Full span hsr guideway 02 12 2015

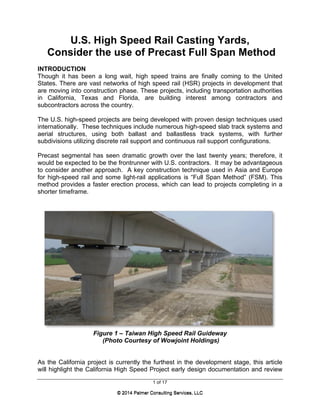

- 1. 1 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC U.S. High Speed Rail Casting Yards, Consider the use of Precast Full Span Method INTRODUCTION Though it has been a long wait, high speed trains are finally coming to the United States. There are vast networks of high speed rail (HSR) projects in development that are moving into construction phase. These projects, including transportation authorities in California, Texas and Florida, are building interest among contractors and subcontractors across the country. The U.S. high-speed projects are being developed with proven design techniques used internationally. These techniques include numerous high-speed slab track systems and aerial structures, using both ballast and ballastless track systems, with further subdivisions utilizing discrete rail support and continuous rail support configurations. Precast segmental has seen dramatic growth over the last twenty years; therefore, it would be expected to be the frontrunner with U.S. contractors. It may be advantageous to consider another approach. A key construction technique used in Asia and Europe for high-speed rail and some light-rail applications is “Full Span Method” (FSM). This method provides a faster erection process, which can lead to projects completing in a shorter timeframe. Figure 1 – Taiwan High Speed Rail Guideway (Photo Courtesy of Wowjoint Holdings) As the California project is currently the furthest in the development stage, this article will highlight the California High Speed Project early design documentation and review

- 2. 2 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC the primary construction techniques being suggested. Additionally, this article will explore full span precast construction technique being used globally for high speed rail (HSR) projects with a quick rundown of the casting yard requirements to transition from precast segmental to full span precast. . FSM casting yard requirements will be similar to standard precast segmental and light rail guideway construction, except for the utilization of must larger, specialized equipment. The specifications of this specialized equipment will dictate the specific elements of casting yard layout and material handling logistics. The project delivery method and the inherent limitations of transporting large precast sections on select roadways will be key components of a successful business opportunity. BACKGROUND As a case-study, let’s review the California High-Speed Train Project (CAHST). Based on the Design Guidelines for High-Speed Train Aerial Structures the basic aerial structure is a prestressed concrete single-cell box girder with spans ranging from 100 to 130 feet. The superstructure design consists of two parallel train tracks (technical memorandum TM 2.3.3 prepared by Parsons Brinckerhoff). In the constructability section, TM 2.3.3 states that the HSR preferred alignment may consist of long lengths of elevated structures. To achieve project goals, it notes that the construction method must be fast, repetitive and versatile, descriptions of the various construction methods available to contractors today are outlined. These include traveling shoring system, precast segmental and full span method. Traveling Shoring System A traveling shoring system is a mobile box girder forming system that self-supports on the columns. It can be adapted for a traditional poured-in-place casting operation, the Movable Scaffolding System or Advance Shoring Method (MSS/ASM) and the more traditional Full Span Method. Most MSS units have self-launching capability from span to span. The traveling shoring system is excellent for minimalizing construction impact. This is of importance for environmental concerns or traffic impact in large cities. Precast Segmental Over the last twenty years, precast segmental construction technique has become a standard in the United States. The American Segmental Bridge Institute has done an excellent job promoting the advantages of precast segmental construction to owners, educating designers and developing interest amongst contractors. Numerous project-specific casting yards have been set up specifically for these projects. A few Precast/Prestressed Concrete Institute(PCI) certified Plants have upgraded their facilities to handle segmental production and been very successful. The versatility of this method allows casting yard to be up to 150 miles from site.

