001 sop of so ps

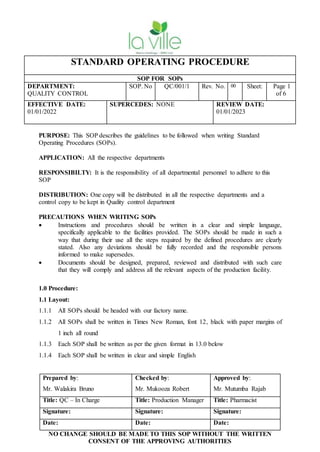

- 1. STANDARD OPERATING PROCEDURE SOP FOR SOPs DEPARTMENT: QUALITY CONTROL SOP. No QC/001/1 Rev. No. 00 Sheet: Page 1 of 6 EFFECTIVE DATE: 01/01/2022 SUPERCEDES: NONE REVIEW DATE: 01/01/2023 Prepared by: Mr. Walakira Bruno Checked by: Mr. Mukooza Robert Approved by: Mr. Mutumba Rajab Title: QC – In Charge Title: Production Manager Title: Pharmacist Signature: Signature: Signature: Date: Date: Date: NO CHANGE SHOULD BE MADE TO THIS SOP WITHOUT THE WRITTEN CONSENT OF THE APPROVING AUTHORITIES PURPOSE: This SOP describes the guidelines to be followed when writing Standard Operating Procedures (SOPs). APPLICATION: All the respective departments RESPONSIBILTY: It is the responsibility of all departmental personnel to adhere to this SOP DISTRIBUTION: One copy will be distributed in all the respective departments and a control copy to be kept in Quality control department PRECAUTIONS WHEN WRITING SOPs Instructions and procedures should be written in a clear and simple language, specifically applicable to the facilities provided. The SOPs should be made in such a way that during their use all the steps required by the defined procedures are clearly stated. Also any deviations should be fully recorded and the responsible persons informed to make supersedes. Documents should be designed, prepared, reviewed and distributed with such care that they will comply and address all the relevant aspects of the production facility. 1.0 Procedure: 1.1 Layout: 1.1.1 All SOPs should be headed with our factory name. 1.1.2 All SOPs shall be written in Times New Roman, font 12, black with paper margins of 1 inch all round 1.1.3 Each SOP shall be written as per the given format in 13.0 below 1.1.4 Each SOP shall be written in clear and simple English

- 2. STANDARD OPERATING PROCEDURE SOP FOR SOPs DEPARTMENT: QUALITY CONTROL SOP. No QC/001/1 Rev. No. 00 Sheet: Page 2 of 6 EFFECTIVE DATE: 01/01/2022 SUPERCEDES: NONE REVIEW DATE: 01/01/2023 Prepared by: Mr. Walakira Bruno Checked by: Mr. Mukooza Robert Approved by: Mr. Mutumba Rajab Title: QC – In Charge Title: Production Manager Title: Pharmacist Signature: Signature: Signature: Date: Date: Date: NO CHANGE SHOULD BE MADE TO THIS SOP WITHOUT THE WRITTEN CONSENT OF THE APPROVING AUTHORITIES 1.1.5 SOPs shall have the title, code number, review number, superseded number, date of revision and effective date. The purpose, application, responsibility and distribution must also be clearly stated. 1.2 Steps: 1.2.1 Each SOP shall be assigned specific numbers as follows: 1.2.2 First two letters representing the department, followed by 01; which is the first SOP of that department, followed by the revision number. Forward slash (/) will be used to separate the numbers. 1.2.3. The following letters shall be assigned to each department SOPs: Quality Control QC Production Department PD Ware Housing WH For example, SOP for SOPs shall be QC/001/1 1.2.4 Page numbering shall be the page over the number of pages in the SOP. And on the right top of each page 2.0 Who can write SOP? 1. Any member of the department can initiate writing an SOP of that department by preparing a draft.

- 3. STANDARD OPERATING PROCEDURE SOP FOR SOPs DEPARTMENT: QUALITY CONTROL SOP. No QC/001/1 Rev. No. 00 Sheet: Page 3 of 6 EFFECTIVE DATE: 01/01/2022 SUPERCEDES: NONE REVIEW DATE: 01/01/2023 Prepared by: Mr. Walakira Bruno Checked by: Mr. Mukooza Robert Approved by: Mr. Mutumba Rajab Title: QC – In Charge Title: Production Manager Title: Pharmacist Signature: Signature: Signature: Date: Date: Date: NO CHANGE SHOULD BE MADE TO THIS SOP WITHOUT THE WRITTEN CONSENT OF THE APPROVING AUTHORITIES 2. The initiator shall present the draft to his/her supervisor and discuss it, if accepted; the supervisor shall sign on the draft document stating his acceptance and then forward the SOP to the head of the department. 3. The Head of department shall review the SOP and if found appropriate shall sign on it and then forward the SOP to the pharmacist for approval and authorization. After authorization an operational copy shall be made for display at the respective departments. 4. Each SOP shall be written in a step by step manner. 5. SOPs must not be changed, amended or added without consent of the approving authorities. 3.0 Approval of SOPs: 3.1 All SOPs shall be approved/authorized by the Pharmacist in charge of Quality assurance. 4.0 Review of SOPs 4.1 Each SOP shall be reviewed yearly. However, upon recommendation by an Inspector or incase of a deviation noted the SOP shall be reviewed and assigned a new review number. 4.2 The Head of each department shall be responsible for reviewing of SOPs in his/her department

