SALMAN CV (8-8-2015)

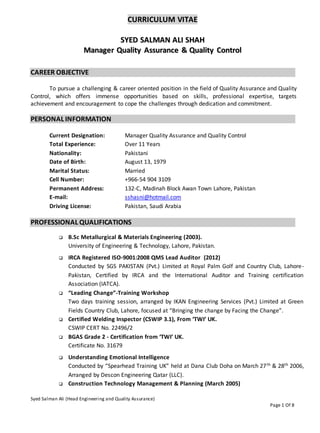

- 1. Syed Salman Ali (Head Engineering and Quality Assurance) Page 1 Of 8 CCUURRRRIICCUULLUUMM VVIITTAAEE SSYYEEDD SSAALLMMAANN AALLII SSHHAAHH MMaannaaggeerr QQuuaalliittyy AAssssuurraannccee && QQuuaalliittyy CCoonnttrrooll CAREER OBJECTIVE To pursue a challenging & career oriented position in the field of Quality Assurance and Quality Control, which offers immense opportunities based on skills, professional expertise, targets achievement and encouragement to cope the challenges through dedication and commitment. PERSONAL INFORMATION Current Designation: Manager Quality Assurance and Quality Control Total Experience: Over 11 Years Nationality: Pakistani Date of Birth: August 13, 1979 Marital Status: Married Cell Number: +966-54 904 3109 Permanent Address: 132-C, Madinah Block Awan Town Lahore, Pakistan E-mail: sshasni@hotmail.com Driving License: Pakistan, Saudi Arabia PROFESSIONAL QUALIFICATIONS B.Sc Metallurgical & Materials Engineering (2003). University of Engineering & Technology, Lahore, Pakistan. IRCA Registered ISO-9001:2008 QMS Lead Auditor (2012) Conducted by SGS PAKISTAN (Pvt.) Limited at Royal Palm Golf and Country Club, Lahore- Pakistan, Certified by IRCA and the International Auditor and Training certification Association (IATCA). “Leading Change”-Training Workshop Two days training session, arranged by IKAN Engineering Services (Pvt.) Limited at Green Fields Country Club, Lahore, focused at “Bringing the change by Facing the Change”. Certified Welding Inspector (CSWIP 3.1), From ‘TWI’ UK. CSWIP CERT No. 22496/2 BGAS Grade 2 - Certification from ‘TWI’ UK. Certificate No. 31679 Understanding Emotional Intelligence Conducted by “Spearhead Training UK” held at Dana Club Doha on March 27th & 28th 2006, Arranged by Descon Engineering Qatar (LLC). Construction Technology Management & Planning (March 2005)

- 2. Syed Salman Ali (Head Engineering and Quality Assurance) Page 2 Of 8 Conducted by Human Resources Department DESCON ENGINEERING LIMITED. PRIMAVERA 3.0, DESCON Engineering Limited (DHQ) Lahore. ASNT Level II in VT, MT, PT, UT, RT, Materials Testing Services Doha, Qatar. COMPUTER LITERACY Microsoft Office ( Word, Excel, Power Point), AutoCAD 2011, Autodesk Inventor 2011, Bentley Staad Pro v8i, Codeware Compress 2011. PROFESSIONAL COMPETENCIES AND EXPERTIES A professional Metallurgist, holding certifications like CSWIP 3.1 and BGAS 2, with over 11 years of fulltime work experience primarily in Quality Assurance and Quality Control in Oil & Gas industry, well worsted in Quality and HSE Management Systems review, compliance and auditing. Experienced in the preparation, certification and maintaining of ASME Quality Control System. Skilled in development, implementation and maintaining of QHSE Management System, Project Specifications, Codes and Standards in Manufacturing Organizations & projects. Proficient in Implementation of Audit program and Auditing of subcontractors/vendors, Internal company IMS audits. Expert in managing the QHSE Team and preparation, review and implementation of Quality Control Procedures, Preparation of Project Quality Plan, Inspection and Test Plans, Welding Procedure Specifications, NDE Procedures, witnessing and approval of welding procedures and welders qualifications, Welding inspections, and leading from the front the ASME certification and revalidation Audits. Review of RT films and NDE reports, witnessing of pressure tests, punch listing, pre-commissioning inspection. Review of final QHSE documentation file for plant hand over, review of corrective actions to close out non conformities. Leading the team of inspectors and assigning day to day inspection tasks to inspectors and supervising and monitoring their performance and timely reporting. PPRROOFFEESSSSIIOONNAALL EEXXPPEERRIIEENNCCEE HHEEAADD EENNGGIINNEEEERRIINNGG AANNDD QQUUAALLIITTYY AASSSSUURRAANNCCEE SESAB International For Industry and Contracting, Jeddah, K.S.A (February 2013 till February 2015) Manufacturing of Industrial Process Equipment, Steel Structures etc. Clients: Saudi Aramco, SK Engineering Korea, Mitsubishi, JGC, SPX (Brussels) etc. Responsibilities: To manage staff and sub-consultants engaged in carrying out investigations, feasibility studies, structural inspections and assessments, and the design and preparation of contract documents for structural engineering works and fabrication supervision. To manage and lead a team of structural engineers and detailers.

