Solar process heating and cooling all pervading

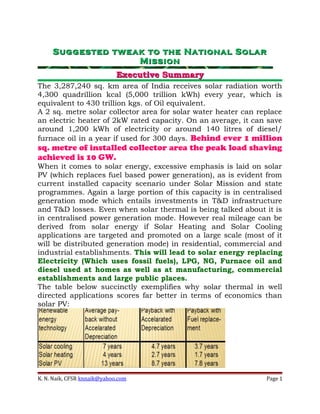

- 1. Suggested tweak to the National SolarSuggested tweak to the National Solar MissionMission Executive SummaryExecutive Summary The 3,287,240 sq. km area of India receives solar radiation worth 4,300 quadrillion kcal (5,000 trillion kWh) every year, which is equivalent to 430 trillion kgs. of Oil equivalent. A 2 sq. metre solar collector area for solar water heater can replace an electric heater of 2kW rated capacity. On an average, it can save around 1,200 kWh of electricity or around 140 litres of diesel/ furnace oil in a year if used for 300 days. Behind ever 1 million sq. metre of installed collector area the peak load shaving achieved is 10 GW. When it comes to solar energy, excessive emphasis is laid on solar PV (which replaces fuel based power generation), as is evident from current installed capacity scenario under Solar Mission and state programmes. Again a large portion of this capacity is in centralised generation mode which entails investments in T&D infrastructure and T&D losses. Even when solar thermal is being talked about it is in centralised power generation mode. However real mileage can be derived from solar energy if Solar Heating and Solar Cooling applications are targeted and promoted on a large scale (most of it will be distributed generation mode) in residential, commercial and industrial establishments. This will lead to solar energy replacing Electricity (Which uses fossil fuels), LPG, NG, Furnace oil and diesel used at homes as well as at manufacturing, commercial establishments and large public places. The table below succinctly exemplifies why solar thermal in well directed applications scores far better in terms of economics than solar PV: K. N. Naik, CFSR knnaik@yahoo.com Page 1

- 2. MNRE with support from the United Nations Development Programme (UNDP) has initiated a project on promotion and market development of solar thermal in process heating/cooling applications in industries, commercial enterprises and large public establishments in India. The project is aimed at targeting low to medium temperature range to satisfy both heating as well as cooling demand for the sector. 30 demonstration and 60 replication projects will be directly supported, installed and monitored during the 5-year project duration. Bottom line is that we need to move faster than that and the individual companies need to act suo-motto instead of waiting for a government programme. Some of them have indeed moved forward as will be described in the article. The pie charts below abundantly justify why solar thermal cooling and other applications should be the most appropriate solution in terms of replacing electricity and fuel usage in urban scenario: A Solar Boiler = Conventional boiler + 25 years fuel tank How much would you pay today for a fuel tank containing 25 years of fuel? India’s National Solar Mission target of 15 million m2 of solar thermal collector area by 2017, and 20 million m2 by 2020. PreamblePreamble K. N. Naik, CFSR knnaik@yahoo.com Page 2

- 3. The 3,287,240 sq. km area of India receives solar radiationThe 3,287,240 sq. km area of India receives solar radiation worth 4,300 quadrillion kcal (5,000 trillion kWh) everyworth 4,300 quadrillion kcal (5,000 trillion kWh) every year, which is equivalent to 430 trillion kgs. of Oilyear, which is equivalent to 430 trillion kgs. of Oil equivalent.equivalent. Low temperature solar thermal systems constitute the major market developed so far largely being solar water heaters. As per figures available from Ministry of New and Renewable Energy (MNRE) until August 2015 cumulative installed capacity of solar water heaters in India was around 10 million sq.metres. A 2 sq. metre solar collector area can replace an electricA 2 sq. metre solar collector area can replace an electric heater of 2kW rated capacity. On an average, it can saveheater of 2kW rated capacity. On an average, it can save around 1,200 kWh of electricity or around 140 litres ofaround 1,200 kWh of electricity or around 140 litres of diesel/ furnace oil in a year if used for 300 days.diesel/ furnace oil in a year if used for 300 days. BehindBehind ever 1 million sq. metre of installed collector area theever 1 million sq. metre of installed collector area the peak load shaving achieved is 10 GW.peak load shaving achieved is 10 GW. When it comes to solar energy, excessive emphasis is laid on solar PV (which replaces fuel based power generation), as is evident from current installed capacity scenario under Solar Mission and state programmes. Again a large portion of this capacity is in centralised generation mode which entails investments in T&D infrastructure and T&D losses. Even when solar thermal is being talked about it is in centralised power generation mode. However real mileage can be derived from solar energy if Solar Heating and Solar Cooling K. N. Naik, CFSR knnaik@yahoo.com Page 3

- 4. applications are targetted and promoted on a large scale (most of it will be distributed generation mode) in residential, commercial and industrial establishments. This will lead to solar energyThis will lead to solar energy replacing Electricity (Which uses fossil fuels), LPG, NG,replacing Electricity (Which uses fossil fuels), LPG, NG, Furnace oil and diesel used at homes as well as atFurnace oil and diesel used at homes as well as at manufacturing, commercial establishments and largemanufacturing, commercial establishments and large public places.public places. The table below succinctly exemplifies why solar thermal in well directed applications scores far better in terms of economics than solar PV: Someone has very aptly observed: “Current trends in energy supply and use are patently unsustainable – economically, environmentally and socially. Without decisive action, energy-related emissions of carbon dioxide (CO2) will more than double by 2050 and increased oil demand will heighten concerns over the security of supplies. We can and must change our current path, but this will take an energy revolution and low-carbon energy technologies will have a crucial role to play.” Thermal Energy Needs • Residential Buildings o Hot water for bathing • Hotels & Hospitals o Steam for Laundry & Cooking o Hot water for bathing, washing, cleaning, etc o Air-conditioning o Steam for canteen cooking • Commercial Buildings – Office & Retail o Air-conditioning o Steam for canteen cooking K. N. Naik, CFSR knnaik@yahoo.com Page 4

- 5. • Industries / Factories o Process Heating o Air-conditioning o Steam for canteen cooking Good news is that MNRE with support from the United Nations Development Programme (UNDP) has initiated a project on promotion and market development of solar thermal in process heating/cooling applications in industries, commercial enterprises and large public establishments in India. The project is aimed at targeting low to medium temperature range to satisfy both heating as well as cooling demand for the sector. The project focuses on demonstrating technical and financial viability of solar thermal projects and enhance local manufacturing capability for industrial applications. 30 demonstration and 60 replication projects will be directly supported, installed and monitored during the 5-year project duration. Bottom line is that we need to move faster than that and theBottom line is that we need to move faster than that and the individual companies need to act suo-motto instead of waiting for aindividual companies need to act suo-motto instead of waiting for a government programme. Some of them have indeed moved forwardgovernment programme. Some of them have indeed moved forward as will be described in the article.as will be described in the article. Some of the Organisations who have successfully used solar thermal technologies to meet their heating and cooling needs are as follows: Solar Cooling India Muni Seva Ashram, Vadodara Siemens Technologies' Bangalore office NTPC, Greater Noida TVS Group, Chennai Abroad Crow Canyon Medical Center Beachside Resort, Hawaii EAR Tower Pristina Olympic Sailing Village China United World College, Singapore METRO shopping centre Istanbul K. N. Naik, CFSR knnaik@yahoo.com Page 5