- 4. STANDARD OPERATING PROCEDURE SOP FOR SOPs DEPARTMENT: QUALITY CONTROL SOP. No QC/001/1 Rev. No. 00 Sheet: Page 4 of 6 EFFECTIVE DATE: 01/01/2022 SUPERCEDES: NONE REVIEW DATE: 01/01/2023 Prepared by: Mr. Walakira Bruno Checked by: Mr. Mukooza Robert Approved by: Mr. Mutumba Rajab Title: QC – In Charge Title: Production Manager Title: Pharmacist Signature: Signature: Signature: Date: Date: Date: NO CHANGE SHOULD BE MADE TO THIS SOP WITHOUT THE WRITTEN CONSENT OF THE APPROVING AUTHORITIES 4.3 SOPs shall be regularly reviewed and kept up to date. When a document is revised, the effective date of the corrected version shall be given and the old SOP shall be preserved for at least one year after the given superceded SOP before its destruction. 5. 0 Control of SOPs 1. The original approved and authorized SOP shall be the master copy; stamped “MASTER COPY” and shall be kept by the Head of QA in the document’s room. 2. The photocopy (ies) of the original shall be stamped as “CONTROLLED COPY” and shall be distributed / displayed in the area of operation. 3. No unauthorized SOP shall be in use. 4. Use only superseding SOP 5. It is the responsibility of the Pharmacist to withdraw the Old SOPs and issue revised ones. 6.0 Signature to SOPs: The following shall sign the SOPs in the format below: Prepared by: Name of initiator Checked by: Head of department Authorised by: Q.A Manager Title: Title: Title: Signature: Signature: Signature: Date: Date: Date: 7.0 Effective and Review date: 7.1 Each SOP shall bear effective and review date as assigned by the QA Manager

- 5. STANDARD OPERATING PROCEDURE SOP FOR SOPs DEPARTMENT: QUALITY CONTROL SOP. No QC/001/1 Rev. No. 00 Sheet: Page 5 of 6 EFFECTIVE DATE: 01/01/2022 SUPERCEDES: NONE REVIEW DATE: 01/01/2023 Prepared by: Mr. Walakira Bruno Checked by: Mr. Mukooza Robert Approved by: Mr. Mutumba Rajab Title: QC – In Charge Title: Production Manager Title: Pharmacist Signature: Signature: Signature: Date: Date: Date: NO CHANGE SHOULD BE MADE TO THIS SOP WITHOUT THE WRITTEN CONSENT OF THE APPROVING AUTHORITIES 8.0 Responsible Person: 8.1 Each SOP shall state the responsible personnel for its implementation 9.0 Display of SOPs 9.1 Each SOP shall be inserted in a transparent paper jacket and displayed prominently, in an orderly fashion with easy access of the user and near to the application area 10.0 Storage & Disposal of old SOPs 10.1 The Pharmacist shall dispose off the Old SOPs one year after their withdrawal from use. 10.2 Disposal method shall be by first shredding into small pieces and then burnt to ash 10.3 Old SOPs should be kept in the quality control department bearing the stamp OBSOLETE immediately after they have been superceded until they are disposed off in the presence of the authorized persons. 11.0 Amendments Incase of errors, omissions or additions relating to the SOP intimate to head of the department to make the necessary correction and review the SOP and a new review date will then be assigned. 12.0 Format

- 6. STANDARD OPERATING PROCEDURE SOP FOR SOPs DEPARTMENT: QUALITY CONTROL SOP. No QC/001/1 Rev. No. 00 Sheet: Page 6 of 6 EFFECTIVE DATE: 01/01/2022 SUPERCEDES: NONE REVIEW DATE: 01/01/2023 Prepared by: Mr. Walakira Bruno Checked by: Mr. Mukooza Robert Approved by: Mr. Mutumba Rajab Title: QC – In Charge Title: Production Manager Title: Pharmacist Signature: Signature: Signature: Date: Date: Date: NO CHANGE SHOULD BE MADE TO THIS SOP WITHOUT THE WRITTEN CONSENT OF THE APPROVING AUTHORITIES PURPOSE: APPLICATION: RESPONSIBILTY: DISTRIBUTION: PROCEDURE: