Research and Developmetn of an Automated Airbrush Paint Spraying Robot

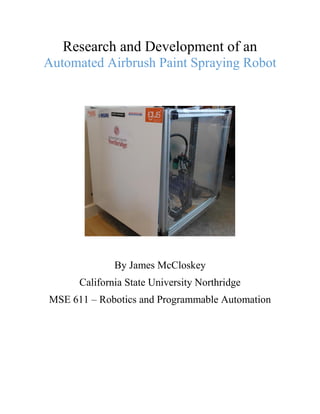

- 1. Research and Development of an Automated Airbrush Paint Spraying Robot By James McCloskey California State University Northridge MSE 611 – Robotics and Programmable Automation

- 2. 2 1 CONTENTS 2 Introduction...........................................................................................................................................3 3 Project Planning and Requirements ......................................................................................................4 3.1 Enclosure: .....................................................................................................................................4 3.2 End Effector:.................................................................................................................................4 3.3 Actuators:......................................................................................................................................5 3.4 Electronics: ...................................................................................................................................6 4 Motor Requirements .............................................................................................................................7 4.1 Motor 1..........................................................................................................................................7 4.2 Motor 2..........................................................................................................................................8 4.3 Motor 3..........................................................................................................................................9 4.4 Motor 4..........................................................................................................................................9 5 Electronics Design ..............................................................................................................................10 5.1 RAMPS 1.4.................................................................................................................................10 5.2 Arduino Mega 2560 ....................................................................................................................11 5.3 A4988 driver...............................................................................................................................11 5.4 NEMA 17 Stepper Motor............................................................................................................12 6 Conclusion ..........................................................................................................................................12 7 Acknowledgements.............................................................................................................................12 8 Appendix A - Wiring Diagram ...........................................................................................................13 9 Appendix B - Bill of Materials ...........................................................................................................14 10 Appendix C – Arduino Sketch........................................................................................................14

- 3. 3 2 INTRODUCTION One of the main limitations with hobbyist 3D printing is that most printers are single filament extrusion and print parts using monochromatic filament. Many hobbyists are forced to spend hundreds of dollars to acquire a collection of multi-colored filaments in order to produce parts in any color. One possible solution to avoid having to purchase multiple spools of pre-colored filament is to airbrush the produced 3D printed parts. Airbrushing produces a streak-free, professional coat of paint that is generally superior to hand painting an object. However, airbrushing a 3D printed part or assembly must be done manually, is time consuming and is heavily dependent on the skill of the artist. The process is prone to human error and often requires multiple rounds of touch ups and rework. This can deter many hobbyists from painting their parts. This project aims to solve these problems by automating the airbrushing of 3D printed parts and assemblies with a low cost robot. Figure 1 - Picture of the robot painting a 3D printed four jaw gripper assembly.

- 4. 4 3 PROJECT PLANNING AND REQUIREMENTS The initial sketch for the robot encompassed five main features: 1. A box frame with panels will enclose the paint area 2. A filter and a ventilation fan 3. An air compressor and airbrush 4. The airbrush will be mounted to a vertical actuator 5. The work piece will be mounted to a rotational plate 3.1 ENCLOSURE: After defining these initial criteria I purchased a 20” box fan from Home Depot. The box fan was measured and an aluminum extrusion 30-30 frame was ordered from MiSUMi using a -$150 promotion, essentially making the aluminum frame free. Once the aluminum frame was built, I purchased a sheet of wood, cut it to size and press fit it into place to create the floor of the robot. The aluminum side panels, plexiglass panel, vinyl cover and Velcro inserts were ordered, cut to size and assembled. 3.2 END EFFECTOR: After defining the initial criteria I purchased an airbrush - air compressor kit from Harbor Freight Tools along with additional airbrush accessories. The airbrush was mounted to the vertical belt drive to spray parts that rotate on the plate. Figure 2 - Sketch of the robot Figure 3 - Robot End Effector (left) and rotating part plate (right)

- 5. 5 3.3 ACTUATORS: Figure 4 - Drilling holes to mount the various motors The next step after building the enclosure was to order a ZLW belt drive from igus as part of their Y.E.S. program. The belt drive was chosen after calculating the estimated airbrush payload and required motor torque. The vertical belt drive actuator was mounted in the enclosure and the stepper motors were installed. The linear guide was a free sample from igus and a machined nut was mounted underneath the carriage. A motor coupled to a lead screw rotates pulling the carriage toward or away from the vertical belt drive actuator when given a command from the microcontroller.

- 6. 6 3.4 ELECTRONICS: Figure 5 - Arduino wiring and enclosure An Arduino Mega with a RAMPS 1.4 shield and four A4988 stepper motor drivers were chosen to control the four stepper motors. Four NEMA-17 stepper motors were chosen because my initial calculations showed that they were able to move each of the payloads. The stepper motors also allowed more accuracy if desired when programming. The Arduino is housed inside of a case that I designed and 3d printed on my own 3d printer.

