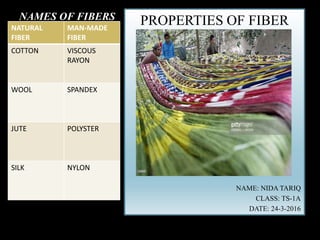

Names of fibers (1)

- 1. NAMES OF FIBERS PROPERTIES OF FIBER NAME: NIDA TARIQ CLASS: TS-1A DATE: 24-3-2016 NATURAL FIBER MAN-MADE FIBER COTTON VISCOUS RAYON WOOL SPANDEX JUTE POLYSTER SILK NYLON

- 2. GLOSSARY • Tenacity: is the customary measure of strength of a fiber or yarn. • Hygroscopic nature: readily absorbing moisture, as from the atmosphere. • Moisture content: Moisture stored in fiber as an integral part of its structure • Elasticity: Ability to stretch than with reference to its original length • Shrinkage: Refers to the dimensionally instability (compression) • Drape: Ability to bend in shapes. • Colour Retention: the capability of a surface finish to maintain its original shade and intensity over a period of time and/or exposure to sunlight. • Abrasion Resistance: Abrasion resistance is the ability of a fabric to resist surface wear caused by flat rubbing contact with another material. • Flammability: The flame and heat resistance of textiles is concerned with the flammability.

- 3. COTTON FIBRE

- 4. Physical Properties Of Cotton Fiber • Length: ranges from 16mm-52 mm (depending upon the type of cotton) • Fineness: ranges from 1.1-2.3 decitex. • Tenacity: 3-3.5g/dtex The strength of cotton fibre is attributed to the good alignment of its long polymers i.e. its polymer system is about 70% crystalline. • Strength: increases when wet (it forms hydrogen bonds), low extension at break 5-7% • Elasticity – Relatively it is elastic due to its crystalline polymer system and for this cause cotton textiles wrinkle and crease readily. • Hydroscopic Nature – The cotton fibre is because of absorbent, owing to the countless polar OH groups. In its polymers, these attract water molecules which are also polar. The hydroscopic nature ordinarily prohibits cotton textile materials from developing static electricity. • Thermal properties – Cotton is not thermoplastic and hence excessive application of heat energy reasons the cotton fibre to char and bum, without prior melting. • Luster – cotton has almost no luster. Therefore in order to make it lustrous they need to be mercerized.

- 5. Physical properties of cotton • Appearance: Cotton fibre is fairly short, fine and creamy white colour. Colour of the fibre depends on soil of growth. ( can be from white to creamy brown) • Comfortable: Cotton fiber has large amorphous portion and this is why the air can be in and out through cotton fiber. So, the fabric made by cotton fiber is quite comfortable to use. • Soft Hand: Cotton fiber is too much regular fiber and if properly ginned; this fibre can be the best soft hand feeling fibre amongst the others. • Absorbent: Cotton fiber has high absorbency power and this is why this fiber can be died properly and without any harassment. • Good Colour Retention: If the printing is applied on cotton fiber, it seems it doesn’t spread the colour outside the design. So printing efficiency is good on cotton fibre. • Cotton Fibre Drapes Well: The drape-ability of cotton fibre is awesome. You can use the cotton fibre made fabric in any kind of wear which needs more flexibility and drapes. • Sewing & Handling Is Easy: The sewing efficiency on Cotton made fabric is easier and comfortable than other fiber. This is why the demand of cotton made fabric is higher in all over the world.

- 6. Chemical Properties of Cotton Fiber • Effects of alkalis – These fibres are resistant to alkalis and are comparatively unaffected by normal laundering. The resistance is because of the lack of attraction between the cotton polymers and alkalis. • Effect of Acids – Cotton fibres are weakened and destroyed by acids. Acids hydrolyze the cotton polymer at the glycosidic oxygen atom which connects the two glucose units to form the cellobiose unit. Mineral acids being stronger than organic acids will hydrolyse the cotton polymer more quickly • Effect of Bleaches – The most common bleaches used on cotton textile materials are sodium hypochlorite and sodium perborate. • Effect of Sunlight and weather – The ultra-violet rays of sunlight provide photo chemical energy whilst the infra-red rays provide heat energy essential to degrade the cotton polymers in the pressure of atmospheric oxygen, moisture and air pollutants. The beginning degradation is noticed as a slight fibre discoloration. Fading of colored cotton textile also takes place. • Colour Fastness – Cotton is easy to dye and print. The classes of dye which may be used to colour cotton are azoic, direct, reactive, sulphur and vat dyes. The polar polymer system easily attracts any polar dye molecules into the polar system. Therefore, dye molecules which can be dispersed in water will be absorbed by the polymer system of cotton. However, the dye molecules can enter solely the amorphous regions of the polymer system of cotton. The small inter polymer spaces in the crystalline regions of the polymer system prohibit the entry of the crystalline molecules. • Mildew – Cotton is damaged by fungi. Heat and dampness support the growth of mildew. The fungi feed on the molecules of sugar: Cotton treated with acrylo nitrite is resistant to mildew. • Insects – Moths and beetles do not change cotton. Silver fish will eat cotton cellulose especially if heavily starched.

- 7. USES OF COTTON FIBRE

- 8. WOOL FIBER

- 9. Physical Properties of wool firber: • Sun safe – wool has naturally high UV protection. • Flame retardant – wool fibre has a higher ignition threshold than many other fibres and is flame retardant up to 600º C. It also produces less toxic fumes in a fire. • Biodegradable – when disposed of, natural wool fibre takes only a few years to decompose, and with a high nitrogen content, wool can even act as a fertilizer. • Breathable – wool’s natural structure allows it to absorb and release water vapour into the atmosphere, keeping you warm in winter and cool in summer. • Non allergenic – wool is not known to cause allergy and does not promote the growth of bacteria. With microscopic scales, wool fibres can trap dust in the top layers until vacuumed away. • Durable and elastic – wool fibre can be bent 20,000 times without breaking and still have the power to recover and return to its natural shape. Quality wool garments look good for longer. • Easy care – modern wool can be machine-washed; retaining a small amount of natural oil, wool fibre resists dirt and grease. • Multi-Climatic – wool acclimatizes to its surroundings. • Naturally insulating – wool can insulate the home providing and retaining warmth, and reducing energy costs. • Colour – colour of wool fiber could be near white, brown and black.

- 10. Physical properties • Moisture Regain: 13-16% , very absorbent, decrease strength when wet, seem warmth, will shrink in washing. • Electrostatic reaction: Highly electrostatic at dry conditions • Strength: Tenacity dry =1.35 g/d, Wet = dry 0.69 weak (Due to few H-bond) • Elasticity: Breaking extension – 42.5 %, Recovery % – 69 at 5% • Elongation at break: Standard elongation is 25 – 35% and 25 – 50% in wet condition. • Feel or Hand: Soft. • Resiliency: Excellent (due to crimp) • Abrasion resistance: Good. • Dimensional stability: Bad (For tendency of felting). • Effect of Sun Light: The fibres become discoloured and develop a harsh feel.

- 11. Chemical properties of wool fiber• Affect of Acids: Wool is attacked by hot concentrated sulphuric acid and decomposes completely. It is in general resistant to mineral acids of all strength even at high temperature though nitric acids tend to cause damage by oxidation. • Effects of Alkalis: The chemical nature of wool keratin is such that it is particularly sensitive to alkaline substances. Wool will dissolve in caustic soda solutions that would have little effects on cotton. Strong alkaline affect on wool fiber but weak alkaline does not affect wool. • Effect of Resistance to Compression: Resistance to compression values are useful in assessing the suitability of wool for specific end uses. Resistance to compression (R to C) is the force per unit area required to compress a fixed mass of wool to a fixed volume. Resistance to compression is related to fiber diameter and the form and frequency of crimp. • Effect of Resilience: Wool fibers can be stretched up to 50 percent of their original length when wet and 30 percent when dry. • Effect of Organic Solvent: Wool does not affect in organic solvents. • Effects of Insects: Wool affected by insects. • Effect of bleach: Chlorine bleach is ordinary harmful to the wool. KMnO4, Na2O2 are utilized for bleaching. • Effect of Micro Organism: It is affected by mildew if it remains wet for long time. • Dyeing ability: Wool absorbs many different dyes deeply, uniformly and directly without the use of other chemicals. Because of this ability, wool is known for the beautiful, rich colours that can be achieved.

- 13. JUTE FIBER

- 14. Physical Properties Of Jute Fiber • Ultimate Jute Length: 1.5 to 4 mm. • Ultimate Diameter : 0.015 to 0.002 mm. • Jute Fiber Length: 150 to 300 CM (5 to 12 Feet). • Jute Colour: Jute fiber can be White, Yellow, Brown or Grey. • Strength : 3.5 to 5 G/Den. • Specific Gravity: 1.48 • Moisture Regain : 13.75 % (Standard). • Elasticity: Breaking Extension 1.8% and Elastic Recovery very low. • Resiliency: Bad. • Dimensional Stability: Good on average. • Jute fibre is 100% bio-degradable and recyclable and thus environmentally friendly. • Moisture content value: 12.8% (under standard testing atmosphere) • Luster : better quality have fairly high luster, inferior quality show matt and pitted surface with very poor strength • Resistance to mechanical wear: low • Exposure in moisture: reduces strength

