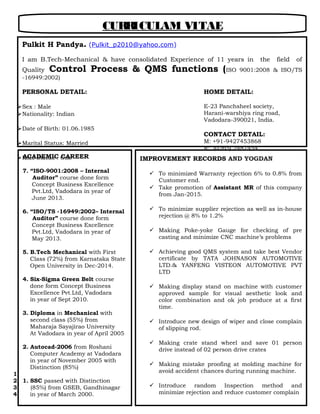

CURRICULAM VITAE_Pulkit Pandya

- 1. Page 1 of 4 CURRICULAM VITAE ACADEMIC CAREER 7. “ISO-9001:2008 – Internal Auditor” course done form Concept Business Excellence Pvt.Ltd, Vadodara in year of June 2013. 6. “ISO/TS -16949:2002– Internal Auditor” course done form Concept Business Excellence Pvt.Ltd, Vadodara in year of May 2013. 5. B.Tech Mechanical with First Class (72%) from Karnataka State Open University in Dec-2014. 4. Six-Sigma Green Belt course done form Concept Business Excellence Pvt.Ltd, Vadodara in year of Sept 2010. 3. Diploma in Mechanical with second class (55%) from Maharaja Sayajirao University At Vadodara in year of April 2005 2. Autocad-2006 from Roshani Computer Academy at Vadodara in year of November 2005 with Distinction (85%) 1) 2) 1. SSC passed with Distinction 3) (85%) from GSEB, Gandhinagar 4) in year of March 2000. IMPROVEMENT RECORDS AND YOGDAN To minimized Warranty rejection 6% to 0.8% from Customer end. Take promotion of Assistant MR of this company from Jan-2015. To minimize supplier rejection as well as in-house rejection @ 8% to 1.2% Making Poke-yoke Gauge for checking of pre casting and minimize CNC machine’s problems Achieving good QMS system and take best Vendor certificate by TATA JOHNASON AUTOMOTIVE LTD.& YANFENG VISTEON AUTOMOTIVE PVT LTD Making display stand on machine with customer approved sample for visual aesthetic look and color combination and ok job produce at a first time. Introduce new design of wiper and close complain of slipping rod. Making crate stand wheel and save 01 person drive instead of 02 person drive crates Making mistake proofing at molding machine for avoid accident chances during running machine. Introduce random Inspection method and minimize rejection and reduce customer complain Introduce & development radiator barcode system Pulkit H Pandya. (Pulkit_p2010@yahoo.com) I am B.Tech-Mechanical & have consolidated Experience of 11 years in the field of Quality Control Process & QMS functions (ISO 9001:2008 & ISO/TS -16949:2002) PERSONAL DETAIL: Sex : Male Nationality: Indian Date of Birth: 01.06.1985 Marital Status: Married Kids Status : One HOME DETAIL: E-23 Panchsheel society, Harani-warshiya ring road, Vadodara-390021, India. CONTACT DETAIL: M: +91-9427453868 R: (0265) 2487454

- 2. Page 2 of 4 PRESENT EMPLOYEE PAST EMPLOYEE: 5 Presently working with Shefield Technoplast (P) Limited at Savali, Vadodara. Company Company IS ISO 9001:2008 certifications & deals in Plastics Components, Precision Machined Components and Industrial Plastics Components with utmost professionalism and serve as one stop solution for Custom Injection Molded Parts and assemblies from a facility in Vadodara, Gujarat, India Designation : Assistant Manager-Q.A/Q.C & MR Reporting : Reports to Director QC Strength : 05 Engineers with 10 Inspectors Duration : 11th April 2016 to till date. To hear Voice of Customer & its special requirement. Maintain QMS system & involves all department for quality requirement. Handle APQP Meeting, Innovative and cost effective Product design and development. Submit PPAP documents for new development. Handle customer complaint & its action plan. Visit customer end and understand their requirement. Prepared MRM data & focus on minimize PPM target. To understand customer requirement & fitment related training to down line operators. Review & Approvals of tool correction in Mold. Product and process capability analysis with defect detection. Worked with EMCO DYNATORQ (P) LTD, at Waghodia unit, Vadodara. Company IS ISO 9001:2008 certifications engaged in the Manufacturing of electromagnetic AC/DC Safe fail brakes & Clutch combinations also making parts for Gunnebo, ABB, Galaxy Sivtek & Kaizen products. Designation : Assistant Manager-Q.A/Q.C & MR Reporting : Reports to W.M & Director QC Strength : 04 Engineers with 02 Inspectors Duration : 5th May 2014 to 8th April 2016, Making PPAP documents and its documentation work. To handle shop floor quality & maintain quality system. Analysis data by the help of 7QC tools,SPC & its advantages Handle customers complain and send CAPA/8D Analysis Maintain calibration and control system for all precision measuring and test equipment Provide and make training programs in house and guide to employees/operators by presentation. Perform internal audits and reports to management on the effectiveness of the QMS and suggestions for improvement Preparing QMS documents (Quality Manual, Quality system procedures and other documentations). Preparing internal audit schedules & conduct the same with the needed process improvement & records Communicating to the department for submit N.C closer with action plan within time Preparing Management Review Meeting Schedule and conducting Management Review Meeting agenda.

