Rakesh CV (4)

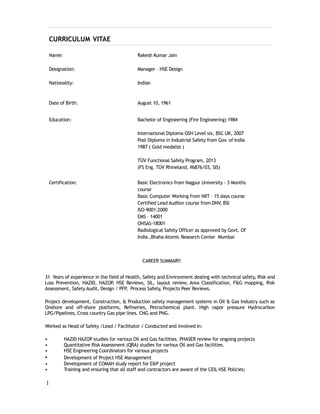

- 1. CURRICULUM VITAE Name: Rakesh Kumar Jain Designation: Manager – HSE Design Nationality: Indian Date of Birth: August 10, 1961 Education: Bachelor of Engineering (Fire Engineering) 1984 International Diploma OSH Level six, BSC UK, 2007 Post Diploma in Industrial Safety from Gov. of India 1987 ( Gold medalist ) TÜV Functional Safety Program, 2013 (FS Eng. TÜV Rhineland, #6876/03, SIS) Certification: Basic Electronics from Nagpur University - 3 Months course Basic Computer Working from NIIT – 15 days course Certified Lead Auditor course from DNV, BSI ISO-9001:2000 EMS – 14001 OHSAS-18001 Radiological Safety Officer as approved by Govt. Of India ,Bhaha Atomic Research Center Mumbai CAREER SUMMARY: 31 Years of experience in the field of Health, Safety and Environment dealing with technical safety, Risk and Loss Prevention, HAZID, HAZOP, HSE Reviews, SIL, layout review, Area Classification, F&G mapping, Risk Assessment, Safety Audit, Design / PFP, Process Safety, Projects Peer Reviews. Project development, Construction, & Production safety management systems in Oil & Gas Industry such as Onshore and off-shore platforms, Refineries, Petrochemical plant. High vapor pressure Hydrocarbon LPG/Pipelines, Cross country Gas pipe lines. CNG and PNG. Worked as Head of Safety /Lead / Facilitator / Conducted and involved in: • HAZID HAZOP studies for various Oil and Gas facilities. PHASER review for ongoing projects • Quantitative Risk Assessment (QRA) studies for various Oil and Gas facilities. • HSE Engineering Coordinators for various projects • Development of Project HSE Management • Development of COMAH study report for E&P project • Training and ensuring that all staff and contractors are aware of the CEIL HSE Policies; 1

- 2. Good all-round HSE Design & Operational Experience: Loss Prevention & Safety Engineering – FEED, Safety in detailed Design, Human Factors, Documentation assessment and review, Auditing, familiar with QRA, HAZID HAZOP, HAZAN, and SIMOPS & Matrix of Permitted Operations (MOPO). Responsible for the management of project risk (Bowtie) evaluation register and tracking system to insure that contractors Design Engineering Practices (DEP’s) are in line with current company design philosophies and Scheduling of deliverable. Loses prevention engineering including Fire Prevention and Protection, F&G mapping, PFP system design etc. Participated and reviewed in Quantitative Risk Assessment (QRA) studies for various Oil and Gas facilities .HAZID HAZOP studies for various Oil and Gas facilities. PHASER review for ongoing projects HSE Engineering Coordinators for various projects Development of Project HSE Management Development of Safety case and COMAH study report for E&P project. HSE Loss Control Management - Implemented and awarded Environmental ISO 14001, OSHA 18001,- Responsible for all environmental site management and systems implantation Professional Trainer in all HSE Management techniques, Good motivator for proactive change Operations safety personnel & Construction safety, Safe working practices, procedure, Officer In charge for HSE training at Gas Technology Institute where I have developed the Gas training simulation models of world class training including BLEVE and jet fire models . Responsible for two fire station and personnel’s training on fire science, firefighting and protection techniques, equipment maintenance and arranging firefighting scenarios e.g. search and rescue, equipment protection, BA equipment & hand on training. Development of Training courses and HSE procedures and standards and ensuring HSE Policies BSC Five Star audit system and management of Change liaised with Health and Safety Executive of India, UK, Good presentation skills. Plant construction /Field Construction/Fabrication yards (Grass root to Brown field) Safety Manager of Construction site during building of E&P Projects consisting of well developments , GGS, Transmission Work experience with Concept, FEED, DD, Brownfield & Greenfield phases, Work experience covers clientele in varied geographical areas i.e. India, Middle East, Managerial and Technical Authority role supporting Lead HSE Engineers since 2003. SKILLS: HAZID, HAZOP, SIL Assessment facilitation. TÜV certified Functional Safety Engineer Software proficiency: DNV PHAST, SAFETI, , Flaresim PHA recording software’s PHAPRO, PHAWORKS 2

