Nebosh unit ib questions ans matrix

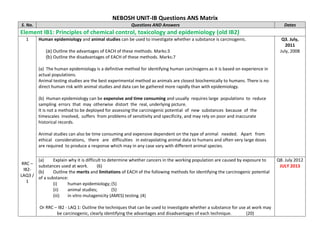

- 1. NEBOSH UNIT-IB Questions ANS Matrix S. No. Questions AND Answers Dates Element IB1: Principles of chemical control, toxicology and epidemiology (old IB2) 1 RRC – IB2- LAQ3 / 1 Human epidemiology and animal studies can be used to investigate whether a substance is carcinogenic. (a) Outline the advantages of EACH of these methods. Marks:3 (b) Outline the disadvantages of EACH of these methods. Marks:7 (a) The human epidemiology is a definitive method for identifying human carcinogens as it is based on experience in actual populations. Animal testing studies are the best experimental method as animals are closest biochemically to humans. There is no direct human risk with animal studies and data can be gathered more rapidly than with epidemiology. (b) Human epidemiology can be expensive and time consuming and usually requires large populations to reduce sampling errors that may otherwise distort the real, underlying picture. It is not a method to be deployed for assessing the carcinogenic potential of new substances because of the timescales involved, suffers from problems of sensitivity and specificity, and may rely on poor and inaccurate historical records. Animal studies can also be time consuming and expensive dependent on the type of animal needed. Apart from ethical considerations, there are difficulties in extrapolating animal data to humans and often very large doses are required to produce a response which may in any case vary with different animal species. Q3. July, 2011 July, 2008 (a) Explain why it is difficult to determine whether cancers in the working population are caused by exposure to substances used at work. (6) (b) Outline the merits and limitations of EACH of the following methods for identifying the carcinogenic potential of a substance: (i) human epidemiology;(5) (ii) animal studies; (5) (iii) in vitro mutagenicity (AMES) testing.(4) Or RRC – IB2 - LAQ 1: Outline the techniques that can be used to investigate whether a substance for use at work may be carcinogenic, clearly identifying the advantages and disadvantages of each technique. (20) Q8. July 2012 JULY 2013

- 2. ANS (a) There are many reasons why it may be very difficult to identify whether cancers occurring in a population are caused by exposure to a substance used in a workplace. First, cancers have a long latency period, so it may be very difficult to detect and trace cancers back to a particular workplace or type of work-related exposure. Many cancers have multiple causes (not just occupation) making it almost impossible to exclude other possible causes that an individual may well have been exposed to during their life. There may be synergism (e.g. smoking and asbestos exposure together) that is difficult to identify. Many cancers are common in the general population and therefore an occupational cause would be very difficult to detect against this background prevalence. Individual factors (susceptibility) and poor records (exposure history, etc.) are two other reasons. (b) Chemical Analogy – using expert knowledge about chemicals that have a similar structure and reactivity to the one under study to make predictions about the study chemical’s properties. Advantages – quick, economical, indicative. Disadvantages – not conclusive, restricted application. Any findings would have to be confirmed by other methods. (i) Human Epidemiology – making use of statistical analysis of historic data to link exposure to the substance to the risk of cancer. Advantages – definitive method for identifying human carcinogens. Disadvantages – Expensive and time consuming, Limited applicability (can’t really assess carcinogenic potential of new substances); Requires large populations (statistical validity); Relies on accuracy of historical records for substances currently in use; Problems with sensitivity and specificity (no test is 100% specific – can get false positives and false negatives when testing the population to see if they have the disease). (ii) Animal studies – using test animals of various species to determine and quantify the carcinogenicity of the substance. Advantages – best experimental method, data collected faster than by epidemiology Disadvantages – Expensive/time consuming (although quicker than epidemiology);

- 3. difficulties in extrapolating animal data to humans since large doses may be used Variation of effects between species of animal. Ethical considerations and adverse public opinion. (iii)In vitro mutagenicity testing / Short-term Testing, e.g. Ames Test – quick, cheap, avoids ethical issues, mutagenicity is indicative of carcinogenic potential but raises issues of reliability (false positives and false negatives). 2 Stone masons are exposed to silica dust during grinding operations. You have collected exposure data for one worker using standard sampling equipment suitable for dusts. The results are presented in the table below. Measurement type Initial mass of clean filter Final mass of filter and collected dust Pump flow rate Duration Respirable silica dust 262.15 mg 266.45mg 2.2 litres/min 4 hours (during the morning) X-ray diffraction analysis of the collected dust sample has determined that the crystalline silica (quartz) content is 6% by weight (a) OUTLINE the meaning of the term ‘respirable dust’. Marks: (b) Using the data in the table, calculate in mg/m3 the average concentration of ‘respirable crystalline silica (quartz) to which the worker was exposed during the sampling period. You should calculate the value in units of mg/m3 (there are 1000 litres in each cubic metre). Marks:5 (c) OUTLINE why there may be errors in the measurement values. Marks:3 ANS (a) The term ‘Respirable Dust’ refers to dust which penetrates to the gas exchange region of the lungs. The respirable dust was typically less than seven microns in aerodynamic diameter. (b) an average concentration of respirable crystalline silica during the sampling period of 0.49mg/m³. Total pump running time = 240 minutes giving a throughput of air of 528 litres (2.2 x 240) or 0.528m³ (528/1000). The mass of dust collected was 4.30 mg (266.45 - 262.15). July, 2011

- 4. The mean dust concentration was 8.14mg/m³ (4.30/0.528) and the mean crystalline silica concentration was 0.49 mg/m³ (0.06 x 8.14). (c ) Reasons for errors in the measurement values such as Pump and balance calibration errors; Filter contamination; Variations in pump rate perhaps because of battery power variation and incorrect recording of either mass or time. 3 RRC – IB1 - LAQ1 (a) Describe the structure of the skin and how hazardous substances may enter the body by this route. Marks:6 (b) Explain how contact (primary) dermatitis can occur. Marks:4 (c) A number of employees working in a hair salon have reported problems of skin irritation on their hands, which for at least one employee has been diagnosed as contact dermatitis. Advise the salon manager on the likely causes and the steps that could be taken to try to overcome these instances of contact dermatitis. Marks:10 Ans (a) The skin essentially consists of three layers: Epidermis – the outer tough layer consisting of a horny zone of dead cells (continually being lost) together with a germinal zone below, from which these dead cells develop. Dermis – true living skin containing blood vessels, sweat glands and nerve endings. Subcutaneous adipose tissues – fatty tissues used for storage purposes. In addition, the epidermis benefits from protective layer of glandular secretions, sebum in particular, which affords a good degree of waterproofing. The skin is semi-permeable and some chemicals in liquid/solution form can go straight through it. This is particularly the case with organic solvents such as phenol, carbon tetrachloride and dimethyl sulphoxide (DMSO). Once through the skin these chemicals can then permeate the tissues beneath the skin and enter blood vessels. The skin route is particularly available if the glandular secretions are removed (e.g. by solvents or washing) and when hot/sweaty (pores/sweat glands open). July, 2008