- 6. FESTO near Stuttgart, Germany Shouldice Hospital Note: Quite a few of these use solar thermal energy for a variety of heat services in addition to cooling Solar Cooking India Swaminarayan Akshardham Mandir in New Delhi Harmandar Sahib's Guru Ram Dass 'langar' The Sabarmati Central Jail Sri Sai Baba Sansthan Tirupati Solar industrial process heat India Tapi Foods Mahanand Dairy Mahindra & Mahindra, Pune Abroad Milk processing LESA Bever, Switzerland EMMI Saignelégier, Switzerland CREMO Fribourg, Switzerland Galvanization Blum, Austria, 2011 Galvanization Zehnder, Switzerland, 2012 Galvanization Hustert, Germany, 2011 Water Preheating for Steam Boilers in China Dairy, TYRAS S.A., Trikala, Greece Solar Heat for Copper Mining in Cyprus Frito Lay Headquarters Williams-Selyem Estate Winery "Solar Process Heat" installation in a concrete factory in Upper Austria Stapleton-Spence Packing Company Project SoPro-IndiaProject SoPro-India: K. N. Naik, CFSR knnaik@yahoo.com Page 6

- 7. Indian industries consume roughly 15 million tons of fuelIndian industries consume roughly 15 million tons of fuel oil every year in thermal application below 250°C.oil every year in thermal application below 250°C. Solar heating systems for industrial processes (SHIP) have a substantial potential to replace fossil fuels in Indian industry, reducing greenhouse gas emissions and costs. Experts estimate less thanExperts estimate less than one percent of existing 5.73 GWth capacity is installed inone percent of existing 5.73 GWth capacity is installed in process heat applications in Indian industries.process heat applications in Indian industries. The Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) India, with the support of the Fraunhofer Institute of Solar Energy ISE, Germany, are implementing the project SoPro-Indiaproject SoPro-India, to increase awareness of solar water heating technology and to improve the confidence in the technology by developing solutions to monitor the performance of solar water heating systems. It aims to support the SHIP deployment in IndianIt aims to support the SHIP deployment in Indian Industries in low-mid temperature applications forIndustries in low-mid temperature applications for reducing green-house-gas emissions thus mitigatingreducing green-house-gas emissions thus mitigating climate change.climate change. SoPro-IndiaSoPro-India is carried out within theis carried out within the framework of the projectframework of the project ComSolarComSolar (commercialization(commercialization of solar energy in urban and industrial areas).of solar energy in urban and industrial areas). ComSolar is financed by German Federal Ministry of Environment, Nature conservation, Building and Nuclear Safety (BMUB). Solar Payback projectSolar Payback project aims to raise awareness and improve the economic and policy conditions for solar process heat in Brazil, Mexico, India and South Africa. The 3-year project is coordinated by the German Solar Industry Association (BSW-Solar) and funded by the International Climate Initiative of the German Federal Environment Ministry. It runs until September of 2019. It is coordinated by the German Solar Association BSW-Solar and eleven partner organisations: three German companies, plus each target country’s national solar industry association and German chamber of commerce. The project will be jointly implemented in India by Pune-based STFI and IGCC with its head office in Mumbai. It was launched in October 2016 and will end in September 2019. India’s industrial companies, which are responsible for 38 % of the country’s total energy consumption, have installed a total of 40,000 m2 of collector area for solar process heat so far. K. N. Naik, CFSR knnaik@yahoo.com Page 7

- 8. Solar Payback is likely to increase the confidence ofSolar Payback is likely to increase the confidence of industrial customers to supplement carbon-based fuels.industrial customers to supplement carbon-based fuels. Solar Payback focuses on an in-depth analysis of market barriers and drivers by drafting a solar process heat roadmapsolar process heat roadmap and making policy recommendations. In addition, it intends to strengthen the industry by offering training for planners and raise awareness by organising an industry conference. Urban Area Solar Thermal SolutionsUrban Area Solar Thermal Solutions Solar CoolingSolar Cooling The peak of solar radiation and the peak demand of cooling match perfectly. We can use the same radiation that creates the demand to cover the cooling demand, cut off electricity peakscut off electricity peaks and avoid extreme operations on the distribution grid. One ARUN®160 solar concentrator delivers about 1 ton ofOne ARUN®160 solar concentrator delivers about 1 ton of steam per day, while occupying ground area of less than 10steam per day, while occupying ground area of less than 10 sq.m. It can deliver steam up to 25 bars pressure orsq.m. It can deliver steam up to 25 bars pressure or thermic oil up to 400°C.thermic oil up to 400°C. This technology offers an opportunity for replication in power stations. Why solar air conditioning? • The buildings sector accounts for 42% of global electricity consumption (IEA 2007) • Steadily increasing electricity price • Air-Conditioning (AC) represents the biggest single energy/power consumer in public and commercial sectors • AC key driver of Electric Peak power demand growth - negative impact on grid load factor, electricity price and environment In 2011, worldwide, about 750 solar cooling systems were installed, including installations with small capacity (<20kW). A number of very large installations have been completed. Examples are the system at the headquarters of the CGD bank in Lisbon, Portugal with a cooling capacity of 400 kW and a collector field of 1560m²; and the system installed at the United World College in Singapore, K. N. Naik, CFSR knnaik@yahoo.com Page 8

- 9. completed in 2011, with a cooling capacity of 1470 kW and a collector field of 3900 m². This Singapore installation isThis Singapore installation is reportedly fully cost competitive and was executed on anreportedly fully cost competitive and was executed on an energy services company (ESCO) model under which theenergy services company (ESCO) model under which the customer is not exposed to equipment or project costs,customer is not exposed to equipment or project costs, rather the ESCO sells the resultant cooling capacity torather the ESCO sells the resultant cooling capacity to the customer.the customer. The pie charts below abundantly justify why solar thermal cooling and other applications should be the most appropriate solution in terms of replacing electricity and fuel usage in urban scenario: Some Case Studies of Solar Thermal Cooling India’s latest and probably largest solar thermal based air- conditioning system went operational at Muni Seva AshramMuni Seva Ashram in Goraj, near Vadodara. A total of 100 parabolic dishes (Scheffler type) - each 12.5 m2 in size - now supply the already existing 100-ton air-conditioning system of the 160-bed hospital. Siemens Technologies' Bangalore officeSiemens Technologies' Bangalore office has a system that runs the cooling system entirely on solar thermal technology. Flareum has installed a 10 TR solar air-conditioning system which uses the vapour absorption mechanism (VAM) to cool the building, for up to eight hours a day by producing 200 kWh of cooling. The savings from this system for Siemens is an estimated Rs 6.50 lakh annually. It is also expected to reduce 30,000 ton of carbon emissions per annum, with a payback period of 4-5 years. Turbo Energy Limited (TEL)Turbo Energy Limited (TEL) • Paiyanoor near Chennai • TEL is a leading manufacturer and supplier of turbochargers to many Automobile Manufacturers in India. K. N. Naik, CFSR knnaik@yahoo.com Page 9

- 10. • TEL has successfully installed one ARUN solar boiler system for fulfilling its hot water requirements for operating a Vapour Absorption Machine (VAM) for air- conditioning/comfort cooling for its administrative block. • Pressurized water at 180°C is required for the machine to operate at an optimal level. The return temperature of the hot water is 160 °C. The machine with 40 TR capacity requires 5 m³/hr of the pressurized hot water which can be catered to by 2 ARUN dishes. The solar circuit is kept pressurized at 15 bar using the nitrogen pressurization system. • The average heat output from the two dishes is about 1,00,000 kcal/hr, which is sufficient for the heat requirement of the vapour absorption machine. NETRA (NETRA ((NTPC Energy Technology Research(NTPC Energy Technology Research Alliance)Alliance) SOLAR HVAC SYSTEM AT NTPCSOLAR HVAC SYSTEM AT NTPC • World’s Largest Solar Thermal enabled air-conditioning / comfort cooling system with storage • This Solar Thermal air-conditioning or solar thermal air cooling system consists of two dual-axis tracking solar concentrator of Fresnel design, named ARUN®. The ARUN solar boiler provides dry saturated steam at 180°C at about 200kg per hour. The steam is fed to a 50 TR (i.e. about 175 kW of cooling) Vapour Absorption Machine (VAM). • The distinguishing feature of the system is theThe distinguishing feature of the system is the storage tank that can store up to 2 days of chillingstorage tank that can store up to 2 days of chilling capabilities.capabilities. Offices are generally closed on weekends. To avoid wasting the solar energy, this 2-day storage facility has been included. • It has an efficiency of 80%, consumes negligible auxiliary power and occupies less area compared to conventional AC system. Crow Canyon Medical CenterCrow Canyon Medical Center • Danville, CA • 50RT Thermax Chiller • 75 MCT panels • 3,352 square feet K. N. Naik, CFSR knnaik@yahoo.com Page 10

