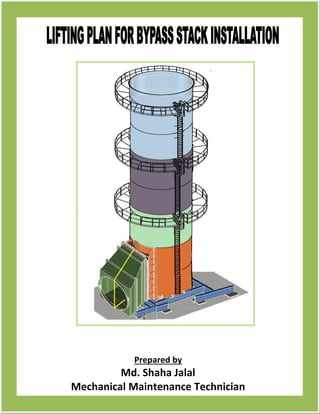

Lifting plan for bypass stack installation

- 1. Prepared by Md. Shaha Jalal Mechanical Maintenance Technician

- 2. Figure: schematic of bypass stack

- 3. Lifting Plan for bypass stack Tools & equipment to be used: i. Manitowoc 4000 W Vicon Crawler Crane : 1 no. Purpose : To lift the load. Capacity : 150 ton ii. Manitowoc Crawler Crane : 1 no. Purpose : To shift the load Capacity : 100 ton iii. P&H (70 ton capacity) Crane (trailing crane) : 1 no. Purpose : To shift the load. Capacity : 70 ton iv. Trailer with Prime Mover. : 1 no. Purpose : To shift the load. Capacity : 50 ton Length : 12.195 m (40 feet) Width : 10 m (33 feet) v. Chain Blocks : 3 nos. Purpose : To balance the load Capacity : 15 ton vi. Spreader Beam : 2 no. vii. D-Shackles ,35 ton : 6 nos viii. D-Shackles ,25 ton : 6 nos ix. Wire Rope, 20 ton, length- 2 m (6.56 ft) : 8 nos x. Wire Rope , 20 ton, length- 3 m (10 feet) : 4 nos xi. Wire Rope , 20 ton, length- 4 m (13 feet) : 4 nos xii. Wire Rope , 10 ton, length- 6.3 m(20.66 feet) : 12 nos xiii. Wire Rope , 20 ton, length- 9 m(30 feet) : 4 nos xiv. Nylon Rope (Tag Line) – Diameter 1 inch : 2 rolls xv. Warning Tape : 2 rolls xvi. Walkie -Talkie System of same channel : 4 sets

- 4. Rigging Plan for Lifting of Stack with 100 ton and 150 ton Crawler crane. Specification of 150 ton crane: Load capacity (Max) : 150 ton Boom Length : 170 feet Counter Weight : 104.4 klb Distance from mass center of the load : 11.5 m (38 ft) Angle of boom : 77.08 degree. Allowable capacity (Max) : 39.78 ton Specification of 100 ton crane: Load capacity (Max) : 100 ton Boom Length : 110 feet Counter Weight : 82.22 klb Distance from mass center of the load : 11.5 m (38 ft) Angle of boom : 69.79 degree Allowable capacity (Max) : 24.07 ton Specifications of rigging accessories: Wire sling: Capacity Length Qty 10 ton 6.3 m (20.66 ft) 06 pcs Shackle 25 ton 06 pcs Nylon Rope 1’’ --- 1 roll

- 5. Detail Arrangement: All rigging accessories will be arranged as per drawing shown below. Fig: Rigging arrangement for lifting bypass stack

- 6. Lifting Procedure for Stack Part #1: by Considering 150 ton crane Showing below calculation for stack part#01 by 150 ton crane: Boom Length : 170 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/170ft) = 77.08 degree Lifting height = 38 tan 77.08° = 165 ft

- 7. Fig: Lifting of Stack part#01 by 150 ton crane Lifting Procedure for Stack Part #1: by Considering 100 ton crane Available lifting height: = 165 – Load height – boom top to load touching point distance = 165– 37 – 45.5 = 82.5 ft Lifting accessories length =20.66 ft Load Capacity : 39.78 ton (from load chart: annex 02) Load weight : 15 ton Accessories : 2 ton Total load weight : 17 ton

