Spinning parameters

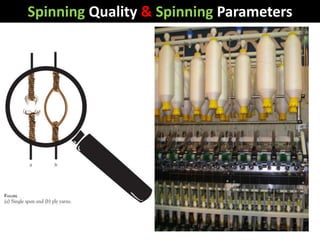

- 1. Spinning Quality & Spinning Parameters

- 2. Name : MAZADUL HASAN SHESHIR ID: 2010000400008 Batch: 13th Batch (Session 2009-2013) Department: Wet Processing Technology Email: mazadulhasan@yahoo.com (FB) Blog: www. Textilelab.blogspot.com Southeast University,Bangladesh Department of Textile Engineering PREPARED BY ©right

- 6. The following terms & definitions are used to describe and explain cotton fiber maturity. Circularity : The degree of thickening which is calculated by the cross sectional area of the fiber wall divided by the area of a circle of the same perimeter. Theta : Average circularity of the matured fibers also described as the degree of thickening. Fineness (mtex) : Average fiber fineness (weight per unit length) in millitex. 1000 meters of fibers with a mass of 1 milligram equals 1 millitex. IFC (%) : Immature fiber content in percent. Percentage of fibers with less than 0.25 circularity. The lower the IFC% the better the fiber is for dyeing. Maturity Ratio : Maturity Ratio is the ratio of fibers with a 0.5 (or more) circularity ratio devided by the amount of fibers with a 0.25 (or less) circularity. The higher the maturity ratio, the more mature the fibers are and the better the fibers are for dyeing. Terms & Definitions:

- 7. Type of yarn Count Cotton Yarn 16s ,20s, 22s, 24s, 26S, 28S, 30S, 34S, 40S Polyester Yarn 75D, 100D,150D Spandex yarn 20D,40D,70D Grey Mellange (C-90% V-10%) 20S ,22S ,24S, 26S ,30S ,34S PC (65%Polyester & 35% cotton) 24S, 26S, 28S, 30S 24S, 26S, 28S, 30S RAW MATERIALS USE FOR KNITTING:

- 8. Relation between count and staple length For Weaving For Knitting 20 Nec 22.5 ~ 24.5 mm 20 ~ 25 Nec 26.5 ~ 27.5 mm 24 Nec 23.0 ~ 25.5 mm 26 ~ 30 Nec 27.5 ~ 28.5 mm 26 Nec 24.0 ~ 26.5 mm 32 ~ 34 Nec 28.5 ~ 29.5 mm 30 Nec 25.0 ~ 27.0 mm 36 ~ 40 Nec 29.5 ~ 30.5 mm 36 Nec 26.0 ~ 28.0 mm

- 10. Types of yarns Type of yarn Count Cotton 20S ,24S, 26S, 28S, 30S, 32S, 34S, 36S ,40S, 45S Polyester 70D,100D,150D Spandex yarn 20D,40D,70D Grey Mélange (C-90% V-10%) 24S, 26S Ecru Mélange (C-85% V-15%) 24S, 26S, 28S Cotton Mélange (100%) 24S, 26S, 28S PC (65%Polyester & 35% cotton) 24S, 26S, 28S, 30S CVC(60% Polyester & 40% Cotton) 24S, 26S, 28S, 30S

- 11. Yarn Fibre Evenness ( U% / CV% ) Thin places Thick places Neps/1000 m yarn Classimat faults/100 km yarn Breaking tenacity (Fmax/tex) Breaking elongation (% ) Hairiness (H) Fibre length 1 2 3 4 5 Micronaire value 6 7 8 9 10 Nep content Leaf content Trash content Microdust content Fibre fragments content 11 12 13 14 15 1/8 Breaking strength 16 17 18 19 20 1/8 Elongation 21 22 23 24 25 Colour / reflectance 26 27 28 29 30 Relationship between fibre strength & the yarn tensile properties.