- 3. 3 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Full Span Method (FSM) For the CAHST, the FSM would involve casting full span segments. Segments of 100' length weigh 750 Tons. This is an incredible section of concrete and may appear to be challenging to produce. Yet, HSR projects around the world have used this construction method and the casting cells and all associated equipment have been employed for many years. According to the CAHST technical report, an advantage of this method is faster development for multi-span structures. In addition, FSM may be the most cost effective construction method. Obviously, the economy of scale would weigh favorably for extremely long, elevated HSR contracts. Alternately the casting operation could be utilized across multiple contracts to ensure the expense of the equipment will be allocated over hundreds of full span segments. The Full Span Method can employ two methods for laying track- ballasted or ballast- less. With ballasted track, the rail lines are installed on the top of the ballast for load distribution. With ballast-less track, the tracks lay directly on the concrete slab or elevated structure deck by direct fixation or slab track. To establish the proper mindset necessary for envisioning these casting yards - The typical FSM box girders range from 25m to 55m, with weights from 450 Tons to 1500 Tons. Casting cycle is approximately two days per box girder. Figure 3 – Casting Yard (Photo Courtesy of Wowjoint Holdings) CASTING YARD SPECIFICS With the alignment survey criteria of high-speed rail, most of the superstructure elevation can be developed with the ballast track technique. This combination lends itself to optimizing full span construction, if the project is large enough to support the underlying investment. The economies scale demand a large volume of spans to be cost effective.

- 4. 4 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC To establish the proper mindset necessary for envisioning these casting yards - The typical FSM box girders range from 25m to 55m, with weights from 450 Tons to 1500 Tons. Casting cycle is approximately two days per box girder. With the transportation difficulties of hauling FSM box girders, proximity to the jobsite is essential. The maximum distance traveled to date while transporting with a tire trolley carrier is approximately 16 miles (25 km). For large projects covering great distances, this would mean a casting yard area is required approximately every 30 miles. We are all accustom to the temporary nature of casting yard setups, but these large projects may require that every component of the casting operation be ultraportable. Each casting yard would be setup, incorporating appropriate commissioning process, cast out the specified number of FSM box girders, demob and relocate to the next location. Figure 4 – Cast Cell in Pre-Engineered Building (Photo Courtesy of Wowjoint Holdings) The casting yard for full span sections will take an increased land area over precast segmental. In the initial project assessment, factor all the differences between typical precast segmental casting yards and an FSM casting yard. Develop and adhere to a strict methodic approach to ensure a successful transition to FSM. Ensure a full implementation of OSHA, state and local regulations to safeguard the workforce and public.

- 5. 5 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Depending on local climate, the casting cells can be housed within pre-engineered metal buildings or engineered fabric structures. These structures can be upgraded with many conveniences depending on the life cycle duration of the operation, including overhead cranes. Casting Cells Each project’s design needs will determine the optimum casting cell specifications and functional requirements for full-span precasting. The integrated design process must focus on constructability and worker safety to ensure labor efficiencies and high productivity. An ergonomic approach to work stations will improve labor output and crew morale. The casting cell material strength and rigidity must be based on intended life cycle. Taking the time to standarize embeds and utility attachment points is mandatory for these larger casting cells. An FSM casting cell will utilize prestressing or partial post-tensioning to allow stripping of the box girder sooner and full post-tensioning once full design strength has developed. The casting bed must be designed for the prestressing hold-down points and maximum load requirement, include the proper safety factors Figure 5 - Quality Check on Reinforcement prior to tying cage _ Courtesy of Ninive Casseforme - • Strand Hold-Downs or Push Down Devices Full span segments will typically have harped or draped post-tensioning strands. Even self-stressing forms will not be able to handle the vertical forces of the draped prestessing strands without assistance. Perhaps the cast cell could be designed the handle the vertical loads, but it would be cost prohibitive.

- 6. 6 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC The casting cell and casting bed must be designed together to ensure full engineering compliance and worker safety factors are properly integrated. A common sense approach is necessary to keep designs simple and value engineering as a core mindset. Typically a large concrete deadman is cast beneath or piling installed below these areas to anchor the strand hold-down devices to withstand these forces. Figure 6 – Inspection of Inner Form - Courtesy of Wowjoint Holdings Note: The PCI Membership Safety Program: Harping Safety DVD discusses proper procedures for draped strand and harping equipment, which can be used in conjunction with their Stressing Safely DVD. Both are great employee orientation presentations to teach proper casting yard procedures.. • Core Form or Inner Shutter The most crucial form component for smooth, efficient production is the synchronized-hydraulic design of the core form pull and push equipment. The form design must meet the functional needs of the project, conform to the setup and striping time restraints and fulfill the ergonomic/OSHA requirements. It also must be designed for all attachments and embeds to ensure a quick erection, fit- up phase and commissioning necessities of the project.

