Dhopeshwar Engineering Private Limited, Hyderabad, Process Plant & Equipment

- 1. Poultry Dressing Plants Conveyorised Dressing Plant, Mini Processing Plant & Hybrid Plant INNOVATIONS FOR POULTRY E N G I N E E R I N G

- 2. Poultry ProcessingasHUBof Integration Poultry ProcessingPlants. Conveyorised Processingplant TheConveyor systemgoes through following stages: Poultry processing as the Hub for integrated poultry operations. It forms an extension of farming / breeding operations giving farmer / breeders a directpresenceintheconsumermindandmarket.Itstabilizesthefarming activity by providing a crucial link to actual consumer market and provides important value addition to farm produce of live birds. It helps thefarmstocreateabrandofitsowninthemeatmarket. Dhopeshwar manufactures high quality plant and machineries for Poultry processing. These plants are supplied in 3 different configurations,namely;FullyConveyorized,Non-Conveyorizedandour latest addition, the Hybrid Plant with Partial Conveyor along with other equipment. Each of these come in different capacities to cater to the needs ofprocessingcompaniesdependingonthescaleofoperations. Dhopeshwar supplies Conveyorized plants having different capacities ranging from 250 BPH to 2000 BPH. These Dressing plants consist of an overhead Conveyor, and various other processing equipment. The Conveyor has a Conveyor Track with Rolling trolleys which moves in a looped formation while each trolley carries a stainless steel shackle on which the live bird is hung to start the process. The birds on shackle move through different processes till the bird is cleaned both internally and externally. The bird after dressing is discharged at the last processingstage asafreshlychilleddressedbirdwith skin. Loading : Thelive bird ishung upsidedownon the steel shackle. Stunning : T Halal /Bleeding : The vein of the un-conscious bird is cut manually to allowdraining ofblood. Hot water Scalding : This is a crucial step in which birds are passed though hot water maintained at fixed temperature to softenthe feathers. Feather plucking : Feathers are removed by rotating rubber fingers with- out damagingthe skin. Evisceration : All the internal organs such as lungs, intestine,etc.areremovedandthehockcut. Chilling : The bird (carcass) is put in chilled water topreservethe quality ofmeat. Portioning /Refrigeration : The slaughtered bird can be sold as a Whole bird / Portioned bird after processing as Fresh chilled / Refrigerated asrequired. he bird un-conscious for a painless slaughteringprocess. Poultry Processing - Conveyorised Hot Water Scalder INNOVATIONS FOR POULTRY E N G I N E E R I N G Capacity : 100 to 2000 Birds / Hour

- 3. D re s s i n g P l a nt SemiAutomaticOperation Stages of Bird loading, Halal and Evisceration are done manually while the rest of the processing happens automatically through the processing machines. Conveyor based operations require minimumhuman handling of meat whichensuresthe highest level of hygiene during processing. The process stages are based on well-established scientific principles of bleeding, scalding and chilling. These factorsensurethebestqualityofmeat. 1. Conveyorbasedautomationrequireslessmanpower andreducesdependenceonlabour&skill. 2. Plant canprocessbirdsweighing 1to3kg. 3. Allthe machineriesaremadeinStainlesssteel. 4. Process and plant designed on scientific basis, ensuresBestquality meat 5. Entire plant made in our works in Hyderabad ensuring highest standard of engineering & workmanship. As a result, our plants excel performanceexpectationsandlastformanyyears. Uniquefeatures of our Conveyor basedplant DhopeshwarOffers : Dhopeshwar has successfully delivered Poultry Processing plants in different capacities in India and other countries. Our plants are fully Integrated and custom-built. The design and manufacturing is of the highest standard and all the plant & machineries are fabricated in our Hyderabad works, shipped to sites, then Installed and commissioned at customer’s site onTurn-key basis. Feather Plucker Plucker Discs Screw Chiller & Dripper Drum Dressed Bird INNOVATIONS FOR POULTRY E N G I N E E R I N G

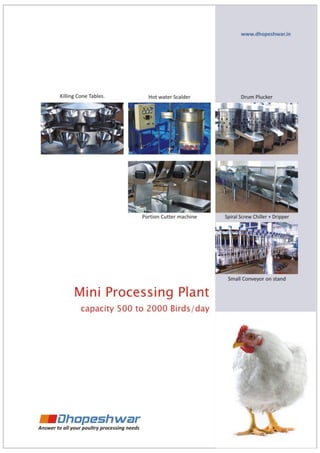

- 4. MiniProcessingPlant TheEquipmentof MiniPlant comesin3 capacities: KillingconeTablefor Halal Hot water Scalder Dhopeshwar supplies process specific equipment for small and mid- sized dressing units. These equipment are ideal for operations ranging from 500 birds to 2000 birds per day. All the equipment are made in food grade stainless steel and built to the highest standard of engineering. They can be easily set up at farms, retail shops or at at larger establishments.Thestainlesssteelconstruction excellenthygiene, lowmaintenanceandlonglifeoftheequipment. 250to1000Birdsperday,8/24cones Stainless steel rotating shell with cones for holding birds. Splash guard to contain spill, blood collection trough with easy hold clamps. Total Argon TIG welded.CompleteconstructioninfoodgradeSS. Different models - 24 inches’ diameter, 1.5 hp for 5-6 birds at a time and 30 3.0 hp for 20 birdsat atime. Heavy duty stainless steel drum with rotating disc. Heavy duty MS angle stand with 2 coat Enamel paint. Base cover, Side panels & bird discharge hopper in SS Separate discharge chute for feathers. Motorised drive either through V Belt & pulleys or Gearbox. Rubber fingers,water showerwith shutoffvalve. butcheries ensures inches'diameter, 200 to 500 birdsperday - basic4items+work tables etc. 500 to 1000 birdsperday - basic5items+work tables etc. 1000 to 2000birdsper day - basic5items+work tables etc. Capacity : Construction : Capacity Construction Capacity Construction MainEquipmentof MiniPlant : Different models from 5 to 20 birds at a time (500 to 2000Birds/day) : Total Stainless steel construction Water heating by gas as well as Electricity Thermostat control Automatic On/Off. Temperaturesettingrangefrom40to70deg.CBirdlifting cagewithliftingstrongearm. totalArgonTIGwelded. : : Drum Plucker Poultry Processing - Mini Plant Killing Cone Tables. INNOVATIONS FOR POULTRY E N G I N E E R I N G Capacity : 2000 Birds / Day

- 5. Portion Cutter machine Capacity Construction Purpose : Chilling the bird carcass with chilled water or ice flakes to arrest bacterial growth and maintain meatquality. Capacity : 1000to 2000 birdsperday Construction : Heavy duty U shaped body & Spiral screw in SS 304. Turbo Air jet with piping. Side panels to prevent splash. Discharge hopper andamotoriseddrive. Mainfeatures : Sturdy construction for low maintenance&longlife. : : 50-60birdsperhour. Entirely made in SS 304 food grade construction. Available in Single phase or three phase motor. 10” diameter, disc cutter, bird placing rod, cover / dome for V-belt pulleys&motor. SpiralScrewChiller +DripperM i n i P l a nt Drum Plucker Advantagesof MiniPlant Uniquefeaturesof MiniDressingPlant - Easyto setup,Easytomaintain. - Lowpowerconsumption - Sturdy construction,Longlife. 1. Theplant canprocessbirdsweighing 1-3kgs. 2. Allthe machineriesaremadeinStainlesssteel. 3. Scientificprocessensuresmosthygienic processing. 4. Advancedengineering forsemiautomaticprocessing Hot water Scalder Spiral Screw Chiller + Dripper Portion Cutter machineDrum Plucker INNOVATIONS FOR POULTRY E N G I N E E R I N G

