Om0015 maintenance management

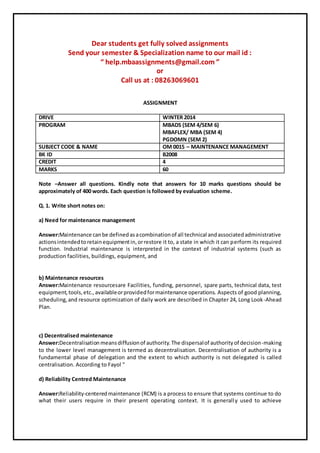

- 1. Dear students get fully solved assignments Send your semester & Specialization name to our mail id : “ help.mbaassignments@gmail.com ” or Call us at : 08263069601 ASSIGNMENT DRIVE WINTER 2014 PROGRAM MBADS (SEM 4/SEM 6) MBAFLEX/ MBA (SEM 4) PGDOMN (SEM 2) SUBJECT CODE & NAME OM 0015 – MAINTENANCE MANAGEMENT BK ID B2008 CREDIT 4 MARKS 60 Note –Answer all questions. Kindly note that answers for 10 marks questions should be approximately of 400 words. Each question is followed by evaluation scheme. Q. 1. Write short notes on: a) Need for maintenance management Answer:Maintenance canbe definedasacombinationof all technical andassociatedadministrative actionsintendedtoretainequipmentin,orrestore it to, a state in which it can perform its required function. Industrial maintenance is interpreted in the context of industrial systems (such as production facilities, buildings, equipment, and b) Maintenance resources Answer:Maintenance resourcesare Facilities, funding, personnel, spare parts, technical data, test equipment,tools,etc.,availableorprovidedformaintenance operations. Aspects of good planning, scheduling,and resource optimization of daily work are described in Chapter 24, Long Look-Ahead Plan. c) Decentralised maintenance Answer:Decentralisation meansdiffusionof authority.The dispersalof authorityof decision-making to the lower level management is termed as decentralisation. Decentralisation of authority is a fundamental phase of delegation and the extent to which authority is not delegated is called centralisation. According to Fayol " d) Reliability Centred Maintenance Answer:Reliability-centeredmaintenance (RCM) is a process to ensure that systems continue to do what their users require in their present operating context. It is generally used to achieve

- 2. improvementsinfieldssuchasthe establishmentof safe minimumlevelsof maintenance.Successful implementation of RCMwill lead to increase in Q. 2. Optimizing Maintenance at XYZ Electricals XYZ Electricals is one of the leading manufacturers of electrical utilities. The organisation is well known for delivering quality products to consumers. It has adopted A preventive maintenance (PM) approach for the maintenance of its machines and equipment. However, in the last few months, the organisation has observed an increase in: Maintenance costs Facility downtime Frequent failures of components After thorough analysis, it has been found that the main cause behind all the problems is the excessive use of preventive maintenance. The organisation also realized that it must adopt a maintenance process that maintains a balance between the requirements and resources of maintenance. Therefore, XYZ decided to implement maintenance optimization procedures in the plant. Various optimizationtechniqueswere developedtoconverttraditional preventive maintenance intoa cost - effective program. These techniques aimed at: Identifying assets that affect plant operations Identifying assets that may benefit most from preventive maintenance Selecting the most appropriate preventive tasks Combining appropriate traditional maintenance tasks with predictivemaintenance tasks Implementing appropriate training methods to apply optimization techniques After implementing maintenance optimisation techniques, the benefits that XYZ received after optimising its maintenance are: Reduction in maintenance costs by removing unnecessary corrective maintenance expenses Improvement in understanding of assets Application of cost – effective preventive maintenance techniques Better assessment of functioning of assets when they are in operation What are the problems at XYZ Electricals? Which was adopted to overcome the problems? Assess if the solution is effective in resolving the problem. Answer:XYZElectricalsisone of the leadingmanufacturersof electrical utilities. The organisation is well knownfordeliveringqualityproducts to consumers. It has adopted A preventive maintenance (PM) approach for the maintenance of its machines and equipment. However, in the last few months, the organisation has observed an increase in: Maintenance costs Q. 2. List the problems at XYZ