- 5. Cuts/abrasions are another significant entry route. Here the defensive layers of the skin have been physically damaged, so any hazardous substance introduced to this area can come into direct contact with body tissues and the bloodstream. This is a particular risk with biological agents, as a very small amount of the agent may be enough to cause infection and the agent then reproduces within the body to cause disease. The final route of entry is very similar to the last, and that is direct physical injection through the skin, by puncture of the skin with a sharp object, such as a hypodermic needle (e.g. a needle stick injury) or by high pressure gas or fluid injection (e.g. from a burst hydraulic pipe). (c)Dermatitis in the Salon: Advice to the Salon Manager The hairdressing industry is a workplace where contact dermatitis is common. Essentially, dermatitis in this case is caused by frequent wet working; (washing/ shampooing/dying of hair) as well as from direct contact with the chemical irritants in shampoos, dyes, “perm” preparations, bleaching agents, sterilising fluids, etc. Such contact can occur directly (such as deliberately working without gloves) or accidentally (splashes to skin, touching contaminated equipment/clothing, etc.). Various factors affect whether a worker will contract dermatitis or not. Factors such as individual susceptibility (people’s personal response to wet working and dermatitic agents is different), frequency and duration of exposure, the presence of existing damage to skin, failure to wear gloves, etc. The steps that should be taken or considered to control the dermatitis include: Pre-employment identification of susceptible individuals by health questionnaire or medical examination. Making sure that information on the risks of contact dermatitis is brought to the attention of all workers through leaflets and training. Ensuring that substance information is available to all workers (in the form of MSDSs, etc.). Elimination or substitution, where possible, of the dermatitic agents. Job rotation to minimise the amount of time that workers have wet hands. Wearing protective gloves (non-latex) when wet working or dealing with chemicals (these must be of an appropriate type and should be examined routinely to ensure they still afford protection). Drying hands properly and promptly. Using moisturising creams. Health surveillance in the form of regular visual checking of skin (for dryness, itching, cracking) followed by

- 6. referral for workers with symptoms. In certain instances, workers with a pre-existing condition may have to be prevented from working with dermatitic agents. 4 RRC- IB01- SAQ1 The table below shows data provided in a supplier’s catalogue for three different grades of the same industrial chemical. Product Code Description Average Particle Size (microns) Particle Size Distribution (Microns) AS1/01 Fine white powder 15 12-20 AS1/02 Fine white powder 8 7-10 AS1/03 Fine white powder 2 1-5 Use the data to identify where EACH of these powders may be deposited in the respiratory tract following inhalation. In EACH case outline the mechanisms the body may use to defend itself. Marks:10 ANS The particle size will determine how far into the body the chemical will penetrate. For AS1/01, the particles are greater than 10 microns therefore they will enter the nasal cavity only. The nasal hairs will trap and filter out these particles. They may also be trapped by mucous in the nose and mouth and subsequently ejected by sneezing and coughing. As far as AS1/02 is concerned, particles between seven and ten microns reach the Respiratory track (trachea and bronchioles). They are swept upwards by tiny hairs - the ciliary escalator- towards the throat and are then removed either by coughing or swallowing. Particles smaller than 5 microns, as for AS1/03, are likely to reach the deep lung tissue. When deposited in the alveoli, they may diffuse directly into the blood stream and be transported to other organs, trigger a defence mechanism where phagocytes engulf the particulate as a foreign body and migrate away through the lymphatic channels or may stay in the spaces in the lungs and depending on their chemical properties may cause fibrosis or pneumoconiosis. Q6.July, 2010

- 7. 5 (a) Describe the ways the body may defend itself against inhaled dusts. Marks:12 (b) A company uses a range of coloured powders in the manufacture of paints. These powders are added directly to a mixing vessel from sacks. The company is concerned about the level of exposure to its workers from the powders during this part of the process. Outline the practical control measures that could be used to minimise exposure to these powders during the addition. Marks:8 ANS a) The body’s first line of defence against inhaled dusts is the nasal hairs which trap and filter out dust particles greater than ten microns in size. Mucus in the nose and mouth also traps these particles which are subsequently ejected by sneezing, blowing the nose and spitting. Dust particles between five and ten microns tend to settle in the mucus covering the bronchi and broncioles and are wafted upwards by tiny hairs – the ciliary escalator – towards the throat. They are then coughed and spat out. Particles smaller than five microns are more likely to reach deep into the lungs, as far as the alveoli. These particles are ingested by macrophages – a type of white blood cell – in a process known as phagocytosis and transported back to the ciliary escalator or to the lymphatic system. They may also be transported across the alveolar membrane into the blood stream. b) The elimination of the coloured powder was not an option since the colour range was required. Even some practical control measures could be taken to minimize the exposure such as Introducing the colouring agent in a pellet or dye solution form. If this was not possible, then the powder could be fed into the mixing vessel by means of an automated feed system (such as a screw conveyor). Local exhaust ventilation is also an option. A vacuum system would need to be introduced to clear up spillages and Employees should be provided with personal protective equipment such as overalls, gloves and goggles. Some form of respiratory protection would also have to be provided. If the dust was thought to be nuisance only, then a particle filtering face piece – a disposable face mask – changed on a regular basis could suffice. However, a mask and filter respirator would have to be worn if the powder were found to be harmful. Adequate supervision to enforce use is important. Jan, 2009

- 8. Use of appropriate handling techniques to minimise dust creation when emptying sacks was also relevant. 6 RRC - IB2 – SAQ2 (a) Outline the following toxicological terms: (i) LD 50; Marks:2 (ii) LC 50. Marks:2 (b) (i) Outline the toxicity test known as the fixed dose procedure. Marks:4 (ii) Outline the possible reasons why the fixed dose procedure has replaced previous methods that estimated LD 50. Marks:2 (a) LD50 is the dose at which 50% of test subjects die (administered orally or dermally). Given in mg of substance per kg body weight of test animal. LC50 is the concentration in air of airborne substance at which 50% of test subjects die. Specified in mg of substance per litre of air and typically an exposure period of 4 hours. (b) (i) The toxicity test is known as the fixed dose procedure, used to determine acute oral toxicity with a rat normally being used as the test animal. An initial study is carried out to determine the starting dose for the main study and this uses single animals and a successively increased dose to determine the range of toxic effects. The initial test dose for the main study is chosen as the dose which can identify toxicity without mortality. In the main study, an animal is tested at one of four fixed does namely 5, 50, 300, and 2000 mg/kg, with observation being carried out over fourteen days. The discriminating dose (i.e. That causes evident toxicity but not mortality) is determined and is used as the basis for classification such as very toxic, toxic or harmful or equivalent GHS classification. (ii) Possible reasons for substituting the fixed dose procedure for previous methods that estimated LD50 include the fact that a smaller number of animals is used; it uses morbidity rather than mortality as the end point; and it is considered more humane by many. Jan, 2011 July, 2008 7 (a) Explain the meaning of the term ‘toxicity’. Marks:2 (b) Describe the physical characteristics of asbestos and give TWO occupational examples where it is likely to be encountered. Marks:4 (c) Outline the diseases caused by exposure to asbestos AND their signs and symptoms. Marks:7 (d) Outline the equipment and method that should be used to determine the level of asbestos fibres in the air in the workplace. Marks:7 Jan, 2011

- 9. (a) The term ‘toxicity’ is a degree to which a substance is able to cause damage to an organism. Toxicity may be systemic or local, can be acute or chronic and can be divided into different classes such as, for example, carcinogenic. (b) Asbestos is a fibrous substance and occurs in different forms such as white (chrysotile), blue (crocidolite) and brown (grunerite). It is thermally very stable and is widely used as insulation material because of its fire resistance. It has good absorption qualities, is of average tensile strength and is chemically inert. Asbestos may be encountered in the removal of pipe lagging or in drilling into wall or roof panels. (c) One disease caused by exposure to asbestos is mesothelioma, a cancer that develops in the mesothelium, a lining covering major organs. It most commonly develops around the lung lining though the abdominal lining (peritoneum) may also be affected. Other diseases are cancer of the bronchus (lung cancer) and asbestosis, pneumoconiosis where scar tissue is irreversibly formed. Signs and symptoms are generally common to all the diseases and include chest pain, coughing, shortness of breath and emphysema. An additional symptom of lung cancer is spitting up blood while those of asbestosis are a progressive reduction in lung capacity and a pre-disposition to lung cancer. As far as latency is concerned, symptoms may not be apparent for some time. (d) The equipment that should be used to determine the level of asbestos fibres in the air of a workplace comprises a controlled flow sampling pump fitted with a filter head with cowl and a membrane filter to capture fibres. The method used follows a published standard and involves the calibration of the pump and drawing a known volume of air (calculated from time and the pump flow rate) through a membrane filter. The filter is removed after sampling and mounted on a microscope slide and the number of fibres counted. The concentration is calculated as fibres per ml from the fibres counted and the calculated volume of air used in obtaining the sample. 8 (a) Give the meaning of the following AND give an example: (i) carcinogen; Marks:2 (ii) mutagen. Marks:2 (b) A health and safety practitioner and an occupational health nurse are preparing a training presentation to be given to workers who could be exposed to carcinogens in the workplace. Describe control measures specific to carcinogens that should be included in the presentation. Marks:6 (c) Other than assisting health and safety practitioners outline additional functions an occupational health nurse may have in a large organisation. Marks:10 July, 2010

