rodCaGnuKmn_eTAnwgKMlat trusses, mMuCMralrbs; Ggát;xagelI/ ersuIsþg;rbs;édrENgTb;nwgkarBt;RbePTenH ¬rUbragPaKeRcInrbs;EdkEdleRbICaédr ENgmanlkçN³exSayNas;sMrab;karBt;tamTisenH¦ nigcMnYnTMrEdlpþl;edaydMbUl. RbsinebIeKeRbI bnÞHEdk CaTUeTAvaRtUv)aneKP¢ab;y:agrwgCamYyédrENg dUcenHeKmincaM)ac;RtUvkar sag rod eT. Et eBlxøH EtTMgn;pÞal;rbs;édrENgKWvaRKb;RKan;kñúgkarbgábBaðaenH dUcenHeKcaM)ac;dak; sag rod edIm,IRT kñúgGMLúgeBlsagsg;muneBldak;kMraldMbUl. 58 Tension Members

- 32. T.chhay RbsinebIeKeRbI sag rod eKcaM)ac;KNnavaedIm,IRTbgÁMúbnÞúkdMbUlEdlRsbeTAnwgdMbUl. Ggát; nImYy²cenøaHédrENgRtUv)ansnμt;eGayRTGVI²TaMgGs;BIxageRkamva dUcenHGgát;xagelIRtUv)anKNna sMrab;bnÞúkenAelIépÞdMbUlEdlmanGMeBIelIGgát;enaH BIcugdMbUldl;kMBUldMbUldUcbgðajenAkñúg rUbTI 3> 59 eRKOgbgÁúMrgkarTaj

- 33. NPIC 28. eTaHbICakMlaMgenAkñúgGgát;nImYy²xusKñak¾eday EtCakarGnuvtþn_TUeTAeKeRbITMhMEtmYysMrab;RKb; Ggát; sag rod enaH. kareRbIR)as;nUvmuxkat;dUcKñasMrYldl;kargarsagsg; ÉbrimaNEdkelIsminCaFM b:unμaneT. rUbTI 3>29 a bgðajBIkarcgP¢ab;édrENgenARtg;RBMdMbUl. Tie rod cenøaHédrENgxagRtUvTb; nwgbnÞúkBIRKb; sag rod TaMgGs;EdlenAsgçagsøabdMbUl. kMlaMgTajenAkñúgGgát;edkmYyCabgÁúMkMlaMg rbs;Ggát; sag rod EdlenAxagelI. düaRkamGgÁesrI (free-body diagram) rbs;édrENgkMBUl RtUv)anbgðajenAkñúgrUbTI 3>29 b . ]TahrN_TI3>13³ Fink trusses EdlmanKMlat 6m KitBIGkS½eTAGkS½nigRTédrENg W 150 × 0.18 dUcbgðajenAkñúg rUbTI 3>30 a. édrENgRtUv)anRTeday sag rod enAcMnuckNþal. edayeRbIEdk A36 KNna sag rod nig tie rod enAédrENgkMBUlsMrab;bnÞúk service load dUcxageRkam³ kMraldMbUlEdk (metal deck)³ 0.1kN / m 2 Built-up roof: 0.25kN / m 2 RBwl³ 0.85kN / m elIbøg;edk 2 TMgn;édrENg³ 0.18kN kñúgmYyEm:RtRbEvg 60 Tension Members

- 34. T.chhay dMeNaHRsay³ KNnabnÞúk³ TTwgrgbnÞúksMrab; sag rod nImYy² = 6m / 2 = 3m RkLaépÞrgbnÞúksMrab;kMraldMbUl nig Built-up roof = 3 ×14 = 42m 2 bnÞúkefr ¬kMraldMbUl nig Built-up roof¦ = (0.1 + 0.25) × 42 = 14.7kN TMgn;édrENgsrub = 0.18 × 3 × 9 = 4.86kN bnÞúkefrsrub = 14.7 + 4.86 = 19.56kN épÞrgbnÞúkRBwl = 3 ×13.6 = 40.8m 2 bnÞúkRBwlsrub = 34.68kN RtYtBinitübnSMbnÞúk³ (A4-2)³ 1.2 D + 0.5S = 1.2 × 19.56 + 0.5 × 34.68 = 40.8kN (A4-3)³ 1.2 D + 1.6 S = 1.2 × 19.56 + 1.6 × 34.68 = 79kN bnSMbnÞúk A4-3 lub. ¬tamkarGegát A4-1, A4-4 nig A4-5 nwgminmantMélFMeT¦. sMrab;bgÁMkMlaMgRsbeTAnwgpÞdMbUl ¬rUbTI 3>30 b¦ 3.6 T = 79 = 20.3kN 14 61 eRKOgbgÁúMrgkarTaj