- 3. Answer:Maintenance costs,Facilitydowntime andFrequentfailuresof components. After thorough analysis, it has been found that the main cause behind all the problems is the excessive use of preventive maintenance. The organisation also realized that it must adopt a maintenance process that maintains a balance between the requirements and resources of maintenance. Therefore, XYZ decided to implement Q. 3. Write short notes on: a) Production philosophy Answer:The product philosophy was the dominant marketing philosophy prior to the Industrial Revolution and continued to the 1920s. The product philosophy holds that the organization knows itsproduct betterthananyone or anyorganization.The companyknowswhatwill work in designing and producing the product and what will not work. For example, the company may decide to emphasize the low cost or high quality of b) Mean Time to Repair Answer:MeanTime To Repair(MTTR) isa basicmeasure of the maintainabilityof repairable items.It represents the average time required to repair a failed component or device. Expressed mathematically,itisthe total corrective maintenancetime dividedbythe total numberof corrective maintenance actionsduringagivenperiodof time. It generally does not include lead time for parts not readily available or other Administrative or Logistic Downtime (ALDT). c) Maintenance documentation Answer: Maintenance is part of the Change Management process. Creating maintainable documentationshouldbe amajorobjective forall Policies, Processes, and Procedures. The ease or difficultyof maintenanceisdependentuponthe foundationestablished during the Planning phase. With age, the quality of the Policies, Processes, and Procedures will lessen, if the Plan, Build, and Change phases are not properly performed. d) Online or permanent condition monitoring Answer:Condition monitoring (or, colloquially, CM) is the process of monitoring a parameter of conditioninmachinery(vibration,temperature etc.), in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance. The use of conditional monitoring allows maintenance Q. 4. Which are the common tasks performed in maintenance management? Answer:Most Preventive Maintenance (PM) programs were set up many years ago. Each departmentinaplant setup their ownprogramin isolationfromeachother.As an example, a plant set up a PM program covering mechanical equipment, then another program was set up for electrical equipmentandanotherto cover automation and control system. A lubricant vendor then added lubrication routes and on top of this other PM activities such as Vibration Analysis and Operator Inspections was added in addition to all Q. 5. What are the benefits and issues related to predictive maintenance?

- 4. Answer:While many companies are perfectly satisfied with the performance of their outsourced predictive maintenance (PdM) programs, some do not get the desired results for the time and money expended. Others recognize that they have a pool of in-house talent that could do the job givenenoughtime andtraining,orare facingbudgetcuts andpressuresthatforce limiting, reducing or defunding PdM contracts.Vibration analysis is one of the most commonly used predictive maintenance technologies in industry. Q. 6. Write short notes on a) Structure of maintenance budget Answer:InFormerBudgeting,the budgetstructure representsall the fundscentersandcommitment items in hierarchical form for each fund. The budget structure is year-dependent and is therefore valid up until the time it has to be redefined due to new requirements. You define an individual budgetstructure thatis year-independentforeachfundif youare using overall values for this fund. By using posting objects you specify which BS elements can be posted. The standard setting for Funds Management supports postings of actual b) Role of maintenance auditor Answer: Audit is the process of checking accounting entries as per norms and guideline by the accounting professionals. The Companies Act,1956 provides for compulsory appointment of an independentpersonasthe 'auditor'of the companywhose responsibilityistoexamine the affairs of the company and to report it to the c) Codification of spare parts Answer:Codification /cataloguingisbasicallyanidentificationsystemforeachitemof the inventory. Normally, it is the custodian who does the codification for the items he keeps in his inventory. However, in firms of substantial sizes where good number of items are received on regular basis , codification is usually done by a team d) Types of maintenance benchmarking Answer:Benchmarkingisthe processthroughwhichacompanymeasuresitsproducts, services, and practicesagainstitstoughestcompetitors,orthose companiesrecognized as leaders in its industry. Benchmarkingisone of a manager'sbesttoolsfor determining whether the company is performing particularfunctionsandactivitiesefficiently,whetheritscostsare in line with those of competitors, and whether its internal activities and business processes need improvement. The idea behind benchmarking is to measure internal processes Dear students get fully solved assignments Send your semester & Specialization name to our mail id : “ help.mbaassignments@gmail.com ” or Call us at : 08263069601