CoFold Mortice Sliding Folding Door Gear Installation Instructions

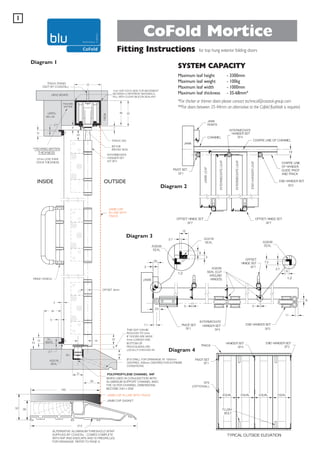

- 1. 1 CoFold Mortice Fitting Instructions Diagram 1 for top hung exterior folding doors SYSTEM CAPACITY Maximum leaf height Maximum leaf weight Maximum leaf width Maximum leaf thickness - 3300mm - 100kg - 1000mm - 35-68mm* *For thicker or thinner doors please contact technical@coastal-group.com. **For doors between 35-44mm an alternative to the Cofold flushbolt is required. INSIDE OUTSIDE Diagram 2 JAMB CAP IN LINE WITH TRACK Diagram 3 Diagram 4 34 140 WHEN USED IN CONJUNCTION WITH ALUMINIUM SUPPORT CHANNEL 94SC THE OUTER CHANNEL DIMENSIONS BECOME 23H x 25W JAMB CAP IN LINE WITH TRACK JAMB CAP GASKET 52 39 212 ALTERNATIVE ALUMINIUM THRESHOLD SF94T SUPPLIED BY COASTAL - COMES COMPLETE WITH 94P AND ENDCAPS AND IS PREDRILLED FOR DRAINAGE. REFER TO PAGE 9

- 2. 2 PREPARATION SF1 SF2R SF2L SF3 SF4 SF5 SF6 SF7 SF8 SF9 SF10 - Pivot Assembly Set End Hanger Set Right Hand End Hanger Set Left Hand Hinge Set with Handle Intermediate Hanger Set Hinge Set Inward Opening Hinge Set Offset Inward Opening Hinge Set Offset Outward Opening Rebated End Hanger Meeting Pivot Hinge for Doors Over 2200mm High Face Fix Handle (Optional) Diagram 6 Diagram 5

- 3. 3 Preparing the opening Ensure the opening is square and all load bearing areas are suitable for the weight of the system.Take particular care to ensure there is sufficient strength in the structure above the opening to take the concentrated weight of the doors, when in the open stacked position. The Cofold system provides +/- 3mm of horizontal and vertical adjustment. Use a plumb line to ensure that the centre line of the track and the centre line of the channel are offset by 19mm. Diagram 8 OR USE ALUMINIUM THRESHOLD BY COASTAL Diagram 7 Diagram 9 Preparing the door frame Refer to page 10 = = Diagram 10

- 4. 4 Preparing the door leaves Door leaf width calculation 1. Decide how many door leaves you want in the opening. 2. Add together all the 3mm clearances required between door leaves and the jambs (there will be one more than the number of door leaves).This is the total clearance figure. 3. Measure the finished opening width (W) and deduct from this the total clearance figure. 4. Divide this new figure (finished opening width minus total clearance) by the number of doors to produce the actual door width. (N.B. all doors with the CoFold system are the same width). For example: For a 4 door leaf system with a finished opening width of 2345mm the door leaf width would be 2345mm minus (5x3mm) divided by 4 (number of door leaves) = 582.5mm. Door leaf height calculation Leaf height = finished opening height (see diagram 7) minus 66mm. Diagram 11 PREPARING THE DOOR LEAF AT THE JAMB Door Seals Prepare the door leaves to accept the AQ63B seal. BETWEEN DOOR EDGES Diagram 12 ADD 10mm TO WIDTH OF EACH LEAF TO CREATE REBATE ADD 10mm TO WIDTH OF END HANGER LEAF FOR REBATE Meeting Doors Use the SF8 set for 2+2 rebated timber door configurations. For all other configurations use SF2L (left hand) or SF2R (right hand) end hanger sets. For kit handing refer to diagram 6. Diagram 13