- 11. • 150KWt peak • Annual Outputs • 340 MWH CHW • 3,840 therms DHW • Installed 2012 Beachside Resort, HawaiiBeachside Resort, Hawaii • 50 RT gas/solar heat pump solution (150 MCTs) • Annual Electricity offset: 278 MWh* • Propane Gross Offset: 177,700 gallons (before absorber consumption) • Net LPG Consumption cut by 58% EAR Tower Pristina (2002/2003)EAR Tower Pristina (2002/2003) • 2 thermal driven absorption cooling machines with a total load of 70 kW • 226 m² solar collectors 4 m³ storage tank back up for peak load: electric chiller 30 kW. Olympic Sailing Village China (2008)Olympic Sailing Village China (2008) • Solar Hot Water for Sports Center and Olympic Village • Solar Air Conditioning for Logistic Building • Solar Panels: • 1296 m²/910 kW United World College, SingaporeUnited World College, Singapore • 3,900 m² collector field • 1.4 MW cooling + all DHW for the centralized grid of the campus. • Today the world’s largest Solar Cooling + Heating installation METRO shopping centre IstanbulMETRO shopping centre Istanbul K. N. Naik, CFSR knnaik@yahoo.com Page 11

- 12. • Solar cooling in summer, heating in winter, finished in 2009 • solar temperatures 80...95 °C • Gross collector area 1030 m² • Storage tank 15 m³ • Peak power 1.1 MW • Max. continual power 0.6 MW • Guaranteed yield p. a. 650 MWh FESTO near Stuttgart, GermanyFESTO near Stuttgart, Germany • Solar cooling in summer, space heating in winter, finished in 2007 • solar temperatures 80...95 °C • Gross collector area 1330 m² • Storage tank 17 m³ • Peak power 1.2 MW • Max. continual power 0.65 MW • Guaranteed yield p. a. 500 MWh • 2011(+ 35 %!) 676 MWh NTPC, Greater NoidaNTPC, Greater Noida • Steam for Comfort Cooling • Location Greater Noida • Delivery 10 bar and 180°C • Capacity 80 – 100 kWth per dish • Dish numbers 2 dishes • Commissioning July 2012 Shouldice HospitalShouldice Hospital • Shouldice Hospital is located in Ontario equipped with 5 operating rooms and 89 hospital beds. • Operation Domestic Hot Water, Cooling and Heating • Solar Storage 4,364L • Displaced Natural Gas and Electricity • Solar Collectors: 131 Thermomax Collectors • Solar Chiller: 10 ClimateWell Solar Chillers • Heat Sink: Wet Cooling Tower • Distributions Type: Air Ducts • Project Highlights: • Forecasted Energy Savings: • Cooling 306,295,104 (BTU) 36% • Heating 136,407,859 (BTU) 44% K. N. Naik, CFSR knnaik@yahoo.com Page 12

- 13. • DHW 536,690,050 (BTU) 91% • 56% the Total Energy Load • Provided Energy: • Solar System 56% • Auxiliary System 44% •• Reduction Peak Cooling:Reduction Peak Cooling: 80+%80+% For a city like DelhiFor a city like Delhi The peak of solar radiation and the peak demand for cooling demand match perfectly. We can utilise the same radiation that creates the demand for meeting the cooling demand, Cut off electricity demand peaks and avoid extreme operations on the distribution grid. Solar air conditioning saves the most expensiveSolar air conditioning saves the most expensive electricity.electricity. Solar Water HeatingSolar Water Heating A significant portion of electricity and LPG is used in homes, hotels and hospitals for hot water. Some cities like Pune have made it mandatory for all new housing schemes to have solar water heating. If the same is implemented all over the country, it could have an enormous amount of electricity/LPG saving for the country which is heavily import-dependent for all fuels including coal and which suffers electricity shortage. The average annual cost over the lifetime of an electric water heaterThe average annual cost over the lifetime of an electric water heater is USD 95 and a gas water heater USD 82 whereas a solar wateris USD 95 and a gas water heater USD 82 whereas a solar water heater only has a USD 27 average annual cost (IEA, 2010).heater only has a USD 27 average annual cost (IEA, 2010). Although the upfront capital cost of solar water heaters is higherAlthough the upfront capital cost of solar water heaters is higher than for electric or gas water heaters, the average annualthan for electric or gas water heaters, the average annual investment over the lifetime of the heater is only a fourth to a thirdinvestment over the lifetime of the heater is only a fourth to a third of gas water and electric water heaters.of gas water and electric water heaters. ITC Maurya Hotel, New DelhiITC Maurya Hotel, New Delhi • Steam for Hospitality applications like Laundry, Cooking, Bathing • Delivery 8 bar (g) and 175°C • Capacity 80 – 100 kWth per dish K. N. Naik, CFSR knnaik@yahoo.com Page 13

- 14. • Dish numbers 2 dishes • Commissioning Nov 2009 • It saves ITC an equivalent of almost 40,000 to 42,000 litres of fossil fuel (furnace oil) per annum It is worthwhile imagining how much fuel andIt is worthwhile imagining how much fuel and electricity could be saved if all the 47 5-star hotelselectricity could be saved if all the 47 5-star hotels adopted solar thermal to meet their hot water and steamadopted solar thermal to meet their hot water and steam needs. And then extend the logic to all luxury hotels inneeds. And then extend the logic to all luxury hotels in Delhi and then all over the country!!!!Delhi and then all over the country!!!! As the major part of the used energy is produced using conventional fuels like gas, coal and petroleum products, reducing the energy consumption would contribute to reduction CO2 emissions. One of the best ways to reduce emission is by using solar thermal concentrators as most of the hotels’ thermal requirement canmost of the hotels’ thermal requirement can be met with i.e.: (Hot water &steam)be met with i.e.: (Hot water &steam) •• Solar water heating systems for bathing, washing,Solar water heating systems for bathing, washing, cleaning, pre-boiler applications etc.cleaning, pre-boiler applications etc. •• Solar steam generating systems for cooking, laundry,Solar steam generating systems for cooking, laundry, air conditioning etc.air conditioning etc. Solar CookingSolar Cooking A number of religious establishments and some others have set up huge solar cooking systems which are described below. Why not make it mandatory for industrial, commercial and public establishments involving large community cooking facilities (Canteens)?? Swaminarayan Akshardham MandirSwaminarayan Akshardham Mandir in New Delhi launched ARUN®100 at the Mandir premises. ARUN®100 solar thermal system will provide enough steam to cook an equivalent of 3500-4000 meals (consisting of rice, vegetables and dal) daily. Harmandar Sahib's Guru Ram Dass 'langar'Harmandar Sahib's Guru Ram Dass 'langar' (community kitchen) based on solar energy will save a great deal of wood, LPG (liquefied petroleum gas) and also electricity in the community kitchen. K. N. Naik, CFSR knnaik@yahoo.com Page 14

