Lean production drives quality and performance in Malaysian manufacturing

- 1. The current issue and full text archive of this journal is available at www.emeraldinsight.com/0265-671X.htm IJQRM 29,1 Lean production supply chain management as driver towards enhancing product quality and 92 business performance Case study of manufacturing companies in Malaysia Arawati Agus Graduate School of Business, Universiti Kebangsaan Malaysia, Bangi, Malaysia, and Mohd Shukri Hajinoor Faculty of Economics and Management, Universiti Kebangsaan Malaysia, Bangi, Malaysia Abstract Purpose – The purpose of this paper is to obtain a better understanding of the extent to which lean production permeates manufacturing companies in Malaysia by drawing on supply chain management (SCM) managers’ or production managers’ perception of lean production practices and level of performances in the industry. Design/methodology/approach – The instrument used in this study is a structured survey questionnaire consisting of two major parts. The first part comprises several variables measuring lean production practices, and the second part consists of several performance measurements. Sample companies are chosen from Malaysian manufacturing companies listed in the Federation of Malaysian Manufacturers directory. From the 300 companies sampled, 200 responses were completed, representing a 67 per cent response rate. Findings – The results support the conceptual model, demonstrating strong association between lean production, product quality performance, and business performance. The structural equation modelling (SEM) results reveal that “reduced setup time” appears to be of primary importance in the linkage between lean production, product quality performance and business performance. It is also instructive, from a score of 67.21 on the Malaysian Lean Production Index (MLPI), that manufacturing companies in Malaysia must marshal their effort to implement a more effective lean production SCM in order to improve on product quality performance and business performance. Practical implications – This research adds to the body of knowledge on lean production SCM in manufacturing industry. This paper may be of particular interest to practicing production managers, or SCM managers, as it suggests what factors should be emphasized in lean production. Originality/value – The originality of this paper lies within the context in which this study is undertaken as it seeks to address key relationships between lean production, product quality performance and business performance within the Malaysian manufacturing industry, where International Journal of Quality relatively few studies are available. In addition, relationships between constructs are analyzed through & Reliability Management SEM that measures not only magnitude but also the causal direction of the relationships. Vol. 29 No. 1, 2012 pp. 92-121 Keywords Malaysia, Manufacturing industries, Supply chain management, Lean production, q Emerald Group Publishing Limited Product quality management, Business performance, Structural equation modeling 0265-671X DOI 10.1108/02656711211190891 Paper type Research paper

- 2. Introduction Lean production Over the past two decades, the theory and practice of supply chain management (SCM) SCM has received considerable attention from academics and practitioners alike. The pursuit for quality product and waste reduction are driven by the need to survive and remain competitive. Indeed, lean production is an integrated activity in SCM designed to achieve high-volume flexible production using minimal inventories of raw materials. Lean production focuses on continuously improving the processes, a philosophy of 93 eliminating all non-value adding activities and reducing waste within an organization (Alabama Technology Network, 1998; Inman, 1999; Davis and Heineke, 2005). According to Lambert et al. (1998), “supply chain management is the integration of key business processes from end-user through original suppliers that provides products, service, and information that add value for customers and other stakeholders.” Many manufacturing companies have fought the global pressures of competition by becoming increasingly technologically advanced, moving up-market to more value-added products, and upgrading the skills of their work force. However, irrespective of these aforementioned strategies, manufacturing companies have come under increasing pressure to deliver quality products (Randall and Senior, 1994) and to increase efficiencies (Robinson et al., 1992). To compete successfully in today’s challenging business environment, manufacturing companies ought to be able to effectively integrate internal functions within a company and effectively link them to the external operations of suppliers and supply chain members. The process of producing and distributing products and services to customers is becoming the most effective and efficient way for businesses to stay successful and is central to the practice of SCM. As global competition intensifies, manufacturing companies must have greater knowledge on how their suppliers and customers conduct business. They need to focus on processes that have critical impacts on enhancing product quality performance (PQP) and business performance. Reminiscent of most “new” operations management practices, it is the manufacturing sector that has adopted SCM principles at a much faster pace compared with other sectors including that of services. In developed countries in particular production concepts such as SCM and total quality management (TQM) were adopted by the manufacturing sector around the early 1990s. This is largely attributed to the inherent differences associated with the historical and environmental contexts in which each sector operates. In Malaysia, practices of lean SCM perhaps can be traced back to two important policy initiatives introduced in mid-1980s, namely the Look East Policy (a policy of learning from Japan and South Korea) and the Malaysia Incorporated and Privatization Policy. Malaysia Incorporated in particular was introduced in the public sector in order to turn the sector into facilitator and regulator of the economic functions of the private sector (Triantafillou, 2002). It has been noted that previously relatively little attention had been given to the application of quality and efficiency in the Malaysian public service sector (Kadir et al., 2000). Furthermore, while quality schemes are becoming an integral part of public service management, their impact on service delivery remains largely unknown (Robinson et al., 1992). With huge Japanese and American foreign direct investment driving Malaysia’s export-oriented economy in the 1900s, outcomes from the two policies later culminated into the Second (1995-2005) and Third Industrial Master Plan (IMP) (2006-2020). The Second IMP introduces the cluster approach

- 3. IJQRM to moving up the value chain while the Third IMP focuses on gaining global 29,1 competitiveness throughout the value chain. The purpose of this paper is to examine the relationship between lean production of SCM to product quality improvement and business performance in the Malaysian manufacturing industry. Although SCM practices are becoming integral part of the manufacturing sector, their impacts on product quality and business performance 94 remain largely unknown. Therefore, this paper seeks to enhance our managerial understanding of lean production and performance by addressing the following research questions: RQ1. What are the production indicators that are correlated to lean production practices? RQ2. Which lean production variables do have a significant impact on quality and business performances? Following the two research questions, the objectives of this paper are: (1) to empirically investigate the correlations between lean production and performance; (2) to empirically assess the importance of each lean production indicator on performance; (3) to empirically determine whether lean production have significant impact on PQP; (4) to empirically examine whether lean production have significant impact on business performance; and (5) to empirically test whether there is a direct effect of PQP on business performance. This paper is divided into five sections. After this introduction, second section provides a description of lean production as found in the literature. Third section constructs a conceptual model that attempts to link lean production to product quality improvement and business performance. Here the model is tested through an exploratory study in order to determine the extent to which the adoption of lean production has an impact on product quality improvement and business performance in the Malaysian manufacturing industry. Fourth section discusses the results followed by the fifth section that concludes this paper with implications for both academics and practitioners. Lean production system of SCM A supply chain is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials into intermediate and finished products, and the distribution of these finished products to customers (Ganeshan and Harrison, 1999). SCM is a theory grounded in the field of logistics. Introduced by Houlihan (1984), it developed initially along the lines of physical distribution and transport using the technique of industrial dynamics based on the work of Forrester (Lamming, 1996, p. 2). Later in the 1990s attention focused on a debate regarding the need for closer relationship between customers, suppliers and other relevant parties in the search of competitive advantage (Lamming, 1996, p. 2).

