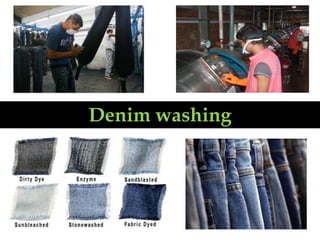

Denim washing techniques

- 2. Prepared By : Mazadul Hasan sheshir ID: 2010000400008 13th Batch (session 2009-2013) Department : Wet Processing Technology Email: mazadulhasan@yahoo.com Blog : www. Textilelab.blogspot.com (visit) Southeast University Department Of Textile Engineering I/A 251,252 Tejgaon Dhaka Bangladesh Prepared By : ©right

- 3. What type of Denim wash it is ???

- 4. Enzyme & bleach are used in denim apparel washing .Acid enzyme & neutral enzyme both are used in denim apparel .Enzyme is more suitable than bleach for environment on the other hand bleach are suitable for production but it’s a hazardous in environment .So enzyme is more popular. INTRODUCTION Depending on garments construction different types of washing process can be done. 1.Twill/Canvas/Knitted/Corduroy - Normal wash, Pigment wash, Caustic ,Si wash 2.Denim/Jeans/Gabardine - Enzyme wash, Stone wash, Bleach wash , Acid wash 3.Grey fabric- Super white wash

- 5. Washing: It is a technology by which outlook, size and fashion of garments are changed or modified is called garment washing. Washing is mainly applied on denim garments and any other casual garments. Purpose of washing: To remove sizing materials and to soften the garment. To modify the appearance to make fashion. To create different effects and finishes. To create vintage look and used effect.

- 6. Denim washing is the aesthetic finish given to the denim fabric to enhance the appeal and to provide strength. Dry denim, as opposed to washed denim, is a denim fabric that is not washed after being dyed during its production. Much of the appeal of dry denim lies in the fact that with time the fabric will fade in a manner similar to that which artificially distressed denim attempts to replicate. With dry denim, however, such fading is affected by the body of the person who wears the jeans and the activities of their daily life. This creates what many feel to be a more natural, unique look than pre-distressed denim. DENIM WASHING

- 8. What is denim ? Denim is a twill-weave woven & 100% cotton fabric that uses different colors for the warp and weft. One color is predominant on the fabric surface. Denim wears well and resists snags and tears. It is available in different weights and is usually made of cotton, although hemp denim is also available. Denim is commonly used for jeans and work clothes, as well as for casings for organic futons and pillows. Characteristics of Denim Fabric It is for long wearing. It is hard wearing. It is very strong and durable. It resists snags and tears It creases easily. Denim fabric process :- Desizing → Enzyme → Caustic → bleaching → Hypo → Softening → Hydro extractor→ Dryer m/c → Garments Delivery. DENIM

- 9. Denim are dye by indiga dye: IndigoBackground Indigo, or indigotin, is a dyestuff originally extracted from the varieties of the indigo and woad plants. Indigo was known throughout the ancient world for its ability to color fabrics a deep blue. Egyptian artifacts suggest that indigo was employed as early as 1600 B.C. and it has been found in Africa, India, Indonesia, and China. The dye imparts a brilliant blue hue to fabric. In the dying process, cotton and linen threads are usually soaked and dried 15-20 times. By comparison, silk threads must be died over 40 times. After dying, the yarn may be sun dried to deepen the color. Indigo is unique in its ability to impart surface color while only partially penetrating fibers. When yarn died with indigo is untwisted, it can be seen that the inner layers remain uncolored. The dye also fades to give a characteristic wom look and for this reason it is commonly used to color denim. Originally extracted from plants, today indigo is synthetically produced on an industrial scale. It is most commonly sold as either a 100% powder or as a 20% solution DENIM

- 10. Garments receive from sewing Scraping Tearing Whickering P.P spray Curing/Tearing Washing Drying Hot + cold Checking Disposes Production sequence of Washing ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓

- 11. GARMENT WASHING: The technology which is used to modify the appearance, out look comfort ability & fashion of the garments is called garment washing. Since 1978, garments pre washing has become more and more popular. It began with denim jeans for the following reasons, 1. Before garments pre washing was done on jeans, consumers had to wash them at home before wearing them because before washing they were too stiff, too long and too big to wear. 2. After pre washing, the consumers do not have to worry about the fit after they wash them as pre washing has taken away almost all the shrinkage and made the jeans stable. 3. After pre washing the denim color looks more lively particular with the pronounced washed look left on the double needled seams. DENIM GARMENT WASHING:

- 12. Mechanical washes 1. Stone wash 2. Micro-sanding Chemical washes 1. Denim bleaching 2. Enzyme wash 3. Acid wash DENIM WASHES ARE OF TWO TYPES

- 13. TYPES OF WET WASH PROCESS: 1. Normal wash/ garments wash/ rinse wash. 2. Pigment wash. 3. Caustic wash. 4. Silicon wash. 5. Stone wash. 6. Enzyme wash. 7. Stone Enzyme wash. 8. Acid wash. 9. Bleach wash. 10. Tinting wash TYPES OF DRY WASH PROCESS: 1. Sand Blasting. 2. Hands scraping. 3. Over all wrinkles. 4. Permanent wrinkle. 5. Grinding &Destroy. 6. Broken & tagging. 7. P P Spray & P P Sponging. 8. Etc. TYPES OF DENIM WASHES

- 14. 1. Sample washing Machine (Horizontal / Vertical Type) 2. Washing Machine (Side loading) 3. Washing Machine (Front loading) 4. Hydro extractor Machine 5. Dryer Machine (Steam) 6. Dryer Machine (Gas) 7. Chemical Mixture Machine 8. Industrial Oven (Gas/Electric) 9. Boiler 10. Submersible Pump 11. Grinding Machine 12. Tagging Machine 13. Steam chamber for crinkle 14. E.T.P (Effluent Treatment Plant) 15. Generator 16. Sand Blasting Gun 17. Sand Blasting chamber 18. Spray gun and dummy 19. Screw compressor 20. Laser draw TYPE OF MACHINE USED IN WASHING PLANT:

- 15. TYPES OF CHEMICAL USE IN WASHING PLANT: 1. Enzyme 2. Detergent 3. Acetic Acid 4. Anti-stain 5.Bleaching powder 6.Sodium hyposulfite 7. Caustic Soda 8. Soda Ash 9. Sodium Bicarbonate 10. potassium Permanganate 11. cationic/nonionic Flax softener 12. Micro Emulsion Silicon 13. Salt (sodium chloride) 14. Buffer 15. Hydrogen peroxide 16. Stabilizer 17. Fixing 18. Catanizer 19. Optical Brightener 20. Resin 21. Sodium Metabisulphite 22. Desizing agent

- 16. Desizing Agent : DesizingHts, D-Peast Anti Back Stain Agent : Antistain – Lp-30 Fastness Improvers For Dyeing : Albafix® Levelling Agents For Dyeing : Albatex® Fastness Improvers For Dyeing : Albafix® Enzyme : G Enzyme S89, G Enzyme – Sl, InnozymeNpe S89 Salt : G/Salt. Alkali : Naso4 Ph Control : Using Buffer & Acid Bleaching Agent : Sodium Hypochlorite Naocl; 15% Cl2 Available Calcium Hypochlorite. Neutralizing Agent : Hydro Peroxide, Bisulphate OrThiosulphate. Softener : Innosoft 1070 Some Washing Chemical List

- 17. 1. Bleach fast Indigo Value addition to denim Retains indigo on certain parts Kind of resist effect Chemical applied by brush, cured at 150ºC Ex. Indigofix AXN 2. Anti-depositing agent Prevents “back staining” of fabric by loose indigo during washing Improves contrast in denim Used in stone wash step 3. Dye stuffs with softener To carry dyeing and softening in one step Soft and supple hand Saves time, money and energy as added to final rinse Gives used and worn out effect Function of Chemicals used on denims

