2062

•

3 gostaram•1,014 visualizações

The document outlines Indian Standard 2062:2006 which specifies requirements for nine grades of hot rolled low, medium, and high tensile structural steel. It describes the chemical composition, mechanical properties, permissible variations, testing procedures, and other quality requirements for the steel grades. Destructive and non-destructive tests are specified to ensure freedom from defects and compliance with mechanical properties.

Denunciar

Compartilhar

Denunciar

Compartilhar

Recomendados

Mais conteúdo relacionado

Mais procurados

Mais procurados (18)

Fabrication and Quality Control of structural steel

Fabrication and Quality Control of structural steel

Semelhante a 2062

Semelhante a 2062 (20)

B16 c360 free-cutting brass rod, bar and shapes for use in screw machines1

B16 c360 free-cutting brass rod, bar and shapes for use in screw machines1

107 weldox 700_uk_data sheet -Ficha técnica Aço estrutural Weldox 700

107 weldox 700_uk_data sheet -Ficha técnica Aço estrutural Weldox 700

A493 09(2013) standard specification for stainless steel wire and wire rods f...

A493 09(2013) standard specification for stainless steel wire and wire rods f...

Surface hybrid nanocomposites via friction stir processing

Surface hybrid nanocomposites via friction stir processing

A111 99a(2014) standard specification for zinc-coated (galvanized) “iron” tel...

A111 99a(2014) standard specification for zinc-coated (galvanized) “iron” tel...

Malleable iron pipe fittings from Hebei Jianzhi Casting Group

Malleable iron pipe fittings from Hebei Jianzhi Casting Group

2062

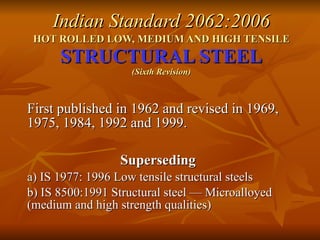

- 1. Indian Standard 2062:2006 HOT ROLLED LOW, MEDIUM AND HIGH TENSILE STRUCTURAL STEEL (Sixth Revision) First published in 1962 and revised in 1969, 1975, 1984, 1992 and 1999. Superseding a) IS 1977: 1996 Low tensile structural steels b) IS 8500:1991 Structural steel — Microalloyed (medium and high strength qualities)

- 3. Grades of Steel Nine grades of steel, Table -1 chemical Composition Semi-killed or killed 0.48 0.45 0,045 0.045 1.80 0.22 E E 450 (Fe 590) Semi-killed or .killed 0.46 0.45 0.045 0.045 1.60 0.22 D E 450 (Fe 570) Semi-killed or killed 0.44 0.45 0.045 0.045 1.60 0.20 E410 (Fe 540) Semi-killed or killed 0.42 0.45 0,045 0.045 1.50 0.20 — E 350 (Fe 490) Semi-killed or killed 0.40 0,45 0,045 0.045 1,30 0.20 E 300 (Fe 440) Killed 0:39 0.40 0,040 0.040 1.50 0.20 C E 250 (Fe410W) Killed 0.41 0.40 0.045 0.045 1,50 0.22 B E 250 (F.41OW) Semi-killed or killed 0.42 0.40 0.045 0.045 1.50 0.23 A E 250 (F.41OW) Semi-killed or killed — - 0.045 0.045 1.25 0.25 — E 165 (Fe 290) (9) (8) (7) (6) (5) (4) (3) (2) (1) Deoxidation Equivalent Si P S Mn C Designation Method of Max,Carbon Ladle Analysis, Percent, Max Qua lity Grade

- 4. Table-2 mechanical Properties Note3: The more stringent requirements than those given above may be as agreed to between the purchaser and the manufacturer.

- 10. Position and Orientation of Sample

- 14. Fig-2: Minimum Impact Energy Values for test pieces width 5mm to 10mm