- 4. The theory of SCM holds that, for the eventual product or services to be commercially Lean production advantageous to the organizations involved in its creation and provision, value must be SCM added to a process faster than cost (Lamming, 1996, p. 3). Fundamental to the theory of SCM is the notion of exercising control of an identified sequence of activities from a vantage point. This vantage point is usually occupied by the firm or organization conducting the last significant transformation of the product before it reaches the consumer (through the downstream supply chain) (Lamming, 1996, p. 3). Christopher 95 (1998) simplifies that SCM is “the management of upstream and downstream relationships with suppliers and customers to deliver superior customer value at less cost to the supply chain as a whole.” SCM involves integration, co-ordination and collaboration across organizations and throughout the supply chain of such functions as distribution planning, demand forecasting, purchasing, requirement planning, production planning, warehousing, material handling, inventory, packaging, order processing, and transportation, etc. All these functions are considered as building blocks of SCM in today’s business environment. SCM seeks to enhance performance by closely integrating the internal functions within a company and effectively linking them with the external operations of suppliers and chain members. This effort requires a firm’s activities to be closely coordinated with that of customers and suppliers. More often than not, the dynamics of the market makes this coordination complicated as other firms continue to search and build strategic alliances. As a result, internally firms must have achieved a relatively high degree of integration in order to effectively reap benefits of SCM from the external coordination. This is a tall order as it calls for integration, coordination, and collaboration across organizations and throughout the supply chain. Christopher (1998) argues that SCM has the potential to assist organizations in achieving both cost and value advantages. Many researchers claim that SCM can result in better supply chain performance (Christopher, 1998; Christiansee and Kumar, 2000), however very few empirical studies have been carried out to investigate the impact of SCM on itself (i.e. supply chain performance) along with that on profitability and return on sales. The core of SCM is lean production which is defined as a set of tools and methodologies that aims for the continuous elimination of all waste in the production process. Main benefits are lower production costs, increased output and shorter production lead times. The first attempts at reducing waste in production began in late 1980s when Frederick Taylor and the early industrial engineers began to study work methods. Taylor called his ideas “scientific management” and created planning departments staffed by engineers whose responsibilities were to develop scientific methods for doing work, establish goals for productivity, establish reward systems for meeting the goals, and train workers on how to meet the goals by using the methods (Taylor, 1964, p. 25). As noted by Womack et al. (1990), Shingo (1989) and Krafcik (1988), in early 1990s lean production concept was viewed as a counter-intuitive alternative to traditional Fordism manufacturing model. By mid-1990s, lean production has become a dominant strategy for organizing production systems (Karlsson and Ahlstrom, 1996). Womack et al. (1990, p. 7) argues that the principles of lean production can be applied equally in every industry across the globe. The modern concept of lean management can be traced to the Toyota production system, a manufacturing philosophy pioneered by Japanese engineers Taiichi Ohno and Shigeo Shingo (Inman, 1999) that emphasizes minimization of all waste and focuses

- 5. IJQRM on “doing it right the first time” (Davis and Heineke, 2005, p. 349). Although lean 29,1 production has its roots in Japan, it has been implemented successfully all over the world (Davis and Heineke, 2005, p. 349). Waste is something that customers are not willing to pay for and it should therefore be eliminated. One of the most important sources of waste is inventory. Keeping parts and products in stock does not add value to them, and should be eliminated (Karlsson and Ahlstrom, 1996). 96 Lean production is an integrated activity in SCM designed to achieve high-volume flexible production using minimal inventories of raw materials. Lean production is based on the premise that nothing will be produced until it is needed. Ideally, lean production is implemented throughout the supply chain with the signal moving backward from the customer all the way back to the most basic raw materials (Davis and Heineke, 2005). Lean production is a whole new way of thinking, and includes the integration of vision, culture, and strategy to serve the customer with high quality, low cost and short delivery times. Despite the virtues of lean production system, implementation challenges are surmountable. To highlight a vital one, lean production changes how people work but not necessarily the way they think. Most people – including so-called blue collar workers – will find their jobs more challenging as lean production spreads. They are more likely to become productive but at the same time they may find their work more stressful because a key objective of lean production is to push responsibility far down the organizational ladder (Womack et al., 1990, p. 14). The logic of lean production, leaving aside for a moment its implications for working practices and social impact, describes value-adding processes unencumbered by waste (non-value adding activities) (Lamming, 1996, p. 2). Wastes are usually grouped into the following categories: overproduction, motion, inventory, defects, waiting, transportation, extra processing, and underutilized people (Alabama Technology Network, 1998). Lean production is derived from the need to increase product flow velocity through the elimination of all non value-added activities (Arnheiter and Maleyeff, 2005, pp. 10-11). Lean production is essentially process oriented as it seeks to eliminate all non-value adding activities and reducing waste within an organization. It does so by purging out unnecessary processes and aligning the whole processes in a systematically continuous flow to optimize the utilization of resources in order to solve problems. A company that has adopted lean production concept can design, manufacture, and distribute products in less than half the time taken by other companies by using less than half of their resources (Womack et al., 1990). Lean production can also be consumer oriented. Quoting Rizzardo and Brooks, 2008), lean production is about doing things that add value from customer’s perspective. Individual and collective responsibility and accountability are at the crux of lean production system whereby workers perform challenging and fulfilling jobs in a collaborative environment. Such a system aims to avoid the shortcomings of Taylorism, including that of routinization and segregation of tasks and the division between “doing” and “planning” (Braverman, 1974). A lean production system makes worker’s production responsibility central to the continuous improvement of productivity and quality (Lee and Peccei, 2008, p. 4). This will improve productivity through reduced lead times (Lewis, 2000). As a result, companies will have a stronger focus on performance (Sohal and Egglestone, 1994) and this in turn leads toward maximizing productivity (Forza, 1996; Sohal and Egglestone, 1994).

- 6. Hanson and Voss (1998) posit that adopting a range of lean production practices Lean production bears a direct relationship to improvements in performance. Womack and Jones (2003) SCM argue that a lean system is the superior way of producing manufactured goods. Rizzardo and Brooks (2008) note that the lean process itself almost always results in company growth due to the benefits gained of quicker deliveries, higher quality, and increased responsiveness to customers. The essence of lean manufacturing is to compress the time from the receipt of a 97 customer order all the way through to receipt of payment which will result in increased productivity, increased throughput, reduced costs, improved quality, and increased customer satisfaction (Rizzardo and Brooks, 2008). A report by Mekong Capital (2004) elaborates that since lean manufacturing eliminates many of the problems associated with poor production scheduling and line balancing, it is particularly appropriate for companies that do not have enterprise requirements planning system in place or do not have a strong material requirements planning, production scheduling, or production allocation system in place. Applications of lean manufacturing is most appropriate in industries whose strategic priority is to shorten the production cycle time to the absolute minimum as the main source of competitive advantage. Examples are aplenty, most prominent are the electronics and automobile manufacturing industries whereby shorter production cycle determines competitive advantage that often includes the first mover advantage. Comm and Mathaisel (2000) and Weiss (2001) suggest that securing the full benefits of lean manufacturing requires lean production throughout the value chain. Bicheno (1999) argues that lean production need to apply to every aspect of the value chain. Womack et al. (1990) and Womack and Jones (1996) attribute advantageous manufacturing performance to lean production system by the adherence to three key principles: (1) improving flow of material and information across business functions; (2) an emphasis on customer pull rather than organization push enabled on the shop floor with a kanban system; and (3) a commitment to continuous improvement through people development. As such, lean manufacturing has evolved into comprehensive management system whose effective implementation involves cultural changes in organizations and new approaches to production, customer service, and supplier link. Success stories of lean production implementation have been somewhat mixed. Samson et al. (1993) and Dawson and Palmer (1995) describe the successful adoption of a variety of lean production programs while Sohal et al. (1993) on the other hand provide evidence of failures by which improvement initiatives “faded away” or “simply died” after a few years. According to Mekong Capital (2004) some companies that have actively conducted and implemented lean manufacturing have resulted in an improvement to their production and service lead times. Techniques of lean production vary from a company or country to another, however, most if not all focus on minimization and eventual elimination non-value adding activities. These include setup time reduction, continuous improvement programs (kaizen), pull production system, shorter lead time, and small lot sizes. Arnheiter and Maleyeff (2005, p. 9) emphasizes small batch sizes and ultimately single-piece flow. Bhasin (2008, p. 5) notes that faster setup, shorter cycle time and better