- 8. Showing below calculation for Stack part#01 by 100 ton crane: Fig: Lifting of Stack part#01 by 100 ton crane a. Part #01 of bypass stack will be mobilized in front of water treatment building from the assembling area by trailer when main crane will be set beside BFP shelter (annex#02). b. Part#01 will be hung by main crane with help of lifting accessories (annex#01). c. The crane will be swung 180 degree anti clockwise and will be moved from main road to inlet duct area with the load. d. Then the load will be set on base frame of bypass stack. Note: Part#01 can be lifted by both 100 ton and 150 ton crane. Boom Length : 110 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/100ft) = 69.79 degree Lifting height = 38 tan 69.79° = 103 ft Available lifting height: = 103 – Load height – boom top to load touching point distance = 103 – 37 – 32 = 34 ft Lifting accessories length =20.66 ft Load Capacity : 24.07 ton (from load chart: annex 02) Load weight : 15 ton Accessories : 2 ton Total load weight : 17 ton

- 9. Trailing procedure for inlet duct: a. Place the trailing crane beside (east side of trailer) and in line (east to west) with trailer. b. Hook up the trailing crane to duct lower lug with the help of wire sling as shown in the below arrangement (Annex #03). c. The load will be lifting up by main crane and trail crane together, then trailer move from under the load. d. The load will be tilted down by lowering the trailing crane and lifting up the Main crane as shown in the below figure.

- 10. Lifting procedure for inlet duct by considering 150 ton crane: Showing below calculation for inlet duct by 150 ton crane: Boom Length : 170 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/170ft) = 77.08 degree Lifting height = 38 tan 77.08° = 165 ft

- 11. Lifting procedure for inlet duct by considering 100 ton crane: Available lifting height: = 165 – Load height – boom top to load touching point distance = 165– 34 – 45.5 = 85.5 ft Lifting accessories length =20.66 ft Load Capacity : 39.78 ton (from load chart: annex 02) Load weight : 16 ton Accessories : 2 ton Total load weight : 18 ton

- 12. a. Inlet duct part of bypass stack will be mobilized in front of water treatment building from the assembling area by trailer when main crane will be set beside BFP shelter (annex#02). b. Duct part will be hung by main crane with help of lifting accessories (annex#03). c. The crane will be swung 180 degree anti clockwise and will be moved from main road to inlet duct area with the load. d. Then the load will be set on base frame of bypass stack. Inlet duct can be lifted by both 100 ton and 150 ton crane. Boom Length : 110 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/100ft) = 69.79 degree Lifting height = 38 tan 69.79° = 103 ft Available lifting height: = 103 – Load height – boom top to load touching point distance = 103 – 34 – 32 = 37 ft Lifting accessories length =20.66 ft Load Capacity : 24.07 ton (from load chart: annex 02) Load weight : 16 ton Accessories : 2 ton Total load weight : 18 ton

- 13. Lifting procedure for stack part#02 by considering 150 ton crane: Showing below calculation for Duct Part #02 by 150 ton crane: Boom Length : 170 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/170ft) = 77.08 degree Lifting height = 38 tan 77.08° = 165 ft

- 14. Fig: Lifting of stack part#02 by 150 ton crane Lifting procedure for stack part #02 by considering 100 ton crane: Available lifting height: = 165 – Load height – boom top to load touching point distance = 165– 14 – 45.5 = 105.5 ft Lifting accessories length =20.66 ft Load Capacity : 39.78 ton (from load chart: annex 02) Load weight : 10 ton Accessories : 2 ton Total load weight : 12 ton

- 15. Showing below calculation for Duct part#02 by 100 ton crane: Fig: Lifting of stack part#02 by 100 ton crane a. Part #02 of bypass stack will be mobilized in front of water treatment building from the assembling area by trailer when main crane will be set beside BFP shelter #01 (annex#02). b. Part#01 will be hung by main crane with help of lifting accessories (annex#01). c. The crane will be swung 180 degree anti clockwise and will be moved from main road to inlet duct area with the load. d. Then the load will be set on part#01 of bypass stack. Note: Part#02 also can be lifted by both 100 ton and 150 ton crane. Boom Length : 110 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/100ft) = 69.79 degree Lifting height = 38 tan 69.79° = 103 ft Available lifting height: = 103 – Load height – boom top to load touching point distance = 103– 14 – 32 = 57 ft Lifting accessories length =20.66 ft Load Capacity : 24.07 ton (from load chart: annex 02) Load weight : 10 ton Accessories : 2 ton Total load weight : 12 ton