- 3. CAREER HISTORY Petrofac International Ltd. (March, 2015– to Date) Manager – HSE Design – March, 2015 – to Date Responsibilities - Provide technical and managerial support to proposal and projects; support proposal engineering activities. Discipline Technical Authority (TA) /GATE reviews, Project /Proposal Handled IGD Expansion PKG 4 Of ADGAS , Abu Dhabi MGT (Manifold Group Trunk line) System for the GCs 29,30, and 31 In North Kuwait Working as Lead Safety Engineer in MGT (Manifold Group Trunk line) System for the GCs 29,30, and 31 In North Kuwait of KOC • Supervise a team of engineers and designers to support HSE Engineering for Design & Bid preparation. • Acts as the main interface between all discipline managers & HSE discipline for all Design /proposal related HSE issues. • Organize and participate in risk reviews like Bid stage HAZID/ENVID, Technical risk review of HAZOP/HAZID, SIL, HSE Design Case, PEER review etc. Review and BOQ finalization of PFP, F&G, and Loss Preventions Design items • Promote initiatives to improve cost effectiveness & productivity In design . • Work with Client group, customer and vendor representatives to resolve technical issues & finalize the design basis to work out the proposal costing • Responsible for activities for MGT project Of KOC MGT such as Review of Contract / Feed documents , Scope of work , preparation of TDR , technical requirements, preparation of engg. Deliverables as applicable etc. Responsibility includes but not limited to--- • Leading the HSE team to carry out Contract & Detail engineering of Project. • Assign engineers in accordance to areas of specialization. Monitor and track their delivers as per the proposal requirement. • Organize and participate in risk reviews HAZID/ENVID, Technical risk review, PEER review etc. • Review of various modelling results & safety studies to ensure all safety requirement incorporate in project design. • Provide safety inputs in the preparation and evaluation of Plot Plans. • Assist Discipline Supervisor in employee performance evaluation and training needs for immediate subordinates. • Perform related duties as and when directed by Discipline Manager • Development of HSE Design Basis/ F&G/loss prevention philosophy 3

- 4. • Prepare of area classification /PFP schedule & layout • Work with project group, customer and vendor representatives to resolve technical issues & finalize the Contract stage deliverables. • Assign engineers in accordance to areas of specialization. Monitor and track their delivers as per the FEED schedule & quality requirement. • Organize and participate in contract stage safety reviews like HAZID/ENVID,HAZOP/SIL/RAM etc. • Support to develop Fire Hazard / risk assessment, blast over pressure study • Managing Third party to develop safety & environment studies. • Provide safety inputs in the preparation and evaluation of Plot Plans. Cairn Energy India Pty Limited, India E&P Company DGM –Project (HSE), Head HSE Design March 2012 - to Feb 2015 Responsibilities - Technical and managerial support with approving authority to projects in , HSE Design • Top quartile HSE performance among peers, Top Lines and line Focus supporting 29 projects OU, s of more than 2 Billion USD worth • HSE design review, action tracking, HSE studies / PHSER review • HSE Construction Management at Site • Regulatory compliance & risk assurance • Gates process reviews and signatory as gate keeper for HSE • RFSU, PHSER Review and team lead • Technical Authority for HSE design Petrofac International Ltd, UAE Dy, Manager (HSE Design) Oct 2010 – Feb 2012 • Leading team of engineers across all Engineering and construction Offices of Petrofac having offices in 29 countries for preparation of Proposals involving Loss Prevention design, Plot plan review, Hazardous area classification review, Fire zone analysis, Blast Over pressure design, Explosion analysis using CFD modelling, Furnishing inputs for Fire proofing, Fire& Gas systems, Preparation of fire protection system layouts, Fire &Safety equipment layouts. Flare radiation study, Review of HSE study Safety case, COMAH, HSEIA, HAZOP, HAZID, QRA study, (proposal stage) Review of FEED requirements, Participate in Inter departmental meetings, Preparation of costing for HSE items. Proposal involved in More than $ 100 Million to 2.3 Billion • Ware Pressure Maintenance Project of KOC • Lekhwair Gas Development project 4

