Osborn Apron Feeders Guide: Sizes, Capacities, Design & Application

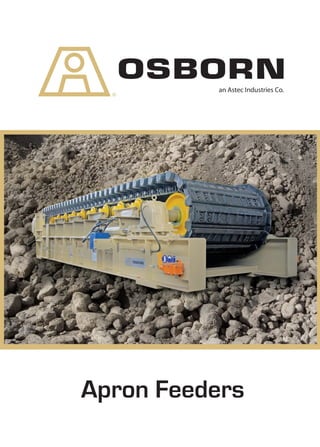

- 2. Osborn Range Introduction to Apron Feeders Type Widths Capacities TPH D4 900 – 2100 mm up to 1500 D6 1200 – 2400 mm up to 2000 D7 1500 – 3000 mm up to 2500 D8 1500 – 3000 mm up to 2500 D9 2000 – 3500 mm up to 5000 Lengths vary from 3 000 mm - 19 000 mm or more depending on design. The capacities shown are based on a material mass of 1.6 tonnes per cubic meter and are indicative only. Upon receipt of all the material characteristics and design parameters, Osborn would be able to provide a more exact capacity for the selected Apron Feeder. 2 Lengths vary from 3 000 mm - 19 000 mm or more depending on design. The capacities shown are based on a material mass of Feed Capacity Burden Depth (mm) Chain Speed (m/min) Pan Width (mm) 900 1050 1250 1500 1800 2100 2400 3000 3500 Inside skirts (mm) 800 950 1150 1400 1700 2000 2300 2900 3400 m³/h m³/h m³/h m³/h m³/h m³/h m³/h m³/h m³/h 1000 4 192 228 276 336 408 480 552 696 816 6 288 342 414 504 612 720 828 1044 1224 8 384 456 552 672 816 960 1104 1392 1632 10 480 570 690 840 1020 1200 1380 1740 2040 Note: Machines with heavier duty chains can be designed and built to suit specific duty requirements Osborn Apron Feeders provide reliable means of controlling the feed rate to prevent surge loads to the Primary Crusher or other plant equipment. An Apron Feeder is run at very low speeds and at a controlled feed rate as it absorbs the impact loads of the material falling from a dump truck or a front-end loader and is ideal for withdrawing material from under a stockpile or from under a Primary Crusher. Apron Feeders are of rugged, heavy duty construction and designed to handle feed sizes of up to 1500 mm and where no fines removal is required or where fines are removed by a separate Vibrating Grizzly. When the feed material is wet, sticky or clay like, and where other feeding equipment cannot handle it, the Apron Feeder is the machine to select. Generally, the Apron Feeder can be installed in a horizontal or inclined position (up to 15°)depending on space limitations. Drives can be electromechanical or hydraulic. The manganese flights are designed to overlap so as to reduce spillage. Osborn Apron Feeders range in sizes from 900 mm wide to 3500 mm wide and are constructed using traditional D4, D6, D7 and D9 track components.

- 3. 3 It is very important to ensure that the loading hopper or bin is designed to achieve the most efficient feed onto the Apron Feeder. The machine often has to cope with high loads at start-up and reduced loads whilst running, hence load distribution via the correctly designed hopper needs to be optimised. Ideally, the dumping of material into the hopper needs to be controlled so that the impact of the new load is absorbed by the last of the material from the previous load. The dumping of material into an empty hopper should be discouraged. If it becomes impossible to dump onto a bed of material, then the load should be tipped towards the tail end of the hopper so that the greater portion of the impact is borne by the sloping rear wall or drop box. This method would be beneficial if the bed of material on the sloping wall comes to rest on the Apron Feeder flights in such a position that it forms a bed for the succeeding portion of the load which is discharged from a greater height. SIZING AN APRON FEEDER The data sheet on the rear of this brochure, illustrates the information that Osborn requires to correctly size the Apron Feeder. Of significant importance on any Apron Feeder installation is the design of the bin or hopper which will be used to feed the machine. To enable Osborn engineers to calculate the optimum size Apron Feeder, also taken into consideration as well as the completed data sheet are the following points that we insert into our formulae: • Flights and chain mass • Start-up and running torque • Chain factor of safety - Start-up conditions – 5:1 minimum - Running conditions – greater than 7.5:1 For Drive sizing we calculate: • Breakaway torque • Running torque • Absorbed power • Installed power • Head shaft speed. • Chain pull (taking material shear resistance, installation inclination resistance etc, into consideration) Osborn generally works on twice the maximum lump size feed to be the minimum width of the Apron Feeder pan as an indicator. Grading analysis is important for correct sizing of feeder width. Apron Feeder with built in Dribble or Fines Belt. Leave at least 4 -5 flights or 800 mm (minimum) clearance at tail shaft for maintenance. Loading Hopper / Bin