- 18. 4. Anti creasing agent Provides fabric to fabric lubrication Prevents formation of crack marks and streaks Minimizes abrasion and gives strength 5. Wrinkle formation Creating smooth and permanent wrinkle Cross linking concept Ex. DMDHEU White pigment Can be applied by brush, spray or screen Then cured at 150ºC Washed and treated with softener 6. White pigment Can be applied by brush, spray or screen Then cured at 150ºC Washed and treated with softener. Function of Chemicals used on denims

- 19. CHEMICAL WASHES

- 20. Process: Garments received from sewing room / section is subjected to following process: 1. Batching, 2. Desizeing, 3. Enzyme/stone wash treatment, 4. Decolonization, (Bleach wash or Acid wash) 5. Finishing A Typical Denim Garments Washing

- 21. Desizing: 1. Batching: Garments are often turned inside out first; this is a very time- consuming labor oriented task. Garments are weighted in a suitable wt. as per m/c capacity. Desizing: Mainly it is done to remove the water insoluble starch from the fabric of garments as well as it gives a degree of absorbency & soft handfeel to the garments. There are three methods of desizing. 1. Enzymatic Desizing 2. Oxidative Desizing 3. Mechanical Desizing

- 22. Enzymatic Desizing: Here amylase enzyme is used widely and this is the most popular method of removing starch. Amylase breaks down the long water insoluble starch molecular chain into water-soluble smaller sections (sugar), which can be washed away very easily. During removal of starch it also removes some indigo from the fabric, which is also a great advantage for Denim wash as this produces frosty effect. In case of size binder components, PVA, sizing waxes lubricants, which are not cleaved by enzyme or impossible to remove by enzymes, are removed by hot wash with detergent. But this detergent should be compatible with enzyme. Enzymatic Desizing

- 23. Chemicals Name Dose % WOG Purpose Amylase Enzyme 1-3%; As recommended Breaks down the longer starch molecular chin into smaller section & this is soluble in water Surfactant As recommended 0.2- 1.0% Wash off the sizing Compatible with enzyme & others. Fixing agent As recommended 0.5- 2.0% Fixing the dyes & reduce Wash-off of dyes. Temperature & Time As recommended 140 F- 150 F & 40-60 min Smaller section of starch, Wax binder converted to Water soluble components L: R 1:5-1:10 PH 6-8 It helps to prevent back staining. Recipe & Purpose Of Chemicals: After drain a hot wash 50C for 5-3 min required for cleaning the desize chemicals. Here it is very important to introduce hot water because introduction of cold water re-solidify the fat and wax. Enzymatic Desizing

- 24. Reaction Of Alpha Amylase With Starch: O O OH CH3 OH O OH CH2OH OH O OH CH2OH OH O O OH CH2OH OH O OH CH2OH OH O OH OH OH Alpha-amylase enzyme attacks the starch only at the alpha 1-4 linkage, producing water-soluble dextrine i.e. soluble sugars. The progress like as: Starch → dextrine → maltose → glucose (water-soluble) Enzymatic Desizing

- 25. Oxidative Desizing: This method is considered as faster than biological process & this can also cleaves PVA sizes, which are not broken by amylase enzyme. As many denim fabric manufacturers apply size with a combination of starch and PVA this process gives us an advantages over biological or enzymatic desizing in case of removal of PVA. O O OH CH3 OH O OH CH2OH OH O OH CH2OH OH O OH CH3 OH O OH CH2OH OH Oxidative Desizing

- 26. Recipe & Purpose Of Chemicals Chemicals Name Dose % WOG Purpose Non-ionic/Anionic Surfactant As recommended 0.5-1.0% Wash off of the size ingredients Hydrogen per oxide 35% 2-4% It cleaves the starch & make it water soluble. Alkali (Soda,NaOH) 0.5-1.0% Maintain PH 9-11, Increase of sulpher dyed garments PH should be below 10.5. Stabilizer 0.6-1.5% To stable H2O2 Fixing agent As recommended 0.5-2.0% Fixing the dyes & reduce Wash-off of dyes. Temperature & Time As recommended 140 F-150 F & 10-30 min Broken starch, wax, Binders converted to water soluble with the help of temp & time. L: R 1:5-1:10 After drainage a hot wash or hot rinse required for removing the desize chemicals. A neutralizing (with acid) process is required which depends on the type and requirement of next process. Oxidative Desizing