- 3. Page 3 of 4 PAST EMPLOYEE: 4 PAST EMPLOYEE: 3 Worked with JEWEL CONSUMER CARE (P) LTD, at Luna plant, padre Vadodara, Company is ISO 9001:2008 certifications engaged in the Manufacturing of Export & Domestic brushes, House Hold plastic products, HUL, TATA NANO & GM Auto parts. Designation : Assistant Manager-Q.A/Q.CR Reporting : Reports to Manager –Q.C & Director QC Strength : 05 Engineers with 32 Inspectors Duration : 13th September 2012 to 28th April 2014, Monitoring & controlling in process quality and final Assembly inspection area. Handling product & process audit, customer Audits & customer complain. Maintain quality standards & root cause analysis of non- conformances and implementation of corrective actions through 8D/5Y analysis. Communicating with customer, understanding their needs requirement and same with the QC - team members. Working in core tools like: MSA, SPC, 8D Form, PPAP, Control Plan, PPSR Form, IMMR Form SOP & CAPA. Handle third party inspection like: SISCO, WALL MART, SYNPART, INTERTECH, and Ranir India etc... Worked with BANCO PRODUCTS (I) LTD. at Vadodara SEZ Plant Company is ISO/TS 16949:2009 certifications and Manufacturing of OE and Export automobile Aluminum radiators. DESIGNATION: Senior Engineer –Q.A/Q.C Reporting : Reports to Manager –Q.C & DGM-QA QC Strength : 04 Engineers with 12 Inspectors Duration : 19th April 2007 to 10th September 2012 Leading a team with quality inspectors for process, Product & system audits like: Shop floor audit, FGS audit, Vendor audit, patrols inspection Etc… To assist quality review meetings & design review Meetings for new products and continually monitoring on line related issues and customer issue. New product Development and process Validation done in my under Inspection. Review all customer specifications & Finalized display to easy understand by inspectors. Handling Customer Complain, Manpower and Monitoring of Final Inspection and solving on-line problem. Ensure and Monitoring instruments and gauges which are used on shop floor are calibrated. Working with CFT (Cross functional Team) to eliminate the customer complaint Proficient in Knowledge & application of following system tools : PPAP , FMEA Control Plan , SPC , Process Plan , SOP, 8D form , CAPA , Process flow diagram , Control Plan etc…

- 4. Page 4 of 4 PAST EMPLOYEE: 2 PAST EMPLOYEE: 1 COMPUTER SKILL Worked with ELMEX CONTROL (P) LTD. at GIDC Vadodara, company is making all Types of Switches, Channels, and Plastics Products & Other Electrical Components. DESIGNATION : ENGINEER – Q.C Reporting : Reports to Manager-QC QC Strength : 01 Engineer with 05 Inspectors Duration : 1st Jan 2007 to 17th April 2007 Inspection of Raw Materials, bought-out component checking & Subcontractors components. Checking as Per Drawing Dimensions. Generating Inspection of Finish good & inward inspection, Terminals & channels, Patrol Inspection & process audit done in making of Switch section. Conduct third party inspection from ABB side. Patrol Inspection of SAS Riveting & AUX Switch. Also Verification of Switch-Contact Diagram Controlling as well as reporting to all Quality Non conformances at plant level. Maintain Calibration Report and its History Card. Worked with STANDARAD RADIATOR (P) LTD. at BIDC Vadodara. Company Is Making All Types of copper brass radiator, CAC & Oil cooler and heat Exchanger. DESIGNATION : ENGINEER – Q.C Reporting : Reports to Manager-QC QC Strength : 02 Engineers with 12 Inspectors Duration : 15th September 2005 to 30th December 2006 Man power handling. Check Bought Out Component of Rad. Conduct Product Audit, Patrol Inspection & Process Audit, Calibration Activity. Vendor Audit. Maintain 5S.Kizen & My Machine System. Customer complains analysis. Checked & Analysis of Warranty Radiators. Lay-Out Inspection of OE radiator. Involvement in New product development. Operating knowledge of Minitab-15, SPCXL, Windows 2000/2008, Open and Microsoft Office, World-Excel, Power Point, ERP and SAP QM Module