SandBlasting Products

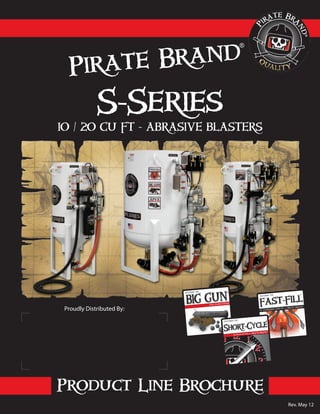

- 1. 10 / 20 CU FT - ABRASIVE BLASTERS Pirate Brand ® Product Line Brochure S-Series Proudly Distributed By: Rev. May 12

- 2. ® (570 Liters)20 cu ft Stationary Abrasive Blasters (Pressure Hold) (Field Applications) Available with: • 1 or 2 Outlets • Abrasive Cut-Off • Pneumatic Controls • Optional Fork Pockets • Electric Controls • Optional Bulk Bag Rack BIG GUN™ Full Flow System Standard! Fast-Fill™ Oversized Pop-Up Standard! Abrasive Umbrella Standard! APVII™ Metering Valve Standard! (285 Liters) 10 cu ft Stationary Abrasive Blasters (Pressure Release) (Blast Room Applications) Available with: • 1 or 2 Outlets • Pneumatic Controls • Abrasive Cut-Off • Electric Controls • Short-Cycle™ Remote Blow-Down BIG GUN™ Full Flow System Standard! Abrasive Umbrella Standard! APVII™ Metering Valve Standard! BIG GUN™ Full Flow System High Performance = More Productivity The BIG GUN™ Full Flow System provides a less restrictive air path resulting in higher pressures at the blast nozzle. Testing has revealed blasters equipped with the BIG GUN™ System show a 36% - 40.5% increase in performance over similar non-Full Flow blasters. The BIG GUN™ Full Flow System is STANDARD on all 10 & 20 Cu. Ft. Blasters. Short-Cycle™ System Saver Quick Blasts Destroy Pressure Release Blasters Short-Cycle™ Blasters are pressure release blasters that depressurize (blow-down) only when a wall- mounted button is activated. This prevents the damage caused by blasting and depressurizing rapidly with an overhead abrasive feeding system. See pg 6 for more details. The Short-Cycle™ System Saver is available on 10 (& 6.5) Cu. Ft. Blasters. Fast-Fill™ Oversized Pop-Up You Can’t Blast And Fill At The Same Time 20 Cu. Ft. of abrasive just takes too long to flow through a standard 4” pop-up. The solution is our 6” Fast-Fill™ Pop-Up with 150% the flow-through area of a standard pop-up. The result is more blasting and less waiting for filling during the work day. The Fast Fill™ 6” Oversized Pop-Up is STANDARD on all 20 Cu. Ft. Blasters. Abrasive Umbrella Keep The Weight Off Your Pop-Up Abrasive umbrellas keep the weight of abrasive from pressing down on the pop-up. Excessive weight on the pop-up can cause excessive wear and even prevent the pop-up from doing its job of sealing the pot. Go ahead, use your overhead abrasive feeding system with confidence . Abrasive Umbrellas are STANDARD on all 10 & 20 Cu. Ft. Blasters. Featuring The ADVANCED METERING SYSTEM ™eaturing The ADVANCED METERING SYSTE ™ APV II APVII™ Advanced Metering Valve There Is No Substitute For A Reliable Metering Valve The APVII™ (Automatic Plunger Valve II) is our most advanced metering valve available. It is packed full of features including quadruple plunger seals, a stainless steel/tungsten carbide plunger, a solid tungsten carbide sleeve, anti-vibration disc & filtered breather hole. There are too many features to list them all here but the bottom line is they add up to make a valve that is tough and reliable. The APVII™ is STANDARD on all 10 & 20 Cu. Ft. Blasters Except Single Outlet SPR Models. 2 3