- 27. Denim bleach In this process a strong oxidative bleaching agent such as sodium hypochlorite or KMnO4 is added during the washing with or without stone addition. Discoloration produced is usually more apparent depending on strength of the bleach liquor quantity, temperature and treatment time. It is preferable to have strong bleach with short treatment time. Care should be taken for the bleached goods so that they should be adequately antichlored or after washed with peroxide to minimize yellowing. Materials should be carefully sorted before processing for color uniformity. DENIM BLEACH

- 28. WHAT IS BLEACH: A bleach is a chemical that removes colors or whitens, often via oxidation. Common chemical bleaches include household chlorine bleach, a solution of approximately 3– 6% sodium hypochlorite (NaClO), and oxygen bleach, which contains hydrogen peroxide or a peroxide-releasing compound such as sodium perborate, sodium percarbonate, sodium persulfate, tetrasodium pyrophosphate, or urea peroxide together with catalysts and activators, e.g. tetraacetylethylenediamine and/or sodium nonanoyloxybenzenesulfonate. To bleach something is to apply bleach, sometimes as a preliminary step in the process of dyeing. Bleaching powder is calcium hypochlorite. Many bleaches have strong bactericidal properties, and are used for disinfecting and sterilizing. Most bleaches are hazardous if ingested or inhaled, and should be used with care. DENIM BLEACH

- 29. This way be considered as a preparatory process of mercerizing ,dyeing, or printing .therefore proper bleaching should be carried out other wish the subsequent process would be fault. Objective: 1. To remove the size material from the garments. 2. To remove the starch present on the garments. 3. For soft feeling to wear the garments. 4. To increase the color fastness and rubbing fastness. 5. Especially develop the “Bio-polishing’’ affect cotton/Denim. 6. Enzyme improves the anti-pilling properties. 7. Enzyme attacks more the surface of the fabrics and gives a very smooth surface. DENIM BLEACH BLEACHING WASHING

- 30. Different type of bleaching: 1) OXIDIZING AGENT: 1. OZONE (O3) 2. HYDOGEN PEROXIDE (H2O2) 3. SODIUM HYPOCHLORIDE (NaOCl) 4. SODIUM CHLORITE (NaClO2) 5. POTASSIUM DICHROMATE (K2Cr2O7) 2) REDUCING AGENT 1. ZINC DUST (ZnO) 2. SODIUM HYPO-SULPHITE (Na2S2O2) 3. HYDROGEN SULPHIDE (H2S) DENIM BLEACH

- 31. MECHANISM OF BLEACH ACTION: Color in most dyes and pigments is produced by molecules, such as beta carotene, which contain chromophores. Chemical bleaches work in one of two ways •An oxidizing bleach works by breaking the chemical bonds that make up the chromophore. This changes the molecule into a different substance that either does not contain a chromophore, or contains a chromophore that does not absorb visible light. A reducing bleach works by converting double bonds in the chromophore into single bonds. This eliminates the ability of the chromophore to absorb visible light. Mechanism of bleach action:

- 32. PROCESS CYCLE:

- 33. WHAT IS ENZYME: Enzymes are proteins Bio catalyze.Its has huge life cell .The cell is the basic structural and functional unit of all known living organisms. It is the smallest unit of life that is classified as a living thing, and is often called the building block of life.Some organisms, such as most bacteria, are unicellular (consist of a single cell). Other organisms, such as humans, are multicellular. (Humans have an estimated 100 trillion or 1014 cells; a typical cell size is 10 µm; a typical cell mass is 1 nanogram.) The largest known cell is an unfertilized ostrich egg cell.In enzymatic reactions, the molecules at the beginning of the process are called substrates, and the enzyme converts them into different molecules, called the products. Almost all processes in a biological cell need enzymes to occur at significant rates. Since enzymes are selective for their substrates and speed up only a few reactions from among many possibilities, the set of enzymes made in a cell determines which metabolic pathways occur in that cell. ENZYME WASH

