2 fire risk assessment template risk assessment templates

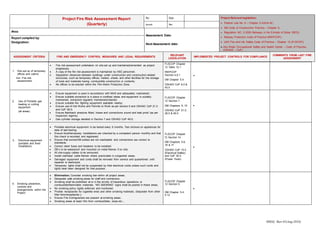

- 1. HSEQ -Rev-01(Aug-2018) 1. Site set up of temporary offices and cabins Incl. Fire risk assessment; Fire risk assessment undertaken on site set up and maintained/amended as project progresses; A copy of the fire risk assessment is maintained by HSE personnel; Separation distances between buildings under construction and construction-related structures, such as temporary offices, trailers, sheds, and other facilities for the storage of tools and materials having combustible construction or contents; No offices to be erected within the 70m Metro Protection Zone; FLSCOP Chapter 12 Table 12.1 RWPCOP Section 4.6.1 DM Chapter 5.4 OSHAD CoP 8.0 & 43.0 2. Use of Portable gas heating or cutting equipment. (all areas) Ensure equipment is used in accordance with MAS and adequately maintained; Ensure suitable extraction is in place in confined areas and equipment is suitably maintained, extractors regularly maintained/cleaned; Ensure suitable fire- fighting equipment available nearby; Ensure use of Hot Works and Permits to Work as per section 5 and OSHAD CoP 21.0 and CoP 28.0; Ensure flashback arrestors fitted, hoses and connections sound and leak proof (as per inspection regime); Gas cylinder storage detailed in Section 7 and OSHAD CoP 49.0; FLSCOP Chapter 12 Section 7 DM Chapters 5, 15 OSHAD CoP 21.0, 28.0 & 49.0 3. Electrical equipment (portable and fixed installation) Portable electrical equipment to be tested every 6 months. Test stickers on appliances for date of last testing; Ensure fixed/temporary installations are checked by a competent person monthly and that this check is recorded and registered; Ensure that socket/DB outlets are not overloaded and connections are correct to standards; Correct rated fuses and breakers to be installed; DB’s to be waterproof and mounted on metal frames if on site; All site supply cables to be armoured; Install overhead cable frames where practicable in congested areas; Damaged equipment and cords shall be removed from service and quarantined until repaired or destroyed; Temporary lights shall not be suspended by their electrical cords unless such cords and lights have been designed for that purpose; FLSCOP Chapter 12 Section 14 DM Chapters 5.6, 16 & 17 OSHAD CoP 15.0 (Electrical Safety) and CoP 35.0 (Power Tools) 4. Smoking prevention, controls and arrangements within the Project Elimination; Consider smoking ban within all project areas; Designate safe smoking areas for staff and contractors; Smoking shall be prohibited at or in the vicinity of hazardous operations or combustible/flammable materials. “NO SMOKING” signs shall be posted in these areas; No smoking policy rigidly enforced and monitored; Provide receptacles for cigarette ends and other smoking materials; (Separate from other litter bins/receptacles.); Ensure Fire Extinguishers are present at smoking areas; Smoking areas at least 10m from combustibles, skips etc.; FLSCOP Chapter 12 Section 5 DM Chapter 5.4, 5.12 Project Fire Risk Assessment Report (Quarterly) By: App: Project Relevant legislation: Federal Law No. 8 – Chapter 5 Article 92 ; DM Code of Construction Practice – Chapter 5; Regulation NO. 5 2009 Railways in the Emirate of Dubai (RED); Railway Protection Code of Practice (RWPCOP); UAE Fire and Life Safety Code of Practice – Chapter 12 (FLSCOP); Abu Dhabi Occupational Safety and Health Center – Code of Practise (OSHAD – CoP) Issued: Rev. Area: Assessment Date: Next Assessment date: Report compiled by: Designation: ASSESSMENT CRITERIA FIRE AND EMERGENCY CONTROL MEASURES AND LEGAL REQUIREMENTS RELEVANT LEGISLATION IMPLEMENTED PROJECT CONTROLS FOR COMPLIANCE COMMENTS FROM LAST FIRE ASSESSMENT

- 2. HSEQ -Rev-01(Aug-2018) 5. Hot Works activity controls (Grinding, Welding, Cutting etc.) Elimination; Consider undertaking Hot Works in safe area then transferring to work area (welding, gas cutting etc.); Ensure use of Hot Works and Permits to Work specific to the task; Ensure Welding transformers are adequately earthed, all equipment inspected and to standard; Ensure all flammable materials are removed from area prior to undertaking work; Ensure spark barriers and blankets are used where practicable; Min. 30min Fire Watch maintained after completion of task; In-date Fire Extinguisher in place at all times; Equipment checked, Flash-back preventers in place, correct gauges etc.; Special PTW required for works in Metro Protection Zone corridor; FLSCOP Chapter 12 Section 7 DM Chapters 5.4, 14 Serco HSQE 2.16.7 OSHAD CoP 21.0, 28.0 & 49.0 6. Waste disposal: Combustible materials controlled and disposed of correctly. (E.g. paper, cardboard plastics or wood.) Ensure good general housekeeping maintained throughout project; Arrangements for disposal of