- 3. ADDING ABRASIVE Abrasive is added through the hole in the top of the Abrasive Blaster where the Pop-up and its seat are located. When abrasive is added, it flows down through the hole, around the Pop-up, and down to the bottom of the pressure vessel where it will exit through the Metering Valve when blasting is started. PRESSURIZATION When a compressed air source (such as an air- compressor) is connected to the inlet of the Abrasive Blaster and the Inlet Valve is opened, compressed air flows through the Moisture Separator (if equipped) and reaches the Combination Valve where it is stopped. When the control handle is activated, the Combination Valve pinches the Blow-down Hose and air flows through the Combination Valve into the pressure vessel causing the Pop-up (located internally) to seal against its seat. The pressure vessel is now sealed and pressurized. Air will also continue past the Choke Valve to the Metering Valve where it is mixed with abrasive. The mixture of compressed air will now exit the Abrasive Blaster through a blast hose and nozzle connected to the coupling on the Metering Valve and blasting begins. It is important to note that in SPR abrasive blasters equipped with MPV Metering Valves, some abrasive will collect at the base of the valve causing the blast hose to pulsate and spray abrasive erratically for a short time when blasting is started. This is normal and will not hurt the Abrasive Blaster. DEPRESSURIZATION (BLOW-DOWN) When the control handle is released in a pressure release (SPR) system (or the blow down button is pressed in a Short-Cycle™ system), the Combination Valve automatically closes stopping the flow of compressed air and releasing the Blow-down Hose. The compressed air remaining in the pressure vessel is released through the Blow-down Hose and blasting ends. ADDING ABRASIVE Abrasive is added through the hole in the top of the Abrasive Blaster where the Pop-up and its seat are located. When abrasive is added, it flows down through the hole, around the Pop-up and, down to the bottom of the pressure vessel where it will exit through the Metering Valve when blasting is started. PRESSURIZATION Before pressurization can take place in a pressure hold system, the Blow-down Valve must be closed. Then, when a compressed air source (such as an air- compressor) is connected to the inlet of the Abrasive Blaster and the Inlet Valve is opened, compressed air can flow through the Moisture Separator (if equipped) and into the pressure vessel causing the Pop-up (located internally) to seal against its seat allowing the pressure vessel to become pressurized. When the control handle is activated, the Auto Air Valve and Metering Valve open allowing compressed air & abrasive to flow and mix. The mixture of compressed air and abrasive will now exit the Abrasive Blaster through a blast hose and nozzle connected to the coupling on the Metering Valve and blasting begins. DEPRESSURIZATION (BLOW-DOWN) When the control handle is released in a pressure hold (SPH) system, the pressure vessel remains filled with compressed air. The compressed air remaining in the pressure vessel is released when the inlet valve is manually closed and the blow-down valve is manually opened. Exhausted Air Compressed Air Air / Abrasive Mix To Blasting Nozzle Loaded Abrasive Inlet Valve Combination Valve Choke Valve Metering Valve Moisture Separator Drain Blow-down Hose Pop-up Flow of Compressed Air Flow of Abrasive Flow of Exhaust Air During Blow-down Exhausted Air Compressed Air Air / Abrasive Mix To Blasting Nozzle Loaded Abrasive Inlet Valve Choke Valve Metering Valve Moisture Separator Drain Blow-down Valve Auto Air Valve Pop-up Flow of Compressed Air Flow of Abrasive Flow of Exhaust Air During Blow-down (Pressure Hold)(Pressure Release) 4 5

