New microsoft office power point presentation

•Transferir como PPTX, PDF•

0 gostou•455 visualizações

Denunciar

Compartilhar

Denunciar

Compartilhar

Recomendados

Recomendados

Supply all type of White Rice, Brown Rice & Value Added Products:

WHITE RICE

100% Sortexed

With definite attention to quality, As-Navadhane offers customizable white rice. The famous short and medium grain rice.

Varieties

• Thin

• Wide

BROWN RICE

100% Sortexed

The top choice in terms of both nutritional and other inherent healthy benefits. Brown rice is considered a whole grain that hasn’t lost its “wholeness” through the refinement process. It is high in manganese, thiamine, healthy omega-oils, antioxidants and fibers that make it perfect for promoting weight loss.

HUSK

Available in both coarse and ground husk.

White Rice, Brown Rice & Value Added Products from Navadhane-Global Agro comm...

White Rice, Brown Rice & Value Added Products from Navadhane-Global Agro comm...Karthikeyan Dhanushkodi

Rusk Production

Introduction: Rusk production involves a series of unit operations comprising dough mixing, molding, dividing and panning, proving, baking, cooling and wrapping. Measurements of final product quality are made, typically after baking, and few measurements are made at intermediate stages of processing (e.g., dough properties). The quality of the final product and the processing requirements of the dough are critically dependent on the flour properties.

Principle of bread making

Rusk is a double-baked product. At first, Bread is made from the first baking of dough, and the second baking transfer the bread into Rusk.

Raw materials for bread making

The raw materials which used for making bread are:

Wheat flour: This is the composition of the wheat grain and flour. Among other things, one can determine the quality of flour using the following methods: Chopin, amylograph, falling number, moisture content, etc.

Water: Water plays an important role in bread preparation. An essential element of any recipe is water, the importance of which is very often overlooked. A bread dough is roughly 40 % water.

Yeast: Yeast is a microorganism cultivated in yeast factories. Its scientific name is Saccharomyces cerevisiae. The name stems from Latin: "saccharo" which means sugar and "myces" which means fungus. Baker's yeast is a single-celled mold which is capable of transforming sugars in alcohol, carbon dioxide and various aromatic compounds. We call the process of this transformation "the fermentation".

Sourdough: Sourdough bread is made by the fermentation of dough using naturally occurring lactobacilli and yeast. The lactic acid produced by the lactobacilli gives it a sourer taste and improved keeping qualities.

Enzymes: Enzymes are proteins that catalyze chemical reactions. This means that they help to initiate the chemical reaction. In this reaction, the enzymes are not converted or broken down, but they are deactivated by baking. One does not have to be afraid of enzymes. Our bodies are full of them and if they didn't exist there would be no life.

Gums and hydrocolloids: Today, products in general, and bakery products in particular, need to be kept fresh for longer. This is mainly stimulated by the supermarket chains who have a total aversion to "unsold" products because they represent an outright loss. Gums and hydrocolloids can help extend the life of products in certain cases.

Salt and salt product: Today's consumers are increasingly in need of healthy products, and are aware that too much salt is not good for health. It is sometimes claimed that bread is a "culprit" in that regard. But that is not the case at all. This does not alter the fact that the baker can intervene to reduce the salt content of his products and still make tasty products.Rusk production processing/Technology of Bangladesh and India

Rusk production processing/Technology of Bangladesh and IndiaJessore University Of Science and Technology

Mais conteúdo relacionado

Mais procurados

Supply all type of White Rice, Brown Rice & Value Added Products:

WHITE RICE

100% Sortexed

With definite attention to quality, As-Navadhane offers customizable white rice. The famous short and medium grain rice.

Varieties

• Thin

• Wide

BROWN RICE

100% Sortexed

The top choice in terms of both nutritional and other inherent healthy benefits. Brown rice is considered a whole grain that hasn’t lost its “wholeness” through the refinement process. It is high in manganese, thiamine, healthy omega-oils, antioxidants and fibers that make it perfect for promoting weight loss.

HUSK

Available in both coarse and ground husk.

