SHAMSHAD QAQC RESUME

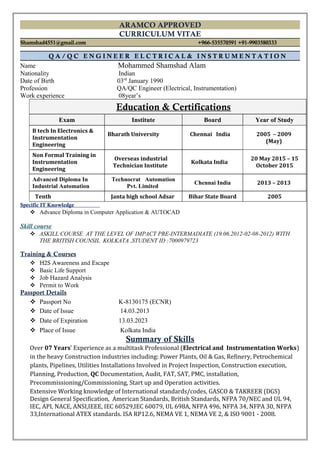

- 1. ARAMCO APPROVED CURRICULUM VITAE Shamshad4551@gmail.com +966-535570591 +91-9903580333 Q A / Q C E N G I N E E R E L C T R I C A L & I N S T R U M E N T A T I O N Name Mohammed Shamshad Alam Nationality Indian Date of Birth 03rd January 1990 Profession QA/QC Engineer (Electrical, Instrumentation) Work experience 08year’s Education & Certifications Exam Institute Board Year of Study B tech In Electronics & Instrumentation Engineering Bharath University Chennai India 2005 – 2009 (May) Non Formal Training in Instrumentation Engineering Overseas industrial Technician Institute Kolkata India 20 May 2015 – 15 October 2015 Advanced Diploma In Industrial Automation Technocrat Automation Pvt. Limited Chennai India 2013 – 2013 Tenth Janta high school Adsar Bihar State Board 2005 Specific IT Knowledge Advance Diploma in Computer Application & AUTOCAD Skill course ASKILL COURSE AT THE LEVEL OF IMPACT PRE-INTERMADIATE (19.06.2012-02-08-2012) WITH THE BRITISH COUNSIL KOLKATA ,STUDENT ID :7000979723 Training & Courses H2S Awareness and Escape Basic Life Support Job Hazard Analysis Permit to Work Passport Details Passport No K-8130175 (ECNR) Date of Issue 14.03.2013 Date of Expiration 13.03.2023 Place of Issue Kolkata India Summary of Skills Over 07 Years’ Experience as a multitask Professional (Electrical and Instrumentation Works) in the heavy Construction industries including: Power Plants, Oil & Gas, Refinery, Petrochemical plants, Pipelines, Utilities Installations Involved in Project Inspection, Construction execution, Planning, Production, QC Documentation, Audit, FAT, SAT, PMC, installation, Precommissioning/Commissioning, Start up and Operation activities. Extensive Working knowledge of International standards/codes, GASCO & TAKREER (DGS) Design General Specification, American Standards, British Standards, NFPA 70/NEC and UL 94, IEC, API, NACE, ANSI,IEEE, IEC 60529,IEC 60079, UL 698A, NFPA 496, NFPA 34, NFPA 30, NFPA 33,International ATEX standards. ISA RP12.6, NEMA VE 1, NEMA VE 2, & ISO 9001 - 2008.

- 2. and their application to the operation of Petrochemical Plants, Power Plants, Refineries, oil and gas facilities & Ability to interpret project Specs, procedures and drawings. Specialties: Good interpersonal and communication skills, Coordinates/Preparation of the Project ITP's & Project Quality Plan/Procedures which comply with Client contractual requirements and Project Specifications. Implement QMS. Conduct Internal/Subcon. Audits. Plans & allocates Quality functions to the various area of the project. Resolve Inspection Disputes & Provide the necessary back-up to Project Management regarding issues relating to Quality during work execution & Field Inspection. Profile • Regular surveillance/inspection of construction activities as per project inspection and test plan. • Assign and monitor respective duties of other QA/QC inspector • Store and maintain all quality records. • Coordinate with construction personnel about on going inspection issues. • Regular reporting to QA/QC Engineer & Manager, on any major issues which require immediate action. • Ensure proper implementation of ISO 9001. • QC inspection for instrumentation/electrical system as per quality control procedure, instrument test plan and project specification. • Inspection of cable trays, conduit, instrument, marshalling cabinet, interface cabinet, control desk and low voltage distribution system. • Ensuring all instrument were installed& tested as per project quality procedure and project specification and prepare ITP forms (Instrumentation Installation Inspection). • Pre loop inspection • Prepare RFI (Report for Inspection) to client for joint inspection of completed work • All activities during the construction & commissioning of control cable megering and measuring earth resistance test. • Ensuring all instrumentation were installed and tested as per project quality procedure and project specification and preparation of ITP forms for instrument installation inspection. • Coordination with pressure testing team of impulse lines and preparation of ITP forms and Test Reports. • To ensure that all inspection and test records are properly documented and made available to the client on completion in accordance with contract requirements. • Review of design and construction related document conducting material inspections. • Conduct all instrument inspection as per Approved ITP. • Prepare non-conformance with the customer’s representative to ensure good quality. • Familiarized & deep understanding of industry codes practices- API-RP-550 (Manual for the Installation of Refinery Instruments and control system), ISA, NEC / NFPA, NEMA & IEEE. • Awareness of ISO-9001 (Year 2000 version) • Awareness on Computer Application Software (windows 98, MS Office, 2003, Word, Excel, etc Overseas Project & Work History Company : DODSAL AND COMPANY Project : Aramco MGS 56" EWG-2 Loop-2 and 56" KAEC Pipeline Project at Saudi Arabia Role : QA/QC Engineer (Electrical & Instrumentation) Duration : 15th March 2016 to Till date