- 4. 1 Outlet - Pneumatic Controls STANDARD CONTROLS Includes: • Standard 110’ Pneumatic Controls • MPV Metering Valve • BIG GUN™ Moisture Separator Part # 888-0731-12914PB-E W/ ON-HOSE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Hose- Mounted Abrasive Cut-Off Button • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-1731-33914PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Wall- Mounted Abrasive Cut-Off Button • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-3731-33914PB-E 1 Outlet - Electric Controls STANDARD CONTROLS Includes: • Standard 110’ Electric Controls • MPV Metering Valve • BIG GUN™ Moisture Separator Part # 888-0732-12914PB-E W/ ON-CORD ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Cord- Mounted Abrasive Cut-Off Switch • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-4732-33914PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Wall- Mounted Abrasive Cut-Off Switch • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-5732-33914PB-E 2 Outlet - Pneumatic Controls STANDARD CONTROLS Includes: • Standard 110’ Pneumatic Controls • (2) APVII™ Metering Valves Part # 888-0741-33910PB-E W/ ON-HOSE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Hose- Mounted Abrasive Cut-Off Button • (2) APVII™ Metering Valves Part # 888-1741-33910PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Wall- Mounted Abrasive Cut-Off Button • (2) APVII™ Metering Valves Part # 888-3741-33910PB-E 2 Outlet - Electric Controls STANDARD CONTROLS Includes: • Standard 110’ Electric Controls • (2) APVII™ Metering Valves Part # 888-0742-33910PB-E W/ ON-CORD ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Cord- Mounted Abrasive Cut-Off Switch • (2) APVII™ Metering Valves Part # 888-4742-33910PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Wall- Mounted Abrasive Cut-Off Switch • (2) APVII™ Metering Valves Part # 888-5742-33910PB-E 10 CU FT 1 Outlet Blaster with Electric Controls 10 CU FT 2 Outlet Blaster with Pneumatic Controls 10 Cu. Ft. capacity SPR (Pressure Release) blasters are a great choice for your blast room or other applications where you require a stationary vessel. All Pirate Brand® 10 Cu. Ft. blasters come standard with the BIG GUN™ Full Flow System providing a low restriction air path for better productivity. Whether you require pneumatic or electric controls, an abrasive cut-off feature, single or double outlets, our line of 10 Cu. Ft. Blasters have got you covered. • Pressure Release (Auto Blow-Down) • Single Or Dual Outlet Configurations • 110’ Pneumatic or Electric Controls • BIG GUN™ Full Flow System Standard • Abrasive Cut-Off Options Available • 10 Cu. Ft. Capacity • Abrasive Umbrella Over Pop-Up Featuring The ADVANCED METERING SYSTEM ™eaturing The ADVANCED METERING SYSTE ™ APV II 6 7

- 5. Short-Cycle™ 10 CU FT 1 Outlet Blaster with Pneumatic Controls Short-Cycle™ blasters are designed to withstand the punishing effects of quick on-off blasting while retaining the convenience of a pressure release system. Pressure release blasters (Like our standard 10 Cu. Ft. Blasters) are great for blast rooms because when paired with an overhead abrasive hopper, they can be refilled by simply releasing the control handle and allowing the blaster to depressurize and automatically fill. Unfortunately, when blasting frequently for