- 35. NPIC 20.3 ⋅ 103 muxkat;EdkEdlRtUvkar Ag = T = φt (0.75Fu ) 0.75(0.75 × 400) = 90.2mm 2 cMeLIy eRbIEdk threaded rod Ggát;p©it 16mm ¬ A = 201mm ¦ g 2 Edk tie rod EdlP¢ab;drENgenARBMdMbUl ¬rUbTI 3>30 c¦ 14 P = 20.3 = 20.9kN 13.6 ⋅ 3 muxkat;EdkEdlRtUvkar A = φ (0.T F ) = 0.75200..37510 400) = 90.2mm g 75 ( × 2 t u cMeLIy eRbIEdk threaded rod Ggát;p©it 16mm ¬ A = 201mm ¦ g 2 sMrab;ragFrNImaRtrbs; truss nigkardak;bnÞúk Ggát;xageRkam (bottom chord) nigrgkugRtaMg Taj ehIyGgát;xagelI (top chord) nigrgkugRtaMgsgát;. Ggát;RTnugxøHrgkugRtaMgTaj nigxøHeTot rgkugRtaMgsgát;. enAeBleKbBa¢ÚlT§iBlxül;kñúgkarviPaK Tisxül;epSgKñaRtUv)aneKykmkBicarNa eBlenaHkMlaMgenAkñúgGgát;RTnug (web member) xøHGacnwgERbRbYlcenøaHkugRtaMgsgát; nigkugRtaMg Taj. kñúgkrNIEbbenH Ggát;EdlrgGMeBIRtUv)anKNnaedayeGaymannaTICaGgát;rgkarsgát;pg nig rgkarTajpg. sMrab; truss Edlcab;b‘ULúg (bolted truss) muxkat;EdkEkgDub (double-angle section) RtUv)aneRbICajwkjab;sMeb;Ggát;xagelI (top chord) nigGgát;RTnug (web member) . karKNnaenH sMrYldl;karP¢ab;Ggát;EdlCYbKñaenARtg;dMNedayGnuBaØatnUvkareRbIR)as;bnÞHEdkeTal (single gusset plate) dUcbgðajenAkñúgrUbTI 3>31. enAeBlGgát;xagelIrbs;eRKOgbgÁúM truss EdlpSareRbIEdkmuxkat; GkSret EdkRTnugEdlmanmuxkat;EdkEkgGacpSarP¢ab;CamYyeCIg (stem) rbs;Edkmuxkat;GkSret. RbsinebI kMlaMgenAkñúgGgát;RTnug (web member) mantMéltUc eKGaceRbIEdkEkgeTal (single angle) ebIeTaHbIkareFVIEbbenaH)ankat;bnßybøg;sIuemRTIBI truss ehIybNþaleGayGgát;RTnugrgnUv bnÞúkcakp©itk¾eday. CaTUeTAGgát;xagelI nigxageRkam (chord member) CaGgát;Cab; ehIyeKGac kat;vaCakMNat;²RbsinebIcaM)ac;. 62 Tension Members