- 10. ANS (a) Carcinogen is an agent which has the ability to produce malignant tumours and which may attack the cell reproduction mechanism. It causes changes in the cell’s DNA such as the production of abnormal cells with uncontrollable growth and its effects are irreversible, continuing well after exposure to the agent has taken place. A mutagen causes mutations or changes in the DNA of cells and the damage caused can be passed on to future generations. The damage to the cell may kill it and there is always the danger that it can in addition lead to cancer. (b) it would be beneficial to begin the presentation (to workers be exposed to carcinogens) with An explanation of the nature of carcinogens such as their special properties and how they differ from normal toxins. Information should also be included as to how they might be identified such as through labels with reference given to warning phrases and hazard symbols that might be used. As for control measures, these would include limiting their use to a level as low as reasonably practicable and by using a totally enclosed system. It would also be necessary to provide appropriate storage including the use of closed/sealed containers which should, for transfer be labelled and securely closed. Areas where the carcinogens are used should be designated with identifying signs to indicate their boundaries. Precautions should also be taken against contamination including the prohibition of eating and drinking in contaminated areas and the provision of adequate washing facilities. While personal protective equipment such as overalls and gloves should be worn, Workers should be made aware that the equipment is only useful as a secondary control in combination with other controls. (c) The occupational health nurse would have an important part to play in carrying out a General assessment of health risks in the workplace, Preventing health problems and Promoting healthy working conditions. The nurse’s functions might include among others, Health screening and surveillance; Providing first aid treatment or training others to carry this out; Interviewing workers following periods of sickness or on their rehabilitation; Taking part in pre-employment assessments; and Very importantly offering counselling and support when this is needed.

- 11. 9 RRC- IB4- SAQ2 Describe the control measures that should be adopted when, because of the nature of the work, it is not possible to eliminate a carcinogen or substitute it with an alternative substance. (16) Specific control measures that should be adopted when it is not possible to eliminate a carcinogen or substitute it with an alternative substance include Reducing exposure to a level as low as reasonably practicable by minimising quantities used and/or changing the physical form; The use of a totally enclosed system or automation of the process to physically separate workers from the process and, where this is not possible, the use of a partial enclosure in the workplace or appropriate local exhaust ventilation. It would also be necessary to provide appropriate storage including the use of closed/sealed containers and recognition that it may be better to store one large quantity in a controlled manner than to deal with frequent supplies of smaller amounts. Materials would have to be correctly labelled and the areas of use restricted with identifying signs to indicate their boundaries. Any waste carcinogenic products should be labelled and stored in a secure area pending removal by a specialist contractor. The numbers working in the restricted areas should be minimised and non-essential personnel excluded. Precautions should also be taken against contamination including prohibiting eating, drinking and applying cosmetics in contaminated areas; Providing appropriate warning signs to demark these areas; and Providing adequate washing facilities. 10.July, 2008 + carcinogen / mutagen def (4m) RRC – IB4 – SAQ1 Outline a hierarchy of control measures which would be applied to carcinogens in the workplace. (10) Plan Eliminate, substitute, minimise amounts, total enclosure, LEV, control exposure, procedural controls, PPE, health surveillance, emergency. Suggested Answer A hierarchy of control measures that would be appropriate when using carcinogens in a workplace would be: Eliminate the carcinogen where reasonably practicable. Prevent exposure, preferably by substitution for a non-hazardous substance or a considerably less hazardous substance. Design and use work processes, systems and engineering controls so as to minimise the amounts of carcinogens needed or produced as by- products.

- 12. Control at source, by using totally enclosed systems or by the use of local exhaust ventilation systems. Use organisational measures to control numbers exposed and level/duration of exposure and quantities used/stored in the workplace. Control the working environment (including using general ventilation). Prohibit eating/drinking/smoking in potentially contaminated areas. Clean surfaces (walls, etc.). Designate potentially contaminated areas and use warning signs. Use safe storage, handling and disposal methods (includes using closed and labelled containers). PPE (e.g. RPE) as a last resort (in addition to all the above). Health surveillance for exposed workers. Develop emergency and spillage procedures. 10 (a) Outline, using a relevant example, why and how a retrospective case control study is carried out. Marks:5 (b) Outline factors that affect the reliability of this type of study. Marks:5 Jan, 2008 11 RRC - IB2- LAQ2 As part of a foam manufacturing process, a resin is mixed with a hardener that contains toluene di-isocyanate (TDI). Pre-employment screening is undertaken in order to exclude susceptible individuals. (i) Identify the possible health effects of TDI. (6) (ii) Identify the type of health screening that is likely to be conducted and outline the signs and symptoms that might lead to the exclusion of potential employees from the process. (4) (iii) Describe measures that could be taken to reduce the employees’ exposure to TDI. (10) ANS (i) Isocyanates can cause eye irritation, allergic dermatitis and respiratory sensitisation (leading to asthma). Allergic dermatitis is where the skin becomes sensitized to the isocyanate. This occurs over time, as a result of over- exposure to the solvent. Once sensitized, exposure to the solvent will lead to a whole skin reaction, i.e. the skin all over the body may become red, inflamed, itchy and this may lead to cracked skin, flaking, suppuration, etc. Respiratory sensitisation involves the same process occurring to the lungs through inhalation of solvent vapours. Once sensitised, any exposure to isocyanate vapour may bring on an asthma attack. (ii) Health screening – questionnaires (skin, breathing function), medical examination, health assessment (lung

- 13. function). Signs/symptoms – existing allergies, asthma, predisposition to asthmatic conditions, depressed lung function. (iii) In order to reduce employee exposure to the TDI there are a range of options that might be considered: Eliminate TDI and all other forms of isocyanate from the workplace. This might be done by moving to a totally new production process, or by buying in foam pre-manufactured, so that the isocyanate-dependant part of the process is avoided. Substitute TDI for less harmful forms of isocyanate solvent, such as MDI or HDI. Apply an engineering solution and totally enclose the part of the process where TDI is handled and solvent fumes are generated. This might be done by direct dosing of the solvent (rather than hand dosing) and by automation of plant. If total removal of workers from the process is not possible, then total enclosure in a handling booth (so that workers who do not need to be exposed are not exposed) should be considered. In this instance, any workers who have to come into contact with TDI must wear PPE which would include appropriate gloves, apron, face protection and respiratory protection. Minimisation of the quantities of TDI being handled is a very practical step. Local exhaust ventilation (LEV) must be applied to any enclosures where TDI is handled/exposed. This LEV must be maintained, cleaned, inspected and tested. Training must be given to all employees on the hazards associated with TDI and the precautions to follow. This would be particularly important, of course, to the employees who actually work with the solvent. 12 RRC- IB2- LAQ2 A small motor vehicle repair workshop uses paints known to contain isocyanates. (a) Outline the health effects from exposure to isocyanates. Marks:3 (b) Outline the factors to consider when assessing the risks arising from using these paints. Marks:7 (c) Outline the practical measures to control exposure to the isocyanates when spray painting the vehicles in the workshop. Marks:10 Q8 Jan 2013 Jan, 2011

