amol thakare -

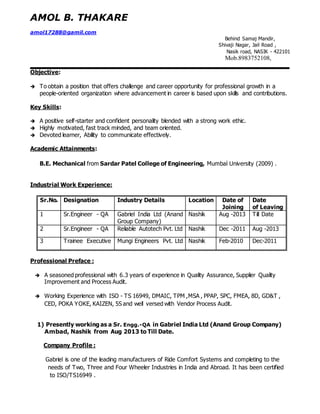

- 1. AMOL B. THAKARE amol17288@gamil.com Behind Samaj Mandir, Shivaji Nagar, Jail Road , Nasik road, NASIK - 422101 Mob.8983752108, Objective: To obtain a position that offers challenge and career opportunity for professional growth in a people-oriented organization where advancement in career is based upon skills and contributions. Key Skills: A positive self-starter and confident personality blended with a strong work ethic. Highly motivated, fast track minded, and team oriented. Devoted learner, Ability to communicate effectively. Academic Attainments: B.E. Mechanical from Sardar Patel College of Engineering, Mumbai University (2009) . Industrial Work Experience: Sr.No. Designation Industry Details Location Date of Joining Date of Leaving 1 Sr.Engineer - QA Gabriel India Ltd (Anand Group Company) Nashik Aug -2013 Till Date 2 Sr.Engineer - QA Reliable Autotech Pvt. Ltd Nashik Dec -2011 Aug -2013 3 Trainee Executive Mungi Engineers Pvt. Ltd Nashik Feb-2010 Dec-2011 Professional Preface : A seasoned professional with 6.3 years of experience in Quality Assurance, Supplier Quality Improvement and Process Audit. Working Experience with ISO - TS 16949, DMAIC, TPM ,MSA , PPAP, SPC, FMEA, 8D, GD&T , CED, POKA YOKE, KAIZEN, 5S and well versed with Vendor Process Audit. 1) Presently working as a Sr. Engg.-QA in Gabriel India Ltd (Anand Group Company) Ambad, Nashik from Aug 2013 to Till Date. Company Profile : Gabriel is one of the leading manufacturers of Ride Comfort Systems and completing to the needs of Two, Three and Four Wheeler Industries in India and Abroad. It has been certified to ISO/TS16949 .

- 2. AMOL B. THAKARE amol17288@gamil.com Behind Samaj Mandir, Shivaji Nagar, Jail Road , Nasik road, NASIK - 422101 Mob.8983752108, Job responsibility: Calculating internal and Customer PPM per month cell wise and Represent graphs on Dash Board on shop Floor. Handling Customer Complaints by using 5 Why Analysis, SCAP, 8D Formats & reduce level of rejection by taking & implementing corrective actions Visiting to customer for warranty related issue and get the defective samples, analysis of defects with the help of 7QC Tools and taking necessary actions on findings. In house Rejection & Rework Analysis by Root Cause Analysis to reduce Rejection & Rework Percentage and monitoring effectiveness of CA/PA . Working with New process development team and identify process requirements for NPD On time completion of Customer PPAP documentation & get approval from customer. Review, Updation & Issue of Process Flow Diagrams, Process FMEA’s, Control Plan, in process inspection reports, Work instruction based on New product Development and the corrective action results. To take daily morning meeting with production operators and officer, discuss about quality Issues . Identification & Implementation of Kaizen & pokayoke for process & quality improvement & to achieve cost saving. Conducting Dock Audit, In-process & Product audit for ensuring good Quality of products & Manufacturing Process, analyzes gaps, initiate corrective & preventive actions & monitor effectiveness of actions. Planning & execution of MSA as per plan along with rectification of instruments To Conduct Corrosion resistance testing & material testing as per plan Implementation of Lay-Out & SPC plan as per Schedule & their monitoring status . If PISI observed > 100 then take a action on resp. part. Contamination Audit on weekly basis to improve the working conditions on the shop floor. Planning Calibration of Instruments, Gauges, Pokayoke sample ,master sample and Visual aids as per plan and maintain calibration records . Conduct Training Program of Inspectors to improve their multi skills level To Conduct Quality month on shop floor per year Formation of team and leading the same to reduce COPQ Facing “Customer Audit & Internal Quality Audit” & timely closing NCR raised during Audit To maintained the TS related documentation. Hands on Experience for precise Instruments QA functions. Having Knowledge of SAP activity , related to Quality management system . (ex:- Rejection entry , internal PPM, Lot inspection, Purchase requisition for material ) 5S implementation in Std room and final inspection stations. 2) Worked as a Sr. Quality Assurance Officer in Reliable Autotech Pvt. Ltd . Ambad, Nashik from Dec 2011 to Aug 2013. Job responsibility: To Handle Customer Complaints & take corrective & preventive action & monitor effectiveness of actions