waste shall be adequate to prevent a build-up, especially in high risk areas; Accumulations of combustible waste material, dust, and debris shall be removed from the structure or building and its immediate vicinity at the end of each work shift or more frequently as necessary for safe operations; Prevent unauthorised access to combustible materials; Ensure generators, electrical switch rooms, etc. are clear of combustible materials; Adhere to approved Waste Management Plan; Combustible construction materials shall be stored a minimum of 6m from buildings or structures under construction; Wherever possible: Waste skips stored 10 metres from buildings and plant. Metal wheel bins at least 6 metres. Plastic wheel bins at least 10 metres. Consider secure storage particularly where there is a risk of arson; Do not store loose combustible waste close to work areas or 6 metres of buildings; No burning of waste or wood allowed on site; FLSCOP Chapter 12 Section 7; RWPCOP Section 4.6. DM Chapter 5.7, 5.10 Serco HSQE 4.5 OSHAD CoP 54.0 7. Storage of Flammable Gas within the project (Acetylene, propane, butane, LPG etc.) All flammable gases to be stored in mesh cages in the open air where practicable, away from office buildings; Storage areas shall be kept free of weeds and extraneous combustible material; No smoking and warning signage displayed in prominent positions (see section 4); Full and Empty cylinders stored separately, clearly marked; Combustible materials shall be kept a minimum of 3m from gas containers; Cylinders stored away from sources of ignition; Cylinders stored and transported upright by suitable trolleys; Cylinder connection guards must be place and not removed; Cylinders shall not be placed near elevators, unprotected platform edges or other areas where they drop more than 0.6m; Cylinders shall not be placed in areas where they may be damaged by falling objects; When cylinders are not in use, valve protective caps shall be in place; Ropes, chains or slings shall not be used to suspend gas cylinders, unless the cylinder was manufactured with appropriate lifting attachments; FLSCOP Chapter 12 Sections 8 and 11 RWPCOP Section 4.6.1 DM Chapter 5 OSHAD CoP 49.0 8. Flammable or highly flammable materials or substances on site and point of use. (e.g. solvents, paints, adhesives, aerosols etc.) Elimination; Avoid use of flammable materials and substances, by replacing with non- flammable materials; Reduce levels to the minimum required for the undertaking of the task, stored in correct receptacles; Ensure flammable substances are handled, transported, stored and used properly, as per manufacturers specifications; (specific risk assessment undertaken with MSDS); Store highly flammable substances in fire resistant, ventilated stores or cabinets and away from ignition sources. Do not store in plant rooms (e.g. electrical switch rooms, boiler rooms); Ensure use of flammable substances in confined spaces is controlled and under the ATC Permit to Work; At least one portable fire extinguisher (10 pound ABC type or 20-B type) shall be located no less than 10 feet (3m) and no more than 50 feet (15m) from the flammable liquids storage area; FLSCOP Chapter 12 Section 8 DM Chapter 7 RWPCOP Section 4.6.1 OSHAD CoP 1.0

- 3. HSEQ -Rev-01(Aug-2018) Discharge devices shall not cause an internal pressure on the container. Individual containers shall not be interconnected and shall be kept closed when not in use; 9. Steps to reduce the potential sources of oxygen to a fire. Close all windows, doors and other openings not required for ventilation and safe operation of equipment (e.g. gas fired equipment) particularly out of working hours; Do not store oxidising materials near to any heat source or flammable materials. (Check COSHH assessments and/or product data to identify oxidising materials.); 10. Any operations (or proposed) that may affect the Fire risk assessment Ensure changes to exit routes, doors, exits, etc. are considered and amended before undertaking; Alterations to buildings can have adverse effects on risk assessments, review as required; 11. Clear access to electrical components and equipment. Ensure plant rooms are free of obstructions, allowing unrestricted access to equipment (fuse boxes, switchgear) in the event of emergency situations; Storage of materials near to electrical switchgear (fuse boxes, switchgear, etc.) must be avoided; FLSCOP Chapter 12 Section 14 OSHAD CoP 15.0 12. Suspended ceilings within temporary buildings (Offices, cabins etc.) Areas with suspended ceilings must be separated from escape routes (corridors, stairways) with fire resisting partitions. Fire-resisting partitions must continue to the main structure of the building (i.e. no gap in the ceiling void through which fire could spread); If services (e.g. electric