PolyFoam Series

•

0 gostou•6 visualizações

PolyFoam Series casting foams consist of two parts (A and B) that, after mixing, form rigid or flexible foam products with densities in the range of 3 to 20 lb/ft³. PolyFoam R-2, R-5 and R-8 are rigid foams. PolyFoam F-3 and F-5 are flexible for casting soft parts. Consider PolyFoams for production of decorative objects, lightweight mold shells, production parts, models, patterns, fixtures, duplicate masters and general tooling use. PolyFoam systems are practically odorless and do not contain toluene diisocyanate, MOCA, heavy metals or HCFCs

Denunciar

Compartilhar

Denunciar

Compartilhar

Baixar para ler offline

Recomendados

Recomendados

Mais conteúdo relacionado

Mais procurados

Mais procurados (12)

Semelhante a PolyFoam Series

Semelhante a PolyFoam Series (11)

Mais de Polytek Development Corp

Mais de Polytek Development Corp (20)

Último

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS Live

Booking Contact Details :-

WhatsApp Chat :- [+91-9999965857 ]

The Best Call Girls Delhi At Your Service

Russian Call Girls Delhi Doing anything intimate with can be a wonderful way to unwind from life's stresses, while having some fun. These girls specialize in providing sexual pleasure that will satisfy your fetishes; from tease and seduce their clients to keeping it all confidential - these services are also available both install and outcall, making them great additions for parties or business events alike. Their expert sex skills include deep penetration, oral sex, cum eating and cum eating - always respecting your wishes as part of the experience

(07-May-2024(PSS)VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...Call Girls In Delhi Whatsup 9873940964 Enjoy Unlimited Pleasure

Último (20)

Business Model Canvas (BMC)- A new venture concept

Business Model Canvas (BMC)- A new venture concept

Mysore Call Girls 8617370543 WhatsApp Number 24x7 Best Services

Mysore Call Girls 8617370543 WhatsApp Number 24x7 Best Services

Call Girls In DLf Gurgaon ➥99902@11544 ( Best price)100% Genuine Escort In 24...

Call Girls In DLf Gurgaon ➥99902@11544 ( Best price)100% Genuine Escort In 24...

How to Get Started in Social Media for Art League City

How to Get Started in Social Media for Art League City

Value Proposition canvas- Customer needs and pains

Value Proposition canvas- Customer needs and pains

Insurers' journeys to build a mastery in the IoT usage

Insurers' journeys to build a mastery in the IoT usage

Call Girls in Delhi, Escort Service Available 24x7 in Delhi 959961-/-3876

Call Girls in Delhi, Escort Service Available 24x7 in Delhi 959961-/-3876

Ensure the security of your HCL environment by applying the Zero Trust princi...

Ensure the security of your HCL environment by applying the Zero Trust princi...

0183760ssssssssssssssssssssssssssss00101011 (27).pdf

0183760ssssssssssssssssssssssssssss00101011 (27).pdf

Call Girls Jp Nagar Just Call 👗 7737669865 👗 Top Class Call Girl Service Bang...

Call Girls Jp Nagar Just Call 👗 7737669865 👗 Top Class Call Girl Service Bang...

Call Girls Pune Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Pune Just Call 9907093804 Top Class Call Girl Service Available

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

👉Chandigarh Call Girls 👉9878799926👉Just Call👉Chandigarh Call Girl In Chandiga...

👉Chandigarh Call Girls 👉9878799926👉Just Call👉Chandigarh Call Girl In Chandiga...

Call Girls From Pari Chowk Greater Noida ❤️8448577510 ⊹Best Escorts Service I...

Call Girls From Pari Chowk Greater Noida ❤️8448577510 ⊹Best Escorts Service I...

Falcon's Invoice Discounting: Your Path to Prosperity

Falcon's Invoice Discounting: Your Path to Prosperity

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

VVVIP Call Girls In Greater Kailash ➡️ Delhi ➡️ 9999965857 🚀 No Advance 24HRS...