- 3. Syed Salman Ali (Head Engineering and Quality Assurance) Page 3 Of 8 To provide the highest level of technical sufficiency within the Structural Engineering Section, including the identification and promotion of innovative and practical design solutions. To assume technical and administrative responsibility for the preparation of quality plans, scheme programs, estimations, assessments and design work, contract documents, tender invitation and tender assessments. To organize and provide technical support and training of project engineers and technical staff on structural engineering, fabrication supervision. To review and update technical standards, office procedures, construction techniques, and use of materials to ensure that specifications and schemes prepared by the Engineering department reflect best practices. To provide professional input to the training of graduate engineers and trainee technicians. To provide input for the estimation and monitoring of bids, resource schedules and targets. To prepare and present top management, financial, technical and performance reports as directed. To liaise with and provide advice to top management and internal and external clients on technical matters. To undertake corporate development and management activities as required by the top management. To establish quality and reliability standards by studying product and consumer requirements with other members of management and with production operators, technicians, and engineers. To establish raw material standards by studying manufacturing and engineering requirements; conferring and negotiating with suppliers; devising testing methods and procedures. To establish in-process product inspection standards by studying manufacturing methods; devising testing methods and procedures. To establish standards for the disposition of finished product by devising evaluation tests, methods, and procedures. To establish rework standards by devising inspection and physical testing methods and procedures. To establish product quality documentation system by writing and updating quality assurance procedures. To maintain product quality by enforcing quality assurance policies and procedures and government requirements; collaborating with other members of management to develop new product and engineering designs and manufacturing and training methods. To Prepare product and process quality reports by collecting, analyzing, and summarizing information and trends. To Complete quality assurance operational requirements by scheduling and assigning employees; following up on work results. To maintain quality assurance staff job results by coaching, counseling, and disciplining employees; planning, monitoring, and appraising job results. To maintain professional and technical knowledge by attending educational workshops; reviewing professional publications; establishing personal networks; participating in professional societies. To Achieve financial objectives by preparing the quality assurance budget; scheduling expenditures; analyzing variances; initiating corrective actions. To Contribute to team effort by accomplishing related results as needed.