cables) are present in the void, fire detection equipment required in the void and on the suspended ceiling. Fire detection in both areas may also be required where there is a deep ceiling void. OSHAD CoP 43.0 13. Alterations to structure and installations designed to prevent fire spread Ensure any work taken place which may have made holes in walls or damaged any fire resistant wall/ceiling linings is repaired to standards; When area separation walls are required, the construction shall be completed (with all opening protected) immediately after the building is sufficiently weather-protected at the location of the wall(s). FLSCOP Chapter 12 Section 15 14. Arson Prevention (including security) Ensure site security personnel are deployed to minimise risk of unauthorised access (reducing potential for arson); Ensure constant supervision in place where a risk of arson exists; Offices to be locked if possible out of work hours; Security to undertake random walk rounds on nightshift; FLSCOP Chapter 12 Section 5 15. Smoke/heat detectors installed in high risk areas Installation in ‘high risk’ areas and unoccupied areas e.g. storage rooms, offices, basements, plant rooms, etc.; Ensure a competent engineer carries out regular back-up power supply checks if available; Ensure competent engineer services detectors in temporary buildings at least annually; FLSCOP Chapter 12 Section 15.1 DM Chapter 5 OSHAD CoP 43.0 16. Fire call points (break glass) installation. Install Fire alarms at earliest opportunity within site offices to ensure adequate fire warning; Ensure a competent person undertakes regular checks and the results are documented; FLSCOP Chapter 12 Section 15.9 17. Audible/visual fire alarms. All the required Fire Alarm, Communication, Fire Fighting and Fire Extinguishing Systems are installed, tested and maintained according to applicable NFPA regulations to ensure the readiness and operability of the systems; In noisy areas on site or inside buildings (where audible signals may not be heard) additional alarms may be necessary. ATC staff must be instructed in their use and form part of the Fire Evacuation drills; Test fire alarm system regularly at a set time. Ensure clearly audible under normal working conditions. Complete a record of test; Ensure competent engineer services alarm system in temporary site offices every 6 months. Complete a record of services; Audible alarms such as air horns to be used in site work areas; FLSCOP Chapter 12 Sections 5, 15.9 DM Chapter 5

- 4. HSEQ -Rev-01(Aug-2018) 18. Frequency and adequacy of fire drills. Ensure that at least one fire drill is undertaken every 3 months for site areas or as required due to project progression. To include offices and work areas; Fire drills shall be formally reviewed to identify problems encountered and any further actions required. Documented; (E.g. lack of staff awareness, unable to hear alarm in certain areas.) DM Chapter 5.4 19. Established escape routes (I.e. a place beyond the building/area in which a person is no longer in danger.) Evacuation routes shall be short enough to enable all site personnel to get to the designated muster point as soon as possible; Multiple escape routes shall be considered when establishing offices and site cabins at site set up; If there is only one means of escape (e.g. one staircase from floor under construction or basement) personnel shall be able to reach a final exit door, within one minute; Ensure adequate directional signage is implemented and communicated to staff; FLSCOP Chapter 12 Section 18 DM Chapter 5.4 OSHAD CoP 8.0 and CoP 43.0 20. Width of emergency exits, both fixed and temporary Exit doorways or routes should ideally be at least 750 mm wide when up to 40 people per minute expected to use exit route. No less than 1 metre wide when up to 80 are expected. Increase of 75mm for each additional group of 15 people; Corridors must be a minimum of 1 metre wide within temporary offices; Stairways should generally be a minimum of 1 metre wide. May need to be wider dependant on the number of people who are likely to use it, to form part of emergency plan and assessment; FLSCOP Chapter 12 Section 18 OSHAD CoP 8.0 21. Escape routes within buildings and site locations and assembly points Changes in level, steps or other hazards on escape routes that are not obvious shall be marked to make them conspicuous; Escape routes must be kept free of waste, materials, trip hazards and remain unlocked at all times; If remedial work dictates the closure of an evacuation route then another must be established before closure and be suitably communicated to personnel; Sub-contractor offices to be included in assessment if present; Emergency exits must be shown on plans posted around the offices and work areas as applicable; Designated assembly points established