- 7. 7 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Figure 7 – Inner Form Extracted and Supported by Overhead Cranes - Courtesy of Ninive Casseforme Integrate the modular core form design with each different box girder length anticipated during the project. Efficiency of the core design will ensure attainable daily casting yard productivity goals. As shown above (see Figure 7), many FSM box girder designs require unique core form configuration on each end. Review the complexity of design for functionality and constructability. The collapsible nature of the core form must translate into a smooth mechanical operation that quickly transforms from the box girder inner form to an extractable core beam. This operation must maintain this functionality from the 1st concrete placement until the last box girder cast. Work closely with the manufacturer and submit RFIs for proposing slight box girder configuration changes that would increase functionality.

- 8. 8 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Figure 8 – Inner Mould Being Extracted, Sliding on Base Support Frame - Courtesy of Wowjoint Holding The inner mould is removed by sliding along the base support frame (see Figure 8). Some extraction methods incorporate this base extraction beam, and others utilize overhead cranes to withdraw the inner mould. The Figure 7 and Figure 8 pictures above show both methods. The method chosen is dependent on facilty setup and equipment utilization rates during a typical casting day. Discuss your requirements with the casting cell manufacturer to ensure the casting yard is designed to suit every facet of the fabrication process. • Reinforcement Cage FSM rebar cages must incorporate high-production measures and fabrication quality to ensure fast and efficient utilization of manpower. Standardization of rebar sizes and shapes can effectively increase production rates and mitigate tolerance issues. This size of the rebar cage requires the use of spot-welding. This must be reviewed during pre-construction phase and incorporate ASTM A706 weldable rebar where necessary. This welding operation must be completed before prestress strands are present to avoid potential damage.

- 9. 9 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Figure 9 – Anchor abutments transfer prestress forces to continuous concrete beams under wings (Photo Courtesy of Ninive Casseforme) • Self-Stressing Casting Cells A self-stressing form is designed to withstand the prestressing forces itself without destortion. Normally each end of the form is attached to steel beams held down to the foundation. Due to the expansion characteristics of steel during accelerated curing, the attachment mechanisms hold the casting cell frame down but allow for expansion. Procuring self-stressing casting cells will made setting up a casting yard easier. Understandably, a true self-stressing bed for FSM are costly. However, a full cost-benefit analysis should be conducted based on all relevant project-specific factors before committing. Prestressing calculations and the associated factors to consider: Theoretical bed shortening total and loss per strand, *live end seating, *dead end seating, strand length between anchors, modulus of elasticity of bed, modulus of elasticity of strand, cross section area of the bed, cross-sectional area of the bed, casting cell length, etc. AASHTO refers to time-dependent losses as the Lump Sum Method calculation. Since AASHTO, PCI, ACI and state to state have variations, we will not dictate a precise formula requirement here. The casting manual should be sufficiently detailed for the crew members to understand exact procedures. *These calculations will be different for draped or harped strands due to potential fictional losses.

- 10. 10 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Figure 10 – Tendons Installed for Partial Post-Tensioning - Courtesy of Wowjoint Holdings • Non-Self Stressing Casting Cells The casting bed itself can be designed to handle the prestress forces through the use of abutments. The design of anchor abutments on either side of the casting cell is required, in combination with vertical bucks (can be removable) or concrete walls built between the abutments on both sides of the casting cell. Design should factor in minimal deflection of each component during the prestressing operation, or it must be accounted for in the elongation calculations. Prestressing calculations and the associated factors to consider: Theoretical anchorage movement and movement per strand, estimated force correction for anchorage movement per strand, *live end seating, *dead end seating, strand length between anchors, modulus of elasticity of bed, modulus of elasticity of strand, cross section area of the bed, casting cell length, temperature variation factors will have to be used in the force calculations when the difference between ambient temperature and concrete temperature vary by 25 degrees F (14 degrees C) or more. etc. (AASHTO refers to time-dependent losses as the Lump Sum Method calculation. Since AASHTO, PCI, ACI and state to state have variations, we will not dictate a formula requirement here. *These calculations will be different for draped or harped strands due to potential fictional losses.