- 7. IJQRM visual management improve the operation of a factory. Lebow (1999) shows that the need 29,1 to reduce costs and shorten lead times ranked highest amongst the quoted objectives. Setup time reduction is driven by the need to being able to change over a given process to producing a different product in the most efficient manner. Reduction in setup time is necessary for cost per unit to be constant (Karlsson and Ahlstrom, 1996). Reducing the time to change from making one item to another can shorten lead times and 98 reduce inventory (Shingo, 1981; Schonberger, 1982; Krajewski and Ritzman, 2002; Suzaki, 1987). Reducing setup time will increase productivity, reduce lead time, lower total costs, and increase flexibility to adapt to a changing market and/or product mix (Rizzardo and Brooks, 2008). Reducing setup time is essentially a lean production technique that allows the mixing of production without slowing output or creating higher costs associated with non-value adding activity. The goal is to reduce or eliminate downtime. As reported by Mekong Capital (2004, p. 16) machine downtime is a significant source of unnecessary waste. One way to minimizing the changeover/setup time includes changing the physical layout of a process, having all materials and tools needed available, and using dual/spare storage bin to eliminate cleaning downtime (Mekong Capital, 2004, p. 16). Kaizen (continuous improvement) is another concept closely associated with lean production. If the elimination of waste is the most fundamental principle of lean production, then continuous improvement can be said to come second. Kaizen is a methodology focusing on continuously improving the process and emphasis on small incremental improvements. Mekong Capital (2004, p. 10) instruct teach recommends that the focus of continuous improvement should be on identifying the root causes of non value-added activities and eliminating those by improving the production process. According to Salem et al. (2006, p. 170), kaizen cannot be associated with a specific technique. However, for lean production, the kaizen system needs to be focused towards continuous improvement in line with the lean philosophy (Bhasin, 2008, p. 8). Neely et al. (2005) proposes that for continuous improvement there should be a periodic re-evaluation of the appropriateness of the established performance measurement system in response to the current competitive environment. Some of the main objectives of kaizen are to reduce waste, improve quality, reduces delivery time, assure a safer work area and increase customer satisfaction. Lean production requires striving for perfection by continually removing layers of waste as they are uncovered. This in turn requires a high level of workers involvement in the continuous improvement process. Efforts focused on the reduction of waste are pursued through continuous improvement or kaizen events, as well as radical improvement activities, or kaikaku (Arnheiter and Maleyeff, 2005, p. 9). Pull production system is a method of controlling the flow of resources by replacing only what the customer has consumed, thus eliminating not only waste but also the sources of waste. The pull system consists of production based on the actual consumption, small lot sizes, low inventories, management by sight, and better communications. In manufacturing, pull system regulates the flows on the factory floor driven by demand from downstream that pulls production upstream as opposed to traditional batch-based production in which production is pushed from upstream to downstream by a production schedule. The term pull is used to imply that nothing is made until it is needed by the downstream customer. This means that all inventory in the factory is being processed, as opposed to waiting to be processed, and that the customer usually must plan ahead by anticipating what will be require based on the turnaround

- 8. time for the supplier (Mekong Capital, 2004, pp. 7-8). As a result, major benefits of pull Lean production production system include reduction of work-in-progress or work-in-process and SCM reduction of scheduling complexities. In reality however, implementation of pull production may see, as noted by Mekong Capital (2004, p. 8), many lean manufacturers intentionally maintain certain inventories of raw materials, semi-finished products, and finished products in order to protect against variations in customer demand and unexpected late shipments from 99 supplier or from production slowdowns, and to smoothen production flow by producing some items on a continuous basis even if not required by the customer in order to accommodate the lean practice that raw materials must be delivered in batches, finished products must be shipped in batches and some processing must be done in batches due to the nature of the equipment or the process. The now famous Japanese kanban ( just-in-time ( JIT)) production system is essentially pull production such that raw materials or work-in-progress are delivered with the exact amount and “JIT” for when the downstream workstation needs it. The principle of JIT in its basic meaning implies that each process should be provided with the right part, in the right quantity at exactly the right point in time (Shingo, 1981). Another element of lean management is the reduction of variability at every opportunity, including demand variability, manufacturing variability, and supplier variability (e.g. uncertainties in quality and delivery times). Manufacturing variability includes not only variation of product quality characteristic (e.g. length, width, weight) but also variation present in task times (e.g. downtime, absenteeism, operator skill levels). Lean SCM seeks to reduce task time variation by establishing standard work procedures. The reduction in supplier variability is often achieved through partnerships and other forms of supplier-producer cooperation (Arnheiter and Maleyeff, 2005, p. 10). Lean SCM also applies to indirect and overhead activities. Any policy or procedure having a goal of optimizing the performance of a single portion of a company risks violating lean management rules (Arnheiter and Maleyeff, 2005, p. 10). Quality management practices in lean production emphasize the concept of zero quality control includes mistake proofing, source inspection, automated 100 percent inspection, stopping operations instantly when a mistake is made, and ensuring setup quality (Shingo, 1986). The essence of lean production is the compression of time and perhaps space as well from the receipt of a customer order all the way through to receipt of payment (shorter lead time). The results of this time and space compressions are increased productivity, increased throughput, reduced costs, improved quality, and increased customer satisfaction. In lean production, small lot size is preferred. Lean production focuses on materials to flow on the factory floor in the smallest lot sizes possible, with the ideal being one piece flow, so that works-in-progress between processing stages can be minimized. The smaller the lot size, the more likely that each upstream workstation will produce exactly what its customer needs, exactly when its customer needs it. Karlsson and Ahlstrom (1996) quips that a reduction of lot sizes also has other positive effect such as increasing flexibility since it is possible to switch between different parts more often. The idea of small lot size is to drive all queues toward zero in order to minimize inventory investment, shorten production lead time, reduction in downtime and disruptions due to setup time, react faster to demand changes and uncover any quality problems. Smaller production lines have fewer workers and therefore lead to greater accountability among workers at each line (Davis and Heineke, 2005; Mekong Capital, 2004). As a result

- 9. IJQRM of the implementation of lean production most companies claim that structural changes 29,1 have occurred in their organizations such as flattening the management structure (Sohal and Egglestone, 1994). A system with more decentralization of authority enabled a company to handle uncertainty and improve the efficiency of the decision-making process (Forza, 1996). Lean production will have a profound effect on human society (Womack et al., 1990) 100 and several implications for human resources (Hiltrop, 1992) such as increased autonomy and job variety (Schonberger, 1982). With lean production workers not only have higher levels of responsibility due to delegation and transfer of tasks (Womack et al., 1990) but it also drives a company to become more proactive and to have greater sensitivity to market changes (Sohal and Egglestone, 1994). Furthermore, lean production enhances workforce flexibility so that the production system can be adapted to changes of mix and volume. Flexibility is important to ensure that production scheduling and work flow advancement will become smoother (Forza, 1996). In addition, workforce flexibility helps to develop a multi-skilled work force competent of running multiple machines, doing their own quality control and solving quality problems (Klein, 1989; Aggarwal, 1985; Monden, 1983). The lean production system manages to integrate a complex plurality of productive segments into one single synchronic flow, take for example, the pull system within the plant and the pull link with the market and with suppliers (Forza, 1996). The principle of stock reduction eliminates unnecessary sequences and movements (Forza, 1996). In manufacturing, lean production leads towards operational efficiency, increased efficiency of material flow, improved supplier bond, simplified scheduling, a focus on quality orientation, and increased manufacturing flexibility (Sohal and Egglestone, 1994). Lean production enables companies to identify waste more aggressively especially in the area of raw materials scheduling and manpower utilization (Sohal and Egglestone, 1994). A lean production system has the characteristic of being able to adapt quickly to small variations in demand and trying to reduce process variance. Greater and faster feedback directly to workers and supervisors are essential in order to achieve this systemic performance (Forza, 1996). Lean production enables companies to achieve good process management and better documentation (Flynn et al., 1994) allowing companies to acquire useful knowledge and information (Forza, 1996). Clear and up-to-date documentation also increases the flexibility of operators (Flynn et al., 1994) since they can more easily find out about and learn the actual activities to be carried out (Forza, 1996). Ten3 Business e-Coach www. 1000ventures.com/business_guide/lean_production_main.html lists out some of the many benefits of the adoption of lean production system: waste reduction, production cost reduction, decrease manufacturing cycle times, work force optimization, inventory reduction, increase in facilities capacity, higher quality, higher profits, higher system flexibility, more strategic focus, improved cash flow through increasing shipping and billing frequencies. Conceptual framework of this research Exploring lean production SCM in Malaysian manufacturing industry According to the Ninth Malaysia Plan 2006-2010, the manufacturing sector contributes 31.4 percent to Malaysia’s gross domestic product and 28.7 percent of total employment in 2005. Exports from the sector constitute 80.5 percent of total merchandise exports.