- 16. Lifting procedure of Duct Part # 03: by considering 150 ton crane Showing below calculation for stack part#03 by 150 ton crane: Boom Length : 170 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/170ft) = 77.08 degree Lifting height = 38 tan 77.08° = 165 ft

- 17. Fig: Lifting of stack part#03 150 ton crane Lifting procedure for stack part#03 considering by 100 ton crane: Available lifting height: = 165 – Load height – boom top to load touching point distance = 165– 32 – 45.5 = 87.5 ft Lifting accessories length =20.66 ft Load Capacity : 39.78 ton (from load chart: annex 02) Load weight : 23 ton Accessories : 2 ton Total load weight : 25 ton

- 18. Showing below calculation for stack part#03 by considering 100 ton crane: a. Part #03 of bypass stack will be mobilized in front of water treatment building from the assembling area by trailer when main crane will be set beside BFP shelter #01 (annex#02). b. Part#01 will be hung by main crane with help of lifting accessories (annex#01). c. The crane will be swung 180 degree anti clockwise and will be moved from main road to inlet duct area with the load. d. Then the load will be set on part#02 of bypass stack. Note: Due to unavailable lifting height & less capacity (at 110 ft boom with 38 ft radius) part#03 can’t be lifted by 100 ton crane. Boom Length : 110 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/100ft) = 69.79 degree Lifting height = 38 tan 69.79° = 103 ft Available lifting height: = 103 – Load height – boom top to load touching point distance = 103– 32 – 32 = 39 ft Lifting accessories length =20.66 ft Load Capacity : 24.07 ton (from load chart: annex 02) Load weight : 23 ton Accessories : 2 ton Total load weight : 25 ton

- 19. Lifting procedure of Duct Part # 04: by considering 150 ton crane Showing below calculation for Stack Part # 04: by considering 150 ton crane Boom Length : 170 ft Radius : 38 ft Angle of boom = Cos-1 (38ft/170ft) = 77.08 degree Lifting height = 38 tan 77.08° = 165 ft

- 20. Fig: Lifting of Stack part#04 by 150 ton crane a. Part #04 of bypass stack will be mobilized in front of water treatment building from the assembling area by trailer when main crane will be set beside BFP shelter #01 (annex#02). b. Part#01 will be hung by main crane with help of lifting accessories (annex#01). c. The crane will be swung 180 degree anti clockwise and will be moved from main road to inlet duct area with the load. d. Then the load will be set on part#03 of bypass stack. Annex-01: Name Size Qty. Wire Sling 10 ton x 6.3 m (20.66 ft) 06 pcs Shackle 25 ton 06 pcs Nylon Rope 1’’ ------- 1 roll Fig: Table of lifting accessories Available lifting height: = 165 – Load height – boom top to load touching point distance = 165– 29.6 – 45.5 = 89.9 ft Lifting accessories length =20.66 ft Load Capacity : 39.78 ton (from load chart: annex 02) Load weight : 23 ton Accessories : 2 ton Total load weight : 25 ton

- 21. Fig: Drawing of load width and height

- 22. Annex-02:

- 23. Table-01: Load chart for 150 ton crane. Table-02: Load chart for 100 ton crane

- 24. Annex: 03 Name Size Qty. Wire Sling 20 ton x 2 m (6.56 ft) 4pcs Wire Sling 20 ton x 3 m (9.84 ft) 8pcs Shackle 25 ton 14pcs Chain block 10 ton 2pcs Spreader beam 42 ton, 8400X219mm 2pcs Nylon Rope 1’’ ------- 1 roll