- 14. Element IB2: Hazardous substances and other chemicals – assessment of risk IB3: HAZARDOUS SUBSTANCES – EVALUATING RISK 1 RRC- IB3 – SAQ1 (a) Use the data below to calculate the 8-hour Time-Weighted Average (TWA) exposure to a solvent for a factory worker. Your answer should include the detail of calculation to show your understanding of how the exposure is determined. Marks:7 Assuming that exposure is zero during all other times Also assume that a legally enforceable Exposure Limit (8 hours TWA) of 100 ppm is applicable to the solvent (b) The factory decides to change the working patterns so that each worker does a single job for a 12-hour shift. A factory worker is assigned the job of charging the mixers for his 12-hour shift. Within the shift he is allowed two 45 minute breaks where the exposure is assumed to be zero. (total break is 1.5 hours) Using the relevant data above, recalculate the equivalent 8-hour TWA exposure in the worker’s new role AND outline the legal implications of this change. Marks:3 ANS (a) How the 8 hour TWA exposure to the solvent for the worker could be calculated: Firstly by multiplying together each time period and exposure including the periods of zero exposure, then adding the results of the calculations together and finally dividing by eight (8). This would give an answer of 75 ppm. Numerically, this could be expressed as: ((140 x 2.5) + (0 x 0.25) + (100 X 2) + (0 X 1) + (25 X 2) + (0 X 0.25))/8 = 350 + 0 + 200 + 0 + 50 + 0 = 600 600/8 = 75 ppm. This is below the legally enforceable exposure limit of 100 ppm. Working Period (Total shift time = 8 hours) Tasks undertaken by worker Exposure to solvent (ppm) 08.00 – 10.30 Weighing ingredients 140 10.30 – 10.45 Break 0 10.45 – 12.45 Charging the mixers 100 12.45 – 13.45 Lunch 0 13.45 – 15.45 Cleaning equipment 25 15.45 – 16.00 Assisting maintenance staff 0 July, 2010 Jan, 2009

- 15. (b), a similar calculation would have shown an exposure of 131.25 ppm viz: ((100 x 10.5) + (0 x 1.5))/8 = 1050/8 = 131.25 The change in the mode of working has increased the individual’s exposure so it is now more than the legal exposure limit and accordingly the employer is no longer adequately controlling exposure and must introduce additional controls. 2 Workers in a chemical plant are provided with gloves to protect against the possible effects of the chemicals. In recent months, there has been an increase in the number of hand and lower arm skin complaints amongst these workers. OUTLINE possible reasons for this increase in skin complaints. Marks:10 The possible reasons for the increase in skin complaints such as - An incorrect initial selection of the protective gloves both as far as their material was concerned and their size and fitting; - The fact that the gloves had degraded over time and had not been replaced or had been damaged either accidentally or intentionally with workers cutting off the finger ends to increase their dexterity / skill; - The possibility of workers having an allergy to materials such as latex or the presence of excess perspiration following long periods of use; - The failure to give the workers training in the methods to be adopted in putting on and removal of the gloves, and in the importance of self-examination, personal hygiene and the use of after-care products; - A failure to clean gloves after use and to store them away from contaminants; - The absence of a system for reporting defects and replacing the protection; - Inadequate levels of supervision to ensure workers used the gloves at all times and finally the possibility that a new chemical together with a change in process and work methods has been introduced. 1.Jan, 2011 JULY 2013 3 RRC – IB3- SAQ2 Safety Data Sheets (SDSs) provide important information to employers who are required to assess exposure to hazardous substances in their workplace. A typical SDS is divided into sections that contain different types of information. Identify FIVE different types of information contained in a SDS, AND for EACH, outline how the information could contribute to the assessment of risk or control of exposure. Marks:10 (a) A SDS would include information on: The substance name. Jan, 2012

- 16. Information on the hazardous nature of the product (its classification, such as toxic, together with Risk and Safety phrases) and toxicological data (such as LD50, carcinogenicity). Information on the hazardous ingredients/composition (as opposed to the overall product). Physical and chemical properties (such as boiling point, volatility, physical form). Information on exposure controls/personal protection and standards (such as applicable occupational exposure limits, glove breakthrough times and measures normally recommended to reduce exposure). Stability and reactivity data (such as identification of incompatibles). Measures to be taken in emergencies (spillage, first aid, fire). (b) When assessing exposure to hazardous substances, the assessment must take account of numerous factors including How the task is carried out (e.g. pouring/spraying), Frequency and duration of exposure, Amounts used, Inherent properties (health, physical and chemical), Potential for accidental release (when exposure may be considerably greater) and the efficacy of any existing controls. The SDS is no substitute for a risk assessment, but it can provide some base data for it. Information on hazards will help to identify the inherent nature of the harm that can be caused in the first place (such as irritation or rapid destruction of skin) and the basic sites of attack (e.g. “harmful by inhalation”, “harmful if swallowed”). Physical data (such as form and volatility/dustiness) can help identify the realistic exposure potential for various routes (high volatility/dustiness means easily inhaled). Data on standards such as occupational exposure limits, etc. defines limits on what constitutes acceptable control for airborne contaminants (so gives a concrete exposure target to aim for). Recommendations on controls/PPE help choose appropriate controls to reduce/avoid personal exposure or compare with existing controls. Reactivity data informs decisions about how to avoid/limit potential higher exposure from unplanned releases (from undesirable reactions). 4 RRC IB3– Operators use a range of solvents in a manufacturing process. Describe a monitoring strategy that could be used to measure the exposure of the operators to solvent vapours. Marks:10 Jan, 2012 July, 2009

- 17. LAQ- 01 HSG173 describes a three-stage approach to a monitoring strategy. In this case the strategy might consider people/areas to monitor, timing and duration of monitoring, how to monitor. There would need to be some basic data so that an initial evaluation of exposure level might be made. This initial evaluation might make use of simple grab- sampling data (stain tubes or other methods), and possibly other techniques might be used, to get quantitative data on exposures (including personal monitoring and biological monitoring). There would also be the need to consider the analysis methods to be used. This would require reference to MDHSs (Methods for the Determination of Hazardous Substances) and other recognised sources of standard methods 5 Workers manufacturing lead-acid batteries may be exposed to a range of hazardous substances. (a) Identify the main hazardous substances likely to be in use. Marks:2 (b) Outline the control measures that should be in place to reduce the risks of exposure to the main hazardous substances in use in this process. Marks:8 ANS (a) The hazardous substances likely to be used such as lead, lead oxide, lead dioxide, lead trioxide (red lead), lead sulphate and sulphuric acid (b) Having established that elimination or substitution of the hazardous substances was not an option, the control measures may be included Prohibiting vulnerable groups such as pregnant women, those of reproductive capacity and young workers from working with lead; Designing work systems and processes, for example automation, to minimise exposure; The use of engineering controls such as exhaust ventilation and ensuring the controls were maintained and their performance monitored at regular intervals; Prohibiting eating and drinking in contaminated areas and providing facilities free from lead for this purpose and also for washing and changing; The provision and use of respiratory protective equipment to counter exposure to acid mist and lead fume; The provision of acid resistant gloves, goggles and face shields as a protection against acid splashes; 2. Jan, 2010