- 15. CHEMICAL PROPERTIES OF JUTE FIBER • Effect of acids and alkalis: Easily damaged by hot and cold concentrated acids but resistant to alkali. • Effect of bleaching agent: Not effected by oxidizing and reducing agent. • Effect of organic solvent: Resistance to organic solvent. • Dye ability: Jute fiber has good affinity to basic dye. • Effect of sun light: Due to presence of lignin in jute fiber it may be damaged by sun light. • Flammability: its flammability may be reduced by treating with boras and boric acid mixture. • Effect of microorganism: Jute has more resistance to microbiological attack than either grey cotton or flax. • Reaction with water: Jute is a hygroscopic fibre i.e. it takes in or gives out moisture to its surrounding atmosphere. • Effect of biological agents and light: It is attacked and damaged by the action of micro-biological agents like bacteria, fungus, moths, insects etc. in warm damp condition. Yellowing of the fibre is observed due to the effect of sunlight.

- 17. SILK FIBER

- 18. Physical Properties Of Silk Fiber • Tenacity: The silk filament is strong. This strength is due to its linear, beta configuration polymers and very crystalline polymer system. The strength reduces when wet. • Specific gravity: Degummed silk has a specific gravity of 1.25. • Draping quality: silk fibre is flexible enough and if used to make garments then the fabric drapes well • Elongation - Silk fibre has an elongation at break of 20-25% under normal condition. At 100% R.H. the extension at break is 33%. • electrical properties - Silk is a poor conductor of electricity and tends to form static charge when it is handled. This causes difficulties during processing, particularly in dry atmosphere. • Elastic/Plastic nature: Silk is considered to be more plastic than elastic because it’s very crystalline polymer system does not permit the amount of polymer movement which could occur in a more amorphous system • Hygroscopic nature - Because silk has a very crystalline polymer system, it is less absorbent than wool but it is more absorbent than cotton. The greater crystallinity of silk's polymer system allows fewer water molecules to enter than do the amorphous polymer system of wool. It absorbs water well (M.R.11%), but it dries fairly quickly

- 19. Physical properties • Thermal properties - Silk is more sensitive to heat than wool. • Hand feel - The handle of the silk is described as a medium and its very crystalline polymer system imparts a certain amount of stiffness to the filaments. This is often misinterpreted, in that the handle is regarded as a soft, because of the smooth, even and regular surface of silk filaments. • Effect of sunlight - Silk is more sensitive light than any other natural fibre. Prolonged exposure to sunlight can cause partially spotted color change. Yellowing of silk fibre is generally occurred due to photo degradation by the action of UV radiation of sunlight. • Heat conductivity: like wool, silk is a protein fibre and is a non-conductor of heat. • Absorbency: Silk fiber can absorb about 11% of its weight in moisture but range varies from 10%-30%. • Luster: high

- 20. Chemical properties of Silk Fiber • Action of water: Treatment of silk in boiling water for a short period of time does not cause any detrimental effect on the properties of silk fibre. But on prolonged boiling, silk fibre tends to loss its strength to some degree. • Reaction with Acids: Concentrated mineral silk will dissolve silk faster than wool. Organic acids do not harm silk • Affinity for dyes: Has very good affinity for dyes, it readily absorbs basic, acid and direct dyes. • Reaction to alkalies: Silk is not as sensitive to alkalies as wool but it can be damaged if concentration and temperature are high enough. • Action of oxidising agent: Silk is highly sensitive to oxidising agents. • Effect of heat: Silk is sensitive to heat (decomposes at 165 C) • Reaction to insects: Silk maybe attacked by larvae of clothes mots or carpet beetles • Reaction to bleaches: Strong bleaches containing NaOH will deteriorate silk. A mild bleach of H2O2 or sodium perborate maybe used with normal conditions

- 21. USES OF SILK FIBER It is often used for clothing such as shirts, ties, blouses, formal dresses, high fashion clothes, lining, lingerie, pyjamas, robes, dress suits, sun dresses and Eastern folk costumes.

- 22. VISCOSE RAYON

- 23. Physical Properties Of Viscose Rayon • Tenacity: 2.4-3.2 gm/den • Density: 1.64-1.54gm/c.c • Elognation at break: 13% • Moisture regain (MR%): 11-13% • Melting point: The fiber becomes weak when heated above 150 C • Ability to protest friction: low • Colour: White • Light Reflection ability: Good but UV rays damages fiber • Luster: light to bright • Rayon: It is the most absorbent of all cellulose fiber. • Abrasion resistance: Poor due to inelasticity of fibers, and is easily damged by scraping and will pill . • Flammability: Very high • Drapability: Good • No static build-up

- 24. Chemical Properties Of Viscose Rayon • Effect of alkali: Strong alkali causes this fibre to swell and loose strength. Weak alkalis do not destroy. • Effect of Acids: Hot and concentrated acids cause this fibre to disintegrate. • Effects of bleaching: strong oxidising agents damage the viscose rayon fiber • Organic solvent: Viscose Rayon fibre has enough ability to protest the action of organic solvents • Protection against Mildew: Not good and it damages the fibre • Protection against insects: Viscose rayon is affected and harmed by insects • Dyes: It has good affinity to Direct, vat and sulphur dye. • Effect of iron: Ferrous hydroxide weaken viscose rayon • Resistance to perspiration: Viscose Rayon is fairly resistant to deterioration from perspiration ,The colour however is usually not as resistant.