- 3. Company : SAMSUNG ENGINEERING AND CONSTRUCTION Project : West Qurna phase 2 Project Basra Iraq Role : QA/QC Engineer (Electrical & Instrumentation) Duration : 03rd May 2014 to 10th May 2015 Responsible for: • Monitoring daily electrical & instrument installation and testing activities and verifying that it complies with the project specification. Preparing daily documentation of the work progress. Review project drawings & apply contract codes, standard, & specifications. Co-ordinate with other discipline quality control personal for ensuring that all other discipline activities. Responsible for the inspection of installation of instruments, conduits & fittings (above & below ground), cable trays / ladder racks & cables , junction boxes, control panels, consoles wiring termination impulse tubing inline with the approved drawings, method statement, ITPs, project specification & applicable international codes & standards. • QC inspection for instrument system as per inspection and test plan, project specification. • Inspection for Installation of cable trays, conduit, instrument, marshalling cabinets, low voltage distribution system. Continuity & Megger Test, Impulse line, Air Line and Loop Folder Inspection. • Ensuring all instruments were installed & tested as per project quality procedure, project specification and preparation of ITP forms (Instrument Installation Inspection). • Pre-loop inspection • Inspection for all activities during the construction and commissioning of instrumentation. • Punch list clearing. • Performed Surveillance for ongoing construction activities. • Carried out inspection of material to make sure it meets the requirement of project specification. • Ensuring all instruments were installed and tested as per project quality procedures and project specification and instrument installation. • Coordination with BGP in pressure testing of impulse lines and inspection and test plan. • Assign and monitors respective duties of other QA/QC inspector. • Store and maintain all quality records for client. • Coordinate with construction personal about ongoing inspection issues. • Ensure proper implementation of ISO 9001. • Regular reporting to QA/QC Engineer & manager discussion with on any major issues which required immediate action. Company : SK ENGINEERINFG & CONSTRUCTION Project : Ruwais Refinery Project Ruwais Abu Dhabi Role : QA/QC Supervisor Electrical & Instrumentation Duration : 13th April 2012 to 15th April 2014 Responsible for: • Ensuring all instrument works carried out comply with project quality documents and standards. • Preparing punch list items, making surveillance of construction activities. • Witness of instrument calibration. • Installation of cable tray, conduit, junction boxes, instrument system. • Coordination with client in pressure