- 18. Carrying out regular atmospheric monitoring for the presence of lead and acid mist; Introducing procedures for medical surveillance including testing for the presence of lead in blood and providing workers with information, instruction and training on the risks associated with the process and the control measures that should be taken. There were only a few candidates who seemed to have any understanding of the process of manufacturing lead acid batteries and those who did have the knowledge, did not outline all the control measures necessary often omitting to refer to vulnerable groups, minimising exposure and the reasons for providing RPE. 6 A factory produces a range of painted and varnished furniture. Outline the factors to be considered when assessing the health risks to employees from exposure to solvents in this factory. Marks:10 The health risks from exposure to solvents are determined initially by how the substances can enter the body (eg inhalation, skin absorption) and by the effects that they might cause (eg dermatitis, toxic effects). The physical properties of the materials (volatility in particular), the quantities used, the frequency and duration of exposure, and the work methods employed will determine the level of exposure or dose. In the scenario given, it is foreseeable, for example, that the range of painted and varnished finishes may be applied by brush or by spraying and each method will result in differing levels of exposure and therefore present different levels of risk. When making any assessment of risk it is necessary to consider who is being affected. This is in terms of the number of individuals exposed and also whether there are any individuals who are at particular risk. In this scenario, those with certain pre-existing health conditions and pregnant workers may require special consideration. An assessment of health risks needs to be based on good information. Much of this can be found in written form from manufacturers’ material safety data sheets but other sources (eg published guidance) may also need to be referred to, in particular to identify whether any of the solvents in question have been assigned exposure limits. July, 2007

- 19. If there are multiple exposures to different solvents, then additive effects will need to be taken into account. Synergistic effects may also be a possibility, although more difficult to determine. Analysis of health records and recorded incidents of ill-health will also form part of a proper assessment. Finally, the assessment should consider existing control measures in terms of their nature and adequacy. However, this is only one issue amongst a wide range of other risk factors. 7 RRC – IB3 – LAQ2 Workplace Exposure Limits (WELs) are a type of Occupational Exposure Limit (OEL) used in the UK. (a) Define what is meant by a WEL and outline the criteria upon which they are set. (8) (b) Discuss the limitations of accepting the control of hazardous substances solely on the basis of minimal compliance with a WEL.(12) (a) A WEL is defined as the maximum concentration of an airborne substance, averaged over a reference period, to which employees may be exposed by inhalation. Two reference periods are used - either 15 minutes or 8 hours, referred to as the short-term exposure limit (STEL) and the long-term exposure limit (LTEL) respectively. A WEL value is set at a level at which no adverse effects on human health would be expected to occur, based on the known and/or predicted effects of the substance. This prediction is based on animal studies in most instances and sometimes on human epidemiological data. Where such a level cannot be identified with reasonable confidence, or is not reasonably achievable, then the WEL value is based at a level corresponding to what is considered to represent good control, taking into account the severity of the likely health hazards and the costs and efficacy of control solutions. Wherever possible, the WEL is not set at a level at which there is evidence of adverse effects on human health. (b) Simply achieving minimal compliance with the WEL will not guarantee legal compliance and it will not guarantee that employees are not being overexposed to hazardous substances that may be damaging their health. There are many reasons why simply working to minimal compliance cannot guarantee health and they vary depending on the nature of the substances and the exposed individual. The reasons are detailed below:

- 20. WELs take into account inhalation only, i.e. they are intended to act as OELs for airborne contaminants only. If a substance is able to enter the body through alternative routes, then compliance with WELs will not guarantee safe exposure. For example, phenol can be absorbed into the body through the skin. Phenol concentration in the atmosphere may be so low as to remain below WELs on all occasions. However, if phenol is splashed onto the skin, the skin absorption route may be enough to deliver a lethal dose to the worker. In other instances there is no known safe level of exposure. This is the case for carcinogens, mutagens and asthmagens. Where these chemicals are concerned the only safe level of exposure is zero; above zero risk exists (albeit very low risk). Consequently the law clearly indicates that control of exposure to carcinogens, mutagens and asthmagens will only be considered under control if the exposure by inhalation is to the lowest level reasonably practicable (not just under the WEL). There can be great variations in individual susceptibility to hazardous substances. Consequently, adopting the WEL approach may not ensure protection for all employees. Asthmagens are an example where low levels of exposure can severely affect a susceptible individual. In these instances, that individual will have to be removed away from any potential exposure. Another issue to consider is that these standards are all set based on the available scientific evidence. There is not complete agreement on the scientific evidence and consequently it must be recognised that WELs are not perfect standards. There will also be inevitable variations in control within a workplace. Controls may be very good one day and then not work as well the next. If monitoring and assessment is carried out during good periods and exposure is just below the WEL; then during times when controls are not working so effectively the WEL will be exceeded. Any determination of exposure levels will be subject to variation (it is not possible to apply laboratory precision in most real world workplaces) consequently there are inherent inaccuracies in readings taken in the workplace. Finally, there are issues associated with possible synergistic effects of different substances (where one exposure causes a greater effect from a simultaneous exposure). Since these possible synergies are not considered when setting WELs, they may go unnoticed in the workplace despite the fact that independent WELs are being adhered to. 8 RRC – IB3 – SAQ1 (a) Describe the physiological effects of carbon monoxide on the body and identify the symptoms that may be experienced by an exposed person. (4) (b) Outline the control measures that could be used to reduce levels of carbon monoxide in motor vehicle premises. (6)

- 21. Plan (a) CO and haemoglobin; headache, weariness, unconsciousness. (b) Eliminate, substitute, reduce production, LEV, workplace ventilation, PPE, maintenance of controls. Suggested Answer (a) Carbon monoxide is an invisible gas which forms part of the exhaust fumes from vehicles. The initial symptoms are giddiness, a sense of oppression in the chest and loss of power in the lower limbs, then the victim will fall to the ground and lose consciousness. Concentrations of about 5% will cause immediate unconsciousness. Coma and death will follow rapidly. The gas is inhaled into the lungs and then absorbed into the blood stream, where it combines with hemoglobin carried within red blood cells. Carbon monoxide molecules bind to the active site of each haemoglobin protein molecule, thus preventing the haemoglobin from carrying oxygen. In this way the blood becomes saturated with carbon monoxide and cannot carry any oxygen around the body. Asphyxiation follows rapidly. (b) The usual method of controlling the exhaust fumes is by Local exhaust ventilation; a flexible hose is fitted over the exhaust pipe and the fumes are sucked away by fans and ducts to atmosphere. This system requires: o Training for workers on correct use; o Development of procedure to ensure that it was used at all appropriate times and o Regular inspection, maintenance and testing to ensure ongoing effectiveness. Other methods of control are to provide plenty of general workplace ventilation, e.g. having the garage doors wide open, or having powered fans fitted to the building to force fresh in or exhaust air out of the building. The length of time that vehicles are left with engines running should be minimised. A carbon monoxide alarm would give early warning of increasing carbon monoxide levels.

- 22. Element IB3: Hazardous chemicals – engineering controls and personal protective equipment IB4: HAZARDOUS SUBSTANCES – PREVENTIVE AND PROTECTIVE MEASURES 1 When respiratory protective equipment is in use, it may not provide the level of protection stated by the manufacturer. Outline the possible reasons for this. Marks:10 The possible reasons include - An inadequate initial assessment which did not take into account work rate, duration of wear required and the anticipated level of contamination; - A poor air flow or a loss of battery power; - The fitting of incorrect cartridges or a failure to replace them before saturation; - Poorly fitting equipment or incompatible with other personal protective equipment being worn; - The presence of other contaminants resulting in a decrease in saturation time; - Inadequate training in its use and particularly in the care that should be taken in its removal; - Poor maintenance and inadequate storage resulting in the face piece being left exposed; - Damage occurring during use and inadequate monitoring and supervision to ensure the equipment was always used when required and - The fact that the equipment might not have been manufactured to the appropriate standards, - The considerations to be taken when selecting respiratory protective equipment rather than why, once selected, it might not provide the stated level of protection. July, 2011 July 2007 2 RRC- IB4 – SAQ3 An airborne contaminant has an Occupational Exposure Limit (OEL) of 10ppm, 8-hour time-weighted average (TWA). Engineering controls have been introduced but the airborne concentration of the contaminant in a workshop has been measured at 180ppm, 8-hour TWA. The occupational hygienist has selected a piece of respiratory protective equipment (RPE) with an assigned protection factor (APF) of 20, which is to be worn temporarily by all workers in the contaminated area. (a) Using the data above outline how the hygienist could have calculated the APF AND whether the hygienist made an appropriate selection. Marks:4 (b) OUTLINE other factors that should be taken into account when selecting appropriate RPE. Marks:6 (c) When RPE is used it may not provide the level of protection stated by the manufacturer. Outline the possible reasons for this. Marks:10 ANS of Q1 Q11 July 2012 July, 2010