- 15. The Sabarmati Central JailThe Sabarmati Central Jail has installed 24 concentrated solar dishes which generate steam at high temperature to cook food for 3000 prisoners daily. World’s largest solar steam system is installed at Sri SaiSri Sai Baba Sansthan.Baba Sansthan. The solar system enables the sansthan to cook food for 20,000 people a day, resulting in a huge annual savings of one lakh kg. LPG translating to nearly Rs.20,00,000 per year. At TirupatiTirupati the system of 106 solar dishes that use solar energy to convert water into steam, which is then used for all the cooking. It saves Tirupati 1.2 lakh litres of diesel every year. It takes less than 20 minutes to cook an entire meal. They have been using this for more than 8-9 years. ISRO AhmedabadISRO Ahmedabad placed an order for Solar Steam Cooking Systems. Due to space constraint it was a very difficult and a challenging job to install the 2 parabolas of 16M2 on the roof of the kitchen. The shape of the terrace was such that water storage tank needed to be placed outside the terrace which would increase the piping cost and other expenses. After the completion of the project, ISRO has been savingAfter the completion of the project, ISRO has been saving 60% of CNG which it used before.60% of CNG which it used before. They are so happyThey are so happy with the system that they are planning to install 3with the system that they are planning to install 3 another Steam Cooking System for 1000 people per day.another Steam Cooking System for 1000 people per day. Energy Independent Solar Home may not be far off!!!! Green Power Resource Management (GPRM) plans to start volume production of its solar powered air conditioner and virtual power plant. The packaged unitThe packaged unit provides cooling, AC power out, and backup energy powered directly from solarprovides cooling, AC power out, and backup energy powered directly from solar panels for residential and small commercial buildings.panels for residential and small commercial buildings. The GPRM 100 solar powered air conditioner and virtual power plant runs directly off solar panels, a wind turbine, batteries or the AC power in a home or office. It also provides renewable energy to other devices like a TV, lights, refrigerator or a computer even when the grid is down. The GPRM 100 introductory package includes: 13,500 BTU/hr cooling capacity (up to 1,000 SF depending on energy efficiency of structure), battery backup providing 450 Ah of power, and two plug-in receptacles providing 1,500 W/hr ac power out. K. N. Naik, CFSR knnaik@yahoo.com Page 15

- 16. Industrial Solutions for Solar Thermal Process HeatingIndustrial Solutions for Solar Thermal Process Heating and Coolingand Cooling Large Scale Solar Thermal Systems – Process Heat (potential) Global industrial processes have significant thermal energyGlobal industrial processes have significant thermal energy needs that are addressable by solar thermal energyneeds that are addressable by solar thermal energy conversion systems. Any industrial process that requiresconversion systems. Any industrial process that requires heat at temperatures below 250°C is readily addressable byheat at temperatures below 250°C is readily addressable by a solar thermal energy system.a solar thermal energy system. Sector Heating % Cooling % 1 Automobile -- 30 2 Breweries 25 20 3 Dairy 55 15 4 Food Processing 60 10 5 Leather 10 35 6 Petroleum offshore rigs -- 25 7 Pharmaceuticals 60 20 8 Rubber -- 20 9 Pulp and Paper -- 70 10 Textile (Spinning & weaving) -- 20 11 Textile (Finishing) 5 20 12 Electroplating / Galvanizing -- 25 13 Tea and Tobacco Processing 10 10 14 Agro Malls 5 -- 15 Jute -- 10 Processes and Temperature LevelsProcesses and Temperature Levels K. N. Naik, CFSR knnaik@yahoo.com Page 16

- 17. The key difference is the dispatchable nature of fossil fuels.The key difference is the dispatchable nature of fossil fuels. Solar heat must be stored to achieve some level ofSolar heat must be stored to achieve some level of dispatchability, or the industrial process that uses the heatdispatchability, or the industrial process that uses the heat must be flexible to adjust and only use the heat when themust be flexible to adjust and only use the heat when the solar resource is available.solar resource is available. Most often, some combination ofMost often, some combination of a small storage solution along with modifications to thea small storage solution along with modifications to the industrial process is the best solution.industrial process is the best solution. Solar industrial process heatSolar industrial process heat The global energy need for heat is significant in both OECD and non-OECD countries: in 2009 the IEA reported that global energy demand for heat represented 47% of final energy use. Solar heat thus can make a substantial contribution in meeting climate change and security objectives. Industrial process heat offers enormous potential in sectors that use low- and medium temperature heat for processes such as washing, leaching (mining industry), drying of agricultural products, pre-heating of boiler feed water, pasteurisation and cooking. A number of industrial sectors use a significantA number of industrial sectors use a significant proportion of their process heat at temperatures <120°Cproportion of their process heat at temperatures <120°C and are therefore likely to have a strong potential forand are therefore likely to have a strong potential for solar thermal to meet their process heat needs.solar thermal to meet their process heat needs. Examples of these sectors are transport equipment, machinery, mining and quarrying, dairy, food and tobacco, and textiles and leather. Many processes and activities common to these sectors can use solar thermal systems such as washing, leaching (mining industry), K. N. Naik, CFSR knnaik@yahoo.com Page 17

- 18. cooking, drying, preheating of boiler feed water and space heating in industrial buildings. Solar thermal technologies used for low- temperature applications in industry are similar to those in buildings: typically, flat-plate or evacuated tube collectors. For medium and high-temperature applications, concentrating solar technology will be needed, although these applications will be limited to areas with good DNI. In the vision described in “Technology Roadmap-Solar Heating and Cooling” developed by IEA, solar heat has a significant role to play in the industrial sector. By 2050, the ETP 2012 2DS scenario estimates the potential for solar heat in industrial applications to contribute up to 7.2 EJ per year (1 Exajoule(1 Exajoule [EJ][EJ] == 947817120.31 MMBtu or 26.9 BCM of Natural Gas947817120.31 MMBtu or 26.9 BCM of Natural Gas), on the basis of an installed capacity of over 3200 GWth, in industrial low temperature applications up to 120°C. Since India imports almost eighty percent of its oilimports almost eighty percent of its oil consumption (as also gas and coal)consumption (as also gas and coal), industries are facing a risk due to volatile international crude oil prices. Several applications are possible by harnessing solar thermal energy, utilising it to generate solar steam is the most economically viable. Not only does it offer a potential solution to the oilNot only does it offer a potential solution to the oil security threat confronting India, but also a remedy to thesecurity threat confronting India, but also a remedy to the environmental damage caused by conventional fuels.environmental damage caused by conventional fuels. Since India has a higher share of these energy intensive industries, its shares for low-temperature process heat are somewhat lower. It will have to adopt solar thermal technologies which can service medium and high temperature applications. Advanced flat-plate and evacuated tube collectors that can supply temperatures up to 120°C. For temperatures between 100°C and 400°C current solar collectors are not yet market mature. In this respect, double glazed flat-plate collectors with anti-reflection coated glazing, stationary CPC collectors and Maximum Reflector Collectors should be further developed and commercialised. Challenges consist of material resistance to high temperature levels and durability of components. Concentrating solar heating technology development today is mainly focusing R&D resources on goals related to power production, e.g. realising higher temperatures. But the thermal K. N. Naik, CFSR knnaik@yahoo.com Page 18