- 34. ENZYME WASH OBJECTIVE: 1. To remove the size material from the garments. 2. To remove the starch present on the garments. 3. For soft feeling to wear the garments. 4. To increase the color fastness and rubbing fastness. 5. Especially develop the “Bio-polishing’’ affect cotton/Denim. 6. Enzyme improves the anti-pilling properties. 7. Enzyme attacks more the surface of the fabrics and gives a very smooth surface. Types of Enzyme: Mainly two types of Enzyme: 1. Acid Enzyme (a. Powder b. Liquid form.) 2. Neutral Enzyme (a. Powder b. Liquid form.) After enzyme washing we get thise change: Color Gsm decrease Softener Strength

- 35. ENZYME WASH It is environmentally friendly wash. It involves the Application of organic enzymes that eat away at the fabric, i.e. the cellulose. When the desired color is achieved, the enzymes can be stopped by changing the alkalinity of the bath or its temperature. Post treatment includes final rinsing and softening cycle. The effects produced by the cellulose enzyme are – Use of cellulose making the seams, hems, and pockets more noticeable Salt pepper effect is color contrast effect. Faded garment with acid cellulose enzyme provides less color contrast in proportion to garment washed with neutral cellulose enzymes. Garment load size of the machine is 35-40 jeans per machine and it cannot be overloaded. ENZYME WASH

- 36. ACID WASH It is done by tumbling the garments with pumice stones presoaked in a solution of sodium hypochlorite or potassium permanganate for localized bleaching resulting in a non uniform sharp blue/white contrast. In this wash the color contrast of the denim fabric can be enhanced by optical brightening. The advantage of this process is that it saves water as addition of water is not required. ACID WASH

- 37. PROCESS CYCLE

- 39. Stone wash: In the process of stone washing, freshly dyed jeans are loaded into large washing machines and tumbled with pumice stones to achieve a soft hand and desirable look. Variations in composition, hardness, size shape and porosity make these stones multifunctional. The process is quite expensive and requires high capital investment. Pumice stones give the additional effect of a faded or worn look as it abrades the surface of the jeans like sandpaper, removing some dye particles from the surfaces of the yarn. STONE WASH:

- 40. LIMITATIONS OF STONE WASHING: Quality of the abrasion process is difficult to control Outcome of a load of jeans is never uniform, little percentage always getting ruined by too much abrasion. The process is non-selective. Metal buttons and rivets on the jeans in the washing machines get abraded. This reduces quality of the products and life of equipment, and increases production costs. Stones may turn into powder during the process of making the garment grayish in color and rough too Provides rougher feel than enzyme wash Stone may lead the harm to the machine parts MICRO-SANDING There are 3 ways for this technique: Sandblasting Machine sanding Hand sanding or hand brushing STONE WASH:

- 41. Sand blasting Sand blasting technique is based on blasting an abrasive material in granular, powdered or other form through a nozzle at very high speed and pressure onto specific areas of the garment surface to be treated to give the desired distressed/ abraded/used look. It is purely mechanical process, not using any chemicals. It is a water free process therefore no drying required. Variety of distressed or abraded looks possible. Any number of designs could be created by special techniques.

- 42. Sand blasting

- 43. Other washing: -

- 44. Rinse wash 1. Chemically bleaching jeans so that the color fades away 2. Breaks down the fibers of jeans and creates white streaks or spots on denim 3. Gives a unique rugged look, also called snow wash 4. Earlier involved the use of pumice stone 5. Presently process involves spraying chemical and removing it immediately 6. Come in colors like blue, black, green, brown, grey etc. Cellulose wash 1. This is done to achieve a wash down appearance without the use of stones or with reduced quantities of stones. 2. Cellulose enzymes are selective only to the cellulose and will not degrade starch. 3. Under certain conditions, their ability to react with cellulose (cotton) will result in surface fiber removal (weight loss). 4. This will give the garments a washed appearance and soft hand. Ozone fading 1. By using this technique, the garment can be bleached. 2. Bleaching of denim garment is done in washing machine with ozone dissolved in water. 3. Denim garments can also be bleached or faded by using ozone gas in closed chamber. 4. In the presence of UV light, there is an interaction between the hydrocarbons, oxides of nitrogen and oxygen that causes release of ozone. 5. Indigo dyestuff tends to fade or turn yellow due to ozone reaction.