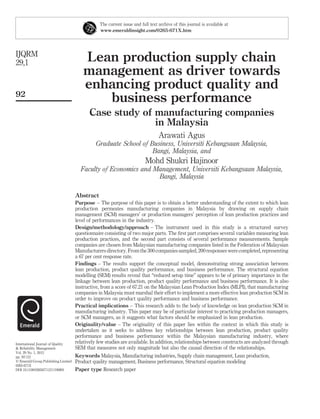

- 10. Most of these exports originate from the electrical and electronics industry; combined Lean production they make up 65.8 percent of manufactured good exports. Under the cluster-based SCM development approach adopted in the Second IMP (1995-2005), six strategic directions were identified to propel the manufacturing sector towards higher value-added activities. One of the six strategic directions was the deepening of the supply chain and one of the three strategies was to strengthen the supply chain vertically and horizontally. The reasons for focusing this study on this the manufacturing sector are threefold. First, 101 manufacturing has emerged as a leading sector in Malaysia in terms of adopting new operating and quality practices and these practices are driven primarily by competitive rather than regulatory forces. Second, the industry is heterogeneous in terms of sub-sectors and product/process complexity. Third, manufacturing as indicated earlier is a very important sector in Malaysia. Increasing global competition with customers demanding higher product quality, greater product selection, and superior customer service amid rising input costs have led many Malaysian manufacturing companies to adopt cooperative and mutual partnership strategies with suppliers in order to minimize wastage and defects, to improve product quality, and to sustain profitability and overall performance. Conceptual model This paper explores the links between lean production in SCM to PQP and business performance within the context of the Malaysian manufacturing industry. The proposed model, as shown in Figure 1, is based on three main construct namely: (1) lean production (LEAN); (2) product quality performance (PQP); and (3) business performance (BUSPERF). PRODUCT CONFORMANCE (CONFORM) PRODUCT PERFORMANCE (PERFORM) Setup time reduction Product Quality Performance PRODUCT (B5LS1) (PQP) RELIABILITY (RELIABLE) Continuous Improvement programs PRODUCT (B5LS2) (DURABLE) Lean Production Pull Production (LEAN) System (B7TI3) PROFITABILITY Shorter Lead (PROFIT) Time (B5LS4) Business MARKET SHARE Performance (MKTSH) (BPERF) Small lot size (B5LS6) RETURN ON SALES Figure 1. (ROS) Linking lean production to PQP and RETURN ON ASSET (ROA) business performance

- 11. IJQRM Lean production in this study – following that of Davis and Heineke (2005) and 29,1 Mekong Capital.com (2004) – represents a manager’s assessment of the overall level of lean production practices in SCM. Lean production not only improves performance levels but has also been shown to provide benefits in terms of outcomes (Inman, 1999; Arnheiter and Maleyeff, 2005). The model proposed here uses lean production dimensions derived from studies and documented references such as from Davis and 102 Heineke (2005) and Mekong Capital (2004). The lean production dimensions are: . Reduced setup time. A technique to reduce or eliminate downtime. . Continuous improvement programs (kaizen). An approach to continuously improving the process. . Pull production system. A method of controlling the flow of resources by replacing only what the customer has consumed. . Shorter lead time. A process of compression of time from customer order to receipt of payment. . Small lot sizes. The idea of driving all production queues toward zero in order to minimize inventory. Validity and reliability of independent and dependent constructs We premise our model on the assumption that variables constituting what we term as lean production are taken as the independent construct. We then postulate that this independent construct has positive structural effects on other variables that we consider to be the dependent construct. In order for this study to yield valid and reliable results, making a “correct” selection of the variables constituting this independent variable is crucially important. With this objective we undertake content validity tests of the constructs. Based on Nunnally (1978), content validity represents the sufficiency with which a specific domain of content (construct) has been sampled. Flynn et al. (1990, 1995) note that content validity is subjective and judgmental but is often based on the two standards set forth by Nunnally (1978): (1) whether the instrument contains a representative set of measures; and (2) whether sensible methods of scale construction have been used. In this paper, we claim that the critical variables of SCM have reasonably good content validity because of an extensive review of the literatures conducted prior to selecting the measurement items and the critical factors, and all the items and factors were evaluated and validated by professionals in the field of operations management. Testing this claim represents our first data analysis. The lean production variables (independent construct) in this study are adopted from prominent studies or sources, namely Gunasekaran et al. (2003), Kuei et al. (2001), Li et al. (2002a, b), Hill (2000), and Vickery et al. (1999). From these sources, we identify five distinctive lean production activities that manufacturers commonly use to integrate their operations with that of suppliers and customers. They are: (1) reduced setup time; (2) continuous improvement programs; (3) pull production system;

- 12. (4) shorter lead time; and Lean production (5) small lot sizes. SCM These five lean production variables constitute our independent construct. As for the dependent construct, we believe that lean production (independent construct) ought to be linked to performance. Several studies have identified performance improvement constructs that are commonly associated with lean production (Voss, 1988; 103 Gunasekaran et al., 2003; Kuei et al., 2001; Cox, 1999). Voss (1988) in particular classifies performance measures into three groups: (1) marketplace competitive advantage; (2) productivity increases; and (3) non-productivity benefits. Marketplace success involves long-term competitive gains including increased market share and greater profitability. Productivity gain comes from decreased labor costs and increased throughput. Non-productivity benefits include quality improvement and lead-time reductions. In order to capture the multi-dimensional nature of SCM performance measures, our study divides performances into two types: (1) product quality performance; and (2) business performance. Table I presents descriptive statistics along with the exploratory factor analysis of the variables. For each construct we develop a multi-item scale and check the data for normality and outliers prior to creating the final scale. Factor loadings corresponding Exploratory factor analysis (varimax rotation) Factor Factor Factor loadings 1 loadings 2 loadings 3 Variables Mean SD (Lean) (PQP) (BP) Lean production Setup time reduction (B5LS1) 5.1900 1.41204 0.845 0.196 0.191 Continuous improvement 5.5450 1.32543 0.752 0.234 0.187 programs (B5LS2) Pull production system (B5LS3) 5.1100 1.38836 0.788 0.223 0.151 Shorter lead time (B5LS4) 5.1400 1.42497 0.827 0.157 0.208 Small lot sizes (B5LS6) 4.6900 1.46788 0.506 0.263 0.147 Product quality performance Product conformance 5.4650 1.06510 0.298 0.842 0.289 Product performance 5.5450 1.03602 0.265 0.828 0.347 Product reliability 5.5750 1.09102 0.285 0.831 0.304 Product durability 5.3900 1.12438 0.271 0.844 0.281 Business performance Profitability (PROFIT) 4.9550 1.20007 0.235 0.249 0.789 Table I. Market share (MKTSH) 4.6900 1.43324 0.133 0.254 0.820 Descriptive statistics Return on sales (ROS) 4.8900 1.23105 0.255 0.301 0.839 and factor loadings Return on assets (ROA) 4.8350 1.15952 0.233 0.278 0.848 of critical variables

- 13. IJQRM to each of the three constructs shown in Table I are reasonably high, thus supporting 29,1 our earlier claim of the validity of variables selected into the model. Following Ahire et al. (1996) we undertake a confirmatory factor analysis (CFA) or model evaluation using AMOS 5 in order to evaluate the construct validity of each scale by assessing how well the individual item is gauged by the scale. Specifically, the CFA is employed to detect the unidimensionality of each construct. According to Hair et al. 104 (1998), unidimensionality is evidence of a single trait or construct underlying a set of measures. Model evaluation for each construct is treated as a single factor congeneric model containing error variances and estimated regression weights. According to Motwani et al. (1997), in order to establish the construct validity, it is crucial to determine: . the extent to which the measure correlates with other measures designed to gauge the same thing; and . whether the measure behaves as expected. As suggested by Hair et al. (1998), a score of more than 0.9 on the goodness of fit index (GFI) establishes the construct validity. Table II reports both the exploratory and confirmatory analyses along with reliability test for the three constructs. Our overall CFA indicates that all the items are loaded highly on their corresponding constructs, thus supporting the independence of the constructs and providing a strong empirical evidence of their validity. Finally, divergent or discriminant validity test is conducted by analyzing bivariate correlation between each of the lean production scales and other variables such as demographic variables and company size, etc. We find no significant correlation between these variables and the lean production variables, thus indicating that the scales measure not the other unintended constructs. Since the data for this study are generated based on scaled responses, following Frohlich and Westbrook (2001) we conduct reliability tests on the three constructs using Cronbach’s a. Items that do not significantly contribute to reliability are eliminated for parsimony purpose. The result in Table II shows that all the three constructs have the Cronbach’s a exceeding the threshold point of 0.70 suggested by Nunnally (1978), thus indicating the constructs are reliable. Alpha coefficients for lean production practices, PQP and business performance ranged between 0.896 and 0.935 Exploratory factor analysis Confirmatory (EFA) factor analysis Reliability (varimaxrotation) Percentage Cummulative (CFA) test of variance variance Construct Eigen value explained explained GFI CFI Cronbach’s a Lean 3.368 30.618 30.618 0.983 0.991 0.896 Product quality performance 3.248 29.525 60.143 0.984 0.995 0.934 Business performance 1.756 15.968 76.111 0.998 0.999 0.935 Table II. Exploratory/CFA and Notes: Extraction method: principal component analysis; rotation method: varimax with Kaiser reliability test normalization