- 36. T.chhay CakarBitEdlfa chord member CaGgát;Cab; ehIytMNRtUv)ancab;b‘ULúg b¤pSarEdleKmin Gacsnμt;fa truss CaeRKOgbgÁúMtMN pin-connected )aneT. Pabrwgrbs;tMNBitCanaMmknUvm:Um:g;Bt;enA kñúgGgát; b:uEnþCaTUeTAvamantMéltUc ehIyRtUv)anBicarNavaCakMlaMgrg (secondary effect) dUcenH kñúgkarGnuvtþTUeTAeK)anecalva. EtkarBt;EdlbNþaledaysarbnÞúkxageRkAEdlGnuvtþedaypÞal; eTAelIGgát;cenøaHtMN RtUvEtykmkKitBicarNadac;xat. eyIgKitkrNIenHenAkñúgemeronTI 6. ExSeFVIkar (working line) Ggát;rbs;eRKOgbgÁúM truss TaMgGs;RtUvkat;KñaRtg;tMNnImYy². sM rab; truss EdlP¢ab;edayb‘ULúg CYrrbs;b‘ULúg (bolt line) Ca working line ehIysMrab; truss pSar GkS½TIRbCMuTMgn;rbs;TwkbnSarCa working line. karsnμt;kñúgdMeNIrkarviPaK truss RbEvgGgát;RtUv)an vas;BIcMnuceFVIkar (working point) eTA working point. ]TahrN_TI3>14³ eRCIserIsmuxkat;GkSretsMrab;Ggát;xageRkam (bottom chord) rbs;eRKOgbgÁúM dMbUl Warren truss dUcbgðajenAkñúgrUbTI 3>32 a. Truss RtUv)anpSar nigmanKMlatcMgay 6m . snμt;fakarP¢ab;rbs;Ggát;xageRkamRtUv)aneFVIeLIgdaykarpSarbuitkaMtambeNþay (longitudinal fillet weld) enAnwgsøabRbEvg 230mm . edayeRbIEdk A36 CamYynwgTinñn½ybnÞúkxageRkam ¬xül;min RtUv)anBicarNaenAkñúg]TahrN_enHeT¦. édrENg (purlin)³ M 200 × 0.097 RBwl³ 0.95kN / m elIbøg;edk 2 kMraldMbUlEdk (metal deck): 0.1kN / m 2 dMbUl³ 0.2kN / m2 kMralGIusULg;³ 0.15kN / m2 63 eRKOgbgÁúMrgkarTaj

- 37. NPIC dMeNaHRsay³ KNnabnÞúk³ RBwl = 0.95 × 6 ×12 = 68.4kN bnÞúkefr ¬elIkElgédrENg¦ = kMraldMbUlEdk 0.1kN / m 2 dMbUl 0.2kN / m 2 kMralGIusULg; 0.15kN / m 2 srub 0.45kN / m 2 bnÞúkefrsrub = 0.45 × 6 × 12 = 32.4kN TMgn;édrENgsrub = 0.097 × 6 ×12 = 7kN 64 Tension Members

- 38. T.chhay snμt;faTMgn; truss esμI 10% énbnÞúkepSg² 0.1(68.4 + 32.4 + 7 ) = 10.78kN bnÞúkenAelItMNxagkñúgKW 32.4 10.78 D= + + 0.097 × 6 = 6kN 8 8 68.4 S= = 8.55kN 8 enAelItMNxageRkA RkLaépÞrgbnÞúkKWesμInwgBak;kNþalRkLaépÞrgbnÞúkrbs;tMNxagkñúg. bnÞúkenAelI tMNxageRkAKW 32.4 10.78 D= + + 0.097 × 6 = 3.28kN 2×8 2×8 68.4 S= = 4.3kN 2×8 karbnSMbnÞúk A4-3 nwgTTYl)antMélFMCageK³ Pu = 1.2 D + 1.6S enAelItMNxagkñúg P = 1.2 × 6 + 1.6 × 8.55 = 20.88kN u enAelItMNxageRkA P = 1.2 × 3.28 + 1.6 × 4.3 = 10.82kN u Truss EdlrgbnÞúkRtUv)anbgðajenAkñúg rUbTI 3>32 b. Ggát;xageRkamRtUv)anKNnaedaykMNt;kMlaMgkñgGgát;nImYy²rbs;Ggát;xageRkam nigeFVIkar ú eRCIserIsmuxkat;smrmüedIm,ITb;nwgkMlaMgEdlFMCageK. enAkñúg]TahrN_enH kMlaMgenAkñúgGgát; IJ mantMélFMCageK. GgÁesrI (free body) enAxageqVgmuxkat; a-a RtUv)anbgðajenAkñúg rUbTI 3>32 c. ∑ M E = 83.9(6) − 10.82(6) − 20.88(4.5 + 3.0 + 1.5) − 1.2 FIJ = 0 FIJ = 208.8kN sMrab;muxkat;eBj (gross section) 8 ⋅ 10 3 muxkat;EdlRtUvkar A = 0.F F = 208.× 250 = 928mm g 9 IJ 0.9 2 y sMrab; net section muxkat;EdlRtUvkar A = 0.75F = 208.8×⋅400 = 696mm 3 F IJ 10 2 e 0.75 u sakl,g WT125 × 0.09 Ag = 1140mm 2 > 928mm 2 65 eRKOgbgÁúMrgkarTaj