PolyFoam Series

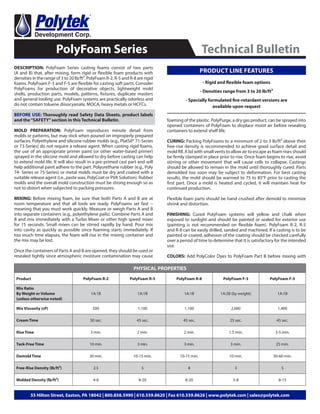

- 1. DESCRIPTION: PolyFoam Series casting foams consist of two parts (A and B) that, after mixing, form rigid or flexible foam products with densities in the range of 3 to 20 lb/ft³. PolyFoam R-2, R-5 and R-8 are rigid foams. PolyFoam F-3 and F-5 are flexible for casting soft parts. Consider PolyFoams for production of decorative objects, lightweight mold shells, production parts, models, patterns, fixtures, duplicate masters and general tooling use. PolyFoam systems are practically odorless and do not contain toluene diisocyanate, MOCA, heavy metals or HCFCs. BEFORE USE: Thoroughly read Safety Data Sheets, product labels and the“SAFETY”section in this Technical Bulletin. MOLD PREPARATION: PolyFoam reproduces minute detail from molds or patterns, but may stick when poured on improperly prepared surfaces. Polyethylene and silicone rubber molds (e.g., PlatSil® 71-Series or 73-Series) do not require a release agent. When casting rigid foams, the use of an appropriate primer paint (or other water-based primer) sprayed in the silicone mold and allowed to dry before casting can help to extend mold life. It will also result in a pre-primed cast part and will help additional paint adhere to the part. Polyurethane rubber (e.g., Poly 74- Series or 75-Series) or metal molds must be dry and coated with a suitable release agent (i.e., paste wax, PolyCoat or PVA Solution). Rubber molds and the overall mold construction must be strong enough so as not to distort when subjected to packing pressures. MIXING: Before mixing foam, be sure that both Parts A and B are at room temperature and that all tools are ready. PolyFoams set fast -- meaning that you must work quickly. Measure or weigh Parts A and B into separate containers (e.g., polyethylene pails). Combine Parts A and B and mix immediately with a Turbo Mixer or other high speed mixer for 15 seconds. Small mixes can be stirred rapidly by hand. Pour mix into cavity as quickly as possible since foaming starts immediately. If too much time elapses, the foam will rise in the mixing container and the mix may be lost. Once the containers of Parts A and B are opened, they should be used or resealed tightly since atmospheric moisture contamination may cause PolyFoam Series Technical Bulletin 55 Hilton Street, Easton, PA 18042 | 800.858.5990 | 610.559.8620 | Fax 610.559.8626 | www.polytek.com | sales@polytek.com foaming of the plastic. PolyPurge, a dry gas product, can be sprayed into opened containers of PolyFoam to displace moist air before resealing containers to extend shelf life. CURING: Packing PolyFoams to a minimum of 2 to 3 lb/ft³ above their free-rise density is recommended to achieve good surface detail and mold fill. A lid with small vents to allow air to escape as foam rises should be firmly clamped in place prior to rise. Once foam begins to rise, avoid stirring or other movement that will cause cells to collapse. Castings should be allowed to remain in the mold until thoroughly cured. Parts demolded too soon may be subject to deformation. For best casting results, the mold should be warmed to 75 to 85°F prior to casting the first part. Once a mold is heated and cycled, it will maintain heat for continued production. Flexible foam parts should be hand crushed after demold to minimize shrink and distortion. FINISHING: Cured PolyFoam systems will yellow and chalk when exposed to sunlight and should be painted or sealed for exterior use (painting is not recommended on flexible foam). PolyFoam R-2, R-5 and R-8 can be easily drilled, sanded and machined. If a casting is to be painted or coated, adhesion of the coating should be checked carefully over a period of time to determine that it is satisfactory for the intended use. COLORS: Add PolyColor Dyes to PolyFoam Part B before mixing with - Rigid and flexible foam options - Densities range from 3 to 20 lb/ft³ - Specially formulated fire-retardant versions are available upon request PHYSICAL PROPERTIES Product PolyFoam R-2 PolyFoam R-5 PolyFoam R-8 PolyFoam F-3 PolyFoam F-5 Mix Ratio By Weight or Volume (unless otherwise noted) 1A:1B 1A:1B 1A:1B 1A:2B (by weight) 1A:1B Mix Viscosity (cP) 500 1,100 1,100 2,000 1,400 Cream Time 30 sec. 45 sec. 45 sec. 25 sec. 45 sec. Rise Time 3 min. 2 min. 2 min. 1.5 min. 3-5 min. Tack-Free Time 10 min. 3 min. 3 min. 3 min. 25 min. Demold Time 30 min. 10-15 min. 10-15 min. 10 min. 30-60 min. Free-Rise Density (lb/ft³) 2.5 5 8 3 5 Molded Density (lb/ft³) 4-8 8-20 8-20 5-8 8-15 PRODUCT LINE FEATURES