- 14. after the alpha maximization process were carried out. As a result, the 13 variables are Lean production retained for the three constructs. SCM Hypotheses On the overall this paper hypothesizes by using a structural model that lean production practices have positive structural effects on performance results. The first hypothesis postulates that implementing an effective lean production program will enhance PQP. 105 Conceptually this makes sense; with lean management product quality will be enhanced. This study seeks to determine whether lean production has significant, positive, and direct or indirect impact on PQP. The second hypothesis proposes that implementing lean production program will improve business performance. A commonly cited benefit of lean production is that it can lead to higher PQP which in turn will lead to higher business performance. Again this study seeks to determine whether lean production has significant, positive, direct or indirect impact on business performance. In addition, we want to test the third hypothesis linking the two dependent constructs whether there is a direct effect of PQP on business performance. Specifically, this study seeks to test the following main hypotheses: H1. Lean production has a positive structural effect on PQP. H2. Lean production has a positive structural effect on business performance (BPERF). H3. PQP has a positive structural effect on business performance (BPERF). In investigating the structural effect of lean production on PQP and business performance, it is also pertinent to determine the structural loadings of each lean production determinant. Therefore, this study also attempts to test the following hypotheses: H1A. Reduced setup time has a positive structural loading on lean production. H1B. Continuous improvement programs have positive structural loading on lean production. H1C. Pull production system has a positive structural loading on lean production. H1D. Shorter lead time has a positive structural loading on lean production. H1E. Small lot size has a positive structural loading on lean production. More importantly, this study aims to test the overall model fit based on the main null hypothesis: H0. The overall hypothesized model has a good fit. For structural modeling, accepting the H0 suggests that the model adequately reproduces the observed covariance matrix (Bollen, 1989; Joreskog and Sorbom, 1989; Mueller, 1996) in order to conclude that the data fit the proposed model. Research design This paper is part of a larger study to assess Malaysian manufacturing companies in terms of the aforementioned dimensions in which a structured survey questionnaire

- 15. IJQRM serves as the main instrument. Consisting of two major parts, the instrument first 29,1 measures several SCM practices including that of lean production followed by the second part which measures performance. To enable respondents to indicate their answers, a seven-point interval scale is use in the questionnaire. Several items of lean production that have been widely referred are extracted. Similarly, the dependent variables, namely PQP and business performance, also use a seven-point interval scale that represents a 106 range of agreement on statement whether over the past three years these performances are high relative to competitors after implementing lean production practices. Research sample Sample companies are chosen from non-food manufacturing industries in Peninsular Malaysia with sampling frame derived from the Federation of Malaysian Manufacturers directory. From a total of 300 sample companies 200 responses are received (representing a 67 percent response rate). The primary purpose of the research is to investigate senior production manager’s and SCM managers’ perception of lean production and to gain insights into the benefits of implementing lean production in the Malaysian manufacturing industry. The goal is to identify the determinants of lean production that can enhance PQP and the bottom line results such as profitability, return on sale, and return on asset. Face-to-face interviews with production managers are carried out to ascertain information accuracy, validate analysis outcomes, and further develop our understanding of the practical aspects of lean production principles. Research findings Correlation analyses Pearson’s correlation analysis were conducted to examine associations among the lean variables themselves (Table III), between each of the lean variables and the overall (mean) PQP as well as the overall (mean) business performance (Table IV), and between each of the lean variables and sub-categories of PQP (Table V) and sub-categories of business performance (Table VI). Table III indicates a significant and strong association (r ¼ 0.713) between shorter lead time variable (B5LS4) and setup time reduction (B5LS1), thus suggesting perhaps it is plausible that the latter may affect the former. Therefore, in order to obtain a shorter lead time (between customer order and receipt of payment) firms can do so by focusing on shortening the setup time. Collinearity statistics Lean variables 1 2 3 4 5 Tolerance VIF 1 Setup time reduction (B5LS1) 1.00 0.362 2.765 2 Continuous improvement programs (B5LS2) 0.664 * * 1.00 0.506 1.977 3 Pull production system (B5LS3) 0.666 * * 0.595 * * 1.00 0.460 2.175 4 Shorter lead time (B5LS4) 0.713 * * 0.574 * * 0.660 * * 1.00 0.406 2.466 Table III. 5 Small lot sizes (B5LS6) 0.433 * * 0.374 * * 0.313 * * 0.448 * * 1.00 0.763 1.311 Pearson’s correlation between lean variables Notes: Significance at: *p # 0.05, * *p # 0.01; all t-tests are two-tailed

- 16. Table IV shows that among the five lean variables, continuous improvement programs Lean production (B5LS2) has the highest correlation with each the overall (mean) PQP and the overall SCM (mean) business performance with an r value higher in the former (r ¼ 0.537) than in the latter (r ¼ 0.438). Similarly small lot sizes (B5LS6) has the second highest correlation in each of the performance indicators, again with an r value higher in the former (r ¼ 0.510) than in the latter (r ¼ 424). Shorter lead time (B5LS4) takes the third place in correlation with PQP and ties with pull production system (B5LS3) in terms of 107 association with business performance. This finding suggests that continuous improvement programs coupled with a production system of small lot sizes with the focus on shortening lead time will have a significant impact both on product quality and business performance. These findings are consistent with several previous studies proclaiming better organizational transformation is a result of lean production initiatives (Inman, 1999; Arnheiter and Maleyeff, 2005). Lean production Product quality performance Business performance 1 Setup time reduction (B5LS1) 0.117 * 0.103 Table IV. 2 Continuous improvement programs (B5LS2) 0.537 * * 0.438 * * Pearson’s correlation 3 Pull production system (B5LS3) 0.382 * * 0.366 * * between lean production 4 Shorter lead time (B5LS4) 0.403 * * 0.366 * * determinants, overall 5 Small lot sizes (B5LS6) 0.510 * * 0.424 * * (mean) PQP, and overall (mean) business Notes: Significance at: *p # 0.05, * *p # 0.01; all t-tests are one-tailed performance indicators Product Product Product Product Lean production conformance performance reliability durability 1 Setup time reduction (B5LS1) 0.067 0.080 0.118 * 0.169 * * 2 Continuous improvement 0.472 * * 0.499 * * 0.503 * * 0.530 * * programs (B5LS2) 3 Pull production system (B5LS3) 0.331 * * 0.343 * * 0.396 * * 0.354 * * 4 Shorter lead time (B5LS4) 0.397 * * 0.357 * * 0.357 * * 0.396 * * Table V. 5 Small lot sizes (B5LS6) 0.464 * * 0.517 * * 0.441 * * 0.484 * * Pearson’s correlation between lean production Notes: Significance at: *p # 0.05, * *p # 0.01; all t-tests are one-tailed and PQP Lean production Profitability Market share Return on sales Return on assets 1 Setup time reduction (B5LS1) 0.058 0.096 0.099 0.112 2 Continuous improvement 0.357 * * 0.408 * * 0.408 * * 0.386 * * programs (B5LS2) 3 Pull production system 0.315 * * 0.371 * * 0.310 * * 0.297 * * (B5LS3) Table VI. 4 Shorter lead time (B5LS4) 0.324 * * 0.308 * * 0.344 * * 0.333 * * Pearson’s correlation 5 Small lot sizes (B5LS6) 0.369 * * 0.401 * * 0.357 * * 0.385 * * between lean production and business Notes: Significance at: *p # 0.05, * *p # 0.01; all t-tests are one-tailed performance

