Om 0015 maintenance management

•Transferir como DOCX, PDF•

0 gostou•56 visualizações

Dear students get fully solved assignments Send your semester & Specialization name to our mail id : help.mbaassignments@gmail.com or call us at : 08263069601

Denunciar

Compartilhar

Denunciar

Compartilhar

Recomendados

Maintenance and reliability has taken great strides toward managing asset reliability by applying known best practices in maintenance and reliability finding that they can optimize reliability and reduce total cost and reduce risk by applying known best practices. However, if not most organizations are still trapped in the old way of thinking. Read this article and see where you stand.Advanced Maintenance And Reliability (Best Maintenance and Reliability Practi...

Advanced Maintenance And Reliability (Best Maintenance and Reliability Practi...Ricky Smith CMRP, CMRT

Recomendados

Maintenance and reliability has taken great strides toward managing asset reliability by applying known best practices in maintenance and reliability finding that they can optimize reliability and reduce total cost and reduce risk by applying known best practices. However, if not most organizations are still trapped in the old way of thinking. Read this article and see where you stand.Advanced Maintenance And Reliability (Best Maintenance and Reliability Practi...

Advanced Maintenance And Reliability (Best Maintenance and Reliability Practi...Ricky Smith CMRP, CMRT

Mais conteúdo relacionado

Mais procurados

Mais procurados (20)

Day in the Life of a Proactive Maintenance Technician Article

Day in the Life of a Proactive Maintenance Technician Article

10 Things an Operations Supervisor can do Today to Improve Reliability

10 Things an Operations Supervisor can do Today to Improve Reliability

Why should you use repeatable maintenance procedures?

Why should you use repeatable maintenance procedures?

Day In the Life Of a Proactive Maintenance Manager

Day In the Life Of a Proactive Maintenance Manager

Preventive Maintenance Best Practices plus PM Optimization Workshop Brochure

Preventive Maintenance Best Practices plus PM Optimization Workshop Brochure

Electrical Department Maintenance Management Vision

Electrical Department Maintenance Management Vision

The Seven Deadly Sins in Measuring Asset Reliability

The Seven Deadly Sins in Measuring Asset Reliability

Best Practices in Maintenance Planning And Scheduling

Best Practices in Maintenance Planning And Scheduling

Business Continuity Plan PowerPoint Presentation Slides

Business Continuity Plan PowerPoint Presentation Slides

Semelhante a Om 0015 maintenance management

Semelhante a Om 0015 maintenance management (20)

The challenges facing in pharmaceutical maintenance

The challenges facing in pharmaceutical maintenance

Boost Equipment Performance, Save Money With Proactive Maintenance

Boost Equipment Performance, Save Money With Proactive Maintenance

Último

Making communications land - Are they received and understood as intended? webinar

Thursday 2 May 2024

A joint webinar created by the APM Enabling Change and APM People Interest Networks, this is the third of our three part series on Making Communications Land.

presented by

Ian Cribbes, Director, IMC&T Ltd

@cribbesheet

The link to the write up page and resources of this webinar:

https://www.apm.org.uk/news/making-communications-land-are-they-received-and-understood-as-intended-webinar/

Content description:

How do we ensure that what we have communicated was received and understood as we intended and how do we course correct if it has not.Making communications land - Are they received and understood as intended? we...

Making communications land - Are they received and understood as intended? we...Association for Project Management

Último (20)

This PowerPoint helps students to consider the concept of infinity.

This PowerPoint helps students to consider the concept of infinity.

Unit 3 Emotional Intelligence and Spiritual Intelligence.pdf

Unit 3 Emotional Intelligence and Spiritual Intelligence.pdf

Beyond_Borders_Understanding_Anime_and_Manga_Fandom_A_Comprehensive_Audience_...

Beyond_Borders_Understanding_Anime_and_Manga_Fandom_A_Comprehensive_Audience_...

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Making communications land - Are they received and understood as intended? we...

Making communications land - Are they received and understood as intended? we...

Python Notes for mca i year students osmania university.docx

Python Notes for mca i year students osmania university.docx

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

General Principles of Intellectual Property: Concepts of Intellectual Proper...

General Principles of Intellectual Property: Concepts of Intellectual Proper...

Unit-V; Pricing (Pharma Marketing Management).pptx

Unit-V; Pricing (Pharma Marketing Management).pptx

Food safety_Challenges food safety laboratories_.pdf

Food safety_Challenges food safety laboratories_.pdf

Om 0015 maintenance management

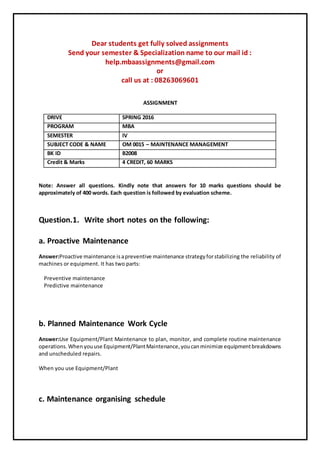

- 1. Dear students get fully solved assignments Send your semester & Specialization name to our mail id : help.mbaassignments@gmail.com or call us at : 08263069601 ASSIGNMENT DRIVE SPRING 2016 PROGRAM MBA SEMESTER IV SUBJECT CODE & NAME OM 0015 – MAINTENANCE MANAGEMENT BK ID B2008 Credit & Marks 4 CREDIT, 60 MARKS Note: Answer all questions. Kindly note that answers for 10 marks questions should be approximately of 400 words. Each question is followed by evaluation scheme. Question.1. Write short notes on the following: a. Proactive Maintenance Answer:Proactive maintenance isapreventive maintenance strategyforstabilizing the reliability of machines or equipment. It has two parts: Preventive maintenance Predictive maintenance b. Planned Maintenance Work Cycle Answer:Use Equipment/Plant Maintenance to plan, monitor, and complete routine maintenance operations.Whenyouuse Equipment/PlantMaintenance,youcanminimize equipmentbreakdowns and unscheduled repairs. When you use Equipment/Plant c. Maintenance organising schedule