- 12. Relationship between yarn & fibre quality characteristics ( Rotor spun yarn ). Yarn Fibre Evenness ( U% / CV% ) Thin places Thick places Neps/1000 m yarn Classimat faults/100 km yarn Breaking tenacity (Fmax/tex) Breaking elongation (% ) Hairiness (H) Fibre length 1 2 3 4 5 Micronaire value 6 7 8 9 10 Nep content Leaf content Trash content Microdust content Fibre fragments content 11 12 13 14 15 1/8 Breaking strength 16 17 18 19 20 1/8 Elongation 21 22 23 24 25 Colour / reflectance 26 27 28 29 30

- 14. Raw material / cotton fibre selection : Fibre length & its uniformity Fibre strength Short fibre content Fineness (mic.) Maturity Nep content Color Mixing : Contamination sorting Consistency of mix Blow Room : Frequency of process / mix change Waste control Carding : Carding Speed Neps content in card sliver Sliver linear density & variation control Waste control Key Control Parameters Of spinning Floor :

- 15. Lap forming & Combing : Control of lap weight Comber speed Noil (Comber waste) extraction Neps in combed sliver Drawing : Drawing speed Sliver uniformity/Regularity control Simplex Fly Frame/Roving Frame : Flyer Speed Twist level Frequency of process change Ring Spinning : Spindle speed Twist level Frequency of process/raw material changes Winding : Winding Speed Frequency of process change Key Control Parameters Of spinning Floor :

- 16. a) Blow-room Function : 1. Opening & Cleaning Wastage 1. Dropping 2. Filter waste 3. Fine Dust b) Carding Function : 1. Parallelization & straightening 2. Nap & dead fiber remove 3. Wt/unit length Sliver Wastage 1. L-in wastage 2. Flat strip 3. Sliver wastage 4. A/C Dust : Back, Ring & Winding Function & Wastage of different section

- 17. Function & Wastage of different section c) Drawing Function 1. Drafting & Doubling 2. Uniform sliver (wt/unit length) 3. More parallelization & straightening (by reduce hook). Wastage 1. Filter wastage 2. Sliver wastage. d) Unilap Function: 1. Lap formation 2. Drafting & doubling. Wastage: 1. Sliver. e) Comber. Function: 1. Short fibers remove 2. Naps remove. Wastage: 1. Comber Noil. f) Simplex Function: 1. Roving formation 2. Drafting & twisting 3. Roving Build up in bobbin. Wastage: 1. Roving wastage.

- 18. g) Ring Frame Function 1. Yarn formation 2. Drafting & twisting 3. Yarn Build up in bobbin. Wastage: 1. Pneumafil 2. Bonda wastage 3. Wooden roller wastage 4. Sweeping 5. Roving wastage. h) Wingding Function 1. Fault free yarn 2. Suitable package. Wastage: 1. Hard waste 2. Filter waste 3. Sweeping waste. Function & Wastage of different section

- 19. Function & Wastage of different section I) Heat set Function 1. Twist set 2. Yarn lustier & dye absorption increase 3. Std. moisture regains. # Importance of FIFO Light patta Yarn strength decrease Overall yarn quality deteorates. # Bag handling & storage Cone damage Count & lot mixing Overall yarn quality deteorates. # Control of SECDS Missing & wrong stickers Missing & wrong lot no Paper cone condition Oil & hand strain Top & bottom stitches Damage Cone Off standard spindle Gara cops Count & lot mix Shaded cone TPI variation Thick & thin problem.

- 20. TOPIC : SELECTION OF RAW COTTON WITH RESPECT TO COUNT AND PROCESSING MACHINERY.

- 21. Pre-Ginning : Cotton Fibre quality depend on the following points to a large extent. 1. Agriculture system 2. Location 3. Weather 4. Picking system & no of pick 5. Ginning preparation Ginning system & type of ginning: 1. Basic working principle of saw & roller ginning 2. Merits & Demerits of roller ginning 3. Merits & Demerits of saw ginning

- 22. Relation between processing machine & trash in the cotton: Normal range: Count 20’s 30’s 40’s 60’s 80’s 100’s Trash 5.0 4.0 3.5 3.0 2.5 2.0 For ring yarn processing: Selection of no of beating point Percentage of seat coat fragment in sliver & cotton Draft roller distance A/C plant performance For OE yarn processing: Selection of no of beating point Trash & dust remaining in sliver Draft roller distance A/C plant performance

- 23. A.Classification of cotton base on 2.5% spun length value. Class 2.5% spun length mm Inch Extra long staple 33.0 & above 1.30 & above Long staple 29.5 to 32.5 1.15 to 1.29 Medium staple 25.0 to 29.0 0.98 to 1.14 Short staple A 20.5 to 24.5 0.81 to 0.97 Short staple B 20.0 & below 0.80 & below Count vs raw cotton selection:

- 39. Quality Characteristics Of Cotton yarn

- 45. CV % (Co Efficient of Variation)

- 46. CV % (Co Efficient of Variation)

- 47. CV % (Co Efficient of Variation)

- 57. Imperfection (Thick & Thin places)

- 62. FAULTS

- 63. FAULTS

- 64. FAULTS