- 23. ANS (a) The assigned protection factor (APF) of an item of respiratory protective equipment is the concentration of contaminant in the air divided by the concentration in the face piece. In the scenario described, the maximum concentration in the face piece to which a worker should be exposed would be the occupational exposure limit (OEL) – 10ppm. Therefore the minimum APF required would be 180/10 =18. An alternative way to arrive at the same answer was to recognise that an APF of 20 would result in a concentration of contaminant in the face piece of 180/20 = 9 ppm which is within the OEL of 10 ppm. The hygienist has therefore made an appropriate selection though respiratory protective equipment with a higher APF might be chosen to provide an increased factor of safety. (b) Lots of factors must be taken into account when selecting RPE. For example: The nature of contaminant; is it a dust, vapour, etc., is there an occupational exposure limit, is the contaminant a carcinogen, mutagen or asthmagen and is it toxic on inhalation? What is the expected duration of use of the RPE? Short duration use might allow the selection of a lower quality item whereas long–term or continual use will require a much higher specification item to be used. What is the type and nature of the work being carried out when wearing the RPE? Is it heavy or light work, what degree of movement is needed, are there space constraints that might prevent the use of larger bulky items? Are there compatibility issues with other PPE needed? If so, how can these issues be overcome without compromising the effectiveness of all PPE items? What about ease of maintenance? Some items of RPE require a high level of maintenance and therefore should only be selected where this maintenance is available and adequately resourced. What standards exist for the RPE and does it meet those standards? i.e. certified to the relevant international standard. What is the nature of the workforce? Are they capable of using the chosen items to an acceptable standard and have they been consulted and involved in the selection (user acceptability)? 3 A slightly corrosive solution is used as a treatment in part of a manufacturing process. The solution is applied by hand brushing. For this process, other methods of application are not practicable. (a) Outline the factors that should be considered in the selection of personal protective equipment to adequately protect the skin and the eyes of those involved in the process. Marks:10 (b) Outline the content of a training programme that will assist workers to use the personal protective equipment Jan, 2012 Jan, 2010 Jan, 2009 Jan, 2008

- 24. correctly. Marks:5 (c) Identify a range of practical measures (other than training) that can be taken to encourage the use of the personal protective equipment and maintain its effectiveness. Marks:5 ANS (a) The factors to be considered in the selection of personal protective equipment firstly for the hands, then for the face and eyes and finally for the rest of the body. For the selection of protective gloves, relevant factors were The chemical resistance to the corrosive solution and the chemical breakthrough time; The length of time that the gloves had to be worn; The level of dexterity required for the task; The length of the glove to afford adequate protection; The durability of the gloves; The need to ensure that a suitable range of sizes is available for the various users; and any worker allergies to the glove material or any other skin problems. In the selection of eye protection, relevant factors were The risk of splashing the face as well as eyes; The provision of advice on the use of goggles or a face shield with the appropriate level of chemical resistance and not glasses; and Their compatibility with other protective equipment if this was required. In the selection of body protection, Aprons and/or overalls and appropriate footwear. Consultation and user trials; Comfort of the equipment; Reference to legislation and ILO guidance and ensuring that that all personal protective equipment provided met the appropriate standards. (b) Workers should receive training in topics such as: The health risks of the chemical in use; The type of personal protection to be used and the reason for its use; The methods to be used for putting on and taking off the equipment without causing contamination including

- 25. decontaminating or discarding gloves after use; The methods of examining the equipment for damage or degradation, particularly gloves, and The methods for reporting defects and obtaining replacements; How to store the equipment correctly and Finally how to carry out self-examination of the skin and the action to be taken if problems were to occur. (c) Practical measures to be taken to encourage the use of the personal protective equipment and maintain its effectiveness such as : Management leading by example; Workers being involved in the selection of the equipment; Ensuring the availability of a range of sizes in gloves and fully adjustable face shields; Ensuring workers were required to sign for their equipment and maintaining records of issue; Issuing the equipment on a personal basis and providing adequate storage facilities; Using propaganda, signs and posters and incentive schemes; Monitoring compliance in the use of the equipment with a recognized code of discipline for non-use; and Finally monitoring the effectiveness of the equipment issued and replacing it with an alternative type if problems were encountered. RRC- IB4 – LAQ1 Describe the factors to consider when selecting, using and maintaining personal protective equipment to protect the hands and arms against a degreasing solvent. 20 M Page 49 4 RRC- IB4 – LAQ2 (a) Outline the routes of entry and the possible effects on the body when someone is exposed to high levels of lead. (6) (b)Outline the risk control measures that a lead-acid battery manufacturer should have in place to adequately control the risks of exposure of their employees to lead. (14) (a)Inorganic – inhalation. − Nausea, vomiting, headaches. − Anaemia, muscle weakness, kidneys. Organic – inhalation and skin. − Muscles, mania, coma. (b) Page 50

- 26. (b)In order to adequately control the risks of exposure of employees to lead, first of all a risk assessment must be done. Elimination/ substitution of the lead should be considered, though it is very likely that it is not reasonably practicable in this scenario. Lead-acid battery manufacture may involve exposure to lead through: manipulation of lead oxides; mixing/pasting; casting/melting of lead; trimming/abrading of pasted plates. Controls will include (in no particular order): Enclosing the process where possible. Changing work methods so that they minimise the generation of lead dust/fumes. Arrangements for safe handling, storage and transport of lead and lead waste (e.g. sealed containers). Reducing numbers of people exposed and their level/duration of exposure to a minimum. Minimise inventory of lead held at the workplace. Use of general dilution ventilation and LEV to control airborne concentrations. Regular cleaning of workplace (so lead dust doesn’t accumulate). Hygiene measures (washing hands before eating – use of nail brushes, facilities for laundering and changing clothes (contamination)). Prohibiting eating/drinking/smoking in contaminated areas. Provision of PPE (RPE, gloves, etc.) where necessary. Enforcing use of control measures. Monitoring airborne concentrations (where exposure is likely to be significant). Medical surveillance with blood/urine lead levels and action taken if limits exceeded. Maintenance. Training/information. Emergency procedures. Young people and pregnant workers should not be permitted to work with lead in lead-acid battery manufacture processes. 5 Workers cutting and finishing stone are exposed to stone dust. Stone dust has been assigned a legally enforceable Occupational Exposure Limit (OEL). (a) Give the meaning of ‘Occupational Exposure Limit’ (OEL). Marks:3 (b) Explain the factors to be considered when undertaking a suitable and sufficient assessment of the risks from exposure to stone dust. Marks:11 (c) Outline a suitable range of control measures that could reduce the risk to these workers from exposure to stone dust. Marks:6 July, 2009

- 27. ANS (a) An occupational Exposure Limit (OEL), is the maximum concentration of a substance to which workers may be exposed by inhalation. The concentration is measured in mg/m3 or ppm and is averaged over a reference period, either long term over a period of eight hours intended to control effects by restricting the total intake by inhalation over one or more work shifts, or short term, usually fifteen minutes, to control effects that may be seen after a brief exposure. For the control of stone dust to be adequate the OEL should not exceeded and the principles of good hygiene practice should be followed. (b) In undertaking an assessment of the risks from exposure to stone dust, factors to be considered include The health effects of the dust such as irritation to the skin, eyes and respiratory tract (physical structure such as crystalline or amorphous may also have a bearing on longer term health effects); The number of persons exposed, the level, duration and frequency of their exposure and the susceptibility of individuals such as to asthma; The routes of entry of the dust such as through inhalation or ingestion; The particle size of the dust which will determine how far into the body the dust will pass; The way in which the work is carried out whether by hand or power tool; The level and effectiveness of existing control measures and results from the monitoring of airborne contaminants and their comparison with the OEL together with the results of health surveillance. (c) As for suitable control measures, for operations carried out in a workshop, The use of local exhaust ventilation would be required but for outside work damping down would be the measure that would have to be used. Controls to be used in both situations include the use of cutting tools with in-built extraction or a damping spray; The provision and use of respiratory protective equipment (RPE) which should be comfortable to wear for extended periods of use, and compatible with other personal protective equipment such as eye and hearing protection, gloves and overalls; and Facilities both for washing, changing and for the laundering and storage of overalls. RPE users should also be subject to face-fit testing and the RPE itself properly cleaned and stored when not in use. Training for workers on hazards and precautions was also relevant.