White Rice, Brown Rice & Value Added Products from Navadhane-Global Agro comm...

White Rice, Brown Rice & Value Added Products from Navadhane-Global Agro comm...Karthikeyan Dhanushkodi

Rusk Production

Introduction: Rusk production involves a series of unit operations comprising dough mixing, molding, dividing and panning, proving, baking, cooling and wrapping. Measurements of final product quality are made, typically after baking, and few measurements are made at intermediate stages of processing (e.g., dough properties). The quality of the final product and the processing requirements of the dough are critically dependent on the flour properties.

Principle of bread making

Rusk is a double-baked product. At first, Bread is made from the first baking of dough, and the second baking transfer the bread into Rusk.

Raw materials for bread making

The raw materials which used for making bread are:

Wheat flour: This is the composition of the wheat grain and flour. Among other things, one can determine the quality of flour using the following methods: Chopin, amylograph, falling number, moisture content, etc.

Water: Water plays an important role in bread preparation. An essential element of any recipe is water, the importance of which is very often overlooked. A bread dough is roughly 40 % water.

Yeast: Yeast is a microorganism cultivated in yeast factories. Its scientific name is Saccharomyces cerevisiae. The name stems from Latin: "saccharo" which means sugar and "myces" which means fungus. Baker's yeast is a single-celled mold which is capable of transforming sugars in alcohol, carbon dioxide and various aromatic compounds. We call the process of this transformation "the fermentation".

Sourdough: Sourdough bread is made by the fermentation of dough using naturally occurring lactobacilli and yeast. The lactic acid produced by the lactobacilli gives it a sourer taste and improved keeping qualities.

Enzymes: Enzymes are proteins that catalyze chemical reactions. This means that they help to initiate the chemical reaction. In this reaction, the enzymes are not converted or broken down, but they are deactivated by baking. One does not have to be afraid of enzymes. Our bodies are full of them and if they didn't exist there would be no life.

Gums and hydrocolloids: Today, products in general, and bakery products in particular, need to be kept fresh for longer. This is mainly stimulated by the supermarket chains who have a total aversion to "unsold" products because they represent an outright loss. Gums and hydrocolloids can help extend the life of products in certain cases.

Salt and salt product: Today's consumers are increasingly in need of healthy products, and are aware that too much salt is not good for health. It is sometimes claimed that bread is a "culprit" in that regard. But that is not the case at all. This does not alter the fact that the baker can intervene to reduce the salt content of his products and still make tasty products.Rusk production processing/Technology of Bangladesh and India

Rusk production processing/Technology of Bangladesh and IndiaJessore University Of Science and Technology

Mais procurados (20)

Effects of Ascorbic Acid on Flour Proteins / Enzyme Activity in Bread Dough

Effects of Ascorbic Acid on Flour Proteins / Enzyme Activity in Bread Dough

Dough Systems: a guide to formulating common systems

Dough Systems: a guide to formulating common systems

Corn Flakes Are Manufacturing Using High Quality Materials

Corn Flakes Are Manufacturing Using High Quality Materials

White Rice, Brown Rice & Value Added Products from Navadhane-Global Agro comm...

White Rice, Brown Rice & Value Added Products from Navadhane-Global Agro comm...

Rusk production processing/Technology of Bangladesh and India

Rusk production processing/Technology of Bangladesh and India

Semelhante a New microsoft office power point presentation

Semelhante a New microsoft office power point presentation (20)

Finishing methods applied to hot and cold desserts

Finishing methods applied to hot and cold desserts

Último

Saudi Arabia [ Abortion pills) Jeddah/riaydh/dammam/++918133066128☎️] cytotec tablets uses abortion pills 💊💊 How effective is the abortion pill? 💊💊 +918133066128) "Abortion pills in Jeddah" how to get cytotec tablets in Riyadh " Abortion pills in dammam*💊💊 The abortion pill is very effective. If you’re taking mifepristone and misoprostol, it depends on how far along the pregnancy is, and how many doses of medicine you take:💊💊 +918133066128) how to buy cytotec pills

