Final CAMP Symposium Poster Design

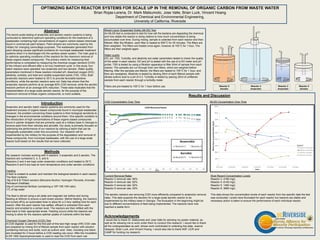

- 1. Results and Discussion COD Concentration Over Time MLSS Concentration Over Time OPTIMIZING BATCH REACTOR SYSTEMS FOR SCALE UP IN THE REMOVAL OF ORGANIC CARBON FROM WASTE WATER Brian Rojas-Lerena, Dr. Mark Matsumoto, Jose Valle, Brian Luck, Vincent Hoang Department of Chemical and Environmental Engineering, University of California, Riverside Abstract The bench-scale testing of anaerobic and aerobic reactor systems is being conducted to determine optimum operating conditions for the treatment of a wastewater containing high concentrations of organic carbon-based chemicals found in commercial paint stripers. Paint stripers are commonly used by the military for changing camouflage purposes. The wastewater generated from paint stripping causes significant problems for municipal wastewater treatment systems when it is discharged into the sanitary sewer system. The main goal is to optimize operating conditions of the reactors for the maximum removal of these organic-based compounds. The primary metric for measuring their performance is completed by measuring the chemical oxygen demand (COD) of the influent and effluent after a 24 hour treatment cycle. In this study, four batch reactors were operated: two anaerobic and two aerobic. Water quality parameters monitored in these reactors included pH, dissolved oxygen (DO), alkalinity, turbidity, and total and volatile suspended solids (TSS, VSS). Both anaerobic reactors were heated to 35°C to provide favorable bacteria conditions, while the aerobic reactors were not. Data has shown that the anaerobic reactors perform at an average 83% COD removal, while the aerobic reactors perform at an average 93% reduction. These data implicates that the implementation of a large-scale aerobic reactor, for the purpose of the maximum removal of these organic compounds, is more suitable. Introduction Anaerobic and aerobic batch reactor systems are commonly used for the treatment process of organic-based compounds found in municipal wastewater. However, the problem concerning these systems is their biological sensitivity to changes in the environmental conditions around them. One specific condition is the introduction of high concentrations of these organic-based compounds found in painter strippers that are primarily used at a military base in Georgia to remove paint from their vehicles and aircrafts. Our study is primarily focused on optimizing the performance of our reactors by utilizing a batch that can be biologically sustainable under this occurrence. Our research will be implemented by the military for the purpose of the degradation and removal of these compounds, from municipal wastewater, with the use of a large-scale reactor built based on the results that we have collected. Methods My research includes working with 4 reactors: 2 anaerobic and 2 aerobic. The reactors are numbered 2, 4, 5, and 6. Reactors 2 and 4 are kept under anaerobic conditions and heated to 35°C. Reactors 5 and 6 are kept at room temperature and under aerobic conditions Feeding A feed is created to sustain and maintain the biological bacteria in each reactor. The feed contains: 18g of B & B Tritech solution (Benzene Alcohol, Hydrogen Peroxide, Aromatic Petroleum Distillate) 24g of commercial fertilizer (containing a 10P:10K:10N ratio) 17L of tap water The feed is stirred using a stir plate and magnetic bar before and during feeding at 400rpm to ensure a well mixed solution. Before feeding, the reactors are turned off by an automated timer to allow for a 3 hour settling time for each reactor. After the each reactor has settled, effluent is extracted from each reactor and emptied to a certain level. The reactors are then refilled with the feed back to their appropriate levels. Feeding occurs while the reactors are mixing to allow for the reactors optimal uptake of nutrients within the feed. Chemical Oxygen Demand (COD) Test A COD digester is used for the first part of this test High range (HR) COD vials are prepared by mixing 2ml of filtered sample from each reactor with solution containing mercury and acids, such as sulfuric acid. Vials, including one blank, are incubated for 2 hours before a COD reading can occur. After the incubation, A DR 1900 Spectrophotometer is used to read the COD from each vial. Mixed Liquor Suspended Solids (MLSS) Test An MLSS test is conducted to test for how will the bacteria are degrading the chemical and how stable the reactor is doing relative to how much concentration is being accumulated over time. During mixing, sample is collected from each reactor and then filtered. After the filtration, each filter is heated to 550°C for 30 minutes. The filters are then weighted. The filters are heated once again, however at 105°C for 1 hour. The filters are then weighed again. Water quality DO, pH, TSS, Turbidity, and alkalinity are water parameters tested to check the quality of the water in each reactor. DO and pH is tested with the use of a DO meter and pH probe. TSS is tested by using a filtration apparatus to filter 50ml of sample from each reactor. The samples are run through their own filters, which are weighed before filtering. After the samples are filtered, the filters are heated to 105°C for 1 hour, and then are reweighed. Alkalinity is tested by diluting 25ml of each filtered sample with diluted sulfuric acid to a pH of 4.3. Turbidity is tested by placing 25ml of unfiltered sample from each reactor through a turbidity meter. Filters are pre-heated to 105°C for 1 hour before use. Current Removal Rates: Reactor 2 removal rate: 85% Reactor 4 removal rate: 82% Reactor 5 removal rate: 92% Reactor 6 removal rate: 93% The aerobic reactors are removing COD more efficiently compared to anaerobic removal rates. This data supports the decision for a large-scale aerobic reactor to be implemented by the military base in Georgia. The fluctuation in the beginning might be due to different concentrations of feed being implemented. The reactors have now reached a stable form. Acknowledgements I would like to thank Dr. Matsumoto and Jose Valle for advising my poster material, as well as for allowing me to work under them to conduct this research. I would like to thank all the undergraduates as well, whose work contributed to collecting this data: Joanna Vasquez, Brian Luck, and Vincent Hoang. I would also like to thank NSF, UCR and CAMP for funding my research. Most Recent Concentration Levels Reactor 2: 4180 mg/L Reactor 4: 8140 mg/L Reactor 5: 1460 mg/L Reactor 6: 3680 mg/L This data shows the concentration levels of each reactor from the specific date the test was conducted. Levels have fluctuated for each reactor but reactors are stable and necessary action is taken to ensure the performance of each individual reactor. Reactor 6 Aerobic Reactor 4 Anaerobic Reactor 2 Anaerobic Reactor 5 Aerobic

Notas do Editor

- Intro: Find sources that includes that can back up my statements. Diagrams: Include more diagrams to visualize a batch reactor (batch reactor, large scale aerobic reactor). Include temperature and volume. (300 gal/day) Feeding: Include chemicals in feed (Benzene Alcohol, Hydrogen Peroxide, Aromatic Petroleum Distillate) Graphs: Minimize the MLSS data from the start of Fall quarter. MLSS: capitalize L Include COD removal rates of other reactors. (Temperature and removal rate changes, optimization) Acknowledgements: Krieger Family Laboratory for funding the lab(2013). Note: The sludge gathered from the water treatment plant is very concentrated (organics, too high COD?) so it needs to be diluted (DI water?). From diluting, feeding the next day brought down the concentration in reactors. Operator Error: Inconsistent feeding time Different chemical concentration levels