- 5. 5 Door hardware positioning Diagram 14 End door leaf Preparation 7.5mm check In for SF1, SF2 and SF8 Diagram 15

- 6. 6 Door hardware attachment 2 WHEEL ASSEMBLY SIDE THRUST BEARING Ø 3mm PILOT HOLES FIXING SCREW (6 OFF) CHECK IN FOR SF9 HANGER BODY COVER (SLIDE) IMPORTANT WASHER HANGER BOLT BOTH SCREWS MUST BE FITTED UNDER THE COVERS OF ALL THE END HINGES Kit SF1 Kit SF2L (or SF2R) Kit SF8 Kit SF4 Diagram 16

- 7. 7 INSTALLATION 1. Ensure that you have all the required parts. Unpack the components and identify the parts. Lay the parts on the ground in the same configuration as they will be when installed. It is recommended that a light smear of general purpose grease is applied to all bolts prior to assembly. Diagram 17 2. Cut the track to the required length and pre-drill for fixings in accordance with diagram 17. Please note that the extra fixings are required where the doors stack together. TOP PIVOT SECURING BLOCK 3. Cut the channel to the required length and fit in the sill. Drill drainage holes (see diagram 1). PIVOT SECURING BLOCK HEX BOLTS 4. Remove all the wheel assemblies and pivot block from the hanger and pivot bolts, and disassemble top pivot block assembly. PIVOT CAM 5. Slide the wheel assemblies and track pivot block into the track in the correct order, orientation, and position and fix the track in position. Reassemble top pivot block assembly (see diagram 18). PIVOT ADJUSTER PIVOT CLAMP PLATE 6. Remove the bottom pivot assembly and guide roller assembly (see diagram 19). Disassemble the bottom pivot assembly. ADJUSTMENT LOCK OFF BOLTS Diagram 18 7. For installation, assemble leaves in pairs via the hinges. To improve the ease of installation pre-drill pilot holes for all hinge parts. Fit kits SF1, SF7,SF4 and SF9 (optional) to first pair of leaves. Please ensure all 5 screws are fixed per end hinge. 8. Screw the bottom anchor of the bottom pivot assembly to the base of the channel 11mm from the jamb. Please note, the screw nearest the end of the bottom anchor is closest to the jamb (see diagram 20). Reassemble the pivot assembly leaving the clamping screws loose (see diagram 24). 9. Suspend pairs of leaves by engaging top pivot and hanger bolts using 5mm allen key supplied (see top of diagram 19). 10. Attach the bottom pivot and guide assembly to their respective hinges, adjust the bottom pivot side plates position so that it engages with the hinge bolt.Tighten pivot and guide strap bolts (see diagram 21). 11. Lift the next pair of leaves into position and support their weight by screwing the hanger strap bolt into the hanger wheel assembly and fixing the second and third leaves together. Diagram 19 JAMB CHANNEL 12. Continue this procedure until all leaves are fitted. BOTTOM ANCHOR Diagram 20 Diagram 21

- 8. 8 ADJUSTMENT Height Adjustment (± 3mm) 1. Close leaves and adjust the door height to achieve an equal gap between the top of the leaves and the track (a 9mm gap is recommended). (see diagram 22). INSIDE LOCKING HANGER GRUB SCREW ON INSIDE OF DOOR 2. Once the adjustment is complete use the allen key to tighten the locking hanger grub screw until secure. Lateral Adjustment 1. With the unit still in the closed position, slide the set of leaves towards the jamb to obtain the desired gap between the jamb and the pivot door.A gap of 3mm is recommended using the adjustment cam. Once in position tighten the clamp screws. (see diagram 24). 2. Fold the leaves and adjust the bottom side plate using the allen key provided so that the gap between the door and the jamb is the same over the full length of the door. 3. Tighten the two clamping screws to lock the side plate to the bottom anchor. 4. Once the pivot door is in the correct position insert and tighten the locking pivot grub screw from the inside position. (as shown in diagram 23) SF4 ILLUSTRATED. SAME METHOD OF ADJUSTMENT APPLIED TO SF1, SF2L, SF2R AND SF8. CLAMP SCREW Diagram 22 INSIDE LOCKING PIVOT GRUB SCREW ON INSIDE OF DOOR CLAMP SCREW ADJUSTMENT CAM Diagram 23 CARE AND MAINTENANCE To provide years of trouble free operation, it is recommended that the track is kept free from dirt and debris. Periodically replace the general purpose grease on all bolts.To prolong the appearance of the exposed hinge parts, it is recommended they are periodically washed with soap and water. Maintenance is required on all components including stainless steel to validate manufacturers warranty. For further maintenance details please refer to our website. ADJUSTMENT CAM CLAMP SCREW BOTTOM SIDE PLATE CLAMP SCREW BOTTOM ANCHOR JAMB SIDE ADJUSTMENT Diagram 24

