Improve Equipment Uptime with Proper Battery Maintenance

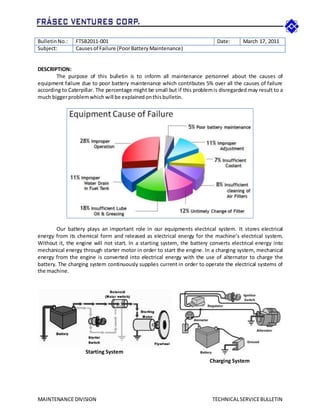

- 1. MAINTENANCE DIVISION TECHNICALSERVICEBULLETIN BulletinNo.: FTSB2011-001 Date: March 17, 2011 Subject: Causesof Failure (PoorBatteryMaintenance) DESCRIPTION: The purpose of this bulletin is to inform all maintenance personnel about the causes of equipment failure due to poor battery maintenance which contributes 5% over all the causes of failure according to Caterpillar. The percentage might be small but if this problemis disregarded may result to a much biggerproblemwhich will be explainedonthisbulletin. Our battery plays an important role in our equipments electrical system. It stores electrical energy from its chemical form and released as electrical energy for the machine’s electrical system. Without it, the engine will not start. In a starting system, the battery converts electrical energy into mechanical energy through starter motor in order to start the engine. In a charging system, mechanical energy from the engine is converted into electrical energy with the use of alternator to charge the battery. The charging system continuously supplies current in order to operate the electrical systems of the machine. Starting System Charging System

- 2. MAINTENANCE DIVISION TECHNICALSERVICEBULLETIN Most of our Caterpillar units are controlled by ECM (Electronic Control Module). An enclosed computer that is used to control the equipment’s operation both engine and hydraulic systems. The other function of an ECM is to gather data for technical analysis when diagnosed by CAT ET. It also controls the EMS (Electronic Monitoring System) which serves as an indicator to alarm the operator about the currentstatus inreal time. ECM works by analyzing input signals from various sensors installed on the different systems of the machine. The machine ECM continuously monitors these input signals in order to control the output flow rate of the hydraulic pumps, engine speed, fuel injection etc. The ECM sends output signals to energize solenoid valves, relays,sensors andotherelectronicaccessories. As a computer, the ECMprocess information through digital signal and analog signals. It supplies 5.0 ± 0.2 VDC to most sensors and a regulated voltage supply of 8.0 ± 0.4 VDC to the speed/timing sensors to calculate engine rpm. And because of these parameters, our unit’s electronic systems are sensitiveenoughtocertain variationof voltage. A voltage fluctuation takes place when a battery kicks to a certain degree of voltage increase due to instantaneous contact between positive and negative poles of the battery in which a spark (electric arc) is mostly created between battery terminals and clamps (can also be found on connectors). And since our equipment operates at 24 VDC, our battery is powerful enough to produce voltage that is destructive toourelectroniccircuitry. OBSEVATIONS AND FINDINGS: AfterCATET Diagnosticswasperformedtoall Caterpillarunits,itwasfoundthatthere are numerous error codesloggeddue topoor batterymaintenance. To name a few,the followingeffectsare listedbelow; 168-5 : Electrical SystemVoltage–CurrentBelow Normal 168-1 : Electrical SystemVoltage–Low 246-9 : ProprietaryCAN DataLink - Abnormal Update Rate 269-4 : SensorPowerSupply –Voltage Below Normal 588-9 : MonitoringSystemDisplay –Abnormal Update Rate 590-9 : Engine Control Module –Abnormal Update Rate 41-6 : 8 VoltDC Supply – CurrentAbove Normal

- 3. MAINTENANCE DIVISION TECHNICALSERVICEBULLETIN The followingphotos are actual batteryinstallationfoundduringinspectionof units. D8N Battery compartment and a closed up view of the battery showing a damaged terminal due to loose clamping which have cause spark within its terminal area. A battery clamp of BH-05 Corroded battery clamp A disconnect switch with a welding rod engaged to switch it on The batteries without the fixture cover

- 4. MAINTENANCE DIVISION TECHNICALSERVICEBULLETIN Battery grounding of D5M A Positive cable loosely attached to the clamp BEST PRACTICE: In response to correct or prevent recurrence of these failures, we recommend the following Best Practice to be followedinordertoperformmaintenance proceduressuccessfully. 1. Strictlyimplementoperator’swalkaroundinspectionunderBLOWAF; a. Checkbatterycables,itshould be tightlyboltedtothe clamp b. Inspectclampsforcorrosions c. Checkbatteryterminalsforcracks d. Batteryfixturesmustbe inplacedtopreventmovementcausedbyvibration&swing 2. Use disconnectkeytoturnon/off the disconnectswitch (notweldingrod). 3. Disconnectswitchmustbe turnedoff aftermachine isparkedandremove key. 4. Use jumpstartcablesif batteryinstalledisdrained. 5. Refrainontransferringbatteriesfromone unittoanother. 6. Be sure to replace the batterywithanotherbatterythatisequal incapacityto the original. There are many positive impacts associated with this Best Practice. Such positive impacts may include: improved equipment reliability, maintenance and repair efficiency, high mechanical availability, and improved mining operation performance. The impact of improving our battery management may leadto greatersavingsonour equipment costresultingtogreaterproductivity andrevenue. Preparedby: Maximo V. Ginez III Maintenance Planner Notedby: Chanito L. Ouano Maintenance Division Head Approvedby: Francis Gerard S. Cañedo President