Whatisabearing

•

0 gostou•129 visualizações

Bearings are machine elements that support moving parts and allow relative motion with minimal friction. They consist of an inner ring, outer ring, rolling elements like balls or rollers, and a cage. The inner ring is mounted on a shaft and rotates, while the outer ring is usually held stationary in a housing. Bearings offer advantages like low friction, ability to support radial and thrust loads at high speeds, accurate performance under varying conditions, high load capacity, ability to operate under extreme speeds and temperatures, minimal wear, simple lubrication, and precision.

Denunciar

Compartilhar

Denunciar

Compartilhar

Baixar para ler offline

Recomendados

Recomendados

Mais conteúdo relacionado

Mais procurados

Mais procurados (20)

Semelhante a Whatisabearing

Semelhante a Whatisabearing (20)

Bearing Description about basic, types, failure causes

Bearing Description about basic, types, failure causes

Último

https://app.box.com/s/7hlvjxjalkrik7fb082xx3jk7xd7liz3TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...

TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...Nguyen Thanh Tu Collection

Último (20)

TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...

TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...

This PowerPoint helps students to consider the concept of infinity.

This PowerPoint helps students to consider the concept of infinity.

Unit 3 Emotional Intelligence and Spiritual Intelligence.pdf

Unit 3 Emotional Intelligence and Spiritual Intelligence.pdf

Sensory_Experience_and_Emotional_Resonance_in_Gabriel_Okaras_The_Piano_and_Th...

Sensory_Experience_and_Emotional_Resonance_in_Gabriel_Okaras_The_Piano_and_Th...

General Principles of Intellectual Property: Concepts of Intellectual Proper...

General Principles of Intellectual Property: Concepts of Intellectual Proper...

Fostering Friendships - Enhancing Social Bonds in the Classroom

Fostering Friendships - Enhancing Social Bonds in the Classroom

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Food safety_Challenges food safety laboratories_.pdf

Food safety_Challenges food safety laboratories_.pdf

ICT Role in 21st Century Education & its Challenges.pptx

ICT Role in 21st Century Education & its Challenges.pptx

Whatisabearing

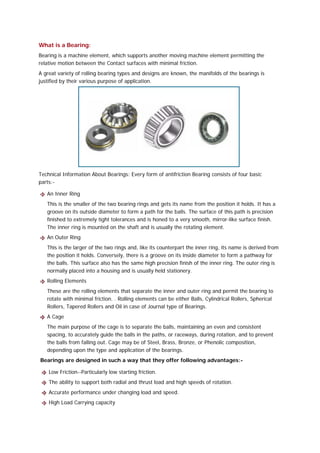

- 1. What is a Bearing: Bearing is a machine element, which supports another moving machine element permitting the relative motion between the Contact surfaces with minimal friction. A great variety of rolling bearing types and designs are known, the manifolds of the bearings is justified by their various purpose of application. Technical Information About Bearings: Every form of antifriction Bearing consists of four basic parts:- An Inner Ring This is the smaller of the two bearing rings and gets its name from the position it holds. It has a groove on its outside diameter to form a path for the balls. The surface of this path is precision finished to extremely tight tolerances and is honed to a very smooth, mirror-like surface finish. The inner ring is mounted on the shaft and is usually the rotating element. An Outer Ring This is the larger of the two rings and, like its counterpart the inner ring, its name is derived from the position it holds. Conversely, there is a groove on its inside diameter to form a pathway for the balls. This surface also has the same high precision finish of the inner ring. The outer ring is normally placed into a housing and is usually held stationery. Rolling Elements These are the rolling elements that separate the inner and outer ring and permit the bearing to rotate with minimal friction. . Rolling elements can be either Balls, Cylindrical Rollers, Spherical Rollers, Tapered Rollers and Oil in case of Journal type of Bearings. A Cage The main purpose of the cage is to separate the balls, maintaining an even and consistent spacing, to accurately guide the balls in the paths, or raceways, during rotation, and to prevent the balls from falling out. Cage may be of Steel, Brass, Bronze, or Phenolic composition, depending upon the type and application of the bearings. Bearings are designed in such a way that they offer following advantages:- Low Friction--Particularly low starting friction. The ability to support both radial and thrust load and high speeds of rotation. Accurate performance under changing load and speed. High Load Carrying capacity

- 2. Operating ability under extreme conditions of speed and performance. Practically no wear in running. Simple methods of Lubrication. Inherently Precision Mechanisms. The above advantages clearly justify the ubiquitous presence of Bearings in our life.