- 11. 11 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Figure 11 – Custom Anchor Abutment for Prestressing - Courtesy of Ninive Casseforme Figure 11 - Note the safety handrails and the yellow walking platform to mitigate accidents. • Prestress Normally mono strand jacks are used for prestressing. Implement proper safety procedures during the casting yard employee orientation training using project specific casting yard layout. Also, incorporate the manufacturer’s recommendations for cleaning the reusable stressing chucks and calibration requirements for the jack. Proper maintenance and component inspection procedures will greatly increase casting yard safety. Whether the casting cell is self-stressing or not, the design engineer will issue a tensioning/detensioning pattern that will detail precise instructions on stressing/detensioning the strands. Detensioning can be accomplished by using the stressing jack to takeoff the tension from the stressing chuck and releasing the force carefully. Another method used is to simultaneously cut the strands on both sides of the casting cell with a straight tip torch. This pattern must be adhered too to avoid damage to the product. Any questions in regard to stripping strength and detensioning sequencing should be clarified prior to 1st cast. The job hazard analysis details should be carefully reviewed by the engineer-in-charge to ensure accuracy. Whether setting up to prestress a self-stressing casting cell or against an abutment, a stressing jack with an A-frame gantry will increase labor efficiencies and ensure jack longevity. NOTE: Stressing jacks require calibration prior to using onsite and require recalibation at specific intervals.

- 12. 12 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC The post-tensioning system will have to be modified to avoid stray electrical current accumulation if a DC electrical power system is used. Properly bonding and capping of the anchor heads will eliminate this issue. One method is the use of a synthetic dielectric resin to protect the strand ends and post-tensioning anchorage heads. CONCRETE PLACEMENT & CURING Typically, concrete is placed and vibrated within an 8 to 10 hour period, though a 5-6 hour target seems achievable. After initial set, the concrete curing process can be accelerated depending on the specific requirements of the casting cycle. There are various options to consider with installing accelerated curing, including low-pressure steam generators and radiant heat systems. Radiant heat may necessitate adding moisture through water jets or fogging jets. Colder weather will necessitate an insulated tarp to ensure consistent heat is maintained within the concrete product. In warm weather climates, a moisture retention enclosure may be needed or a good spray-on membrane may suffice. PCI MNL 133, Section 3.3.5 Concrete Curing and PCI MNL- 116, Section 4.19, Accelerated Curing contain the critical detailed information on these methods and assist in implementing daily QC procedures. Figure 12 – Stripping Casting Cell - Courtesy of Wowjoint Holdings Both steam and radiant heat lines can be setup in zones to handle a variety of casting cell layouts. Depending on the structure used for casting cell weather protection, the lines can be setup above grade or lowered within concrete trenches with removable concrete covers. The thermal action of these lines will typically require expansion loops and lines set on rollers. It is critical to practice safety in design of these systems. Keeping workers from contacting these high temperature lines and avoiding the inherent tripping hazards is important.

- 13. 13 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Accelerated curing used in combination with prestressing and a consistent concrete mix design will ensure concrete stripping strength is achieved in 10 to 14 hours after concrete placement. Figure 13 – Stripped Box Girder - Courtesy of Ninive Casseforme STORAGE AREA Proper grading and drainage are necessary to keep the storage area workable in all weather conditions. Use spotters with the equipment or employ cameras to keep operators free of blind spots. Crane travel lanes between storage rows must allow for post-tensioning and grouting operations. Depending on the complexity of the harped or draped tendons, lift-off on the opposite side from the post-tensioning to assure proper stressing forces have been induced may be required. This is exceptionally true, if elongations are in the lower range or below expectations.