less than 10 minutes at a time, abrasive can overfill the blaster, damage the pop-up causing it not to seal properly, cause abrasive to “burp” from around the popup, and eventually ruin the metering valve. Pirate Brand® Short-Cycle blasters remain pressurized when the control handle is released but feature a remote blow-down button to allow you to depressurize/refill your blaster without leaving the blast room. All Short- Cycle™ blasters come standard with the BIG GUN™ Full Flow System providing a low restriction air path for better productivity. 10 Cu. Ft. Short Cycle™ Blasters can be ordered with pneumatic or electric controls, an abrasive cut-off feature, or with single or double outlets. • Built To Survive Blasting Cycles Less Than 10 Minutes! • Remote Blow-Down Controls • Single Or Dual Outlet Configurations • 110’ Pneumatic or Electric Controls • BIG GUN™ Full Flow System Standard • Abrasive Cut-Off Options Available • 10 Cu. Ft. Capacity • Abrasive Umbrella Over Pop-Up 1 Outlet - Pneumatic Controls STANDARD CONTROLS Includes: • Standard 110’ Pneumatic Controls • APVII™ Metering Valve • BIG GUN™ Moisture Separator • Short-Cycle™ System Part # 888-0731-33954PB-E W/ ON-HOSE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Hose- Mounted Abrasive Cut-Off Button • APVII™ Metering Valve • BIG GUN™ Moisture Separator • Short-Cycle™ System Part # 888-1731-33954PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Wall- Mounted Abrasive Cut-Off Button • APVII™ Metering Valve • BIG GUN™ Moisture Separator • Short-Cycle™ System Part # 888-3731-33954PB-E 1 Outlet - Electric Controls STANDARD CONTROLS Includes: • Standard 110’ Electric Controls • APVII™ Metering Valve • BIG GUN™ Moisture Separator • Short-Cycle™ System Part # 888-0732-33964PB-E W/ ON-CORD ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Cord- Mounted Abrasive Cut-Off Switch • APVII™ Metering Valve • BIG GUN™ Moisture Separator • Short-Cycle™ System Part # 888-4732-33964PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Wall- Mounted Abrasive Cut-Off Switch • APVII™ Metering Valve • BIG GUN™ Moisture Separator • Short-Cycle™ System Part # 888-5732-33964PB-E 2 Outlet - Pneumatic Controls STANDARD CONTROLS Includes: • Standard 110’ Pneumatic Controls • (2) APVII™ Metering Valves • Short-Cycle™ System Part # 888-0741-33950PB-E W/ ON-HOSE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Hose- Mounted Abrasive Cut-Off Button • (2) APVII™ Metering Valves • Short-Cycle™ System Part # 888-1741-33950PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Wall- Mounted Abrasive Cut-Off Button • (2) APVII™ Metering Valves • Short-Cycle™ System Part # 888-3741-33950PB-E 2 Outlet - Electric Controls STANDARD CONTROLS Includes: • Standard 110’ Electric Controls • (2) APVII™ Metering Valves • Short-Cycle™ System Part # 888-0742-33960PB-E W/ ON-CORD ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Cord- Mounted Abrasive Cut-Off Switch • (2) APVII™ Metering Valves • Short-Cycle™ System Part # 888-4742-33960PB-E W/ REMOTE ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Wall- Mounted Abrasive Cut-Off Switch • (2) APVII™ Metering Valves • Short-Cycle™ System Part # 888-5742-33960PB-EElectric Remote Blow-Down Control Featuring The ADVANCED METERING SYSTEM ™eaturing The ADVANCED METERING SYSTE ™ APV II 8 9