- 19. energy produced by concentrating solar technology can also be used for heat applications, e.g. for high-temperature industrial processes in areas with good levels of direct normal irradiance (DNI) although this application has thus far received far less attention. Parabolic trough collectors, parabolic dishes and linearParabolic trough collectors, parabolic dishes and linear concentrating Fresnel collectors can be adapted to serveconcentrating Fresnel collectors can be adapted to serve medium-temperature process heat applications.medium-temperature process heat applications. This requires development of, for example, smaller scale concentrating solar collectors, which can be installed on rooftops of industrial production halls, and which produce the appropriate temperatures for the processes. Deployment of concentrating solar technology in industry will need adapted industrial system designs and optimisation of industrial processes to increase the potential integration of solar concentrating technology. Standardised system integration for solar heat in industrial processes is needed to encourage this use of concentrating solar technology. Concentrated solar thermal:Concentrated solar thermal: • Heat generation with the same quality as the industrial boiler (T, P) • Solar collector field as additional, parallel (or serial) boiler, injects steam or hot water into the existing distribution network • Collectors can be “Switched off” (defocused) Compared to low temperature solar heat:Compared to low temperature solar heat: • No disruption / influence on production processes, very simple interface • Solar heat is delivered to several (all) processes, leading to a smoother load profile • “Self-regulating” system between solar and conventional boiler India’s oil products consumption increased to 196.5 million tons last year from 177.5 million tons in 2015, of which 40 % is consumed in industries. Out of this 40-50 % is used forOut of this 40-50 % is used for thermal energy applications below 250 0C. Use of solarthermal energy applications below 250 0C. Use of solar thermal energy to meet some of these thermal needs will bethermal energy to meet some of these thermal needs will be leading to savings of about 4.5 million tons of LPG, furnaceleading to savings of about 4.5 million tons of LPG, furnace oil, LDO or diesel.oil, LDO or diesel. India has a large number of small,India has a large number of small, K. N. Naik, CFSR knnaik@yahoo.com Page 19

- 20. decentralized industrial units, where this technology candecentralized industrial units, where this technology can be used, leading at the same time to a reduction in oilbe used, leading at the same time to a reduction in oil imports.imports. There are several potential fields of application of solar thermal energy in the temperature range of 60°C to 180 °C, like heat production for industrial processes in the food, textile, wine and chemical industries, solar cooling and air conditioning, solar drying and seawater desalination, thermal detoxification of drinking water, small power generation and water pumping through medium temperature Rankine cycle systems. Solar concentrating collectors can be retrofitted to the existing boiler or heater system in the industry, substituting the use of furnace oil or electricity used for the heating application partially or fully. Heat requirement in some industries is discussed below: Brewing and Malting In the brewing process thermal energy accounts for 77 % of the total final energy demand. The principal consumers are the wort boiling (24-50 %), the bottle washers (25-38 %), and pasteurisation. Solar thermal energy can be used for low pressure steam generation (at 104 – 110 ºC and for refrigeration of the wort (absorption cooling). In the malting process the principal energy consumption is for drying of the barley, before malting, and of the grains after germination to stop germination and for conservation (hot air at 60 – 80 ºC) and for cooling of air in the germination process (during the summer months). A 1,470 m² solar thermal collector field provides hot waterA 1,470 m² solar thermal collector field provides hot water for the mashing process in the breweryfor the mashing process in the brewery Göss, Austria. TheGöss, Austria. The mashing process has been changed to a low-temperature-mashing process has been changed to a low-temperature- process by integrating additional heat exchanger plates.process by integrating additional heat exchanger plates. Hot water is now used instead of steam, which allowsHot water is now used instead of steam, which allows better renewable energy integration.better renewable energy integration. Milk industry The country is the world's largest milk producer,The country is the world's largest milk producer, accounting for more than 13% of world’s total milkaccounting for more than 13% of world’s total milk production.production. K. N. Naik, CFSR knnaik@yahoo.com Page 20

- 21. Pasteurisation (62 – 85 ºC) and sterilisation (130-150 ºC) processes consume 23 % of energy in Portuguese milk industry. Drying of milk powder is another important consumer. Heating waterHeating water accounts for more than 30% of the energy in Dairyaccounts for more than 30% of the energy in Dairy Industry of India.Industry of India. The solar steam or pressurized hot water generated by solar boiler / solar thermal concentrator can be used in the following processes: • Solar thermal assisted Pasteurization • Milk powder • Can Washing • Cleaning in Place(CIP) • Crate washing • Sterilization Food preservation Several processes were identified, where solar thermal energy could be used: scalding of vegetables, sterilisation (vegetables, fish, meat, baby food) with hot water or direct steam, scalding, cleaning and pre-cooking of fish, sealing and cleaning of cans, cooking. In addition cold demand can be covered by solar cooling and refrigeration. The following processes can gainfully utilise solar thermal energy: • Pasteurization – solar steam heating • Drying of vegetables / fruits – solar hot air • Frying of edible items – hot thermic oil • Pasteurization – solar steam The process of drying can be done by various methods. Passing hot air over these products is the most popular method. With modern solar hot air generation systems, temperatures of 110-200°C can be achieved, which can boost the rate of drying to a great extent. A major section of the Food processing industry deals with drying of agricultural products for better preservation, long term storage and exports. In India, a large chunk of the drying is still done byIn India, a large chunk of the drying is still done by drying the product out in the sun. This not only takes a lotdrying the product out in the sun. This not only takes a lot of time (usually in days) but is also very unhygienicof time (usually in days) but is also very unhygienic because of possible contamination.because of possible contamination. Solar dryer can be used for fruits (apples, apricots, grapes, pineapples and banana taste great K. N. Naik, CFSR knnaik@yahoo.com Page 21

- 22. when dried, melon, plums, beets, mangoes, dates, figs), vegetables (cabbage, broccoli, peppers, herbs, onions, squash, tomatoes, asparagus, celery, potatoes, peas, carrots, peppers, cassava, yams, red cedar, mahogany) corn, maize, rise, cassava, cocoa, fish, meat, mushrooms, spices (dried chili peppers, garlic) tea, coffee, cacao, tobacco, cashew and macadamia, milk, hay, copra (kernel of the coconut), but also clothing, wool, kindling and also for treating timber and many more. Solar Dryer removes unnecessary moisture from theSolar Dryer removes unnecessary moisture from the product with retention of original color and taste as well asproduct with retention of original color and taste as well as keeps the product free from any environmental factor,keeps the product free from any environmental factor, dust, dirt, animal or bird droppings.dust, dirt, animal or bird droppings. The recent trend in this industry is frying using thermic oil system. Frying requires thermic oil at temperatures above 250°C. The ARUN® concentrated solar thermal (CST) system can be used to provide thermic oil up to 300°C for solar cooking applications. Many dairy products or other easily perishable products are pasteurized by heating and cooling them immediately one after another. The heating of the product is generally carried out using steam of around 6 bar. This steam can be generated with the help of concentrated solar thermal solar system. Unglazed transpired collectors are perforated sun-facing walls used for preheating ventilation air. Transpired collectors can also be roof mounted for year-round use and can raise the incoming air temperature up to 22 °C and deliver outlet temperatures of 45- 60 °C. As of 2015, over 4000 systems with a combined collector area of 500,000 m2 had been installed worldwide. Representatives include an 860 m2 collector in Costa Rica used for drying coffee beans and a 1300 m2 collector in Coimbatore, India used for drying marigolds. A food processing facility in Modesto, California uses parabolic troughs to produce steam used in the manufacturing process. The 5,000 m2 collector area is expected to provide 15 TJ per year. Textile industry Textile processing requires a lot of hot water in the range of 40– 110˚C at various stages of the process. The requisite heat can easily be generated through solar energy. K. N. Naik, CFSR knnaik@yahoo.com Page 22

- 23. Heating of liquid baths close to 100 ºC for washing, bleaching and dyeing is an important energy consumer in textile industry. Drying processes usually use hot air or gases from 140 to 220 ºC. The following processes can use solar thermal energy: • Yarning – solar hot air • Weaving – solar steam • Dying – solar hot water • Bleaching – solar hot water • Drying – solar hot air • Steam pressing – solar steam • Curing – solar steam Conventional Energy replacement potentialConventional Energy replacement potential K. N. Naik, CFSR knnaik@yahoo.com Page 23