- 3. AMOL B. THAKARE amol17288@gamil.com Behind Samaj Mandir, Shivaji Nagar, Jail Road , Nasik road, NASIK - 422101 Mob.8983752108, Analysis of In process and final rejection, resolve the issues with the help of 8D methodology. To ensure adherence with quality system on shop floor through Layered audit as per check sheet. Daily performance monitoring sheet and discussion in meeting about the problems with production department Planning & execution of Product & Process Audits as per plan Team member in implementation of TPM (QM pillar) for AL 203461 and L-90. Planning & execution of MSA as per plan Preparation of LAYOUT & SPC plan for a year & conducting the same as per due date. Moderating Process FMEA. Planning & conduct Instruments and Gauges calibration as per plan To Display Skill matrix and Lux level cell wise on shop floor . Buyoff activates all fixtures, tools and gauges related to the development project. Hands on Experience for precise Instruments QA functions. Pokayoke Audit on weekly basis to ensure 100% pokayoke running in the plant and implementation of new pokayoke (& kaizen). To maintain weld test penetration Lab and verify penetration reports of parts as per Frequency. Calculating destructive testing scrap of parts and take scrap note per month. To Handle quality Inspectors and Making the Shift Scheduled Conduct Training Program of Inspectors to improve their multi skills level as per ‘TS’ Requirement. Preparation of Operation control plan , SOP and working instruction. Pre dispatch Inspection of final product To maintained the TS related documentation. Verify Corrective Action taken on NCR raised during Internal Quality Audit of TS, EMS & OHSAS. Maintain PPAP ( Prod. Part Approval Process ) files of parts ( In which Control Plan / Flow Process chart / FMEA / Layout of parts / Final inspection Quality Plan / MSA of Attribute & variable Instruments / SPC of SC/CC character / Checking Aid list of Instrument / with respected part Drawing & PSW ) 3) Worked as a Trainee Executive in Mungi Engineers Pvt. Ltd, Ambad, Nasik from Feb 2010 to Dec 2011. Job Profiles:- Monitoring Inspection of In process, Final, Receiving. To handling the Customer Complaints initiate corrective action on Non Conformity Monitoring of In-house rejection Initiate Corrective action on Non Conformity part In case of problems in the parts during assembly process, intimation and solving the dimensional problems from the receiving material side. Daily performance monitoring sheet and discussion in meeting about the problems with production department Co-Coordinator for Plant level Data such as Dash Board charts. Participation & implementation of Kaizen activity.

- 4. AMOL B. THAKARE amol17288@gamil.com Behind Samaj Mandir, Shivaji Nagar, Jail Road , Nasik road, NASIK - 422101 Mob.8983752108, To take Part & Process Audit as per plan Conducting SPC Studies and MSA Studies Making the Shift Scheduled In Quality Inspectors. To identify areas for continuous improvements Pre dispatch Inspection of final product Verify and maintaining Percentage Inspection Points Satisfying Tolerance (PIST) report and take Corrective Actions For Not OK Characteristics . Preparation of PPAP documents as per instruction of project leader. Generation of Master list & Maintain drawing file of all projects. Study of cycle time, operator nos. per stage for all Assembly line . Instruments Handled:- Roundness Tester, HommelTester, Plating thickness tester , Harness Tester, Profile Projector, Linier Height Gauge, Vernier Caliper, Micrometer, Torque wrench , comparator, air gauge ,Bore gauge , shore hardness , Bevel Protector, Height Gauge, feeler gauge , Snap gauge ,Ring gauge , Plug gauge ,slip & Pin Gauges, Radius Gauge. Trainings : ISO/TS 16949 awareness MSA SPC 8 Discipline techniques for root cause analysis. PFMEA TPM (TotalProductive Maintenance) PPAP (Production part approval process) 7 QC TOOLS KAIZEN & POKAYOKE 5s (Seiri, Seiton, Seiso, Seiketsu & Shitsuke) Metal finishing on job taining. G D & T. Spot welding and CO2 welding Brain Storming. Managerial skill. How to Work Together Computer Knowledge: 1. CATIA V5 Modules: Sketcher Part Design Surfacing Assembly Drafting

- 5. AMOL B. THAKARE amol17288@gamil.com Behind Samaj Mandir, Shivaji Nagar, Jail Road , Nasik road, NASIK - 422101 Mob.8983752108, Extra Curricular Activities: Won First Prize in JUNKYARD WARS held at TORQUE 2008. Organizer of TECHNICAL PAPER PRESENTATION at TORQUE 2007 Volunteer of JUNKYARD WARS at TORQUE 2006 Academic Achievement: Project on HAND OPERATED SPRING MAKING MACHINE submitted to Mumbai University. Won first prize in Speech Competition at intra-school level (7th, 8th std). Represented school for science quiz at inter-school level . Personal Details: Name : Amol babulal thakare Date of Birth : 17th Feb 1988 Marital Status : Unmarried Nationality : Indian Per. Add. : Shivaji Nagar,jail Road, Nasik road, NASIK- 422001 Mobile no. : 8983752108 Email ID : amol_170288@yahoo.co.in I here declare that the information furnished above is true to the best of my knowledge. DATE: - PLACE: - Nasik (Amol B. Thakare) **********