- 6. Our 20 Cu. Ft. capacity SPH (Pressure Hold) blasters are a crossover between small blasters and bulk blasters. They have both massive capacity and are still portable enough not to require their own speciality trailer. They feature an oversized Fast-Fill™ pop-up to allow for faster filling. All Pirate Brand® 20 Cu. Ft. blasters come standard with the BIG GUN™ Full Flow System providing a low restriction air path for better productivity. Whether you require pneumatic or electric controls, an abrasive cut-off feature, single or double outlets, the Pirate Brand® line of 20 Cu. Ft. Blasters have got you covered. • Pressure Hold (Manual Blow-Down) • Fast-Fill™ Oversized Pop-Up • Single Or Dual Outlet Configurations • 110’ Pneumatic or Electric Controls • BIG GUN™ Full Flow System Standard • Abrasive Cut-Off Options Available • 20 Cu. Ft. Capacity • Abrasive Umbrella Over Pop-Up • Available Fork Pockets & Overhead Abrasive Bulk Bag Holder 1 Outlet - Pneumatic Controls STANDARD CONTROLS Includes: • Standard 110’ Pneumatic Controls • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-0931-33904PB-E W/ ON-HOSE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Hose- Mounted Abrasive Cut-Off Button • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-1931-33904PB-E W/ ON-VESSEL ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Vessel- Mounted Abrasive Cut-Off Button • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-2931-33904PB-E 1 Outlet - Electric Controls STANDARD CONTROLS Includes: • Standard 110’ Electric Controls • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-0932-33904PB-E W/ ON-CORD ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Cord- Mounted Abrasive Cut-Off Switch • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-4932-33904PB-E W/ ON-VESSEL ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Vessel- Mounted Abrasive Cut-Off Switch • APVII™ Metering Valve • BIG GUN™ Moisture Separator Part # 888-2932-33904PB-E 2 Outlet - Pneumatic Controls STANDARD CONTROLS Includes: • Standard 110’ Pneumatic Controls • (2) APVII™ Metering Valves Part # 888-0941-33900PB-E W/ ON-HOSE ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Hose- Mounted Abrasive Cut-Off Button • (2) APVII™ Metering Valves Part # 888-1941-33900PB-E W/ ON-VESSEL ABRASIVE CUT-OFF Includes: • 110’ Pneumatic Controls W/ Vessel- Mounted Abrasive Cut-Off Button • (2) APVII™ Metering Valves Part # 888-2941-33900PB-E 2 Outlet - Electric Controls STANDARD CONTROLS Includes: • Standard 110’ Electric Controls • (2) APVII™ Metering Valves Part # 888-0942-33900PB-E W/ ON-CORD ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Cord- Mounted Abrasive Cut-Off Switch • (2) APVII™ Metering Valves Part # 888-4942-33900PB-E W/ ON-VESSEL ABRASIVE CUT-OFF Includes: • 110’ Electric Controls W/ Vessel- Mounted Abrasive Cut-Off Switch • (2) APVII™ Metering Valves Part # 888-2942-33900PB-E 20 CU FT 2 Outlet Blaster with Pneumatic Controls 20 CU FT 2 Outlet Blaster with Optional Fork Pockets, Bulk Bag Rack, Pressure Relief Valve Pressure Regulator & 800 CFM Moisture Separator Featuring The ADVANCED METERING SYSTEM ™eaturing The ADVANCED METERING SYSTE ™ APV II 10 11