- 24. Automobile sector and Auxiliary industry for the automobile sector The Indian automobile industry is one of the largest in theThe Indian automobile industry is one of the largest in the world with anworld with an annual production of 2,33,66,246annual production of 2,33,66,246 automobiles.automobiles. Manufacturing of automobiles and auto components involves many steps such as casting, forging, painting and electroplating etc that require heat or steam. Thermal energy in form of heat or steam accounts for around 70% of all automobile industry's total energy consumption Following applications can use solar thermal energy: •• Degreasing through solar steamDegreasing through solar steam •• Drying through solar hot airDrying through solar hot air •• Heating of tanks through solar heaterHeating of tanks through solar heater •• Low temperature tempering through solar hot airLow temperature tempering through solar hot air •• Paint Baking using solar hot airPaint Baking using solar hot air The entire process requires large amount of energy in the form of both heat and electrical energy. Some of the typical processes in the automobile manufacturing are explained in the following figure. K. N. Naik, CFSR knnaik@yahoo.com Page 24

- 25. For textile and plastics hot water and steam is used for preparation, bleaching, dyeing, painting and finishing processes. For tyre manufacturing high pressure steam of 20-25 bar is used for rubber treatment. Pressured Hot water at a temperature of about 90°C sprays over the automobile engine parts to remove the dust content. The hot water needed for spraying is heated either by electrical heaters or natural gas based heating sources. The cleaned parts from Degreasing are dried in the hot air chamber in which the hot air is blown at 90°C. The hot air used is heated by using electrical coil heaters or natural gas based burners. The casted or moulded automobile parts after processing are dried by hot air blown by hot air blower at high temperature of 100°C. A standard 7 tanks or DIP ZINC PHOSPHATING process is used. All heated tanks are heated directly by electrical immersion hot water heaters or closed steam coils. After each coat of paint on automobile, the paint is baked in baking oven using hot air heated either by electrical coils or gas burners. The temperatures needed in baking ovens range around 200 °C. Applications of solar thermal technology in different automobile production process Process steps Energy or fuel being used Application media Temperature need °C Recommended solar technology Degreasing of automobile parts or part cleaning Natural gas Pressured Hot water 90 Evacuated tube collectors K. N. Naik, CFSR knnaik@yahoo.com Page 25

- 26. Drying of cleaned parts Natural gas Hot air 90 Parabolic trough collectors with air as working medium Dip zinc phosphating process Electricity Hot water 80 Flat plate collector Mould drying Electricity Hot air 100 Solar air heaters Tempering in furnace Natural gas Hot air 200 Solar air heaters with Concentrating collectors Paint shop Preconditioning that is Hot water rinsing of automobile body in paint shop Electricity Hot water 40 Flat plate collector Paint shop that is curing of automobile paint in paint baking ovens Natural gas Hot air 200 Linear Fresnel concentrating collectors Paint shop air- conditioning of wet paints in the paint shop Natural gas Hot or Cold air supply 50 Evacuated tube collectors based chillers Paint shop evaporation drying Natural gas Hot air supply 100 Solar air heating Paper industry The pulp and paper sector is one of the most energyThe pulp and paper sector is one of the most energy intensive and highly polluting sectors.intensive and highly polluting sectors. The operations of pulp making, pulp processing and paper making require large amount of thermal energy in the form of hot water (60 °C) or low pressure steam (up to 150°C). This requirement of the thermal energy can be easily fulfilled by the solar thermal systems like ARUN solar boiler. The processes with which solar thermal or concentratedThe processes with which solar thermal or concentrated solar thermal (CST) systems can be integrated are markedsolar thermal (CST) systems can be integrated are marked with (*).with (*). K. N. Naik, CFSR knnaik@yahoo.com Page 26

- 27. Tanning In the tanning industry a potential for solar energy exists for generation of saturated steam at 7 – 10 bar. The retanning process is a common process to be targeted by solar process heat. Currently 9 applications are successfully operating with a total gross solar area of 5,317 m². Chemical Industry The typical energy intensive processes in the chemical plant are distillation, evaporation, packaging, centrifuging and drying. Heat is required in almost all forms such as low and high pressure steam, hot water and hot air. Also there is large demand for refrigeration and air conditioning, for process and storage requirements of some chemicals. The solar steam generator assisted vapour absorption system is perfectly suitable for the air conditioning loads in the plant. The processes that can be integrated with the solar thermalThe processes that can be integrated with the solar thermal system are marked with (*).system are marked with (*). K. N. Naik, CFSR knnaik@yahoo.com Page 27

- 28. Pharmaceutical industry The manufacturing processes are generally highly energy intensive and the requirement of the thermal and electrical energy varies depending on the product. The thermal energy requirement typically consists of low pressure steam (~ 5 bar, 150°C), hot water (60 – 80°C). Some of the industries also require hot air at 60 – 80°C in large quantities. This temperature ranges are very muchThis temperature ranges are very much suitable for the integration of solar thermal systems in thesuitable for the integration of solar thermal systems in the process.process. Two typical processes in pharmaceutical industry that require heat in some form are explained below. • Sterilizers can use either hot air or steam for sterilization of the products (medicines). The hot air is used generally at 160°C at least for 2hours. The sterilizers that use steam have pressure range up to 2 bar-121°C. Concentrated solar thermal technologies (CST) can be of great help in this process. • There are several types of granulation processes e.g. wet granulation, fluid bed granulation, spray drying granulation etc. the granulation process typically requires hot air at 60- 70°C at very high flow rate up to 250 m³/hr. Another process where CST technologies are applicable. Mining Industry K. N. Naik, CFSR knnaik@yahoo.com Page 28

- 29. The Codelco copper mine in Chile not only has the world'sThe Codelco copper mine in Chile not only has the world's largest SHIP application, but also the largest solar thermallargest SHIP application, but also the largest solar thermal collector field (39,300 m²). The system keeps water at acollector field (39,300 m²). The system keeps water at a constant temperature for the leaching process.constant temperature for the leaching process. A similar, but smaller application (790 m²) exists in Cyprus. Modern uses (Modern uses (Evaporation ponds)Evaporation ponds) include concentratinginclude concentrating brine solutions used in leach mining and removingbrine solutions used in leach mining and removing dissolved solids from waste streams. Altogether,dissolved solids from waste streams. Altogether, evaporation ponds represent one of the largest commercialevaporation ponds represent one of the largest commercial applications of solar energy in use today.applications of solar energy in use today. COUPLING OF SOLAR SYSTEM AND CONVENTIONAL HEAT SUPPLY The central system for heat supply in most factories uses steam at a pressure corresponding to the highest temperature needed in the different processes. Typical temperatures are about 180 – 200 ºC. Solar steam production at these temperatures with reasonable efficiencies and cost is possible only with parabolic trough technology. The advantage of this option is the high and continuous demand, the simplicity of the system and no need for additional piping. Hot water or low pressure steam at medium temperatures (< 150 ºC) can be used either for preheating of water (or other fluids) used for processes (washing, dyeing etc) or for steam generation or by direct coupling of the solar system to an individual process working at temperatures lower than that of the central steam supply. Preheating of water yields high efficiencies due to the low input temperature of the solar system. However, an additional piping for preheated water supply to the processes is required. Some Case StudiesSome Case Studies K. N. Naik, CFSR knnaik@yahoo.com Page 29