- 4. Syed Salman Ali (Head Engineering and Quality Assurance) Page 4 Of 8 MMAANNAAGGEERR QQAAQQCC SESAB International For Industry and Contracting, Jeddah, K.S.A (February 2013 till February 2015) Manufacturing of Industrial Process Equipment, Steel Structures etc. Clients: Saudi Aramco, SK Engineering Korea, Mitsubishi, JGC, SPX (Brussels) etc. RESPONSIBILITES: Manage and oversee project quality to ensure compliance to codes, standards, regulations, equipment specific specifications, and QMS requirements. Advancing quality achievement and performance improvement throughout the organization. Managing the development and implementation of the QMS for planning, fabrication, inspection, documentation, and operations activities including: 1- Planning duties within the QA/QC staff and related work schedules; 2- Establishing service standards for end users (i.e., internal department or external customer); 3- Identifying and developing QA/QC personnel certification requirements and continuing education/training needs; 4- Providing leadership, mentorship, and direction of all QA/QC personnel. Taking full responsibility for hold-point releases once all QMS functions have been completed and the equipment is ready to go into the next work stage. Managing products integrity through a failure analysis reporting system and following up on recommendations. Oversee supervision of all visual inspections and NDE, including 3rd party subcontractors. Managing inspection, NDE, and testing plans for new construction, repair work, and alterations. Identify and develop solutions to correct inspection function deficiencies. Manage construction processes, plant equipment, inspection and NDE personnel certification and QMS internal audits. MMAANNAAGGEERR QQHHSSEE IKAN Engineering Services (Pvt.) Limited Lahore (December 2011 till October 2012) Manufacturing of Industrial Process Equipment, Boilers, Heat Exchangers etc. Clients: MOL Pakistan, OGDCL (Oil and Gas Development Corporation Limited) Pakistan, Schlumberger, Telenor Pakistan Etc. RESPONSIBILITIES: Ensuring achievement of IKAN’s Integrated Management System (IIMS) Objectives defined for the QHSE, including those established for continuous improvement. Ensuring that all IMS documents are in line with the concepts of value addition to the business processes. Ensuring that IMS documents and actual role performed by Company’s personnel is in line with the concept “ Say what you do and do what you say”. Implementing QHSE Policy throughout the Company. Planning and conducting

- 5. Syed Salman Ali (Head Engineering and Quality Assurance) Page 5 Of 8 Integrated Management System awareness programs throughout the Company. Document and report findings on the Executive Management Review on the state of Quality Program in the company and recommend actions for the correction and improvement. Responsible for overseeing preparation of Project Quality Plan & HSE plan in the light of Project specifications/Customer requirements. Responsible for establishing IMS objectives, goals and programs for the organization and development of measures to determine the effectiveness and the contribution of the Quality Control function towards the profitability and progress of the company. Responsible for providing the frame work for IMS objectives to all Business Areas and ensure their effectiveness during internal audits. Coordination with external certifying/ surveillance auditors. Responsible for the preparation of schedules for Project Assessment, IMS audits, coordinate with BAs/BSDs/Projects for effective implementation and to ensure compliance with & Company’s policies and procedures. Maintain QHSE policies and circulate Company wide. Monitoring corrective & preventive actions necessary for effectiveness of Integrated Management System. Ensuring that QHSE documents are in line with Company’s Integrated Management System and remain fully updated. Ensuring that all the IMS Records are maintained as per the written procedure. Coordinating with proposal manager in the study of tender documents and specifications especially with regards to QHSE requirements. Prepare QHSE documents for proposals covering general and project specific tender requirements. Coordinating with HR and Project Manager for selection and qualification of selected craftsman required by the BAs/Projects. Development of Management concurrence to promote a recognized system of rules and procedures to prevent accident and property loss. Keeps Management regularly informed regarding the state of HSE effort throughout the Company. Devising pro-active /corrective measures to prevent accidents and ensures the compliance accordingly. Reports to Management in case non-conformities are persistently occurring to the HSE related Method Statements and proposed remedial measures. Issuance of monthly HSE Bulletins to all sites, which include information on unusual accidents, remedial measures and training material. Playing the role of coordinator, facilitator and advisor to all levels of management over the QHSE matters. Maintaining an updated statistical record of all inspections, audits and QHSE performances at all project sites / establishment of Company. Ensuring that all cadres in the Company are fully aware of the potential hazards that they may experience and imparts necessary training for avoiding loss or damage to life and property though a formal organizational effort. SSeenniioorr QQAA//QQCC EEnnggiinneeeerr DESCON Engineering Limited-Lahore Manufacturing Works From September 2010 November 2011. Manufacturing Of Boilers, Heat Exchangers, and Pressure Vessels and a variety of other Indus trial Equipment related to Oil and Gas, Power Plants, Refineries etc. Clients: BYCO Oil Pakistan, FFC Pakistan, Aisha Steel Mills Pakistan, Bhikki Power Plant Etc. Responsibilities Supervising QA/QC Staff for the inspection of Industrial Equipment like Boilers, Reactor/Columns/vessels/Heat Exchangers/Fin Fan Coolers/Filter/Tanks/Heater/PSV etc and Piping made up with materials like Stainless steel, Alloy steels, carbon Steel etc. Assessment of Industrial