- 9. 9 Aluminium Threshold Jamb Kit 51 25.5 25.5 21 94 25 Jamb Cap Jamb Cap Gasket 51 15 34 19 Threshold SF94T 8 27 2.5 83 Pre-drilled 10mm diameter drainage holes at 300mm centres Endcap 2.5 51 140 51 25.5 25.5 23 27 8 15 34 Jamb Cap Jamb Cap 2.5 2.5 Jamb Cap Gasket Jamb Cap Gasket 51 140 21 94 25 52 39 Endcap Endcap 83 Jamb Cap Jamb Cap Gasket 52 (All dimensions in mm) 39 Endcap

- 10. 10 SF9 Intermediate Pivot Set 1. The Cofold SF9 intermediate pivot set shown in Diagram 1, should be fitted to the pivot door approximately mid way between the SF1 top and bottom pivot assemblies. The SF9 hinge must be positioned on the same centre line as the SF1 top and bottom pivot hinge bodies. 5. Fit the pivot door into position using the SF1 pivot set. 2. Route the door and drill the pilot holes as shown on Diagram 2. Fit the hinge body using the five screws provided. 7. Screw the threaded link arm fully into the frame support plate. The centre of the threaded hole in the link arm should be positioned to receive the strap bolt. Screw the strap bolt in to the link arm until there is a 2mm gap between the head of the strap bolt and the hinge body, as shown in Diagram 4. 6. Fit the SF9 cover sleeve on to the SF9 hinge body and drop the hinge strap bolt into position, as shown in Diagram 4. 3. Prepare the frame for the opening by drilling a Ø12mm hole (as shown in Diagram 3), ensuring that the centre point of the hole is 20mm lower than the bottom of the hinge body as shown on Diagram 4. Rebate the frame support plate, if required. 8. Adjust the SF9 pivot set to ensure the clearance between the pivot door and the frame is uniform (Diagram 5). 4. Screw the frame support plate on to the opening frame preparation, as shown in Diagram 3. Note: These fitting instructions should be used in conjunction with the Cofold Fitting Instructions 7.5 17.5 Main strap bolt SF1 Hinge body 100 SF9 Cover plate R17.5 SF1 Cover sleeve Diagram 1. Diagram 2. ole ph dee m 28m Opening frame Ø12 28mm Pilot holes R12.5 Rebate details see diagram 1 2.5 mm dee p 25mm 41m m Door in closed position Hole centre to door face 8mm Ø12 Diagram 3. Door shown in the open position Door shown in the open position 8mm 2mm gap 2mm gap Main strap bolt Adjustment: 3mm in to the frame 6mm out to the frame Line from bottom of the hinge body 20mm Threaded link arm Frame support plate Diagram 4. Diagram 5.