- 14. 14 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Figure 14 – Tight Casting Yard with Casting Cell amongst Stored FSM Box Girders (Photo Courtesy of Wowjoint Holdings) Land acquisition requirements must be adapted to the specific casting cell quantity and configuration needs. Some casting yards with tight storage areas have opted to stack FSM box girders. For smaller projects, a staging area for post-tensioning could be arranged. This could allow narrower crane travel lanes and a smaller overall casting yard configuration. SPECIALIZED FSM CASTING YARD & TRANSPORTATION EQUIPMENT The adaptation, layout and site logistics of the transport route from casting yards to delivery points along the aerial structure, must be determined upfront for an accurate estimate. Prior to the procurement process for your particular equipment needs, develop a complete scope of work for each component of the casting yard and associated erection transportation requirements. Have equipment designed for the optimized speed required to cycle completed FSM product to the site. Compile a good maintenance program and have sufficient inventory of standard replacement parts suggested by the manufacturer.

- 15. 15 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Figure 16 – 56-wheel Portal Crane - Courtesy of Wowjoint Holdings • Portal Cranes These straddlecranes are designed to carry the full span segments from casting cell to storage areas. Many manufacturers incorporate 90-degree steering capacity, this will increase usable storage space at the casting yard. Both rubber- tire models and gantry crane on rails are available. These cranes have been used in the shipbuilding industry for decades. Figure 17 – Portal Crane - Courtesy of Wowjoint Holdings

- 16. 16 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC Lifting capacity, hoisting speed, turning radius, manuverability, elevation climbing limitations under load and travel speed are critical specification to understand casting yard function and adaptability. Maximum girder lifting ground clearance is vital for loading Tyre Trolley and ability to stack units in storage. Figure 18 – Tyre Trolley - Courtesy of Wowjoint Holdings • Tyre Trolley These machines are robust span haulers designed specifically for these projects. Since transportation of these spans cannot be over conventional roadways. The casting yard must be built close to the project. Haul road layout and construction is a component of each project. These specialized carriers can be rubber-tired or built for rail lines. Both methods have been used to transport FSM box girders to the project site. Some casting yards will require transportation by barge. Adapting an FSM casting yard for marine shipping will add additional complexities. As always a thorough upfront planning process will ensure a successful venture. SUMMARY As United States HSR implementation proceeds and FSM becomes a viable option, it would be prudent for contractors to utilize the equipment and expertise gained from decades of global operations. Vendors with HSR and FSM experience, like Wowjoint Holdings and Ninive Casseforme would be helpful in providing the necessary equipment and expertise to shorten the learning curve of a U.S. operation.

- 17. 17 of 17 © 2014 Palmer Consulting Services, LLC© 2014 Palmer Consulting Services, LLC At the appropriate time, it would be sensible for larger PCI Certified Plants and NPCA Certification Plants, to consider adding proven precast products to service high-speed projects. For FSM plant upgrades of an existing precast plant or development of a remote casting yard, the precaster may opt to contract for F.O.B. Plant delivery and have the contractor deal with delivery logistics issues. Granted FSM would require a significant partnering effort or full P3 involvement, authorities dividing HSR projects into a series of contracts need to understand the major cost impact of a FSM casting yard setup. Authorities and designers may wish to discuss the benefits of specific contract breakdown methodology with interested contractors, vendors and local precasters. Aligning sufficient aerial guideway to a contract can afford the viability of FSM, increasing productivity levels and reducing construction schedule. For HSR and LRT, FSM should be a means and methods consideration for your mass transit project. BIBLIOGRAPHY • Rosignoli, M. 2013. Bridge Construction Equipment. London, UK: ICE Publishing • Kang, Kee Dong and Suh, Sunduck D., 2003. Experience with the Precast Span Method on the Korean High-Speed Rail Project, Transportation Research Record 1825, Paper No. 03-3000, Pg. 15-21. • American Segmental Bridge Institute (ASBI). 2008. Construction Practices Handbook for Concrete Segmental and Cable-Supported Bridges. Buda, TX: • California High-Speed Train Project, 2009. Technical Memorandum, Design Guidelines for High-Speed Train Aerial Structures TM 2.3.3 • Palmer, Arthur, May-June 2006. Fundamentals of Launching a Precast Concrete Segmental Operation for Bridge Construction Projects, PCI Journal, Volume 51, No. 3, pg. 32-44 • Palmer, Arthur, October 2004. Contractor Checklist: Precast Yard. ACI Concrete International, V.26, No.10, pg. 45-48 Contact the PCI website for publications mentioned https://www.pci.org/bookstore/storefront.aspx