Imran IME

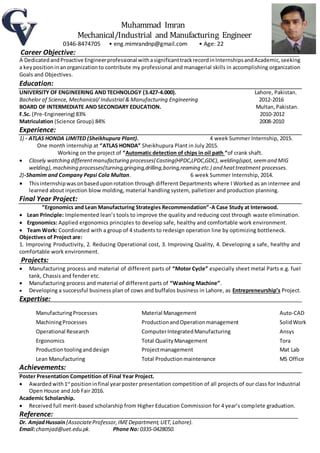

- 1. Muhammad Imran Mechanical/Industrial and Manufacturing Engineer 0346-8474705 • eng.mimrandnp@gmail.com • Age: 22 Career Objective: A DedicatedandProactive Engineerprofessional withasignificanttrackrecordinInternshipsandAcademic,seeking a keypositioninanorganizationto contribute my professional and managerial skills in accomplishing organization Goals and Objectives. Education: UNIVERSITY OF ENGINEERING AND TECHNOLOGY (3.427-4.000). Lahore, Pakistan. Bachelor of Science, Mechanical/ Industrial & Manufacturing Engineering 2012-2016 BOARD OF INTERMEDIATE AND SECONDARY EDUCATION. Multan, Pakistan. F.Sc. (Pre-Engineering) 83% 2010-2012 Matriculation (Science Group) 84% 2008-2010 Experience: 1) - ATLAS HONDA LIMITED (Sheikhupura Plant). 4 week Summer Internship, 2015. One month internship at “ATLAS HONDA” Sheikhupura Plant in July 2015. Working on the project of “Automatic detection of chips in oil path “of crank shaft. Closely watching differentmanufacturing processes(Casting(HPDC,LPDC,GDC),welding(spot,seemand MIG welding),machining processes(turning,gringing,drilling,boring,reaming etc.) and heattreatment processes. 2)-Shamim and Company Pepsi Cola Multan. 6 week Summer Internship, 2014. Thisinternshipwasonbaseduponrotation through different Departments where I Worked as an internee and learned about injection blow molding, material handling system, palletizer and production planning. Final Year Project: “Ergonomics and Lean Manufacturing Strategies Recommendation”-A Case Study at Interwood. Lean Principle: Implemented lean’s tools to improve the quality and reducing cost through waste elimination. Ergonomics: Applied ergonomics principles to develop safe, healthy and comfortable work environment. Team Work: Coordinated with a group of 4 students to redesign operation line by optimizing bottleneck. Objectives of Project are: 1. Improving Productivity, 2. Reducing Operational cost, 3. Improving Quality, 4. Developing a safe, healthy and comfortable work environment. Projects: Manufacturing process and material of different parts of “Motor Cycle” especially sheet metal Parts e.g. fuel tank, Chassis and fender etc. Manufacturing process and material of different parts of “Washing Machine”. Developing a successful business plan of cows and buffalos business in Lahore, as Entrepreneurship’s Project. Expertise: Achievements: Poster Presentation Competition of Final Year Project. Awardedwith1st positioninfinal yearposter presentation competition of all projects of our class for Industrial Open House and Job Fair 2016. Academic Scholarship. Received full merit-based scholarship from Higher Education Commission for 4 year’s complete graduation. Reference: Dr. AmjadHussain (AssociateProfessor,IMEDepartment,UET,Lahore). Email:chamjad@uet.edu.pk. Phone No: 0335-0428050. ManufacturingProcesses Material Management Auto-CAD MachiningProcesses ProductionandOperationmanagement SolidWork Operational Research ComputerIntegratedManufacturing Ansys Ergonomics Total QualityManagement Tora Production toolinganddesign Projectmanagement Mat Lab Lean Manufacturing Total Productionmaintenance MS Office