- 4. • testing of impulse lines. • To ensure that all inspection and test records are properly documented and made available for handover to the client on completion of project in accordance with contract requirement. • Ensuring all instrument works carried out comply with project quality documents and standards. • Preparing punch list items, making surveillance of construction activities. • Witness of instrument calibration. • Installation of cable tray, conduit, junction boxes, instrument system. • Coordination with client in pressure testing of impulse lines& Air Lines • To ensure that all inspection and test records are properly documented and made available for handover to the client on completion of project in accordance with contract requirement. • Conduit inspection on electrical and instrumentation installation. • Prepare and review ITPs for Instrumentation Installation. • Prepare daily surveillance and inspection reports. • Review of design and construction related documents conducting material inspection • Prepare quality control check sheets for all activities like, impulse tubing, instrument installation, tray installation, Junction Boxes, marshalling cabinets, and desk top installation. Company : HYUNDAI HEAVY INDUSTRIES Project : PEARL GTL Project Raslaffan Doha Qatar Role : QA/QC Inspector (Electrical & Instrumentation) Duration : 24th November 2009 to 26th December 2011 Responsible for: • Store and maintain all quality records. • Coordinate with construction personnel about on going inspection issues. • Regular reporting to QA/QC Engineer & Manager, on any major issues which require immediate action. • Ensure proper implementation of ISO 9001. • QC inspection for instrumentation/electrical system as per quality control procedure, instrument test plan and project specification. • Inspection of cable trays, conduit, instrument, marshalling cabinet, interface cabinet, control desk and low voltage distribution system. • Ensuring all instrument were installed& tested as per project quality procedure and project specification and prepare ITP forms (Instrumentation Installation Inspection) • Testing solenoid valves, overhauling of field equipment an control valves loop checking and testing pre-loop checking & commission. • Converter involving calibrating of pneumatics and electronics instrument trouble shooting sequence check, trouble shooting of all types of electronics transmitter & bleed valve, safety relief valve, ESD, MOV. Company : LARSEN & TOUBRO LIMITED Project : TATA IRAON Steel Co Plant Jamshedpur Jharkhand Role : QA/QC Inspector (Electrical & Instrumentation) Duration : 06th May 2008 to 17 September 2009 Responsible for: • Responsible for the calibration of all types of process instrumentation, installation, tubing (Pneumatic and process hookup), cable Tray, Instrument Installation Cable testing, laying, glanding and termination, function test.

- 5. • Loop checking, instrumentation and system, fault finding and trouble shooting of process instrumentation during commissioning period. • Final preparation of various drawings such as P&ID, Logic Drawing, Wiring diagram, Instrument loop diagrams. • Responsible for the calibration of all types of process instrumentation, installation, tubing (Pneumatic and process hookup), cable Tray, Instrument Installation Cable testing, laying, glanding and termination, function test. • Loop checking, instrumentation and system, fault finding and trouble shooting of process instrumentation during commissioning period. Final preparation of various drawings such as P&ID, Logic Drawing, Wiring diagram, Instrument loop diagrams INSPECTION ACTIVITIES: • Underground & aboveground cable inspection • Earthing system inspection and testing • Cable tray installation • Cable installation inspection and testing • Insulation resistance & continuity test, loop checking, marking, laying, glanding and termination of cables. • Hi-pot testing of MV cables • Installation inspection of street/fence lights • Installation inspection of 6.6 KV & low voltage switchgear, battery & battery charger and local control panels. • Calibration and configuration check of various Instruments • Conduiting & Junction box installation • Various field Instruments installation • Instrument impulse tubing & air line leak testing • Instrument loop checking from control panels to different field of devices • Powering up of Instruments & panels • Installation of DCS panels • POP-UP, leak and bubble test of Pressure Safety Relief Valve Inspection of Receiving Project Material at Site - Inspection of Project Receiving Materials as per Purchase Order Number, Delivery Notes, Inspection Release notes, Approved Data Sheet, Specification, Factory Acceptance test Report (FAT), Factory calibration Certificates, Material Test Certificate (MTC),Certificate of conformity (COC), General Arrangement Drawing (GA),Material Approval Report (MAR) and Project requirements. Detail of Engineering drawing – Knowledge of Drawings such as Power & Control Layout, Equipment Layout, Cable Raceway & Power Layout, Lighting Layout, Earthing Layout, Single line Schematic Diagram, Logic, Control Schematic and wiring Diagram for Electrical Distribution System, Project Instrument Index, Plan lay-out Drawing, Cable Routing Lay Out Drawing, P&ID, Isometric Drawing, Instrument Hook Up Drawing, Instrument Loop Drawing, Cable schedule, Panel and Junction Box

- 6. Termination Drawings, Inter connection Drawings, Marshalling Panel, Console Layout, Panel GA Drawings, Cause and Effect Drawings Advantages Good communication skills, excellent negotiator, efficient in multi-tasking, Out of the box thinking with dynamic adaptability. Declaration I hereby declare that the aforementioned information is correct to my knowledge and belief. [MOHAMMAD SHAMSHAD ALAM] Friday, February 17, 2017

- 7. Termination Drawings, Inter connection Drawings, Marshalling Panel, Console Layout, Panel GA Drawings, Cause and Effect Drawings Advantages Good communication skills, excellent negotiator, efficient in multi-tasking, Out of the box thinking with dynamic adaptability. Declaration I hereby declare that the aforementioned information is correct to my knowledge and belief. [MOHAMMAD SHAMSHAD ALAM] Friday, February 17, 2017