- 6. Syed Salman Ali (Head Engineering and Quality Assurance) Page 6 Of 8 Equipment and Piping through inspection and NDE and update their Files, based on the damages give recommendation of repairs and propose repair methods. Preparation of PQP, QA/QC Procedure, ITP/Inspection Checklist and Method Statements, preparation of WPS, qualification of PQRs and reviewed the welder’s qualifications, Day to day monitoring of inspection activities during manufacturing process. Supervision and Monitoring of execution of NDT (RT, MT, PT, UT, Hardness Testing, Thickness Measurement) and ADVANCE NDT (In-situ Replica Metallographic, Profile RT, Thickness Checks) by NDT Subcontractor. Provide recommendations for the repair or replacement work on the finding as a result of NDT in consultation with Company Inspection Engineers. Coordinate with Company Inspection Department. Supervision of Inspection of Painting and Insulation works. Taking ownership of Company’s HSE Policy. QQAA//QQCC EEnnggiinneeeerr Zamil Offshore Services Company K.S.A September 2008 till August 2010 Hook-up, Upgrade Modification & Commissioning Support at BRRI Oil field Jubail K.S.A Client: SAUDI ARAMCO Responsibilities Implementation of Latest Saudi Aramco standards, project specific specifications for NDT, Welding, and Coating Procedures. Supervised Quality Assurance and Quality Control of activities like Welding, Piping, NDT, painting, installation of static and rotary equipment at various Oil Platforms at Offshore BRRI Oil field. Preparation and reviewing of relevant reports and submission to SAUDI ARAMCO PMT. Reviewing Mill Test Certificates of all received materials specially piping and welding consumables at platforms to ensure that all piping materials and welding consumables, gases, flux, filler wires meet the SAUDI ARAMCO requirements and are in good condition prior to use. Took responsibility to control storage, handling, baking and issuance of consumables to welder at site. Responsible for the preparation of Preliminary WPS as per ASME IX, AWS D1.1, ASME B 31.3 and applicable project specs. Conduction of procedure qualification tests as per ASME IX, API 1104, ASME B 31.3 and applicable project specs. Participated in internal Quality Audits for evaluating operational processes are complying with the project specifications, company procedures, international standards, applicable codes. Responsible for ensuring that all process/product non-conformities are highlighted through CAR’S/PAR’S to the relevant supervisor as well as QA/QC Manager for rectification and follow up. Conduction of Welders qualification tests as per AWS D1.1, ASME IX and applicable project specifications, their deployment and maintaining welder qualification record. Review of PWHT, UT, MT, PT reports and Radiographic films. QQCC EEnnggiinneeeerr ((WWeellddiinngg aanndd NNDDTT)) JAPAN GAS CORPORATION (JGC) K.S.A July 2007 till June, 2008 Construction of High Olefins Cracking Plant and Ethan Cracking Plant at Rabigh Refinery, Rabigh K.S.A Client: PETRO RABIGH