- 39. NPIC kartP¢ab;eFVIeLIgedaykarpSartambeNþay ehIyGgát;minEmnCaEdkbnÞHEdksrés dUcenHkartP¢ab; enHminsßitenAkñúgkrNIBiessNamYysMrab;Ggát;EdlpSarEdlrg shear leg. ⎛x⎞ ⎛ 34.5 ⎞ U =1− ⎜ ⎟ =1− ⎜ ⎟ = 0.85 < 0.9 ⎝L⎠ ⎝ 230 ⎠ Ae = CAg = 0.85 × 1140 = 969mm 2 > 696mm 2 (OK) RbsinebIGgát;xageRkamRtUv)anBRgwgenA panel point L 1500 = = 75.4 < 300 (OK) r 19.9 cMeLIy eRbIEdk WT125 × 0.09 3>9> Ggát;EdltPa¢b;edayknøas; Pin-Connection Members enAeBlGgát;RtUv)antP¢ab;edayknøas; rn§RbehagRtUv)aneFVIeLIgenAcugTaMgsgçagrbs;Ggát; nigEpñkEdlvaRtUvP¢ab; ehIyknøas;RtUv)ans‘ktamrn§enaH. kareFVIEbbenHedIm,IkMueGayGgát;rgm:Um:g;Bt;. Ggát;rgkarTajEdltP©ab;tamTMrg;EbbenHRbQmnwgkar)ak;eRcInRbePT EdlRtUv)aneRobrab;enAkñúg AISC D3 nigRtUv)anBnül;dUcxageRkam. Eyebar CaRbePTBiessrbs;Ggát;EdlP¢ab;edayknøas; (pin-connected member) EdlenA xagcugrbs;vamanrn§knøas; dUcbgðajkñúgrUbTI 3>33. ersIusþg;KNnaKWQrelIersIusþg;yalrbs;mux kat;eBj. k,ÜnlMGitsMrab;KNnaTMhM eyebar manenAkñúg AISC D3 EtminRtUv)anykmkerobrab;enATI enHeT. Eyebar RtUv)aneRbIy:agTUlMTUlayenAeBlmunCaGgát;rgkarTajEdleRbIenAkñúg truss s<an b¤enAkñúgs<anBüÜr. vaminRtUv)aneKeRbIeTenAeBlbc©úb,nñ. Ggát;EdltP¢ab;edayknøas;KYrRtUv)anKNnasMrab;sßanPaBkMNt;dUcxageRkam ¬rUbTI 3>34¦ !> kugRtaMgTajenAelI net effective area ¬rUbTI 3>34 a ¦ φt = 0.75, Pn = 2tbeff Fu (ASIC Equation D3.1) @> kugRtaMgkMlaMgkat;enAelI net effective area ¬rUbTI 3>34 b¦ φsf = 0.75, Pn = 0.6 Asf Fu (ASIC Equation D3.21) #> kugRtaMg bearing . tMrUvkarenHmanenAkñúg chapter J (“Connections, Joints and fastener”) ¬rUbTI 3>34 c¦ φ = 0.75, Pn = 1.8Fy Apb (ASIC Equation J8-1) $> kugRtaMgTajenAelI gross area 66 Tension Members

- 40. T.chhay φ = 0.9, Pn = Fy Ag (ASIC Equation D1-1) Edl t= kMras;rbs;EpñkEdltP¢ab; beff = 2t + 16 ≤ b ¬KitCa mm ¦ b = cMgayBIépÞxagrbs;rn§knøas;eTAépÞxagrbs;Ggát; EdlEkgeTAnwgTisrbs;kMlaMg Asf = 2t (a + d / 2) a= cMgayBIépÞxagrbs;rn§knøas;eTAépÞxagrbs;Ggát; EdlRsbeTAnwgTisrbs;kMlaMg d = Ggát;p©itknøas; Apb = projected bearing area = dt tMrUkarbEnßmsMrab;karkMNt;TMhMrbs;knøas; nigGgát;manbkRsayenAkñúg AISC D3. 67 eRKOgbgÁúMrgkarTaj