- 30. Milk processing LESA Bever, SwitzerlandMilk processing LESA Bever, Switzerland • 115m2 / 190°C / Thermal oil / Indirect Steam Generation / Milk processing • Extreme alpine climate conditions at 1700m high site: -30°C, heavy snow, high UV EMMI Saignelégier, SwitzerlandEMMI Saignelégier, Switzerland • 627m2 / 125°C / Water-Antifreeze / Milk processing Project / Cheese Manufacturing • Temperatures as low as -20°C, 0.5m snow cover •• 627m2 Collector aperture, 360kWth, installed on new building627m2 Collector aperture, 360kWth, installed on new building •• Water/Glycol, 110-130°C Supply T.Water/Glycol, 110-130°C Supply T. •• HEX brings heat into existing 15m3 hot water storage.HEX brings heat into existing 15m3 hot water storage. •• In Series/Parallel with 2x 1MW oil fired boilersIn Series/Parallel with 2x 1MW oil fired boilers •• Started up in 2012Started up in 2012 •• Secondary circuit with Heat ExchangerSecondary circuit with Heat Exchanger •• ““Solar only” when solar production is sufficientSolar only” when solar production is sufficient •• In series with boilers (preheating) when solar output too low.In series with boilers (preheating) when solar output too low. CREMO Fribourg, SwitzerlandCREMO Fribourg, Switzerland •• 587m2 / 165°C Water / Waste heat for freeze protection /587m2 / 165°C Water / Waste heat for freeze protection / Milk processingMilk processing Galvanization Blum, Austria, 2011Galvanization Blum, Austria, 2011 •• Process heat for galvanization (5 working days per week)Process heat for galvanization (5 working days per week) Temperatures 75 / 85 °CTemperatures 75 / 85 °C •• Gross collector area 459 m²Gross collector area 459 m² •• Buffer tank volume 8 m³Buffer tank volume 8 m³ •• Max. Continuous power 230 kWMax. Continuous power 230 kW •• Yield / Year 150 MWhYield / Year 150 MWh Galvanization Zehnder, Switzerland, 2012Galvanization Zehnder, Switzerland, 2012 •• Process heat for galvanization (5 working days per week)Process heat for galvanization (5 working days per week) •• Temperatures 70 / 95 °CTemperatures 70 / 95 °C •• Gross collector area 400 m²Gross collector area 400 m² •• Buffer 5 m³Buffer 5 m³ Galvanization Hustert, Germany, 2011Galvanization Hustert, Germany, 2011 •• Process heat for galvanization (5 working days per week)Process heat for galvanization (5 working days per week) •• Temperatures 70 / 85 °CTemperatures 70 / 85 °C K. N. Naik, CFSR knnaik@yahoo.com Page 30

- 31. •• Gross collector area 221 m², no bufferGross collector area 221 m², no buffer Water Preheating for Steam Boilers in ChinaWater Preheating for Steam Boilers in China •• Gross collector area: 5.800 m²Gross collector area: 5.800 m² •• Solar temperature: 90 °C,Solar temperature: 90 °C, •• 2 x 30 m³ storage2 x 30 m³ storage Dairy, TYRAS S.A., Trikala, GreeceDairy, TYRAS S.A., Trikala, Greece •• Installed Capacity: 728 kWth (1040 m² FK)Installed Capacity: 728 kWth (1040 m² FK) Solar Heat for Copper Mining in Cyprus - 0.5MWthSolar Heat for Copper Mining in Cyprus - 0.5MWth •• Solar Leaching Field Pilot Implemented in 3 monthsSolar Leaching Field Pilot Implemented in 3 months Cairn India solves their Waste Water ProblemCairn India solves their Waste Water Problem •• To date, Cairn India has opened 4 frontier basins withTo date, Cairn India has opened 4 frontier basins with numerous discoveries, 38 in Rajasthan alone.numerous discoveries, 38 in Rajasthan alone. •• Exploration lot of Waste Water is generated which isExploration lot of Waste Water is generated which is contaminated with oil and minerals which cannot be thrown incontaminated with oil and minerals which cannot be thrown in the desert or river basinsthe desert or river basins •• it was decided to go in for a Solar based Waste Waterit was decided to go in for a Solar based Waste Water Evaporation on pilot scaleEvaporation on pilot scale •• The total requirement of Waste Water Evaporation is huge andThe total requirement of Waste Water Evaporation is huge and every day thousands of Gallons of Waste Water is generated byevery day thousands of Gallons of Waste Water is generated by oil drilling at Barmer site. At Present they have Solar Ponds tooil drilling at Barmer site. At Present they have Solar Ponds to evaporate water. To expedite the water evaporation CARIN hasevaporate water. To expedite the water evaporation CARIN has decided to go in for such a Pilot Plant which can increase thedecided to go in for such a Pilot Plant which can increase the Waste water evaporation.Waste water evaporation. •• The Waste water will be pumped on a Metal Open trayThe Waste water will be pumped on a Metal Open tray (painted with Marine paint) through a simple 0.5 H.P(painted with Marine paint) through a simple 0.5 H.P pump; from there it is falling on the Receiver bypump; from there it is falling on the Receiver by K. N. Naik, CFSR knnaik@yahoo.com Page 31

- 32. gravity. The receivers are heated by concentratinggravity. The receivers are heated by concentrating solar energy. The temperatures on the Receivers issolar energy. The temperatures on the Receivers is more than 1000 degrees C.more than 1000 degrees C. •• To take this project as a Pilot study, it is agreed upon to installTo take this project as a Pilot study, it is agreed upon to install 8 parabolas of 32 M2 for evaporating 10,000 liters of waste8 parabolas of 32 M2 for evaporating 10,000 liters of waste water per day.water per day. •• The project was successfully installed and is running withoutThe project was successfully installed and is running without any problems for last six months. After this pilot project Cairnany problems for last six months. After this pilot project Cairn India is going in for bigger size projectsIndia is going in for bigger size projects Frito Lay HeadquartersFrito Lay Headquarters •• Solar water-heating appliance provides immediate savings onSolar water-heating appliance provides immediate savings on electric costselectric costs •• 25-year lifetime of the appliance25-year lifetime of the appliance •• Solar energy delivered –First year: 87,000 kWhSolar energy delivered –First year: 87,000 kWh •• Design capacity: 121,000 kWhDesign capacity: 121,000 kWh •• Expandable design allows facility to accommodate larger waterExpandable design allows facility to accommodate larger water loads in the future and further reduce energy costs. Expansionloads in the future and further reduce energy costs. Expansion to fitness center in 2009to fitness center in 2009 •• Retrofit design plumbs into existing electric hot-water tanks.Retrofit design plumbs into existing electric hot-water tanks. Existing tanks act as back-up to ensure hot water is alwaysExisting tanks act as back-up to ensure hot water is always availableavailable •• 5-year payback expected after first year of operation results5-year payback expected after first year of operation results with an annual solar fraction of 65%with an annual solar fraction of 65% Frito Lay, ArizonaFrito Lay, Arizona •• Installed collector area (gross), 5068.0 m²Installed collector area (gross), 5068.0 m² • Installed thermal power (estimated), 3547.6 kWth • Solar thermal energy used for Steam heating the oil to fry potato chips Williams-Selyem Estate WineryWilliams-Selyem Estate Winery System At A GlanceSystem At A Glance LocationLocation Healdsburg, Calif.Healdsburg, Calif. BuildingBuilding WineryWinery CollectorsCollectors 14 Heliodyne Gobi 40814 Heliodyne Gobi 408 Total Collector AreaTotal Collector Area 451 square feet451 square feet Solar Pump StationSolar Pump Station Custom BuiltCustom Built Solar StorageSolar Storage CapacityCapacity 700 gallons700 gallons K. N. Naik, CFSR knnaik@yahoo.com Page 32