- 5. • Petroleum Development Oman • Luke Oil west Qurna Gas and Power Iraq • Luke Oil west CPF Iraq • Banagas Compressor Station CS-9 Bahrain • SASOL Inhassoros test separator Mozambique • SCOP diesel (gas oil) hydrodesulphurization unit in Barah refinery Iraq • Al-KHAFJI JOINT operations construction of Hout( KRL) gas on Shore facility • ENI-Package Mishriff and Hammer , Iraq • Scottish power carbon capture plant UK • Saudi Aramco-Petrorabigh II package 2 common utilities • Saudi Aramco-Petrorabigh II package 3 Tank Form • Ras Tanura Tank form integrated Project Kuwait • Sabic-jubail port facility • CPF facility in Badra Iraq • Galsi Gas Compression station Algeria • EPCC of Gas processing Plant in Iraq Cairn Energy India Pty Limited, India DGM –Project (HSE) Nov 2005 – Oct 2010 Project Field handled Mangla, Rageshwari Bhagyam, Aishwarya Processing Terminal, Barmer, and Rajasthan India 200 Thousand BOPD • For projects HSE requirements from Conceptual, FEED, FEED endorsement Detail Design and Construction. Responsible for HSE Management Implementation in Project in all the Phases. • Responsible Hiring / interviewing of the HSE Team consisting of site HSE team • Leading a team of Safety professionals and review carried out of Quantitative Risk Assessment (QRA) studies for various Oil and Gas facilities of CEIL.HAZID.HAZOP studies for various Oil and Gas facilities of CEIL. PHASER review for ongoing projects of CEIL. HSE Engineering Coordinators for various projects for ALARAP demonstration. Development of Project HSE Management. Development of COMAH study report for E&P project of Cairn. Training and ensuring that all staff and contractors are aware of the CEIL HSE Policies. Liaoning and coordinating with regulatory authorities for approvals and license’s related to Project. Ensuring safe construction and commissioning of Plant reviewed all procedure from road transport NDT, PTW, SWP, Scaffolding etc. and to setup Medical and emergency support systems., Mid-stream project the world’s longest 700Km Heated Pipeline, to ensure the projects are scheduled to the Gated system (PHSER) from Concept – FEED-Detailed design- to construction. 5

- 6. GAIL India Limited, India Chief Manager (HSE) HOD Dec 1992 – Nov 2005 Project /Plant handled • UPPC Petrochemical Plant, at Pata, India with a capacity of producing 400,000 TPA of Ethylene and 410,000 TPA of Polymers • LPG recovery and Gas Processing Plant, 180 MMSCFD • Gas Technology Institute, Technology training Institute • Leading a team of Engineers and professional. Directly supervising and implementation of Plant and Process Safety in Gas processing plants having cryogenic process and storage tanks of Ethylene. Ensuring safe construction and commissioning of Plants, Safety audit. Liaoning with all statutory authorities. Mutual aid with other PSU’s.Inspection and Fire prevention audits of other installations of GAIL. Preparation of Budgets, Inventory controls and other MIS reporting. Conducting safety committee meetings, Designing and ensuring Schemes for promotion of safety, Ensuring Safe practices. Occupational health safety and Industrial Hygiene. Responsible for total development, R&D, and smooth running of HSE dept. HRD Schemes implementation in the Department. Training head with respect to F&S courses, designing training calendar for all personnel including executives. ISO/OHSAS/EMS related programs. In charge of Safety for safe Commissioning JLPL LPG Pipeline – Longest in the world 1280 Kms . Indian Oil Corporation, India Sr. Process Engineer (HSE) Feb 1985 – Dec 1992 Worked at Mathura Oil Refinery, 10.5 MMTPA, Barauni Oil Refinery 8.5 MMTPA • Worked in Supervisory levels within Process and HSE department and was responsible for, Development of Safety practices or all type of jobs arising in a Refinery, having large tank forms processing units, petrochemical plant. Carried out Risk analysis study, calculation of physical damage distances based on computerized Mathematical models. Development of Work Permit System, Preparation of Fire Orders, Fire Manuals, Safety Manuals, Site Safety Procedures, constructional safety Manuals, Plant Safety Manuals, Pocket Manuals for increasing safety awareness. Organizing, conducting fire safety weeks, publication of newsletters, Safety poster competitions, quizzes, debates, etc. Formulation and imparting training programs for plant personnel and officers, specially plant supervisors and GET’s. Preparation of MIS (Management Information Systems) reports and fire orders. Compliance of all statutory rules, regulations i.e. Factories Act, Petroleum Rules, SMPV Rules, MSIHC Rules, etc. and liasioning with statutory authorities. Dealing with TAC, authorities for compliance and insurance rebate. Preparation of specifications and purchase of various Fire Fighting and Safety items and 6

- 7. inventory controls. Preparation of various schemes, for modification, new facilities and for the adoption of new technology. Obtaining CCE approvals for all works. Design and Maintenance of Fire Water Network, fixed firefighting system of refinery. Conducting safety audits, preparation of reports, MIS presentation and action plan for implementation. Hazop studies for refinery. Accident reporting, Investigations and analysis with recommendations. Preparation of Disaster Management Plans “On site as well as offsite” plans. Attending to various fires, emergency and rescue calls Supervision, Administration and control of refinery fire station. Professional Affiliation: Professional Membership: 1. Life Member of National Safety Council, Mumbai 2. Life Member of LPA of India Limited, Mumbai 3. Member of International Institute of Risk & Safety Management, UK (MIIRSM) 4. Associate Member of Institute of Fire Engineer (India) 5. Member of American Society of Safety Engineers, UAE chapter 7