- 17. IJQRM Table V is interesting that from among the PQP it is product durability that has the 29,1 highest correlation with continuous improvement programs (B5LS2) (r ¼ 0.530) followed by product reliability (r ¼ 0.503). It is interesting also to note that small lot sizes (B5LS6) has a strong association with product performance (r ¼ 0.517), thus suggesting that small lot sizes can yield higher product quality. Table VI indicates that continuous improvement programs (B5LS2) is highly 108 correlated with both market share and return on sales (r ¼ 0.408). Small lot sizes (B5LS6) has the greatest association with market share (r ¼ 0.401). Cluster analysis and Friedman’s rank test Two cluster analyses were carried out to further explore on the segmentation of manufacturing companies in this study. The first cluster analysis categorizes companies into one of two groups: (1) “excellent” product quality producers; and (2) “average” product quality producers. Table VII indicates that lean production is implemented more extensively by “excellent” product quality producers than the “average” group. In each group, however, continuous improvement program is ranked number 1 according to Friedman’s test, thus indicating the importance of such program for product quality. Since business performance is a very important bottom-line outcome, therefore the second classification is based on average business performance clustering. This second cluster analysis categorized manufacturing companies into two groups: (1) “high” business performance achievers; and (2) “average” business performance achievers. Table VIII highlights further information about the cluster. The first cluster (“high” business performance achievers) comprises of large-scaled companies with average employees of more than 1,200 and average approximated sales turnover of more than RM 1.5 billion. Meanwhile, the second cluster (“low” business performance achievers) comprises of smaller companies with average employees less than 600 and average approximated sales turnover less than RM 80 million. From the result, we can infer that the higher level of lean production implementations is realized in “high” “Excellent” product quality “Average” product quality producers (n ¼ 66, x 2 ¼ 39.368, producers (n ¼ 54, x 2 ¼ 30.232, significance ¼ 0.000, overall significance ¼ 0.000, overall cluster’s mean ¼ 5) cluster’s mean ¼ 4) Friedman’s Friedman’s Lean production test Rank Mean SD test Rank Mean SD Table VII. Ranking the importance Setup time reduction 3.33 2 5.7424 1.32793 3.34 2 4.4074 1.43433 of lean production Continuous improvement practices to excellent and programs 3.55 1 6.0303 1.10898 3.58 1 4.6667 1.46661 average product quality Pull production system 2.76 4 5.4394 1.36019 2.73 4 4.2778 1.37932 producers using Shorter lead time 3.04 3 5.5152 1.44906 2.98 3 4.3889 1.40641 Friedman’s test Small lot sizes 2.33 5 5.0606 1.31124 2.36 5 3.9630 1.19690

- 18. business performance achievers than in the “average” group. “High” business Lean production performance achievers” put high priorities on continuous improvement programs, setup SCM time reduction, and shorter lead time. Structural equation modeling Our overall premise is that lean production has a positive influence on PQP and business performance and we test that proposition using a statistical analysis technique called 109 structural equation modeling (SEM). An SEM allows us to examine simultaneous linkages and relative strength of relationships among variables. We employ a two-step approach. First, we perform a CFA to ensure that all the indicator variables used to measure the constructs are reliable and valid. Second, we postulate and test the causal relationships between the constructs. Figure 2 shows an overview including the results of our SEM linking lean production practices to PQP and business performance. A test of goodness fit of the SEM is conducted to determine whether the specified variables provide an adequate fit to the model. This requires us to accept the H0 stated much earlier that the “overall hypothesized model has a good fit” (H0). To do so, we look for a probability result of higher than 0.05. The SEM yields a x 2 value of 73.024 with 62 degrees of freedom and p-value of 0.160 (Figure 2). This result supports the H0 that the SEM has a good fit. The p-value is considerably high ( p-value . 0.05), thus well supporting the proposition that the overall model fits the data. The direct structural effect of lean production on PQP (0.622) is considered high given the complex causal linkages, thus suggesting the importance of lean production especially the variables reduced setup time (B5LS1), pull production system (B5LS3) and shorter lead time (B5LS4) in improving product quality of the Malaysian manufacturing industry. Therefore, we have enough evidence to accept the proposition that lean production has a positive and significant structural effect on PQP (H1). The direct structural effect of lean production on business performance (0.207) is relatively low but still moderately supports the H2 of positive structural effect. Nonetheless, the indirect structural effect of lean production on business performance through PQP is significant. The direct structural effect of PQP on business performance is substantial and significant (0.554) (H3). This result suggests that lean production enables firm to enhance PQP and to ultimately improve business performance. “High” business performance “Average” business performance achievers (n ¼ 56, x 2 ¼ 35.725, achievers (n ¼ 64, x 2 ¼ 36.924, significance ¼ 0.000, overall significance ¼ 0.000, overall cluster’s mean ¼ 5.58) cluster’s mean ¼ 3.86) Friedman’s Friedman’s Lean production test Rank Mean SD test Rank Mean SD Table VIII. Setup time reduction 3.79 2 5.607 1.5217 3.44 2 4.734 1.4169 Ranking the importance Continuous improvement 4.22 1 5.946 1.4196 3.56 1 4.953 1.3145 of lean production programs practices to high and Pull production system 3.31 5 5.393 1.5097 2.67 4 4.500 1.333 average business Shorter lead time 3.71 3 5.536 1.5605 2.90 3 4.547 1.3561 performance achievers Small lot sizes 3.36 4 4.946 1.5773 2.43 5 4.234 1.0652 using Friedman’s test

- 19. IJQRM Standardized estimates Chi-square = 73.024 29,1 Degree of Freedom = 62 0.85 Probability = 0.160 CONFORM e3 0.92 0.85 0.74 0.39 0.92 PERFORM e4 d1 B5LS1 zeta1 0.82 0.90 110 0.57 0.86 PQP RELIABLE e5 0.90 0.80 0.62 d2 B5LS2 0.75 DURABLE e7 0.61 0.78 d3 B5LS3 LEAN 0.55 0.67 0.82 d4 B5LS4 0.51 0.62 0.21 0.26 0.79 PROFIT e10 d5 B5LS6 0.49 0.63 0.79 MKTSH e11 zeta2 BUSPERF 0.93 0.86 Figure 2. e12 ROS SEM showing structural 0.91 0.84 linkage between lean ROA e13 production, PQP, and business performance File:SCM-200-LEAN File:scm-200-ZG1PAPERLEAN Furthermore, other statistical structural indices such as the Bentler comparative fit model (0.995), Bollen incremental fit index (0.995) and Tucker and Lewis index (0.993) further suggest that the model has a satisfactory fit (Table IX). Following Hair et al. (1995), since our probability value (0.16 . 0.05) and structural modeling indices in Table IX are well above the recommended level, the model is considered to be a reasonable representation of the data. Besides being able to study the impact of lean production (independent construct) on PQP and business performance (the two dependent constructs) simultaneous, the SEM can also measure the magnitude and contribution of those constructs. Results of our SEM suggest that lean production contributes positively towards enhancing PQP and ultimately business performance. Now examining the loadings on the main construct (of lean production practices) in Table X, we can spot that reduced setup time Statistics Model values Recommended values for good fita x2 73.024 – Probability level 0.160 $ 0.05 Degree of freedom 62 – x 2/df 1.178 # 3.00 Bollen (1989) incremental fit index 0.995 $ 0.90 Tucker and Lewis (1973) 0.993 $ 0.90 Bentler (1990) comparative fit model 0.995 $ 0.90 Normed fit index 0.996 $ 0.90 Table IX. Goodness of fit index 0.948 $ 0.90 Measurement results of SEM Source: aChau (1997)