At 8 weeks pregnant or less, it works about 94-98% of the time. +918133066128[ 💊💊💊 At 8-9 weeks pregnant, it works about 94-96% of the time. +918133066128) At 9-10 weeks pregnant, it works about 91-93% of the time. +918133066128)💊💊 If you take an extra dose of misoprostol, it works about 99% of the time. At 10-11 weeks pregnant, it works about 87% of the time. +918133066128) If you take an extra dose of misoprostol, it works about 98% of the time. In general, taking both mifepristone and+918133066128 misoprostol works a bit better than taking misoprostol only. +918133066128 Taking misoprostol alone works to end the+918133066128 pregnancy about 85-95% of the time — depending on how far along the+918133066128 pregnancy is and how you take the medicine. +918133066128 The abortion pill usually works, but if it doesn’t, you can take more medicine or have an in-clinic abortion. +918133066128 When can I take the abortion pill?+918133066128 In general, you can have a medication abortion up to 77 days (11 weeks)+918133066128 after the first day of your last period. If it’s been 78 days or more since the first day of your last+918133066128 period, you can have an in-clinic abortion to end your pregnancy.+918133066128

Why do people choose the abortion pill? Which kind of abortion you choose all depends on your personal+918133066128 preference and situation. With+918133066128 medication+918133066128 abortion, some people like that you don’t need to have a procedure in a doctor’s office. You can have your medication abortion on your own+918133066128 schedule, at home or in another comfortable place that you choose.+918133066128 You get to decide who you want to be with during your abortion, or you can go it alone. Because+918133066128 medication abortion is similar to a miscarriage, many people feel like it’s more “natural” and less invasive. And some+918133066128 people may not have an in-clinic abortion provider close by, so abortion pills are more available to+918133066128 them. +918133066128 Your doctor, nurse, or health center staff can help you decide which kind of abortion is best for you. +918133066128 More questions from patients: Saudi Arabia+918133066128 CYTOTEC Misoprostol Tablets. Misoprostol is a medication that can prevent stomach ulcers if you also take NSAID medications. It reduces the amount of acid in your stomach, which protects your stomach lining. The brand name of this medication is Cytotec®.+918133066128) Unwanted Kit Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pills

Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pillsAbortion pills in Kuwait Cytotec pills in Kuwait

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS Live

Booking Contact Details :-

WhatsApp Chat :- [+91-9999965857 ]

The Best Call Girls Delhi At Your Service

Russian Call Girls Delhi Doing anything intimate with can be a wonderful way to unwind from life's stresses, while having some fun. These girls specialize in providing sexual pleasure that will satisfy your fetishes; from tease and seduce their clients to keeping it all confidential - these services are also available both install and outcall, making them great additions for parties or business events alike. Their expert sex skills include deep penetration, oral sex, cum eating and cum eating - always respecting your wishes as part of the experience

(07-May-2024(PSS)VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...Call Girls In Delhi Whatsup 9873940964 Enjoy Unlimited Pleasure

Último (20)

Grateful 7 speech thanking everyone that has helped.pdf

Grateful 7 speech thanking everyone that has helped.pdf

Call Girls Pune Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Pune Just Call 9907093804 Top Class Call Girl Service Available

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Insurers' journeys to build a mastery in the IoT usage

Insurers' journeys to build a mastery in the IoT usage

Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pills

Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pills

Enhancing and Restoring Safety & Quality Cultures - Dave Litwiller - May 2024...

Enhancing and Restoring Safety & Quality Cultures - Dave Litwiller - May 2024...

The Path to Product Excellence: Avoiding Common Pitfalls and Enhancing Commun...

The Path to Product Excellence: Avoiding Common Pitfalls and Enhancing Commun...

0183760ssssssssssssssssssssssssssss00101011 (27).pdf

0183760ssssssssssssssssssssssssssss00101011 (27).pdf

Boost the utilization of your HCL environment by reevaluating use cases and f...

Boost the utilization of your HCL environment by reevaluating use cases and f...