- 2. Answer:Organizing your daily schedule is something that you know needs to be done, but where exactlydoesone start? A lot of people see time management as a super-power – there’s surely no way that a mere mortal could fit it all in between 9 and 5! But effectively organizing your daily schedule at work is simple if you have a plan, and it’s a skill that anyone can learn. These four guiding principles will help you while organizing your daily schedule. Think Before You Act: What does the start of your d. Areas of Maintenance Practices Answer:Establishing best practices in production maintenance is an achievable goal. But it’s a goal that manytalk aboutbut fewachieve.Sowhy is it so difficult? And, why are so many manufactures still running at over 90 percent reactive? Many blame it on the age of their manufacturing Question.2. What do you mean by Asset Strategy? Explain briefly Steps Involved in Developing an AssetStrategy. Answer:StrategicAssetManagementinvolvesmanagingthe capital investmenttowards a long-term program of increasingthe ROA.Thisisa top-downfunctionof settingaperformance specificationfor each major operating unit, identifying the critical components of performance, and systematically improving the key controllable variables of operation. Managing assets strategically involves every function Question.3. Assume you are the head of the maintenance department in a manufacturing organisation.You are assigned a responsibility of implementing a maintenance improvement program. Whatcomponents would you include in the maintenance improvement program? Answer:Many confuse availability with equipment reliability. In reality, it is only one part of the calculation. Availability is the actual time that the machine or system is capable of production as a percent of total planned production time. Availability rate should not be confused with overall availability.The latteriscalculatedusing total calendar time as the divisor, not planned production time.

- 3. Question.4. What do you mean by Machine Quality? Which Aspects are to be Considered for MachineQuality? Answer:In business, engineering and manufacturing, quality has a pragmatic interpretation as the non-inferiority or superiority of something; it is also defined as fitness for purpose. Quality is a perceptual,conditional, and somewhat subjective attribute and may be understood differently by differentpeople. Consumers may focus on the specification quality of a product/service, or how it comparesto competitorsinthe marketplace.Producersmightmeasurethe conformance quality, or degree to which the product/service was produced correctly. Question.5. Write short notes on the following a.Zero based budgeting Answer:Zero-based budgeting is an approach to planning and decision-making that reverses the working process of traditional budgeting. In traditional incremental budgeting, departmental managers justify only variances versus past years based on the assumption that the "baseline" is automaticallyapproved.Bycontrast,inzero-basedbudgeting, every line item of the budget, rather than onlythe changes,mustbe approved.Zero-basedbudgetingrequiresthatthe budgetrequestbe re-evaluated thoroughly, starting from the b. Remote maintenance audit Answer:It manages complexity and enables security by providing a single platform from which to manage remote access policy and connections. Our high-definition network security auditing goes beyond federal vendor access requirements. Multiple levels of identification and authentication, agency defined access and control, comprehensive IT security audit reporting, and real-time monitoringcapabilityforeveryremote supportsessionall worktogethertoprovide easily verifiable proof of compliance. c. Codification of spare parts Answer:Codification/cataloguingisbasicallyanidentificationsystemforeachitemof the inventory. There are often three broad approaches to developing a suitable identification system: 1.Arbitrary approach:As the name suggests,this approach does not use any design for codification. Rather, as and when an item is received by Stores in its receiving bay, a running and unique serialnumber is assigned to it. This number becomes d. Maintenance Benchmarking

- 4. Answer:Benchmarkinghas become a common practice in all kinds of businesses, but nowhere is it more prevalent than in manufacturing. The idea of measuring yourself against the best is an attractive one -- one that the gurus say can leadtobreakthroughsinhow you run your business. But like many other great ideas, benchmarking can lead to frustration and disappointment if it isn't approached with proper understanding. Question.6. Discussion questions: 1. Which condition monitoring techniques have been used to improve plant maintenance atXYZ? Answer:Condition monitoring (or, colloquially, CM) is the process of monitoring a parameter of conditioninmachinery(vibration,temperature etc.), in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance. The use of conditionmonitoringallows maintenance to be scheduled, or other actions to be taken to prevent failure andavoiditsconsequences.Conditionmonitoringhasaunique benefitinthatconditionsthat wouldshortennormal lifespancanbe addressedbefore theydevelopintoamajorfailure. Condition monitoring techniques are normally used on rotating 2. Do you think that the implementation of condition monitoring techniques is the rightdecision of XYZ? Justify your agreement/disagreement Answer:Condition monitoring is the process of determining the condition of machinery while in operation. The key to a successful condition monitoring programme includes: Knowing what to listen for How to interpret it When to put this knowledge to use Dear students get fully solved assignments Send your semester & Specialization name to our mail id : help.mbaassignments@gmail.com or call us at : 08263069601