- 6. Poultry Processing - Hybrid Plant HybridPlant A fully Conveyorized plant starts with loading of birds on conveyor trolley / shackles and ends with hock cutting to discharge with bird directlyintoachiller. The Conveyor passes the birds through different processing stages while birds are kept online throughout. Most of the processing is done automatically in special purpose machines while the evisceration processisdonemanuallywhilebirdisstillonthe conveyorshackle. The Hybrid plant uses some of the most important features of a Conveyorized plant with mini processing equipment. It combines the use of Conveyor and some additional equipment for Online processing while the Scalder and Feather Plucker are kept Offline. The Plants are custom built for increasing adaptability of process to get both, birds with skin and birds without skin while lowering the cost of installation. 1000-4000birdsperday. Overhead conveyor, T Track with Nylon Rollers, Non-rust Aluminium trolleys, Non-rust SS shackles drivenby gearedmotor.TotalArgonTIGwelded. Online processing; Offline processing; Stunning, Halal, Bleeding, Neck remover, hock (leg) cutter. Hot water scalder, Feather plucker, Evisceration. Hybrid Plant on stand Capacity Construction : : INNOVATIONS FOR POULTRY E N G I N E E R I N G Capacity : 1000 to 4000 Birds / Day

- 7. Dhopeshwar supplies a Steam Boiler, a Chilled Water System as well as Belt Conveyor and VacuumLungGun indifferentcapacitiesdependingonDressingplantscapacity. TheDressingplantalongwithallrequiredauxiliaryequipmentaresuppliedonTurn-keybasis. INNOVATIONS FOR POULTRY E N G I N E E R I N G Steam Boiler Diesel Fired Boiler Packaged Water Chiller Food Grade Belt Conveyor Auxiliaries Equipment for All DressingPlant: All the Dressing Plants require two important utilities foroperations: 1. SteamBoilerSystem 2.ChilledWater System Steam is required for Hot Water Scalding and chilled water isrequiredforScrewChilling ofbirds. Steamisgeneratedbyaboilerwhichisoperatedeither with wood or diesel. The boiler requires Pressure ReducingValves,WaterSoftenerandChimney. The Chilled Water System consists of Packaged Water Chiller, Insulated Storage Tanks and Insulated Pipelines. The Package Chiller gives chilledwater of5 requiredforchillingthe birds. A food grade Belt Conveyor is required for Conveying Dressedwholebirds/portionedbirds. °C Food GradeBeltConveyor

- 8. A-16, Co-operative Industrial Estate, Balanagar, Hyderabad - 500 037, India : + 91 040 2377 1579 : + 91 9391 05 8963, + 91 9652 15 8908T M Dhopeshwar Engineering Pvt ltd. AboutDhopeshwar Dhopeshwar Engineering specializes in supply of fully Integrated Processing Plants on a Turn-key basis. Established in 1963. We presently supply Processing Plants for3differentsectors,namely;Poultry,Agri.andChemical. Providing Specialised Engineering Solutions -through Process Innovation for Poultry Waste Management. Our recent innovation involves Digestor based technology adopting HTST process & Enzymatic reaction for waste management. These find wide application in Poultry sectors such as Hatchery waste, Layer Manure and Slaughter waste. OurInnovative ProcessPlants Poultry Sector Conveyorised Processing Plants, Mini processing Plant andHybrid Processingplant. Poultry WasteManagementPlants Hatchery waste, Layer Manure, Slaughter waste and Chickenfat extraction. Agri Sector EssentialOil PlantsandAloe-veraPlant. ChemicalSector Stable grade bleaching powder and CNSL based Cardanol. Poultry Dressing and Waste Management plants INNOVATIONS FOR POULTRY E N G I N E E R I N G INNOVATIONS FOR POULTRY E N G I N E E R I N G Bangladesh Bhutan El Salvador Ghana Indonesia Mallawi Nepal Nigeria Oman Papua New Guinea Singapore Sri Lanka Tanzania UAE Uganda Zimbabwe Zambia Exported to 17 countries Vision: Be an innovation lead Engineering organisation for Special Purpose Plants & MachinerIes. Mission: Providing Customised Engineering Solutions through Process Innovation Aim: Continue to be a trusted partner by providing customised engineering solutions. E: sales@dhopeshwar.in W: www. Dhopeshwar.in