Shaper

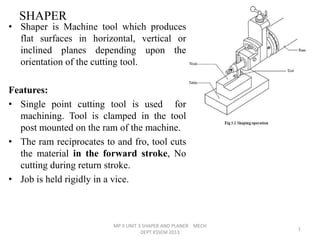

- 1. SHAPER • Shaper is Machine tool which produces flat surfaces in horizontal, vertical or inclined planes depending upon the orientation of the cutting tool. Features: • Single point cutting tool is used for machining. Tool is clamped in the tool post mounted on the ram of the machine. • The ram reciprocates to and fro, tool cuts the material in the forward stroke, No cutting during return stroke. • Job is held rigidly in a vice. MP II UNIT 3 SHAPER AND PLANER MECH 1 DEPT KSSEM 2013

- 2. • PRINCIPLE • HORIZONTAL SHAPER – PARTS AND SKETCH • SHAPER MECHANISMS • OPERTIONS DONE ON SHAPER • CLASSIFICATION OF SHAPER • SPECIFICATIONS OF SHAPER • MACHINING TIME CALCULATIONS • COMPARISON BETWEEN SHAPER AND PLANER MP II UNIT 3 SHAPER AND PLANER MECH 2 DEPT KSSEM 2013

- 3. MP II UNIT 3 SHAPER AND PLANER MECH 3 DEPT KSSEM 2013

- 4. Forward stroke is the cutting stroke. Return stroke the tool does not cut, Double stroke= cutting stroke + return stroke Stroke starts slightly before the work piece (a) and ends after the work piece (b) Total stroke length = l+a+b MP II UNIT 3 SHAPER AND PLANER MECH 4 DEPT KSSEM 2013

- 5. Operations done using a shaper • Machining Horizontal Surfaces • Machining Vertical Surfaces • Machining Angular Surfaces • Cutting Slots, Grooves & Key ways • Machining irregular surfaces • Machining Splines / Cutting Gears MP II UNIT 3 SHAPER AND PLANER MECH 5 DEPT KSSEM 2013

- 6. MP II UNIT 3 SHAPER AND PLANER MECH 6 DEPT KSSEM 2013

- 7. MP II UNIT 3 SHAPER AND PLANER MECH 7 DEPT KSSEM 2013

- 8. Main parts of a shaping machine 1. BASE 5. CROSS RAIL 2. COLUMN 6. SADDLE 3. RAM 7. TOOL HEAD 4. TABLE 8. CLAPPER BOX MP II UNIT 3 SHAPER AND PLANER MECH 8 DEPT KSSEM 2013

- 9. PARTS OF SHAPER BASE made of cast iron. Provides support for other parts of machine. COLUMN- box type casting mounted vertically on top of base. • It has 2 guide ways. One vertical guideway in the front over which a cross slide moves up and down. • 2nd horizontal guide ways on top over which ram reciprocate. • The reciprocating mechanism is housed inside the column MP II UNIT 3 SHAPER AND PLANER MECH 9 DEPT KSSEM 2013

- 10. MP II UNIT 3 SHAPER AND PLANER MECH 10 DEPT KSSEM 2013

- 11. PARTS OF SHAPER TOOL HEAD fitted on the face of CROSS RAIL IT IS MOUNTED ram. Holds the tool rigidly. ON THE F RONT VERTICAL • Provide vertical and angular feeds GUIDE WAYS. for the tool • THE TABLE CAN BE • Tool head can be positioned at LOWERED OR RAISED BY any angle ADJUSTING THE CROSS RAIL TABLE- mounted on a saddle which is located above the cross rail. Top and and sides are accurately machined and have T slots. RAM- supports tool head on its front. It reciprocates on accurately machined guideways on top of column MP II UNIT 3 SHAPER AND PLANER MECH 11 DEPT KSSEM 2013

- 12. MP II UNIT 3 SHAPER AND PLANER MECH 12 DEPT KSSEM 2013

- 13. Classification of shapers 1 Position of ram travel • Horizontal Shaper- Ram holding the cutting tool moves In horizontal plane • Vertical Shaper-The cutting tool moves in vertical plane • Traveling head Shaper-Cutting tool reciprocates & moves cross wise simultaneously 2 Acc. to Cutting Stroke action a) Push Type Shaper- Standard Shaper. • Metal is removed when the ram moves away from column • Most common type used in practice • Unless otherwise specified, the term shaper refers to Push type Shaper b) Draw Type Shaper • Metal is removed when the tool is drawn towards the column • Allows heavier cuts to be made • Less vibration during cutting MP II UNIT 3 SHAPER AND PLANER MECH 13 DEPT KSSEM 2013

- 14. 3 Acc. to Driving Mechanism: a) Crank type - Driving mechanism is by crank & gear b) Geared type - Driven by Rack & Pinion mechanism c) Hydraulic Shaper - Driven by oil pressure developed by a pump, which is run by an electric motor 4 Acc. to the Table Design: a) Standard shaper- Work Table can be moved 1.Vertically & 2. Horizontally b) Universal Shaper- Table can be moved 1. Horizontally 2. Vertically 3. Swivelled & 4. Tilted This is mostly used in Tool Rooms Q HOW ARE SHAPERS CLASSIFIED? EXPLAIN BRIEFLY QUICK RETURN MECHANISM USED IN SHAPER MP II UNIT 3 SHAPER AND PLANER MECH 14 DEPT KSSEM 2013

- 15. SHAPER MP II UNIT 3 SHAPER AND PLANER MECH 15 DEPT KSSEM 2013

- 16. Specifications of Shaping Machine • Max.length of Stroke of Ram • Type of Drive • Power input • Floor Space required • Weight of the Machine • Cutting to Return Stroke ratio • Feed MP II UNIT 3 SHAPER AND PLANER MECH 16 DEPT KSSEM 2013

- 17. SHAPER MP II UNIT 3 SHAPER AND PLANER MECH 17 DEPT KSSEM 2013

- 18. MP II UNIT 3 SHAPER AND PLANER MECH 18 DEPT KSSEM 2013

- 19. MP II UNIT 3 SHAPER AND PLANER MECH 19 DEPT KSSEM 2013

- 20. MP II UNIT 3 SHAPER AND PLANER MECH 20 DEPT KSSEM 2013

- 21. MP II UNIT 3 SHAPER AND PLANER MECH 21 DEPT KSSEM 2013

- 22. SHAPING OPERATIONS 1 Machining of horizontal surface The work surface is held securely on the table and tool is fixed in the tool head with minimum overhang, as shown in figure. The table with fixed work piece is raised close to the tool; the length and position of the stroke are adjusted. The stroke length is about 20mm longer than the work and stroke is adjusted such that the tool starts about 10-15 mm before work piece and continues about 10 mm after the end of cut. 2 Work piece is mounted on the table and the surface to be machined is set parallel to stroke axis. A side cutting tool is fitted in the tool head as shown in figure. The length of stroke is adjusted as described in section 5.1. The cutting feed is given by rotating the down feed screw by hand (0.25 -0.50 mm) MP II UNIT 3 SHAPER AND PLANER MECH 22 DEPT KSSEM 2013