- 26. SPANDEX FIBER

- 27. PHYSICAL PROPERTIES OF SPANDEX FIBER • Density: The density of spandex filament ranges from 1.15 to 1.32 g/cc • Moisture regain: ranges from 0.8 and 1.2% • Length: It can be either in a staple or a filament form. • Luster: It has usually dull surface • Strength: Low strength compared to other synthetic fibres. • Elasticity: Excellent. May stretch 400-700% that is 4-7 times the relaxed state • Breaking Tenacity: 0.6 to 0.9 g/d • Electrical conductivity: low • Flammability: It burns slowly • Heat: Heat resistance varies among different degrades over 300 F. • Colour: has white or nearly white colour • Shrinkage and Growth: Fibres don’t shrink from exposure . • Cleanliness and washability: All these fibers are unaffected by dry- cleaning solvents although temperature of water should be 100 to 120 F, high temperature reduces elasticity of fiber.

- 28. Chemical Properties Of Spandex • Acid: Good resistance to most of acids unless exposure is over 24 hours. • Alkalies: Good resistance to most of the alkalies, but hot alkalies may damage the fibre. • Organic solvents: Offer resistance to dry cleaning solvents. • Bleaches: Can be degraded by sodium hydrochloride. chlorine bleach should not be used. • Dyeing: A full range of colours is available. Some types are more difficult to dye than others. Disperse dye, chrome dye and acid dye are more suited to this fiber. • Protection against insects: It is not harmed by insects. • Resistance to perspiration: Good • Resistance to oil: Very good (which makes this fiber suitable for swim suits) • Effect of seawater: They are unaffected by sea water (that’s why they are used to make swim suits) • Protection against mildew: have excellent resistance to mildew.

- 30. POLYSETER FIBER

- 31. Physical Properties Of Polyster • Tenacity: dry 3.5-7.0. wet 3.5-7.0 • Elognation at break: dry 15-45%, wet 15-45% • Moisture regain: 0.4% • Shrinkage in boiling water: 0-3% • Crimps per inch: 12-14% • Dry heat Shrinkage: 5-8 (at 180 C for 20 min) • Specific gravity: 1.36- 1.41% • Elastic recovery: 2%-5% • Melting Point: 260-270 degrees • Effect of Sunlight: turns yellow, retains 70-80% tenacity at long exposure • Weight: 1.22-1.38 g/cm3 • Static build-up: Because of low moisture regain, it develops static charge. Garments of polyester fibres get soiled easily during wear. • Swelling and Dissolving:The fibre swells in 2% solution of benzoic acid, salycylic acid and phenol.Alcohols, Ketones, soaps, detergents and drycleaning solvents have no chemical action on polyester fibres.

- 32. Chemical Properties Of Polyster • Effect of acids: These Polymer are resistant to acids • Effects of alkalis: damaged by –CON alkali • Effect of bleaches: It doesn’t require bleaching and it retains its whiteness and requires only chlorine bleach to be used when essential • Sunlight: It with stands the suns UV rays and is resistant to acidic pollutants in atmosphere. • Colour Fastness: It is not easy for dye molecule to penetrate the fibre when dyed, it retains its colour after regular wash. • Micro-organisms: It is resistant to bacteria and other micro organisms • Organic Chemical Resistance: Good • Rot Resistance: High

- 34. NYLON FIBER

- 35. Physical properties Of Nylon • Tenacity: 6.0-8.5 gm/den • Density: 1.14 gm/c.c • Elasticity: Very good • Moisture regain: 3.5-5% • Resiliency: Good • Melting point: 215 C • Ability to protest Friction: Excellent • Colour: White • Light reflection ability: Not good • Ability to protect heat: up to 150 C • Lusture: Bright to light • Dimensionally Stability: Good • Hand feel: Soft and smooth • Abrasion Resistance: Excellent • Breaking extension is 20-40%

- 36. Chemical Properties Of Nylon • Flammability: burns slowly • Electrical: High insulation properties lead to static charge on fiber • Biological: Neither micro-organisms nor moth, larvae attack Nylon • Light No discoloration. • Organic Solvent: Most of the solvent have little or no effect on nylon • Alkalis: Nylon is substantially inert to alkalis • Acid: Nylon 6 is attacked by mineral acidbut is inert to acetate acid and formic acid • Bleaches: Not attacked by oxidizing and reducing agent bleaches, may be affected by chlorine bleaches.