- 7. Syed Salman Ali (Head Engineering and Quality Assurance) Page 7 Of 8 Responsibilities Ensure that all Quality Control activities related to Welding and NDT, on site are fully implemented and maintained throughout all stages of contract execution in accordance with Project Specifications and Code requirements. Implementation of QIP/ITPs for project. Ensure that all relevant drawings, codes and/or specifications are applied at Project and only current documents are in use, in accordance with Master Lists of Documents. Took responsibilities to develop written and draft the WPS/PQR (For mechanical discipline). Witnessed the execution of PQRs and mechanical testing at labs. Witnessed Welders Qualification Testing, prepared welder certificates and Cards. Review of NDE reports, RT Film interpretation, PWHT Report and Charts. Carried out the receiving inspection of materials. Monitor Fabrication work going on in the site workshop. Liaise with other departments for inspection activities at site. Carried out Inspections during the preservation of Mechanical Equipment prior to Installation as per vendor recommendations. Ensured that, procedures, method statements and ITPs are followed at site. Planned and conducted Quality Management awareness programs on project. QQAA//QQCC EEnnggiinneeeerr DESCON ENGINEERING QATAR L.L.C 8th MAY 2005 to April 2007 Dolphin Upstream and Compression Facilities Project, Ras Lafan Qatar Client: JGC Responsibilities Preparation of Project Quality Plan, Quality Procedures & Work Instructions as per the Client Specifications. Reviewed Client specifications, Data sheets, bill of material, supplier data requirements and Technical Bid Evaluation and Purchase Order Quality requirements, Vendor Assessment and Pre- qualifications. Monitored the implementation of quality management system in project execution; Supervised the work of the QA/QC inspectors to ensure effective planning, execution and coordination of all Quality activities and inspection of piping, welding, NDE, PWHT, hardness, PMI, Hydrostatic test, painting, mechanical completion package. Developed and implement procedures for quality control, quality audits, and corrective and preventive action system. Monitored and controlled activities requiring critical success factor for quality of deliverables. Ensured that all the quality data (Computer based systems and record are maintained properly. Develop the training matrix for all the employees and conduct trainings for the improvement of Quality of the project. Owned and share company’s QHSE Policy, vision & mission, core & operating values to ensure their implementation at all work places. Responsible for the Monitoring of Corrective/Preventive Action Requests and Maintaining of the Log and ensure timely close out of CARs/PARs. Coordinate investigation of customer complaints and internal quality failures through root-cause analysis and problem solving methods. QQAA//QQCC EEnnggiinneeeerr DESCON ENGINEERING QATAR L.L.C 5th April 2005 to 7th May 2005 Qatar Gas Train 1, Shutdown Client: CTJV (Chiyoda Technip Joint Venture), Qatar Gas Responsibilities Maintenance inspection of Process Equipment like Reactor/Columns/vessels/Heat Exchangers/Fin Fan Coolers/Filter/Flare Tips replacement/Tanks/Heater/PSV etc and Piping works.

- 8. Syed Salman Ali (Head Engineering and Quality Assurance) Page 8 Of 8 Assessment of Process Equipment and Piping through inspection and NDE and update their Files, based on the damages give recommendation of repairs and propose repair methods, Preparation of PQP, QA/QC Procedure, ITP/Inspection Checklist and Method Statements, preparation of WPS, Welders Qualification Testing, Day to day monitoring of inspection activities during shutdown. Supervision and Monitoring of execution of NDT (RT, MT, PT, UT, Hardness Testing, Thickness Measurement) and ADVANCE NDT (IRIS, ECT, In-situ Replica Metallography, Profile RT, Thickness Checks) by NDT Subcontractor. Provide recommendations for the repair or replacement work on the finding as a result of NDT in consultation of Welding Engineer and Manager QA/QC. Supervision of Inspection of Painting and Insulation works. AAssssiissttaanntt EEnnggiinneeeerr DESCON ENGINEERING QATAR L.L.C Qatar Gas De-bottlenecking Project (Ras Lafan Qatar) January 2004 to March 2005 Responsibilities Ensured the Implementation of Quality Management System. Prepared the reports after compiling data from Project site. Maintained the CAR/PAR records at the Project site. Prepared the Audit schedule for the corporate office. Assisted QA Engineer and Incharge QA for the internal audits. Prepared Training material for QA/QC Staff at office and projects. Ensured all the WPS/PQRs from the project are properly filed for the record. Assist QA Engineer in preparing Quality Newsletter. Prepare the Statistical analysis of CARs/PARs for presenting to management. Prepare Project Quality Plans, and QIPs. Collected the Client Feedback Report from client. Analyzed the Document Change Requests and share recommendations for improvement with the concerned functionaries. Kept the record of all the QA/QC Personnel of Company at all locations. Took ownership of Company’s Quality & HSE policies, Core and Operating Values. TTrraaiinneeee EEnnggiinneeeerr ((PPaarrtt TTiimmee)) DESCON Engineering Limited-Lahore Manufacturing Works Manufacturing Of Boilers, Heat Exchangers, and Pressure Vessels and a variety of other Indus trial Equipment related to Oil and Gas, Power Plants, Refineries etc. 27th November 2002 to December 2004 Responsibilities Assisted Welding Engineer in execution and compilation of welding procedures, Welders/Welding Operators qualification testing, In process inspection of pressure vessels, Preparation of Inspection Data Manuals, Incomming Materials Inspections, dimensional Inspections etc. REFERENCE: Reference will be furnished on demand.