- 2. 55 Hilton Street, Easton, PA 18042 | 800.858.5990 | 610.559.8620 | Fax 610.559.8626 | www.polytek.com | sales@polytek.com Sealers & Release Agents: PolyCoat Sealer & Release Agent Poly PVA Solution Product Life Extender: Poly Purge Aerosol Dry Gas Colors: PolyColor Dyes Black - Brown - Blue - Green - Red - Yellow - White - Fleshtone Part A to create foams of any color. Add up to 0.5% PolyColor Dye of the total mixed weight when using PolyColor Black, Brown, Blue, Green, Red andYellow. Add up to 2% PolyColor Dye of the total mixed weight when using PolyColor White and Fleshtone. CLEAN UP: Tools should be scraped clean before the foam cures. Denatured alcohol is a good cleaning solvent, but must be handled with extreme caution owing to its flammability and health hazards. Work surfaces can be coated with wax or release agent so that cured plastic can be easily removed. SAFETY: Before use, thoroughly read Safety Data Sheets and product labels. Follow safety precautions and directions. Part A: Keep out of reach of children. Do not breathe fumes, vapors, or mists. Use only outdoors or with adequate general or local exhaust ventilation to minimize exposure levels. If needed, a NIOSH-approved respirator with organic vapor cartridge may be used. If inhaled, remove victim to fresh air and keep at rest in a position comfortable for breathing. If experiencing respiratory irritation, get medical attention. Wear impervious gloves, such as butyl rubber or nitrile rubber. Wash contaminated clothing before reuse. Wash skin thoroughly with soap and water after handling. If skin irritation occurs, get medical attention. Wear eye protection, such as chemical safety glasses/googles. If in eyes, rinse cautiously with water for several minutes, removing contact lenses if present and easy to do. If eye irritation occurs, get medical attention. Store in a well-ventilated place and keep container tightly closed. If spilled, avoid release to the environment. Part B: Keep out of reach of children. Use with adequate general or local exhaust ventilation to minimize exposure levels. If needed, a NIOSH- approvedrespiratorwithorganicvaporcartridgemaybeused.Ifinhaled, remove victim to fresh air and keep at rest in a position comfortable for breathing. Wear impervious gloves, such as butyl rubber or nitrile rubber. Wash skin thoroughly with soap and water after handling. Wear eye protection, such as chemical safety glasses/googles. If in eyes, rinse cautiously with water for several minutes, removing contact lenses if present and easy to do. STORAGE LIFE: For best results, store products in unopened containers at room temperature (60-90°F/15-32°C). Use products within six months. PolyFoam F-5 Part A may crystallize, develop sediment and become cloudy if stored at temperatures below 60°F. To restore product, loosen lid (to avoid pressure buildup) and warm product to 120-160°F until the liquid is clear. Before use, let product cool to room temperature. Using a crystallized or cloudy Part A may result in a foam with inferior physical properties. DISCLAIMER: The information in this bulletin and otherwise provided by Polytek® Development Corp. is considered accurate. However, no warranty is expressed or implied regarding the accuracy of the data, the results to be obtained by the use thereof, or that any such use will not infringe any patent. Before using, the user shall determine the suitability of the product for the intended use and user assumes all risk and liability whatsoever in connection therewith. December9,2020 PolyFoam Series | Technical Bulletin | Page 2 Determine the volume of the space you want to fill with foam in cubic inches (in³). Convert the volume to ft³ by dividing by 1728 in³/ft³. Determine the desired density of the foam part in pounds per cubic foot (lb/ft³). Note: Foam products are typically compacted to at least 2 pounds more than their free-rise density to produce good quality parts. Therefore, to determine the quantity of foam needed, add at least 2 pounds to the free-rise density (e.g., for R-2, use at least 4 lb/ft³; for R-5 use 7 lb/ft³; and so on). Multiply the volume of the part (ft³) by the desired density (lb/ ft³) to determine how many pounds of PolyFoam liquid to mix. Example: You intend to make a part that is 4320 in³. Convert to ft³: 4320 in³ ÷ 1728 in³/ft³ = 2.5 ft³. Desired density is 5 lb/ft³, so choose R-2 and determine volume to pour based on packing to 5 lb/ft³. 5 lb/ft³ x 2.5 ft³ = 12.5 lb PolyFoam total Note on Foam Compaction Calculation: ACCESSORIES