- 11. 11 Outward Opening Flush Bolt For top hung exterior folding doors. For use in conjunction with standard outward opening fitting instructions. Follow routing instructions for the bolt keep and flush bolt length to be fitted, fit both with the screws supplied. Suitable pilot holes for screws are recommended. Routing detail for 450mm Top Flush Bolt Routing detail for 600mm Top Flush Bolt HEAD BOARD LINTEL 12.5 FASCIA Routing detail for 190mm Top Flush Bolt 18 Routing detail for 190mm Bottom Flush Bolt PLATE 600 450 580 190 430 170 30 INSIDE 4 190 Enlarged detail showing the sectional routing dimensions for all 3 bolt sizes 40 OUTSIDE 170 TOP FLUSH BOLT 22 17 Note: Routing detail is the same for both locking and non-locking flush bolts. Door height Recommended Bolt length for top of door Recommended Bolt length for bottom of door Upto 2200mm 190mm 190mm Upto 2450mm 450mm 190mm Over 2450mm 600mm 190mm BOTTOM FLUSH BOLT Routing detail for bolt keep sockets Top Flush Bolt into Head Bottom Flush Bolt into Sill Fixing screw centres 40 Ø12 PLATE Ø12 10 4 10 12.5 12.5 SILL REBATE 40 10 40 30 25 12 65 40mm fixing screw centres - Use fixing plate as drilling template SILL 18 12.5 Section through door showing flush bolt rebate detail (All dimensions in mm)

- 12. 12 Inward Opening Flush Bolt For top hung exterior folding doors. For use in conjunction with standard inward opening fitting instructions. Follow routing instructions for the bolt keep and flush bolt length to be fitted, fit both with the screws supplied. Suitable pilot holes for screws are recommended. Routing detail for 600mm Top Flush Bolt HEAD BOARD 12 LINTEL 20 Routing detail for 190mm Bottom Flush Bolt 580 430 170 Note: Routing detail is the same for both locking and nonlocking flush bolts. FASCIA Routing detail for 450mm Top Flush Bolt Routing detail for 190mm Top Flush Bolt 80 600 450 190 PLATE 12 29 4 40 22 17 22 40 22 17 INSIDE 4 190 Enlarged detail showing the sectional routing dimensions for all 3 top bolt sizes OUTSIDE 170 TOP FLUSH BOLT Enlarged detail showing the sectional routing dimensions for the bottom bolt 12 Door height Recommended Bolt length for top of door Recommended Bolt length for bottom of door Upto 2200mm 190mm 190mm Upto 2450mm 450mm 190mm Over 2450mm 600mm 190mm BOTTOM FLUSH BOLT (Locking bolt shown) Routing detail for top bolt keep socket Ø12 65 10 12.5 max 7.5 12 SILL REBATE 11 12.5 max 4 40 SILL 10 40 Plate fixing screw centres 40mm fixing screw centres - Use fixing plate as drilling template Section through door showing flush bolt rebate detail (All dimensions in mm) Coastal Joinery Hardware, Global House, Bojea Industrial Estate, Trethowel, St Austell, Cornwall, PL25 5RJ. Tel: 01726 871726 Fax: 01726 871731 Email: sales@coastal-group.com Part No: 220159 Issue 7 -January 2013

- 13. ENQUIRY FORM FOR BI-FOLD DOORS Please enter your address here: Your Details/FAO Address Telephone: Fax: PROJECT TITLE: Email: LOCATION: SPECIFICATION SHEET System Capacity: 1. Opening Size: BI-FOLD DOORS Maximum Leaf Height: 3300mm Maximum Leaf Width: 1000mm Maximum Leaf Weight: 100kg Leaf Thickness: 35mm-68mm mm Height: 2. Door Configuration: Number of leaves sliding (viewed from the outside) Width: mm RH LH 3. Outward Opening: Due to weathering, outward opening Is highly recomended. Yes No 4. Locking None Espagnolette Sash lock 5. Finish Satin Stainless Steel PVD Brass Polished Stainless Steel 6. System CoFold CoFold Ultra (High Security) 7. Gear Types Choice only applies to CoFold system & not the CoFold Ultra. Mortice Non Mortice 8. Weatherseal Required: None Brown White PRE-TENSION Coastal Group | T 01726 871726 | F 01726 871731 Email sales@coastal-group.com | Visit www.coastal-group.com