- 45. Flat finish It is a special process done to impart fabric with an even wash down effect and very clean surface. Originally liquid ammonia was used, but now use mercerization plus calendering processes to achieve the flat surface. Mercerization swells up the cotton fibers and allows the calendering to press flat the surface. They consider this as an imitation process to the use of ammonia, which is toxic and not allowed in commercial use in most countries Over dye 1. Dyeing over the fabric or jeans to add another tone of color 2. Most often used is a 'yellowy' overdye to create a 'dirty' look 3. Also can be applied with spray gun or paintbrush for local coloring Sun-washing 1. A very light shade by bleaching and stoning 2. Looks as if the sun faded the fabric Super dark stone 1. Commercial term for an extra dark indigo color 2. Results from a double-dyeing technique

- 46. Snow wash denim Denim treated with a variation of acid wash that imparts bright white highlights. Quick wash denim 1. Aims at minimizing wash cycle time 2. Results in more economical washes and solving many other washing problems faced by launderes during fashion wash cycles 1. The yarns are ring dyed using indigo giving 25 to 30% less fixed dye to obtain a given shade 2. During wash cycle,indigo dye can be removed quickly,giving washed look

- 47. Other mechanical washing 1. Whiskering 2. Shot gun denim 3. Water jet fading 4. Super stone wash 5. Ice wash 6. Thermo denim 7. Laser technology finish

- 48. Water jet fading 1. Hydrojet treatment is used for enhancing the surface finish, texture, durability of denim garment. 2. Hydroject treatment involves exposing one or both surfaces of the garment through hydrojet nozzles. 3. The degree of color washout, clarity of patterns, and softness of the resulting fabric are related to the type of dye in the fabric and the amount and manner of fluid impact energy applied to the fabric. 4. As this process is not involved with any chemical, it is pollution free. Laser technology 1. It is a computer controlled process for denim fading. 2. This technique enables patterns to be created such as lines and/or dots, images, text or even pictures. 3. It is water free fading of denim. 4. Being an automatic system, chances of human error are slim. 5. Also called spray painting in denims. 6. •This technique has relatively high cost.

- 49. Super stone wash It is type of wash treatment of denim garments in which the denim garments is subjected to prolonged stonewash treatment for more than six hours. Soda ash and soap are used for hard wash. Steam is used up to 60-800C for one hour to finish the washing process. It is followed by acetic acid wash treatment and then the garments are neutralized and rinsed. Ice wash 1. Ice washing in denim fabrics is done to remove more than half the dye during washing Thermo-denim 1. Also called double denim. A lightweight fabric (either plain, fancy or colored) is glued to the denim. The glue comes off after washing and the trousers look like they've been lined Vintage 1. Applies heavy stonewashing or a cellulose enzyme wash, with or without bleach 2. Gives an old and worn look

- 50. DRY WASHING SECTION Dry wash: Dry wash is mainly done by mechanically or by hand. Different process of dry wash is described below-

- 51. Flow chart Of Dry Process:

- 52. Scraping: Removing color from the surface of denim is called scraping. Features: • This process is done before wet washing of the garment. • Fabric is scrapped with different tools in order to get an used effect. • All scraping processes are done manually, so it is difficult to achieve consistent finishes every time. Types: 1. Sand blasting: Compressed air guns shoot sand forcibly onto desired area of jeans to create abrasion. 2. Hand sand: Abrasion of the fabric surface is done with sand paper. This process is done by hand. 3. Hand sand all over: Scraping is done all over the garment by sandpaper. 4. Laser scraping: Laser machine is used to get the effect. This process is very expensive. 5. Central crease mark: Jeans is folded and then scraping is done by ironing with temperature and pressure or by sand paper. 6. Crimping: Fabric is crimped then ironed with high temperature and pressure to create crease marks. 7. Pocket mark: scraping is done to make the inside pocket visible 8. Side seam hand sand: Hand sand is applied on the side seam of the garment. Scraping:

- 53. Spraying: 2) Spraying: Chemical is sprayed onto jeans by a spray gun. It is done for discoloration. Types: Spray PP (Potassium Permanganate): PP sprayed onto desired areas of jeans and PP oxidizes indigo color. This can be done before or after wet washing. There are two steps involved in this process. Step 1: PP is sprayed onto jeans and dried then pink color appears. Step 2: Neutralization is done after spraying to get final effect. Normally sodium meta bisulphate is used as neutralizer. Bleach Spray: Bleach solution is sprayed or rubbed onto desired areas of jeans. Neutralization is done immediately after spraying. It provides more yellowish tone than PP spray Spray pigment color: Pigment color is sprayed on the upper parts to get a vintage and muddy look. Jeans must be cured in order to fix the pigment and to have permanent effect on jeans.

- 54. Resin color spray: A mixed solution of resin and pigment color is sprayed onto the garment. It provides unique color and touch that dyeing can not give. Resin dip: Full garment is dipped into a resin solution to produce coating effect on garment. Resin color dip: Full garment is dipped into a resin solution mixed with pigment color. The aim of resin color dip is to produce coating effect and unique color on garment. Spraying:

- 55. Whiskers: This is also known as “Cats Whiskers” or “Moustaches”. These worn out lines or effects generated by different methods are done mainly on hip and thigh areas of jeans. Types: Whiskers: This is called “normal whiskers”. Effect is achieved with sand paper or sand blasting. Process: 1. This is done mainly with the help of sharp edge emery paper rolled on fine wood stick or pasted on plastic material. 2. Before starting execution placements and pattern must be marked on garments. Stencils can also be used for design. PP spray whiskers or Pigment spray whiskers: Effect is achieved by spraying potassium permanganate or pigment color. Usually done on top of sand paper whiskers (normal whiskers) to highlight them. Shape or design can be achieved by placing a stencil on jeans. Whiskers:

- 56. Whiskers creases: Fabric is folded in many places and then scrapped o the surface. 3D Resin Whiskers: Resin is added after normal or PP spray whiskers to make the effect permanent. Process: Resin is sprayed all over or on local area of the garment with a spray gun. Then whiskers are designed by folding the fabric. To get a permanent effect, garment must be put into oven and dry at high temperature for 30 minutes. Whiskers:

- 57. Tacking: Tacking is done by swift tag machine. Garment is folded three, four or five times and tacked or locked through folds. Then the garment is washed and dried. Permanent fold appears after removal of tag pin. The inner of the fold is dark due to less exposure of rubbing and chemicals. Faded effect come on the folded parts. Most favorite areas are waistband, bottom hem, back pocket, back yoke and front pocket corners. Tacking:

- 58. Spots: Types: PP spot and bleach spot: Spots are created with PP (Potassium Permanganate) or bleach solution. Process depends on the type of fabric. Color spot: Spots are created with pigment color. Oven process (curing is needed to fix permanently the pigment on the garment). Silicon spot: Spots are created with silicon. It creates dirty or wet effect on the garment. SPOTS:

- 59. Rubbing: Rubbing is usually done in combination with spraying. This process allows us to give more contrast and highlight some part of the garment, specially on waistband or on top of tacking effect. Rubbing: Types: Rub pigment: A sponge or piece of fabric is soaked into the solution then rubbed on the garment. Rub PP (Potassium Permanganate): Rubbing PP gives more contrast effect than PP spray. Normally PP is rubbed to highlight tacking effect. Rub bleach: A sponge is soaked into bleach solution then rubbed on the garment.

- 60. Damages: In order to achieve favorite vintage look, many damaging processes are used. Types: Grinding: Mainly used on edges of the garment such as pocket edges and pocket hems. This is done by running the edges against abrasion surface or stone to achieve worn out effect. Normally pen type of stone tools are used for small production. For large production, fixed grinding machines are used. In this machine the operator rub the edges to rotating stone wheel to get the effect. Damages: Abrasion: This is done on desired areas of jeans by pen type of stone tools. If the tool is driven warp wise, weft will be visible. On the other hand if the tool is driven weft wise, warp will be visible. As there is no color contrast, it will not be as clearly visible as weft.