- 28. RRC- IB4- LAQ 3 Stonemasons are exposed to irritant limestone dust in the course of their work. Limestone dust has been assigned a workplace exposure limit (WEL) in accordance with UK legislation. (a) Explain the term Workplace Exposure Limit (WEL) in this context.(3) (b) Stonemasons’ work involves both cutting and finishing of limestone. Explain the factors to be considered when undertaking a suitable and sufficient assessment of the risks from their exposure to limestone dust. (11) (c) Given that stonemasons are required to work both in a workshop and out on site, suggest a range of control measures that would be suitable in each of these situations. (6) 6 It is often necessary to monitor a worker’s personal exposure to hazardous substances using a variety of methods including: gravimetric analysis; microscopy; chemical analysis. For EACH of these three measurement principles: (a) Identify a type of hazardous substance, AND suggest a typical workplace situation, where such a measurement may be necessary; Marks:6 (b) Outline the type of equipment and the methodology used to determine the worker’s personal exposure to the hazardous substance. Marks:14 (a) The gravimetric method for measuring personal exposure to hazardous substances may be used for measuring total inhalable or respirable dusts for instance in a woodworking workshop or in the manufacture of chemicals. Microscopy would be used for the measurement of fibers such as following the accidental disturbance or planned removal of asbestos. Chemical analysis is used in the measurement of gases, vapors, fumes and some dusts in workplaces such as laboratories or those involved in the manufacture of chemicals. (b) With gravimetric, a filter on a sampling head attached to a pump is used. There are various types of sample head depending on the type of dust being determined (e.g. 7 hole, IOM and the cyclone). The filter is weighed before and after sampling and the concentration, expressed in mg/m³, is determined from the weight gain and the volume of air drawn through the pump during the sampling period. With microscopy, a membrane filter fitted on an appropriate sampling head (e.g. cowled) is attached to a pump. After sampling is completed, a phase contrast microscope is used to count the fibers. The number of fibers in a known Jan, 2009

- 29. proportion of the sample is calculated and extrapolated to the whole sample with the result being expressed as fibers per milliliter of air (f/ml). As far as chemical analysis is concerned, there are numerous active and passive collection devices. For example, a tube or sampling head with a filter impregnated with an adsorbing material such as charcoal, tenax or silica attached to a pump. After sampling it is desorbed and analyzed in a laboratory. Analysis techniques include mass spectrometry, spectrometry and gas chromatography. Concentrations are expressed in parts per million or milligrams/m³. General points associated with each monitoring method include the necessity: to calibrate the pumps used; to draw a known volume of air through the filter or tube; to take a number of samples to minimize errors in measurement; and to ensure the sampling head was placed in the breathing zone. 7 A company is considering substituting a solvent it currently uses for one that is thought to be more effective. Outline the factors that should be considered before a decision is taken to make the change. Marks:10 The information that would enable a comparison to be made between the risks from the proposed substance with those of the existing one. - Much of this information might be gained from the manufacturers’ safety data sheets for both substances. - Specific information on the proposed substance would relate to: The physical form of the substance (eg whether aerosol or liquid); The possible routes of entry of the substance into the body; Its flammability and volatility; Its short and long term health effects; Applicable exposure limits such as WELs; the quantity of the substance that would be used; The number of persons likely to be exposed and the level and frequency of their exposure; Personal susceptibilities of those involved with particular reference to workers who might be especially vulnerable such as young persons or workers with a liver or heart condition; Additional control measures that might be required; Storage arrangements for the solvent particularly in the light of its potential flammability and combustibility; The procedures that might have to be introduced for the disposal of the substance and for dealing with any emergency; and Financial issues such as the cost of providing adequate protection such as respirators and gloves. 5.Jan, 2010 Jan, 2008

- 30. 8 Outline the main design features of the following parts of a Local Exhaust Ventilation (LEV) system: (a) inlet/hood; Marks:2 (b) ducting; Marks:3 (c) fan; Marks:2 (d) outlet / exhaust. Marks:3 ANS (a) It should have considered features of the inlet or hood such as its shape and size, the material of its construction, its capture and face velocity and its positioning in relation to the contaminant source. (b) As for ducting, there would be a need to address its internal finish and the nature of its bends, the material of its construction, its transport velocity and the access provided for testing and maintenance. (c) The type of fan required whether centrifugal or axial and propeller giving reasons for the choice, the speed and power required and the possibility of the level of noise it might produce. (d) As for the outlet or exhaust, design features include its positioning, the avoidance of cowls, its ability to achieve environmental standards at the point of discharge and again the level of noise that might be produced. July, 2010 9 RRC – IB3 LAQ3 In a chemical process, workers use a mixture that contains two organic liquids, MMA and PPO. Table 1 below shows the average personal exposure levels to the organic liquids for one worker measured over an 8-hour day and Table 2 shows the exposure limits for the two components (MMA and PPO). Table 1 Assume that exposure is zero at all other times. Task undertaken by worker Duration of task Exposure to MM (PPM) Exposure to PPO (ppm) Measuring out and adding mixtur e to process vessel 15 minutes 70 200 Adding other components to the mix 1 hour 20 200 Supervision of mixing 2 hours 35 200 Transfer of product to containers 2 hours 40 200 Q9. July 2012 JULY 2013

- 31. Substances in a mixture may interact in different ways to cause harm. (a) Outline what is meant by independent, additive and synergistic interactions. (4) (b) Using the information in Table 1, calculate the 8- hour Time- Weighted Average (TWA) exposure of the worker to BOTH MMA AND PPO. (8) Your answer should include detailed working to show you understand how the exposure is determined. (c) Using relevant information from Tables 1 and 2, explain what actions might be required by the employer to control exposure. Assume that the components have independent toxic action. (8) a) Independent means the action is on different organs or tissues (or different mechanism); additive means they act on the same organs/tissues (or similar mechanism); and synergistic is where the combined effect is considerably greater than the sum of the individual effects. had few problems with the calculations in part (b), easily evaluating the MMA concentration as 23.4ppm and PPO as 131.25ppm. For part (c), candidates needed to note that neither the MMA nor the PPO time weighted average concentrations exceeded their respective exposure limits (long-term or short-term). It was important to explain this by reference to the data in the tables. That established, other actions may still be needed. For example, more detailed/extensive measurements to confirm the result was true for other areas and employees. The assumption of independent action may also be invalid, so may require investigation. Other components are also mentioned (in the second step) and these might need to be measured. In any case, routine periodic monitoring should be undertaken going forward. Substance Exposure limit Long-term exposure limit (8-hour TWA limit reference period)ort- term exposure Short-term exposure limit (15-minute reference period) 15-minute MMA 50 100 PPO 200 250 10 (a) Outline why it is important to measure transport (duct) velocity when assessing the efficiency of a local exhaust ventilation (LEV) system. Marks:2 (b) Outline the methods that can be used to measure transport velocity in an LEV system. Marks:5 (c) Identify other measurements that can be used to determine if the LEV system is working as designed. Marks:3 Q6. Jan 2013 Jan, 2011 Jan, 2009 11 Outline the mechanisms by which the body may defend itself against harmful exposures to chemical substances. Marks:10 Q2. Jan 2013 July, 2007