- 7. 10 Cu. Ft. A B C 20 Cu. Ft. A B C D E F G IH J A 888-1200-08007PB-FI 800 CFM MOISTURE SEPARATOR KIT FOR 2-OUTLET10 & 20 CU FT S-SERIES BLASTERS Moisture Separator MOISTURE SEPARATORS ARE YOUR LAST LINE OF DEFENSE AGAINST MOISTURE REACHING YOUR BLAST EQUIPMENT. MOISTURE CAUSES ABRASIVE TO CLUMP TOGETHER CLOGGING YOUR METERING VALVE AND CAN LEAD TO COMPONENT BREAK DOWN. SINGLE OUTLET 10 & 20 CU FT BLASTERS COME STANDARD WITH 350 CFM MOISTURE SEPARATORS. UPGRADE 2 OUTLET 10 & 20 CU FT BLASTERS WITH THE KIT SHOWN BELOW (REQUIRES FORK POCKETS ON 20 CU FT BLASTERS) B 888-2000-007PB-CI 1-1/2" BIG GUN REGULATOR KIT FOR 1 OUTLET 10 & 20 CU FT BLASTERS 888-2000-008PB-CI 2" BIG GUN REGULATOR KIT FOR 2 OUTLET 10 & 20 CU FT BLASTERS 888-2001-00199PB REGULATOR, 1/4", REPAIR KIT 888-2000-00399PB REGULATOR, 1-1/2" & 2" FULL FLOW, REPAIR KIT Regulator Kit ADDING A REGULATOR KIT TO YOUR ABRASIVE BLASTER WILL ALLOW YOU TO BLAST AT LOWER PRESSURES TO ACHIEVE CUSTOM FINISHES OR HELP CONTROL PROFILE C 888-2470-00702PB SMALL BLASTER RELIEF VALVE KIT (FITS 1.3, 3.5, 6.5, 10 & 20 CU FT S- SERIES BLASTERS) Relief Valve Kit ADDING THIS ASME RELIEF VALVE KIT TO YOUR BLASTER CAN PREVENT DANGEROUS OVER PRESSURIZATION. LOCAL CODES MAY REQUIRE A DIFFERENT VALVE D E 888-1108-07220PB-FI BULK BAG RACK W/ SUPPORTS & FORK POCKETS UPGRADE FOR 20 CU FT S- SERIES VESSEL Bulk Bag Rack ADDING THIS BULK BAG RACK AND SUPPORTING MOUNTS ALLOWS YOU TO QUICKLY FILL YOUR 20 CU FT BLASTER W/ BULK MEDIA. INCLUDES FORK POCKETS. (FACTORY INSTALLED - 20 CU FT BLASTERS ONLY) F 888-5010-060PB LID FOR 10 CU FT ABRASIVE BLASTERS 888-5010-200PB LID FOR 20 CU FT ABRASIVE BLASTERS 888-5011-200PB SCREEN FOR 20 CU FT ABRASIVE BLASTERS Lids and Screens LIDS ARE IMPORTANT FOR KEEPING MOISTURE FROM FALLING INTO THE ABRASIVE BLASTER IN OUTDOOR APPLICATIONS. MOISTURE IN THE ABRASIVE BLASTER CAN CAUSE OBSTRUCTIONS IN THE METERING VALVE LEADING TO COSTLY DOWN-TIME. SCREENS ARE IMPORTANT FOR KEEPING FOREIGN OBJECTS FROM FALLING INTO THE ABRASIVE BLASTER. FOREIGN OBJECTS IN THE ABRASIVE BLASTER CAN CAUSE OBSTRUCTIONS IN THE METERING VALVE LEADING TO COSTLY DOWN-TIME. G 888-2011-007PB-FI BLOW-DOWN MUFFLER KIT FOR SPR (PRESSURE RELEASE) ABRASIVE BLASTERS INSTALLING A BLOW-DOWN MUFFLER TO YOUR SPR SERIES ABRASIVE BLASTER WILL REDUCE THE NOISE GENERATED AT BLOW-DOWN. IT WILL ALSO DIFFUSE THE BLAST OF AIR THAT IS RELEASED. SPR Muffler H I J 12 13

- 8. 888-1310-021PB AIR DRYER ADPB-250 CFM @ 100 PSIG OR 359 CFM @ 150 PSIG 888-1310-041PB AIR DRYER ADPB-400 CFM @ 100 PSIG OR 574 CFM @ 150 PSIG 888-1310-071PB AIR DRYER ADBP-750/950, 800 CFM @ 100 PSIG OR 1149 CFM @ 150 PSIG 888-1310-121PB AIR DRYER ADPB-1200 CFM @ 100 PSIG OR 1723 CFM @ 150 PSIG 888-1310-161PB AIR DRYER ADPB-1600 CFM @ 100 PSIG OR 2297 CFM @ 150 PSIG Air Dryers 888- PB 888- PB 888- PB 888- PB 888- PB NOVA 2000™ ASTRO™ DRY LAND Featuring The AIR DRYING SYSTEM ™ SODA STORM Featuring The SODA BLASTING SYSTEM ™ Bulk Blaster Kits Small Blaster Kits 14 15

- 9. About Pirate Brand® At Pirate Brand®, we know abrasive blasting. We have fused our 100+ years of combined experience in the blasting industry with feedback from distributors and end-users to produce abrasive blast equipment and replacement parts that are second to none. In addition to our extensive line of blasting equipment, we produce a full line of aftermarket parts that are 100% compatible replacements for other blast equipment manufacturers. We believe in quality, reliability and productivity so we subject all our products to strict quality control testing to ensure the best possible performance is achieved. In the tough world of abrasive blasting, quality is crucial, ...and Pirate Brand® delivers. ©2012 Pirate Brand, All Rights Reserved