- 20. Lean production Std. loadings SE Critical ratio Probability SCM (i) Constructs and indicators a. Lean production (LEAN) Reduced setup time 0.862 0.088 12.841 *** Continuous improvement program 0.753 0.084 11.008 *** *** Pull production system 0.780 0.099 11.007 *** 111 Shorter lead time 0.817 0.089 12.111 Small lot sizes 0.506 0.107 6.929 *** b. Product quality performance (PQP) Product conformance 0.922 0.047 21.369 *** Product performance 0.920 0.045 21.249 *** Product reliability 0.904 0.049 21.247 *** Product durability 0.896 0.052 19.783 *** c. Business performance (BPERF) Profitability (PROFIT) 0.787 0.067 12.359 *** Market share (MKTSH) 0.793 0.064 15.429 *** Return on sales (ROS) 0.928 0.065 15.430 *** Return on assets (ROA) 0.915 0.062 15.161 *** (ii) Exogenous/endogenous path a. LEAN ! PQP (H1 is supported) 0.622 0.068 8.302 *** Table X. b. PQP ! BPERF (H3 is supported) 0.554 0.095 6.698 *** Measurement results c. LEAN ! BPERF (H2 is supported) 0.207 0.083 2.617 0.009 of the SEM (structural loading ¼ 0.862) has the highest contribution towards lean production, followed by shorter lead time (structural loading ¼ 0.817), pull production system (structural loading ¼ 0.780), and continuous improvement program (structural loading ¼ 0.753). All of these indicators have significant probability values (critical values $ 2.00), thus providing statistical evidence that their contribution towards lean production construct are significant and positive. We can obviously conclude that lean production practices can help Malaysian manufacturing companies improve their PQPs, and as a result, can ultimately enhance their business performance. Our examination of residuals also reveals that variances among variables of the constructs are perfectly explained by the respective constructs. This result highlights the unique contribution of lean production practices towards PQP and business performance such that its contribution is structural with implications of a positive feedback process working from lean production to product quality and to business performance. Malaysian lean production index This paper also attempts using SEM to calculate what we term the Malaysian lean production index (MLPI) in the context of PQP and business performance of the manufacturing industry in Malaysia. The purpose is to determine the extent of the implementation of lean production among manufacturing companies in Malaysia. The calculation follows that of Fornell et al. (1996). This paper proposes the following formula: P5 P5 i¼1 wi xj 2 i¼1 wi MLPI ¼ P5 £ 100 6 i¼1 wi

- 21. IJQRM where: 29,1 MLPI ¼ the Malaysian lean production index. wi’s ¼ the weights. xj ¼ the measurements variables. 112 The result: MLPI ¼ 67.21. A score of 67.21 on the MLPI for the manufacturing industry can be considered moderate but above average. It is instructive that more should be done by manufacturing companies in Malaysia to institute with their organizations an effective implementation of lean production system in order to improve PQP and business performance. Conclusion and implications This paper investigates the structural relationship between lean production, product quality performance and business performance in non-food manufacturing industries in Peninsular Malaysia. However, the results can be generalized for the whole country. This is because roughly more than 80 percent of non-food industries in Malaysia are located on the Peninsular. In addition, data provided in the Ninth Malaysia Plan 2006-2010 (Malaysia, 2006, Table 4-2, p. 109) indicate that 89.8 percent of the country’s manufacturing value added came from non-food industries. To meet the increasing demands for high-quality goods by sophisticated local and overseas markets, Malaysian manufacturing companies must continuously improve their performance in both products and processes. Lean production practices provide a unified vision for everyone in an organization to focus on quality improvement. This pursuit is not only market-driven but also imperative for survival during uncertain economic time. It is important to note here that by using a SEM this paper focuses on examining the strength of the relationships between lean production, PQP, and business performance as a whole rather than on the individual effect of the five lean production practices. This is because, as investigated earlier, all the five lean production practices are strongly correlated and may produce multicollinearity among the variables that will likely to confound their individual effect onto PQP and business performance should multiple regression analysis is used instead. Interestingly, with an SEM method, the strong correlation among lean production practices provides an ideal situation for compounding these variables into a single latent construct. In summary, our findings suggest three important results. First, we can conclude that lean practices such as reduced setup time, pull production system, and shorter lead time have strong positive structural contributions toward PQP. Second, there is a statistically significant but relatively moderate direct link between lean production (independent construct) and business performance (second dependent construct), thus indicating instead a significant indirect effect of lean production on business performance through PQP (first dependent construct). Third, the significant critical values indicate that PQP especially product conformance, product performance, product reliability, product feature, and product durability have positive and direct effects on business performance of the manufacturing industry in Malaysia. Finally we can suggest that reduced setup time, pull production system, shorter lead, continuous improvement program,

- 22. and small lot sizes have strong structural contributions toward implementation of our Lean production main latent construct, that is, lean production. SCM The associations and effects of the five lean production variables evaluated using correlations, Friedman test, and SEM enriches our understanding on how lean production practices influence product quality and business performance of manufacturing industries in Malaysia. Our findings offer evidences that: . Reduced setup time, pull production system, shorter lead, continuous 113 improvement program and small lot sizes have positive and direct effects on PQP. . Lean production has positive but significant indirect effect on business performance through PQP. . PQP has positive and direct effect on business performance. . The MLPI of 67.21 indicates that more should be done by manufacturing companies in Malaysia to adopt and implement lean production SCM in order to improve PQP and business performance. It is important to highlight humble contribution of this research toward our understanding of what other or previous researchers have perhaps established implicitly or explicitly about the relationships between the exogenous (lean production) and endogenous outcomes (performances) and lend credibility to a causal hypothesis that improving (internal) process leads to improvements in (external) performance results. Perhaps in the context of industry study in Malaysia this research is among the few that provide empirical evidence of the magnitude and performance gains from the implementation of lean production system. This paper is relevant to practitioners because the findings may reveal important aspects in the implementation of lean production practices, which may provide significant information managers can use to solve implementation challenges and perhaps to improve performance. The paper would be of particular interest to practicing production managers or top level managers as it suggest what factors should be emphasized to stimulate the adoption of lean production concepts in the Malaysian manufacturing industry. Moreover, the findings may provide support for continued implementation of lean practices. The result indicates that manufacturing companies should emphasize greater attention to the time reduction aspects of the lean production process and a greater degree of management support for lean production programs. Obviously, our results suggest that lean production practices enhance PQP and ultimately improve business performance in manufacturing companies in Malaysia. Limitations and future research directions This study employs a variety of validating procedures including pilot testing, personal interviews and statistically tests all measurement scales for internal reliability. Nonetheless, our primary data collection has several limitations such that the findings should be interpreted with caution. All data are self-administered by mainly senior quality or production managers and the common procedure adopted does raise some concern about method bias. Some systematic bias or common method variance may have been involved in the use of survey questionnaire and filled out by each of the single informants. Given the complexity of getting respondents, the researchers felt that these managers

- 23. IJQRM are the appropriate people to provide information about lean production practices, PQP 29,1 and market performance. However, we believe that the variance impact of systematic bias is minimized because we use relative values, such as median, variance, and covariance, rather than absolute figures. Our selection of variables may have been somewhat pre-determined although they went through appropriate validity and reliability tests. Other researchers such as Sohal and 114 Egglestone (1994) suggest that the strategic advantage generated by the adoption of lean production stems from market competitive positioning, customer relationships, and quality constraints. They also note that implementation of lean production places great benefits on other several areas including higher speed of implementation, increases in customer satisfaction, better co-operation of manufacturing personnel, efficiency of the plant and reduction in technical bottlenecks. Despite our limitation, we believe that this study offers a fresh perspective on lean production as far as how it influences manufacturing industries in Malaysia today: it has been instituted in the Third IMP (2006-2020) and the latest five-year Third Malaysia Plan (2006-2010) but from our MPLI, more efforts (such as the promotion and training) on the implementation of lean SCM at the industry level. This study points to areas of potential future research. Longitudinal research will provide valuable contributions to theory development and refinement in the field of lean production practices. There is a considerable body of knowledge in the lean production literature that suggests that best practices evolve over a considerable period of time within companies and that different challenges are faced at different points in time (Wacker and Sheu, 1994). Research from the customer’s perspective will complement and add to the findings of this study. Future research should examine issues such as customer perceptions of product quality and market performance. Moreover, future research can incorporate joint measures of performance involving product quality and business performance at the same time. Future research should also cover other types of organizations operating in Malaysia, such as other industries, multinationals and their subsidiaries as this will certainly enrich our understanding of the subject. The majority of business organizations existing in Malaysia are categorized as small or medium enterprises (SMEs). It will also be useful to investigate what aspects of lean production these SMEs emphasize and how they introduce quality ideas and practices, in particular with respect to the promotional campaign, training and learning of implementation of lean production SCM and the overall process of change in these organizations. Despite the aforementioned limitations, the researchers believe that this study helps to uncover the dynamics of lean production practices that are often described rather vaguely in the literature. Our overall result is consistent with those in the lean production literature suggesting that lean production is an important driver towards better performance. References Aggarwal, S.C. (1985), “MRP, JIT, OPT, PMS?”, Harvard Business Review, September/October, pp. 8-16. Ahire, S.L., Golhar, D.Y. and Waller, M.A. (1996), “Development and validation of QM implementation constructs”, Decision Sciences, Vol. 27 No. 1, pp. 23-55. Alabama Technology Network (1998), Lean Manufacturing Handbook, University of Alabama, Huntsville, AL.