- 32. Element IB4: Monitoring and measuring IB5: HAZARDOUS SUBSTANCES – MONITORING AND MAINTENANCE OF CONTROL MEASURES 1 RRC- IB4- SAQ1 Outline the tests that could be used to assess the efficiency and effectiveness of local exhaust ventilation systems. (10) LEV depends on the flow of air into the hoods, up the ducts and through any filters; The clean air is then passed out to the atmosphere. The presence of the airborne contaminant that is supposed to be controlled by the LEV might be assessed. This might be done by conducting static sampling or personal dosimetry in the work area that the LEV extracts from. Visual assessment of the areas might also be made (e.g. by looking for excessive build-up of dust on surfaces in a workroom which would indicate the LEV is not working well). Qualitative assessment of the LEV infeed efficiency might be made by either using a Tyndal beam to visualize particulates, or using a smoke generator to track air flow into the hoods. Pitot-static tubes and manometers can be used to measure the static pressure at the hoods and in ducts. The velocity of the flow of air can be measured to ensure that the particulates are not sticking to the sides of the ducts. This might be done using anemometers of various types (e.g. heated head or hot wire type). Flow meters can be used to measure the volume of air passing through the fans. Other tests can be carried out to test the effectiveness of the filters. This might be done using simple manometers to ensure those filters are not going blind (becoming clogged). Tests might be carried out on the purity of the cleaned air on the exhaust side of the ducts. Page 45 2 RRC- IB5- SAQ3 You have been sent a copy of a “local exhaust ventilation (LEV) examination report” conducted by an external organisation and relating to an LEV system in one part of your company’s production area. You have been asked by the production manager to comment on the suitability of this report, before the company goes ahead and commissions further LEV examination work throughout the rest of the factory. Outline the issues you would need to consider when assessing the adequacy and quality of the report in order to provide relevant comments to the production manager. (10) A record of LEV inspection and test should at least cover: Identification of the LEV plant, process and substance(s) being controlled with some reference made to the appropriate local standards. The date of last examination and test. The LEV’s intended (design) performance specification. The current LEV performance (as ascertained by a range of techniques, with results; e.g. static pressure, face velocity, dust lamps, visual inspections, etc.). Page 58

- 33. A clear indication as to whether any improvements/repairs are needed (which will depend on an analysis of current performance relative to design and taking account of any standards). The date of examination/test. The name of person (and their employer) doing the test, along with any relevant credentials (qualifications, accreditations). Reference to appropriate methodologies, standards and details of any calibrations carried out on technical equipment used. The requirement to keep the record for an appropriate period of time. All of these factors would be used to assess the adequacy of the LEV report, along with general impression of the report and whether it was legible or not. 3 Organic solvents, which are classified as harmful and sensitising, are used as a thinning agent for paints which will be used by workers. (a) Outline the principles and methodology of the following air monitoring techniques used to assess the workers’ exposure to the organic solvents: (i) grab sampling using a direct reading instrument; Marks:4 (ii) active static sampling; Marks:4 (iii) active personal sampling. Marks:4 (b) Outline the strategy to be used in the prevention and control of exposure to the organic solvents. Marks:8 (a) (i) Grab sampling with a direct reading instrument, a stain tube detector connected to a bellows or hand piston pump and specific to the contaminant being sampled, would be used. A known volume of air would be drawn across a chemical reagent in the tube and the organic solvents in the air sampled would react with the reagent causing the stain colour to change. The concentration of organic solvent in the sample area may be read off directly from the degree of colour change. (ii), The technique of active static sampling can be used to assess the general level of organic solvents in the environment and may also assist in assessing the effectiveness of any engineering controls provided. A mains/battery operated pump is used with the solvent being absorbed onto or into a suitable sorbent and it is important to place the equipment in strategic positions around the workshop. (iii) The technique of active personal sampling is used to estimate a worker’s level of exposure during a shift. A sampling device connected to a low or constant flow sample pump is worn in the worker’s breathing zone. July, 2011 JULY 2013

- 34. (c) The organic solvents are absorbed onto an absorbent medium whether liquid or solid, and chemical analysis is used to measure the quantity of organic solvent absorbed. In devising a strategy for preventing or controlling exposure to organic solvents, Consideration would have to be given to the substitution of the solvents with substances that are less hazardous and to changing the method of applying the paint particularly if it is currently sprayed. It might also be possible to isolate the process and to minimise the number of workers exposed to the solvents by reducing both the quantity of paint used and the exposure time of the workers. A local exhaust ventilation system could be fitted in the application area and Procedures introduced to deal with any spillages that might occur. Workers could be provided with respiratory protective equipment and other personal protective equipment such as overalls and gloves and Given instruction and training in the hazards associated with the process and the control measures to provided, particularly in the use and fitting of the protective equipment and clothing. Additionally it would be necessary to provide adequate washing facilities and facilities for the storage of clothing and to prohibit eating and drinking in the work area. 4 Construction workers regularly use cement. Several of the long-term workers and one of the new recruits have complained about red and sore skin on their hands. (a) Explain the possible reasons for the symptoms they are experiencing. Marks:6 (b) Outline control measures that could be used to minimise these symptoms in this situation. Marks:4 ANS (a) The symptoms suggest that the workers are suffering from dermatitis caused by a chronic or repeated exposure to an irritant or irritants. Cement is a known irritant which can cause allergic contact dermatitis through contact with a sensitizer - chromium compound impurities in the material-that produces an overreaction from the body’s immune system. Sensitization can occur on first contact such as with the new recruit or after some time in the case of the long term workers. The effect of contact with the irritant de-fats and degreases the skin and overcomes the skin’s own defense and repair systems. Friction and abrasion from general floor lying will not help the condition. (b) The control measures that could be used to minimize the symptoms such as

- 35. Using a non- cement based compound, for example, a polymeric compound; Wearing gloves to protect the skin and minimizing contact by the use of hand tools; Providing washing facilities so that contaminants can be washed from the skin as soon as possible with the hands dried thoroughly after washing; Using pre-work and after work moisturizing creams to replenish the natural oils in the skin; Giving information to the workers on the importance of carrying out their own skin inspections and encouraging them to report any problems with their skin; and Arranging for supervisors to carry out regular skin inspections of the workers. Jan, 2012 July, 2009 5 A contractor is hired to fit a noticeboard in a small meeting room in an office block. This task involves drilling through some asbestos insulating board. (a)Outline the diseases caused by exposure to asbestos including their health effects. (7) (b)Outline the issues the contractor should consider when assessing the risk of exposure to asbestos arising from this task. (5) (c)Outline control measures the contractor should take when carrying out this task. (8) (a), Four main asbestos-related diseases were (Mesothelioma, asbestosis, diffuse pleural thickening and cancer of the bronchus), Together with their associated health effects, such as chest pain, breathing difficulties and spitting up blood. (b), The risk assessment should consider a wide range of issues including The type of asbestos, whether it was likely to become airborne (and in what concentration) and The steps needed to prevent or control exposure. These and others are nothing more than standard risk factors in any hazardous substance assessment. Some misinterpreted this part of the question and instead provided a method statement or a list of controls rather than risk factors. (c), Range of items from the hierarchy of control but often did not give sufficient detail for the marks available. Control measures would include: Limiting numbers of people exposed (various methods to achieve this); Limiting contamination spread; limiting fibre emission at source (work methods) and Capturing fibres that did escape; and use of specific PPE. Q10 Jul 2012