and communicated; FLSCOP Chapter 12 Sections 18,19 DM Chapter 5.4 Serco HSQE 2.16 OSHAD CoP 8.0 and CoP 43.0 22. Lighting to Emergency escape routes. All escape routes shall be sufficiently illuminated for site personnel to evacuate safely; Emergency escape lights are required if areas of the workplace are without natural daylight or are used at nightshift; Emergency lighting shall function not only in a complete failure of normal lighting, but also on a localised failure that would present a hazard to personnel; Emergency lighting shall cover escape routes and be sited to cover specific areas. E.g. intersections of corridors, each exit door, flights of stairs, near fire alarm call points, fire exit signs, and changes in floor level, near fire-fighting equipment, outside each final exit; Competent person shall check the operation of emergency lighting units at least monthly. Ensure record of check produced; A competent engineer shall test emergency lighting system. Ensure record of test made. FLSCOP Chapter 12 Section 18 DM Chapter 5.4 OSHAD CoP 8.0 23. Emergency signage. Ensure fire exit doors are clearly marked. See ‘Means of Escape and Escape Times’ section above Ensure fire exit signs, final fire exit signs and directional fire exit signs are indicated with a green ‘safe condition’ pictogram/graphic symbol (the ‘running person’ symbol). Text only signs are no longer acceptable. Ensure temporary signs stating ‘lifts must not be used in the event of a fire’ are posted outside all lifts; Ensure signs in positions where they can be clearly visible. Ensure all fire signs conspicuous (not covered or painted over, etc.) FLSCOP Chapter 12 Sections 3,17; FL No. 8 Chapter V, Article 92. DM Chapter 5.4

- 5. HSEQ -Rev-01(Aug-2018) 24. Adequacy and numbers of fire extinguisher, correct for use and application Ensure extinguishers are appropriate to the application, CO2, Water, Dry Powder etc.; Ensure extinguishers are fixed near exit doors and at appropriate heights. (Handle of large extinguishers – 1 metre from floor. Handle of small hand held extinguisher– approx. 1.5 metres from floor.); Ensure that fire extinguishers, hose reels, etc. are conspicuous (not blocked, obscured, etc.). Directional arrows and fire-fighting equipment signs must be displayed where equipment is hidden from direct view; Regular inspection of fire extinguishers undertaken and recorded; Use of extinguisher training undertaken; FLSCOP Chapter 12 Sections 5, 15.5 DM-Chapter 5.5 OSHAD CoP 43.0 25. Fuel storage and refuelling of site vehicles and plant All fuel storage bunds (110% of capacity); No smoking and prohibitive signage around fuel storage area; Ensure Fire extinguishers present; Delivery hoses subject to inspection regime; Spillage kits available in areas; No storage of fuels (generator fill etc.) in any receptacle other than specifically designed; No fuel storage in Metro Protection Zone; FLSCOP Chapter 12 Section 8.1 DM-Chapter 5.7 RWPCOP Section 4.6.1 26. Hydrant/fire points and hose reels. (Including hose attachment points for the civil defence.) Ensure risers are tested as required by the civil defence; Free access from the street to fire hydrants and to outside connections for standpipes, sprinklers, or other fire extinguishing equipment, whether permanent or temporary, shall be provided and maintained at all times; Protective pedestrian walkways shall not be constructed so that they impede access to hydrants; No material or construction shall interfere with access to hydrants, Siamese connections, or fire extinguishing equipment; Ensure test record maintained; Dry and wet risers must be labelled ‘dry riser’ or ‘wet riser’ as appropriate (red ‘fire-fighting equipment’ safety signs); A water supply for fire protection, either temporary or permanent, shall be made available as soon as combustible material accumulates; Hose reels, both temporary and permanent must be inspected monthly by a Fire Officer. Records of inspection kept; If temporary, water supply must be sufficient and maintained. Fire pumps must be inspected and maintained; Installed but unpressurized hoses will be clearly marked “Not in Use’; FLSCOP Chapter 12 Section 15.2 DM-Chapter 5.2 RWPCOP Section 4.6.1 OSHAD CoP 43.0 27. Fire sprinkler systems Where automatic Fire Sprinkler systems are required to be installed in new buildings, the system shall be placed in service as soon as possible; Immediately upon the completion of sprinkler pipe installation on each floor level, the piping shall be hydrostatically tested and inspected. After inspection approval from the Civil Defence, each floor level of sprinkler piping shall be connected to the system supply riser and placed into service; Where sprinklers are required for safety to life, the building shall not be occupied until the sprinkler installation