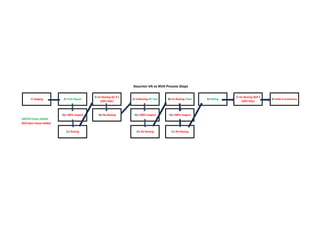

Assurion VA vs NVA Process Steps Comparison

•

0 gostou•496 visualizações

The document outlines the steps in the Assurion VA vs NVA process. The process involves 8 steps: 1) staging, 2) tech repair, 3) un-boxing quality control #1, 4) un-boxing RF test, 5) un-boxing flash, 6) kitting, 7) un-boxing quality control #2, and 8) holding in inventory. Some specific non-value added steps include 2b) 100% inspect, 3b) re-boxing, 4b) 100% inspect, and 5b) 100% inspect.

Denunciar

Compartilhar

Denunciar

Compartilhar

Baixar para ler offline

Recomendados

Mais conteúdo relacionado

Destaque

Destaque (18)

Certificate 20of 20 Participation 20 Silico 20 Petak 20 Fmea[1]![Certificate 20of 20 Participation 20 Silico 20 Petak 20 Fmea[1]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Certificate 20of 20 Participation 20 Silico 20 Petak 20 Fmea[1]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Certificate 20of 20 Participation 20 Silico 20 Petak 20 Fmea[1]

Bob (ababs) Youssef FMEA Workshop Training at Hughes rev3

Bob (ababs) Youssef FMEA Workshop Training at Hughes rev3

Mais de ExerciseLeanLLC

Mais de ExerciseLeanLLC (14)

Trust Tech F119 Rapid Assessment & Hoshin Workshop Report Out

Trust Tech F119 Rapid Assessment & Hoshin Workshop Report Out

Assurion VA vs NVA Process Steps Comparison

- 1. Assurion VA vs NVA Process Steps 3) Un-Boxing QC # 1 7) Un-Boxing QC# 2 1) Staging 2) Tech Repair 4) UnBoxing RF Test 5) Un-Boxing Flash 6) Kitting 8) Hold in Inventory (20% AQL) (20% AQL) 2b) 100% Inspect 3b) Re-Boxing 4b) 100% Inspect 5b) 100% Inspect GREEN=Value Added RED=Non-Value Added 2c) Boxing 4c) Re-Boxing 5c) Re-Boxing