- 4. FRAME Full length beams manufactured from rolledsteeljoistsformthetopandbottom members of this one piece unit. Cross members tie the framework together for maximum strength. Bolted onto these crossmembers are the universal beams which carry the impact rails and the carrier rolls. For ease of removing the carrier rolls, the outside carrier roll channels are sectionalized and bolted to the cross beams. HEAD DRIVE SHAFT This heavy duty shaft is machined from high grade hot rolled steel. Each end of the shaft is machined for a drive unit, even on installations with a single drive specification. This can have either a left-hand or right-hand driven orientation and will assist should one side of the shaft be damaged. DRIVE SPROCKETS The sprockets are of the bolt on segmental type made from wear resisting alloy steel. They are designed with an odd number of teeth which increases the life of the sprocket, because contact with the teeth is only completed after two revolutions. The sprockets are bolted onto keyed on hubs. TAIL TRACTION WHEELS Cast steel traction wheels are lighter duty as they act purely as a directional guide to centralise the track. Long service life can be expected as there is minimal load carried on the traction wheels. FLIGHTS Cast steel flights ( or pans ) are fitted as standard and reinforced with longitudinal packers which run in close proximity to the impact rails thus preventing excessive loads being taken by the carry rollers. Manganese flights are available as an option. All flight sets are individually machined to ensure the optimum overlap of each flight is obtained to minimise leakage. The flights are bolted to the track chain using high tensile grade bolts. 4

- 5. IMPACT RAILS These full length heavy duty steel rails are fitted to the frame to prevent permanent distortion of the flights under severe impact loading. Ample clearance is provided to ensure that the flights do not drag on the rail. BEARINGS Anti-friction spherical roller bearings are fitted to the head and tail shafts and housed in heavy duty plummer blocks. Bearings are grease lubricated and a grease reservoir is included in the design of the bearing housings and end caps. The Apron Feeder has a remote mounted electrically operated automatic greasing system as standard. CARRYING ROLLERS The carrying rollers are standard tractor type featuring a hardened and ground shaft fitted with a centre thrust shoulder and hardened roller. The sleeve bearings on the carrying roller takes high impact loads and, with the duo-clone seals providing lifetime lubrication an extended wear life can be assured. Closely spaced along the length of the Feeder, smooth travel of deck during operation is maintained. RETURN ROLLERS The return rollers on the Apron Feeder are steel rollers with bearing sleeves to support the deck on its return. The rollers are mounted on a stub shaft that is fabricated onto a plate and bolted to the lower joist. CHAIN Crawler tractor type track chains, sealed and lubricated, are used on all Osborn Apron Feeders. The pins and bushes are all made from heat treated alloy steel and hardened on the wearing surfaces. The chain links are drop forged for increased carrying capacity and strength. The chains can be adjusted by means of a threaded screwed take-up arrangement. Hydraulic ram adjustment is available as an option. Removable stub shaft plate. 5

- 6. Osborn Apron Feeder Sectional View SECTIONAL VIEW THROUGH OSBORN APRON FEEDER As an optional extra, the Osborn Apron Feeders can incorporate a Dribble or Fines Conveyor which is located under the feeder to catch the small pieces, fines and lumps of material that became trapped on the feed side of the apron flights and dribble out on the return side. This feature eliminates manual clean up and saves on man hours. The Dribble or Fines Belt conveys this material into a discharge chute. To protect the Apron Feeder return rolls from material build-up caused by spillage over the edges of the apron flights, angle iron deflectors are fitted. The use of impact rails and rail supports are generally determined by the width of the Apron Feeder and range from one to three or more as the width and duties increase. 6 Pan Chain Roller Support Beam Main Beam Cross Member Return Roller Protector Support Roller Return Roller Feeder Skirt Idler Rolls Dribble or Fines Conveyor Frame Return Rolls STD Apron Feeder Optional Scraper Belt Impact Rail Impact Rail Support EFFECTIVE WIDTH Clearance

- 7. 7 Application Data Sheet - Osborn Apron Feeder Customer Contact Person Phone No./Email Phone No./Email Fax.No Enquiry No. Date of Enquiry Tender No. SITE CONDITIONS Location Altitude Metres Operating Temp. Min °C Operating Temp. Max. °C MATERIAL Type Loose Bulk Density Kg/M³ Angle of Repose Degrees Compressive Strength Mpa Abrasiveness High Medium Low Moisture Content % Max % Min Flowability Free Average Sticky Shape of Material DUTY Design Capacity Top speed tph Bottom speed tph Max.Feed Lump Size mm Running hours per day hours Drive selection type Hydraulic Electromechanical Rate control Fixed Variable Variable feed rate 60-100% 0-100% BIN GEOMETRY A) Hopper Wall Angle Deg B) Hopper Length mm C) Hopper Height mm D) Hopper Skirt Height mm E) Bin Height mm F) Bin Length (Calculated) mm G) Burden Depth mm H) Skirt Length mm J) Inside Skirt Width mm K) Rear Projection mm L) Feeder Inclination Deg M) Rear Wall Angle Deg Bin Volume m³ Bin Capacity tonnes HANDING (View from tail end) Left hand Right Hand SPECIAL CONDITIONS NOTE Minimum feeder length should be 1.5 x larger than lumpsize (width or height) Feeder width = 2 x maximum lump size - if high % of max lumps Burden depth = 2 x maximum lump size

- 8. Head Office: PO Box 8182 Elandsfontein, 1406 Johannesburg South Africa Tel: +27 11 820 7600 Fax: +27 11 388 1136 Call Centre: 0861 OSBORN E-mail: osborn@osborn.co.za www.osborn.co.za Companies of the Astec Aggregate and Mining Group www.osborn.co.za www.telsmith.com www.rockbreaker.com www.astrcmobilescreens.com www.kpijci.com All rights reserved. Unless otherwise indicated, all materials on these pages are copyrighted by OSBORN. No part of these pages, either text or image may be used for any purpose other than personal use. Therefore, reproduction, modification, storage in a retrieval system or retransmission, in any form or by any means, electronic, mechanical or otherwise, for reasons other than personal use, is strictly prohibited without prior written permission. ApronFeeder/0812/Rev2