has been entirely completed and tested so that the protection is not susceptible to frequent impairment caused by testing and correction; FLSCOP Chapter 12 Section 15.7 DM-Chapter 5 OSHAD CoP 43.0 28. Standpipe Installations (If required by Authority having jurisdiction) Where required in buildings under construction, a standpipe system, either temporary or permanent in nature, shall be installed; The standpipes shall be provided with conspicuously marked and readily accessible Civil Defence connections on the outside of the building at the street level and shall have at least one standard hose outlet at each floor; The pipe sizes, hose valves, hose, water supply, and other details for new construction shall be in accordance with engineering judgment for adequate Fire-fighting; The standpipes shall be securely supported and restrained at each alternate floor; At least one approved hose valve for attaching Civil Defence hose shall be provided at each intermediate landing or floor level in the exit stairway; Valves shall be kept closed at all times and guarded against mechanical injury. Temporary standpipes shall remain in service until the permanent standpipe installation is complete; FLSCOP Chapter 12 Section 15.4

- 6. HSEQ -Rev-01(Aug-2018) 29. Fire blankets. Light duty blankets - small fires in containers of cooking oils or fats and fires involving clothing to be used where canteens are introduced; Heavy duty blankets - industrial use to be used for site hot works; Tabs on fire blankets should be approximately 1.5 metres from the floor; Ensure relevant staff received instruction on the correct use of fire blankets; 30. Fire and Emergency plan and Drills Ensure there is a plan for raising the alarm, calling the Civil Defence and assembly point locations; Ensure fire action notices are in place and up to date. In general, fire action notices shall be posted next to all fire alarm call points. Ensure visitors, contractors and members of the public (if applicable) are considered as part of the plan. Fire drills shall be formally reviewed to identify problems encountered and any further actions required. Fire plan reviewed as required during the project timescale; FLSCOP Chpt. 12 Sect 3, 16, 19, 26 RWPCOP Section 4.5.10 DM Chapter 5.4 RED Article (19) OSHAD CoP 53.0 31. Personnel training and/or instruction on evacuation arrangements. Agreed evacuation procedures shall be displayed and communicated to staff. Procedures must be clear and understandable in languages as required. Ensure new employees receive instruction on the action to take in event of a fire on Induction. Ensure existing employees receive annual refresher training and/or instruction on what to do in the event of a fire. E.g. through team meetings. FLSCOP Chapter 12 Sections 5.3, 26.1 DM Chapter 5.4 32. Civil Defence access and parking All construction sites shall be accessible by Civil Defence apparatus by means of roadways having an all-weather driving surface of not less than 20 feet (6.1m) of unobstructed width; The roads shall have the ability to withstand the live loads of fire apparatus and have a minimum 4.5m of vertical clearance; The required width of access roadways shall not be obstructed in any manner, including obstruction by parked vehicles; Signs or other appropriate notices, or both, prohibiting obstruction shall be implemented and shall be maintained; The access roadway shall be extended to within 46 m of all portions of the exterior walls of the first story of any building; FLSCOP Chapter 12 Section 17 DM Chapter 5.4 All site entrances 24/7 watchmen 33. Underground Services The location of underground services (electrical, telecoms etc.) to be clearly marked around temporary offices, any permanent sub-stations within project footprint etc.; All excavations around temporary offices and other buildings shall be undertaken under the ATC PTW system, including CAT scan; FLSCOP Chapter 12 Section 25 34. Specialist training in the event of an emergency. Ensure an adequate number of personnel are trained to assist in an emergency (including additional numbers to cover sickness, leave, etc.). E.g. fire wardens, aiding people with mobility impairments, etc. Ensure fire wardens in place and are they fully trained in their duties and responsibilities; Ensure that outside contractors and visitors receive necessary fire safety information (e.g. how to raise the alarm, location of exits, etc.) Ensure an adequate number of personnel are trained to use extinguishers, hose reels and/or fire blankets. (See Guidance and Information Sheet for information on fire extinguishers and training.) FLSCOP Chapter 12 Section 5.3 OSHAD Element 6 Fire warden training ongoing including refresher. Any Additional Information or comments: Signed: HSE Manager Date: Signed: Project Manager Date: