TSUGRC2015-FDFF-Final2

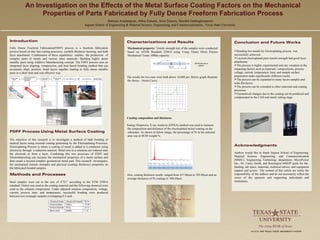

- 1. Presenter name, Associates and Collaborators Department of XXXXXXXXXXXXXXXX, College of XXXXXXXXXXXXXXXXXX, University of Illinois at Urbana-Champaign Template for a 48”x36” poster Bahram Asiabanpour, Abbas Fahami, Aron Zamora, Maedeh Dabbaghianamiri Ingram School of Engineering & Material Science, Engineering, and Commercialization,, Texas State University An Investigation on the Effects of the Metal Surface Coating Factors on the Mechanical Properties of Parts Fabricated by Fully Dense Freeform Fabrication Process Introduction Fully Dense Freeform Fabrication(FDFF) process is a freeform fabrication process based on thin line cutting processes, variable thickness layering, and bulk layer attachment. Combination of these capabilities enables the production of complex parts of metals and various other materials. Building highly dense metallic parts using Additive Manufacturing concept. The FDFF process uses an integrated layer aligning, compression, and heat based bonding method that can accurately align, position, bond layers together leading to fully dense metallic parts in a short time and cost effective way. FDFF Process Using Metal Surface Coating The objective of this research is to investigate a method of bulk bonding of stacked layers using external coating generating by the Electroplating Processes. Electroplating Process is where a coating of metal is added to a conductor using electricity through a reduction reaction. Metal ions in a solutions are reduced onto the electrode to form a layer. Combining this two processes of FDFF and Electrodepositing can increase the mechanical properties of a metal surface and then create a layered complex geometrical metal part. This research investigates, the mechanical (tensile strength) and physical (coating thickness) properties on the fabricated bonded samples. Methods and Processes Steel samples were cut in the size of 4”X1” according to the STM 2294-6 standard. Nickel was used as the coating material and the following chemical were used as the solution composition. Under adjusted solution composition, voltage, current, process time, and temperature, successful bonding were produced between two rectangle samples overlapping 0.5 inch. Characterizations and Results Mechanical property: Tensile strength test of the samples were conducted based on ASTM Standard 2294-6 using Using Tinius Olsen Electro Mechanical Tester, 600kn capacity. The results for two runs were both above 10,000 psi. Below graph illustrate the Stress – Strain Curve. Coating composition and thickness: Energy Dispersive X-ray Analysis (EDXA) method was used to measure the composition and thickness of the electroplated nickel coating on the substrates. As shown in below image, the percentage of Ni in the selected area was at 88.88 weight %. Also, coating thickness results ranged from 417.06µm to 395.08µm and an average thickness of Ni coating of 408.69µm Conclusion and Future Works Bonding two metals by Electroplating process was successfully achieved. Layered electroplated parts tensile strength had good layer attachment. The process is highly experimental and any variation in the impacting factors such as materials’ compositions, process voltage, current, temperature, time, and sample surface preparation make significantly different results. The process can be expanded to many layers samples and none flat layers. The process can be extended to other materials and coating processes. Geometrical changes due to the coating can be predicted and compensated in the CAD and metal cutting stage. Acknowledgments Authors would like to thank Ingram School of Engineering, Material Science, Engineering, and Commercialization (MSEC), Engineering Technology department, MicroPower Inc., Dr. Casey Smith, and Reenergize-MSEIP grant for the funding, lab space, materials, technical advice, and equipment support and access. The content of this article are solely the responsibility of the authors and do not necessarily reflect the views of the sponsors and supporting individuals and institutions. ASTM Standard 2294-6