- 61. Hole: A hole is created on the garment with cutter or other tools. Scratching: Garment is scratched with sharp tool. Scratching is normally done warp wise or horizontally. Needle effect/ cuts: Effect is created by cutting the warp yarn by knife, so that weft yarn becomes visible. Needle is also used to tear out fiber warp wise. Damages:

- 62. WET WASHING SECTION Wet Wash: Wet wash is normally done by using different types of chemicals. Different process of wet wash is described below-

- 63. Flow chart of wet process:

- 64. Wash in hot water with detergent and softener Rinse in plain water Drying in tumble until it is 100% dry Sodium can be added if we want more washed look. Depending on the type of fabric and our desired washing effect we should adjust The temperature of water The amount of detergent or sodium The length of time of wash Effects: Hot water, detergent or sodium will dissolve starch Softener makes the fiber soft Tumble drying makes the fabric more fluffy Use: Casual shirts, pants (non denim), jacket. Normal wash/ Garment wash: WET WASHING SECTION

- 65. Silicon Wash: Silicon wash is normally done on twill, denim, canvas etc. Silicon wash provides high and durable softness, elastic and slippery handle. It also helps ant pilling effects and dimensional stability. Process: 1st Step: De sizing. 2nd Step: Washing with silicon Recipe: M: L = 1:8 Acetic acid = 0.6g/l Softener = 1g/l Silicon = 0.5g/l Temperature = 40ºc Time = 15-20 minutes 3rd Step: Hydro extracting to remove excess water. 4th Step: Drying in tumble dryer. WET WASHING SECTION Silicon Wash:

- 66. Over dye/Tinting: • This is being done mostly on denim garments to give them another look. Process: • First denim garments are washed with stones so that the double needle seams, pocket flaps and those areas exposed the most get washed down to light blue color or white. • Then dye is put into the tumble to dye the garment into the color we want. In this process a coating of new color will come on the garment particularly where it has been washed down to a light shade to create a different look. • Normally reactive dye should be used for better color fixation. WET WASHING SECTION Over dye/Tinting:

- 67. Caustic Wash: • This is applied to the garment made of pigment printed fabric. • In case of fabric printing, we do caustic wash (i.e scouring) at first to clean up fabric surface from greases and impurities then we do printing on fabric. Conversely if we apply caustic wash in garment, we do pigment printing with binder on fabric at first then we make garments with this fabric and then we wash the garments with caustic and hot water. At this time about 30% of the printing will be washed away together with the foreign materials, leaving about 70% of the printing on the fabric making the design or stripe nice and soft. • Special color fading effect is produced as well. WET WASHING SECTION Caustic Wash:

- 80. FINAL FINISHED PRODUCT : -

- 81. Throughout the decades, denim continued to gain a wider market. By the 1970s, women were wearing denim as often as men, and denim skirts and dresses could be found in numerous styles. In the 80s, designer jeans were the rage, and a style once associated with the working class was updated for affluent yuppies. Though denim is still considered a casual material, it is not usually worn for more formal occasions, it is not unusual to see people sporting jeans at high end night clubs, and many designer denim garments cost in the hundreds of US Dollars (USD). An American Fabrics magazine predicted back in 1969 that denim would become a fashion statement for many occasions when it said, "What has happened to denim in the last decade is really a capsule of what happened to America. It has climbed the ladder of taste." CONCLUSION: -

- 82. ©right

- 83. 1. Yarn Manufacturing Technology Link : http://www.facebook.com/pages/Yarn-Manufacturing-Technology/485014954866808 2. Fabric Manufacturing Technology Link : http://www.facebook.com/pages/Fabric-Manufacturing-Technology/459520217425605 3. Garments Manufacturing Technology Link : http://www.facebook.com/pages/Garments-Manufacturing- Technology/472364799463126 3. Wet processing Technology Link : http://www.facebook.com/pages/Wet-Processing-Technology-Dyeing-/468645219825404 4. Fashion-Design-and-Technology Link : http://www.facebook.com/pages/Fashion-Design-and- Technology/587655294583875?ref=ts&fref=ts My Facebook Textile related Pages http://www.textilelab.blogspot.com (Visit My Blog for more Info )