Best VIP Call Girls Noida Sector 40 Call Me: 8448380779

Best VIP Call Girls Noida Sector 40 Call Me: 8448380779

MONA 98765-12871 CALL GIRLS IN LUDHIANA LUDHIANA CALL GIRL

MONA 98765-12871 CALL GIRLS IN LUDHIANA LUDHIANA CALL GIRL

👉Chandigarh Call Girls 👉9878799926👉Just Call👉Chandigarh Call Girl In Chandiga...

👉Chandigarh Call Girls 👉9878799926👉Just Call👉Chandigarh Call Girl In Chandiga...

Regression analysis: Simple Linear Regression Multiple Linear Regression

Regression analysis: Simple Linear Regression Multiple Linear Regression

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

New microsoft office power point presentation

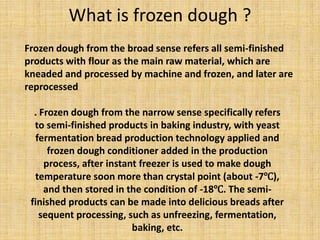

- 1. Frozen dough from the broad sense refers all semi-finished products with flour as the main raw material, which are kneaded and processed by machine and frozen, and later are reprocessed What is frozen dough ? . Frozen dough from the narrow sense specifically refers to semi-finished products in baking industry, with yeast fermentation bread production technology applied and frozen dough conditioner added in the production process, after instant freezer is used to make dough temperature soon more than crystal point (about -7℃), and then stored in the condition of -18℃. The semi- finished products can be made into delicious breads after sequent processing, such as unfreezing, fermentation, baking, etc.

- 2. Preservation of frozen dough: Frozen bread dough needs stricter storage management than other general frozen foods. If it is kept at the stable temperature of -18℃ and baked within 3 months, the product quality can be ensured. Temperature change, dough leavening failure or piriformis during transportation and storage are called freezing obstacle. Just as ice cream, frozen dough cannot become so called commodity any more if it has been unfrozen once.

- 4. Description of the preferred Embodiments Straight dough method • Formulation mixing pre fermentation punching division rounding benching moulding freezing storage in refrigerator thawing ,proofing baking Sponge dough method • Preliminary Formulation mixing pre fermentation Formulation mixing fermentation division rounding benching moulding freezing storage in refrigerator thawing ,proofing baking

- 5. •In the above straight and sponge dough method a frozen dough particularly for bread tends to be of reduced quality after thawing and baking. To eliminate this tendency a slight excess of yeast is used in the mixing step and pre fermentation time is rendered as short as possible. The process for pre preparation of frozen dough may comprise following steps formation

- 6. •Formulation mixing pre fermentation punching cooling incorporation of additional yeast remixing division rounding benching moulding freezing storage in refrigerator thawing ,proofing baking

- 7. Unfreezing Take the dough out of a cold storage (-20℃) and put in on a baking tray to unfreeze it until the center of the dough turns soft (+5℃). The unfrozen dough cannot be unfrozen again. • Natural unfreezing: Unfreeze the dough at room temperature until the center of the dough turns soft, which needs about 1 to 2 hours. (differ from season to season) • Unfreezing after refrigeration: Put the dough in refrigerator (0℃~3℃) and then defreeze it until the center of the dough turns soft. The unfrozen dough should be used up before the noon of the next day preferably. (generally 18 hours after the moment of unfreezing) • ※Put the dough in the refrigeration fermentation room at ±0℃ and refrigerate it for more than 8 hours. The dough can be unfrozen within 1 hour at the temperature of +18℃. Usage of the frozen dough

- 8. Forming Form the dough into needed shape on a panel. Fermentation After unfreezing and forming, put the dough into a fermentor with the temperature of 32℃ and the humidity of 75%, and ferment the dough until its volume is 2 to 2.5 times that of the dough before fermentation. The whole course needs about 60 minutes to 75 minutes. .

- 9. Baking After fermentation, put the dough into an oven of 200℃~ 220℃. About 8 to 12 minutes is needed for small dough (40g) and about 20 to 25 minutes are needed for large dough (250g). Observe the coloring condition of the dough surface and adjust the temperature of the oven.