- 24. Arnheiter, E.D. and Maleyeff, J. (2005), “The integration of lean management and Six Sigma”, Lean production The TQM Magazine, Vol. 17 No. 1, pp. 5-18. Bentler, P.M. (1990), “Comparative fit indices in structural models”, Psychological Bulletin, SCM Vol. 107, pp. 238-46. Bhasin, S. (2008), “Lean and performance measurement”, Journal of Manufacturing Technology Management, Vol. 19 No. 5, pp. 670-84. Bicheno, J. (1999), The New Lean Toolbox, Picsie, London. 115 Bollen, K.A. (1989), Structural Equations with Latent Variables, Wiley, New York, NY. Braverman, H. (1974), Labour and Monopoly Capital: The Degradation of Work in the Twentieth Century, Monthly Review Press, New York, NY. Chau, P.Y.K. (1997), “Reexamining a model for evaluating information center success using a structural equation modeling approach”, Decision Sciences, Vol. 28 No. 2, pp. 309-34. Christiansee, E. and Kumar, K. (2000), “ICT-enabled coordination of dynamic supply webs”, International Journal of Physical Distribution Logistics Management, Vol. 30 Nos 3/4, pp. 268-85. Christopher, M. (1998), Logistics and Supply Chain Management: Strategies for Reducing Cost and Improving Service, Financial Times, Prentice-Hall, London. Comm, C. and Mathaisel, D. (2000), “A paradigm for benchmarking lean initiatives for quality improvement”, Benchmarking, Vol. 7 No. 2, pp. 2-7. Cox, A. (1999), “Power value and supply chain management”, International Journal of Supply Chain Management, Vol. 4 No. 4, pp. 167-75. Davis, M. and Heineke, J. (2005), Operations Management: Integrating Manufacturing and Services, 5th ed., McGraw-Hill, New York, NY. Dawson, P. and Palmer, G. (1995), Quality Management, Longman Australia, Melbourne. Flynn, B.B., Sakakibara, S. and Schroeder, R.G. (1995), “Relationship between JIT and TQM: practices and performance”, Academy of Management Journal, Vol. 38 No. 5, pp. 1325-60. Flynn, B.B., Schroeder, R.G. and Sakakibara, S. (1994), “A framework for quality management research and associated measurement instrument”, Journal of Operations Management, Vol. 11 No. 4, pp. 339-66. Flynn, B.B., Sakakibara, S., Schroeder, R.G., Bates, K.A. and Flynn, E.J. (1990), “Empirical research methods in operations management”, Journal of Operations Management, Vol. 9 No. 2, pp. 250-84. Fornell, C., Johnson, M.D., Anderson, E.W., Cha, J. and Bryant, B.E. (1996), “The American customer satisfaction index: nature purpose and findings”, Journal of Marketing, Vol. 60, October, pp. 7-18. Forza, C. (1996), “Work organization in lean production and traditional plants”, International Journal of Operations Production Management, Vol. 16 No. 2, pp. 42-62. Frohlich, M.T. and Westbrook, R. (2001), “Arcs of integration: an international study of supply chain strategies”, Journal of Operations Management, Vol. 19, pp. 185-200. Ganeshan, R. and Harrison, T.P. (1999), An Introduction to Supply Chain Management, pp. 1-2, available at: http://silmaril.smeal.psu.edu/misc/supply_chain_intro.html Gunasekaran, A., Patel, A. and Mcgaughey, R.E. (2003), “A framework for supply chain performance measurement”, International Journal of Production Economics, Vol. 87 No. 3, pp. 333-47. Hair, J.F., Anderson, R.E., Tatham, R.L. and Black, W.C. (1995), Multivariate Data Analysis, Prentice-Hall, Englewood Cliffs, NJ.

- 25. IJQRM Hair, J.F., Anderson, R.E., Tatham, R.L. and Black, W.C. (1998), Multivariate Data Analysis, Prentice-Hall, Englewood Cliffs, NJ. 29,1 Hanson, S. and Voss, A. (1998), The True State of Britain’s Manufacturing Industry, LBS, London. Hill, T. (2000), Manufacturing Strategy: Text and Cases, 3rd ed., McGraw-Hill, New York, NY. Hiltrop, J.M. (1992), “Just-in-time manufacturing: implications for the management of human 116 resources”, European Management Journal, Vol. 10 No. 1, pp. 49-54. Houlihan, J.B. (1984), “Supply chain management”, Proceedings of the 19th International Technical Conference, BPICS, pp. 101-10. Inman, R.R. (1999), “Are you implementing a pull system by putting the cart before the horse?”, Production Inventory Management Journal, Vol. 40 No. 2, pp. 67-71. Joreskog, K. and Sorbom, D. (1989), LISREL 7: A Guide to the Program and Applications, 2nd ed., Statistical Package for the Social Sciences, Chicago, IL. Kadir, S.L.S.A., Abdullah, M. and Agus, A. (2000), “On service improvement capacity index: a case study of the public service sector in Malaysia”, Total Quality Management, Vol. 11 Nos 4-6, pp. 837-43. Karlsson, C. and Ahlstrom, P. (1996), “Assessing changes towards lean production”, International Journal of Operations, Vol. 16 No. 2, pp. 24-41. Klein, J. (1989), “The human cost of manufacturing reform”, Harvard Business Review, March/April, pp. 60-6. Krafcik, J.F. (1988), “Triumph of the lean production system”, Sloan Management Review, No. 30, pp. 6-15. Krajewski, L. and Ritzman, L. (2002), Operations Management: Strategy and Analysis, 6th ed., Prentice-Hall, Upper Saddle River, NJ. Kuei, C.H., Madu, C.N. and Lin, C. (2001), “The relationship between supply chain quality management practices and organizational performance”, International Journal of Quality Reliability Management, Vol. 18 No. 8, pp. 864-72. Lambert, D.M., Cooper, M.C. and Pagh, J.D. (1998), “Supply chain management: implementation issues and research opportunities”, International Journal of Logistics Management, Vol. 9 No. 2, pp. 1-19. Lamming, R. (1996), “Squaring lean supply with supply chain management”, International Journal of Operating Production Management, Vol. 16 No. 2, pp. 183-96. Lebow, J. (1999), “The last word on lean manufacturing”, Institute of Industrial Engineers Solutions, September, pp. 1-8. Lee, J. and Peccei, R. (2008), “Lean production and quality commitment”, Personnel Review, Vol. 37 No. 1, pp. 5-25. Lewis, M.A. (2000), “Lean production and sustainable competitive advantage”, International Journal of Operations Production Management, Vol. 20 No. 8, pp. 959-78. Li, S., Rao, S., Ragu-Nathan, T.S. and Ragu-Nathan, B. (2002a), “An empirical investigation of supply chain management practices”, Proceedings of Decision Science Institute 2002 Conference, San Diego, CA, USA. Li, S., Rao, S., Ragu-Nathan, T.S. and Ragu-Nathan, B. (2002b), “Developing measures of supply chain management”, Proceedings of Decision Science Institute 2002 Conference, San Diego, CA, USA. Malaysia (2006), Ninth Malaysia Plan 2006-2010, The Economic Planning Unit, Putrajaya.