- 33. Hot Water LoadHot Water Load xxx gallons/dayxxx gallons/day Therms Offset (1 Year)Therms Offset (1 Year) 1,820 therms (estimated)1,820 therms (estimated) Carbon Offset (1 Year)Carbon Offset (1 Year) 1.8 cars off the road1.8 cars off the road Annual SavingsAnnual Savings US$6,000 (propane costs)US$6,000 (propane costs) SunWater Solar designed and installed a closed-loop glycol solar thermal system for process heating at Williams Selyem Estate Winery. Hot water produced by the system is used for wash-down of barrels, tanks, equipment and floors, as well as bottling line/bottle sterilization before filling. Mahanand DairyMahanand Dairy •• (100% on ARUN, since 2006)(100% on ARUN, since 2006) •• Pressurized Hot Water for Milk Pasteurization with storagePressurized Hot Water for Milk Pasteurization with storage •• Saves about 22,000 lit/pa of FOSaves about 22,000 lit/pa of FO Mahindra & Mahindra, PuneMahindra & Mahindra, Pune •• The manufacturing process includes many applications thatThe manufacturing process includes many applications that require thermal energy in the low or medium temperaturerequire thermal energy in the low or medium temperature range (60 – 150°C) for e.g. component cleaning, componentrange (60 – 150°C) for e.g. component cleaning, component drying, 7 tank process etc.drying, 7 tank process etc. These processes are quite suitableThese processes are quite suitable for integration of solar thermal concentrators. One ARUN®160for integration of solar thermal concentrators. One ARUN®160 solar boiler generating system generates hot water undersolar boiler generating system generates hot water under pressure, which is used for engine component cleaningpressure, which is used for engine component cleaning process.process. •• Pressurized Hot Water for Degreasing ProcessPressurized Hot Water for Degreasing Process •• Saves equivalent of 18,000 lit/pa of FOSaves equivalent of 18,000 lit/pa of FO •• The project payback period was around 2 years due to savingsThe project payback period was around 2 years due to savings made in electricity purchase costs and project life cycle was formade in electricity purchase costs and project life cycle was for 25 years.25 years. Harita Seating Systems LtdHarita Seating Systems Ltd • A leading manufacturer of automotive seating systems in India • The company uses liquefied petroleum gas (LPG) for their heating requirements in their pre-treatment processes. • A 360kW online rooftop solar thermal system provides required temperature to the process tanks. This system hasThis system has the potential to replace 20 to 25 tonnes of LPG perthe potential to replace 20 to 25 tonnes of LPG per year.year. K. N. Naik, CFSR knnaik@yahoo.com Page 33

- 34. Sona Koya Steering SystemsSona Koya Steering Systems • They have installed solar water heater systems • It is to replace diesel in their pressurized water heating systems. The solar system delivers 1260 KWh / day solar thermal energy, resulting in Diesel savings of 36,000 litresDiesel savings of 36,000 litres per year.per year. Wheels IndiaWheels India • A solar ESCO has been delivering heat from a 1,365 m² evacuated vacuum collector field for over two years now. • The solar-heated water at 75 °C is used to degrease the wheels prior to final painting, a process which had been supplied by oil boilers before causing high energy costs. • The solar thermal system saves as much as Indian Rupeesaves as much as Indian Rupee (INR) 8 million in fuel oil over the first 2 years in(INR) 8 million in fuel oil over the first 2 years in operation.operation. •• Payback period was around 2 years.Payback period was around 2 years. SKF technologies Private ltd, MysoreSKF technologies Private ltd, Mysore • Manufacturing facility for sealing solutions used in automotive applications • Parabolic trough collectors heat the water used for circulation through treatment tanks for phosphating process where the desired temperature required is 95°C. • Payback period for the entire project was 4 yearsPayback period for the entire project was 4 years due to huge saving for the owner against diesel fuel used earlier for heating purposes. "Solar Process Heat" installation in a concrete factory in Upper"Solar Process Heat" installation in a concrete factory in Upper AustriaAustria • company produces pre-fabricated concrete elements for walls and ceilings • The decision was taken to install a solar process heat system instead of a conventional oil system. The installation is in operation since December 2009 and consists of 315 m² large solar thermal collector plant and 3 buffer storages (12,000 liter each). The total heat demand to be covered (production and space heating) is about 530,000 kWh/a. In addition to the solar thermal plant, a 200 kW wood chip boiler provides heat. K. N. Naik, CFSR knnaik@yahoo.com Page 34

- 35. About 30% of the heat needed for the production and for heating the production facility comes from the solar thermal system. • Compared to heat provision with oil, 25,000 Euro annually can be saved. Stapleton-Spence Packing CompanyStapleton-Spence Packing Company • A California food processor saves thousands of dollars in annual water heating costs using solar thermal system. • Processing and packing over 8,000 tons of dried plums in a year, the company was using roughly 650,000 therms of natural gas annually to preheat the water — at a very high cost. • Before the solar installation, a boiler was used to heat well water from 60° Fahrenheit up to steam temperature. With the solar system installed, the water is now “pre-heated” through the solar thermal system as it comes from the well and is sent to the boiler approximately 30 degrees warmer, where the boiler does the remainder of the heating. This dramatically reduced the energy costs, saving an estimated 37,500 therms per year. That’s equivalent to 1 million kWh or a carbon footprint offset of 1.4 million pounds of CO2. First Year Energy Savings $16,500 Payback in Years 3.5 Return on Investment 25% Tapi FoodTapi Food • Most of the Tapi Food factory’s energy has come from a solar thermal concentrating system installed on its roof. The well- performing system has become a landmark project for India’s food processing sector. Other process industries have already commissioned another 10 of those systems. • It has installed 10 dishes of 10 m² each on the roof of the factory. Using automatic tracking, the dishes produce 400 kg of steam at about 6 bars to heat a special type of steam- jacketed kettle. Even after five years, the system continues to run successfully. K. N. Naik, CFSR knnaik@yahoo.com Page 35

- 36. Chemical Industry Heavy water Board, KotaChemical Industry Heavy water Board, Kota • The heat generated through ARUN solar thermal system is utilized for effluent evaporation application. • The four dish ARUN®160 solar boiler / concentrated solar thermal generating system generates steam at 5 bar pressure at a 150 °C. • Dry saturated steam at 5 bar, 150°C is directly mixed with the effluent tanks to evaporate the water. • Comparison of energy price and collector areaComparison of energy price and collector area Solar Industrial Process CoolingSolar Industrial Process Cooling Industrial refrigeration, as in the food processing sector, is also an attractive candidate for solar thermal air conditioning technology. In fact for all buildings in a power plant should be mandated to replace conventional air conditioning plants by air conditioning plant that use either recycled heat or solar thermal heat. K. N. Naik, CFSR knnaik@yahoo.com Page 36

- 37. TVS Group, ChennaiTVS Group, Chennai • Pressurized Hot Water for Comfort Cooling • Saves about 35,000 lit/pa of diesel Matching Technology with Need Tail Piece Nothing is more powerful than an idea whose time hasNothing is more powerful than an idea whose time has come.come. • Victor Hugo The man with a new idea is a Crank until the ideaThe man with a new idea is a Crank until the idea succeeds.succeeds. • Mark Twain A Solar Boiler = Conventional boiler + 25 years fuel tankA Solar Boiler = Conventional boiler + 25 years fuel tank K. N. Naik, CFSR knnaik@yahoo.com Page 37

- 38. How much would you pay today for a fuel tankHow much would you pay today for a fuel tank containing 25 years of fuel?containing 25 years of fuel? India’s National Solar Mission target of 15 million m2 ofIndia’s National Solar Mission target of 15 million m2 of solar thermal collector area by 2017, and 20 million m2solar thermal collector area by 2017, and 20 million m2 by 2020.by 2020. K. N. Naik, CFSR knnaik@yahoo.com Page 38