- 7. 7 4 MOTOR REQUIREMENTS Figure 6 - Motor positions from top view 4.1 MOTOR 1 1. On when power to system 2. Drives forward until carriage hits a limit switch a. Calculated that 50 steps = 0.5 inches of vertical movement 3. Once the motor reaches the top it will wait until the start button is hit Motor 1 Motor 2 Motor 3 Motor 4 Figure 7 - Depiction of paint coverage as motor 1 drives the carriage down

- 8. 8 4. When the start button is pressed the motor will step down 50 steps for each full revolution of motor 3 5. Off when reaches the bottom 6. Restart of power required to restart motor 4.2 MOTOR 2 Figure 8 – Depiction of activated motor 2 moving the airbrush side to side 1. On when start button is pressed after the paint cycle has occurred 2. Assumed to be in center at system start 3. Medium speed rotates approx. 30 degrees left of center to 30 degrees right of center 4. Off when the start button is pressed during the paint cycle and returns back to start position center

- 9. 9 4.3 MOTOR 3 Figure 9 – Depiction of motor 3 on linear guide with lead screw, also underside of lead screw is shown 1. On when motor one reaches top and start button is pressed 2. Rotates continuously in one direction 3. Off when Motor 1 reaches the bottom limit switch 4.4 MOTOR 4 1. On when secondary push button is held down before the paint cycle starts 2. Continuously drives until it hits a limit switch, which causes it to reverse direction 3. If push button is released the next press will drive in the opposite direction

- 10. 10 5 ELECTRONICS DESIGN Figure 10 - System Block Diagram 5.1 RAMPS 1.4 The RepRap Mega Pololu Shield (RAMPS) has been designed to facilitate control of a RepRap 3D printer. RAMPS interfaces with an Arduino Mega 2560 and the modular design includes plug in A4988 stepper drivers and extruder control electronics. For this project the board is used to control four stepper motors, 4 limit switches and 2 momentary switches. The RAMPS 1.4 was chosen because of its low cost and its ability to control up to five stepper motors. Figure 11 - RAMPS 1.4 board

- 11. 11 5.2 ARDUINO MEGA 2560 The Arduino Mega 2560 is a microcontroller board based on the ATmega2560. It has 54 digital input/output pins (of which 15 can be used as PWM outputs), 16 analog inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP header, and a reset button. For this project I am powering the board with a 12V 6amp extra laptop power supply. The Arduino Mega 2560 was chosen because it is required for the RAMPS 1.4 shield. 5.3 A4988 DRIVER The A4988 stepper motor driver carrier is a breakout board for Allegro’s A4988 microstepping bipolar stepper motor driver. The driver features adjustable current limiting, overcurrent and over temperature protection, and five different microstep resolutions (down to 1/16-step). It operates from 8 – 35 V and can deliver up to approximately 1 A per phase without a heat sink or forced air flow (it is rated for 2 A per coil with sufficient additional cooling). The A4988 drivers were chosen because they are required for the RAMPS 1.4 shield. Figure 12 - Arduino Mega 2560 Figure 13 - A4988 driver

- 12. 12 5.4 NEMA 17 STEPPER MOTOR Stepper motors provide more precise control over projects because they utilize a separate pulse for each step. The NEMA-17 will only enter a continuous rotation as the digital pulses grow in frequencies. The speed of this rotation is proportionate to the frequency of the pulses. Here are some of the key characteristics of the motor: Step Angle Accuracy: ±5%(full step, no load) Frame size 42 x 42mm Shaft diameter Φ5mm Number of Leads 4 Step Angle 1.8° Holding Torque 59Ncm(83.6oz.in) Rated Current/phase 2.0A 6 CONCLUSION The robot is successfully able to paint 3D printed parts and assemblies. The project as a whole can be developed further to incorporate advanced kinematics and CAD/CAM geometries. An ideal system would have software that would allow a user to upload a 3D model of their part. The system would determine the optimal paint path and when a user fixtured their part with Velcro the robot would then coat the part. 7 ACKNOWLEDGEMENTS I would like to thank my father for helping me assemble the enclosure and motor mounts, my girlfriend for putting up with my countless hours of tinkering in our apartment and my best friend Kevin for his advice on the Arduino programming. Figure 14 - NEMA 17 Stepper Motor

- 13. 13 8 APPENDIX A - WIRING DIAGRAM This open source wiring diagram for the RAMPS Shield was very helpful when wiring my project. Figure 15 - Wiring Diagram

- 14. 14 9 APPENDIX B - BILL OF MATERIALS 10 APPENDIX C – ARDUINO SKETCH //MOTOR 4 //Low = forward (from motor) //high = backward (to motor) #define X_STEP_PIN 54 #define X_DIR_PIN 55 #define X_ENABLE_PIN 38 //Most backwards #define X_MIN_PIN 3 //Most forwards #define X_MAX_PIN 2 //MOTOR 1 //Low = up //High = down #define Y_STEP_PIN 60 #define Y_DIR_PIN 61 #define Y_ENABLE_PIN 56

- 15. 15 //Lowest #define Y_MIN_PIN 14 //Highest #define Y_MAX_PIN 15 //MOTOR 2 #define Z_STEP_PIN 46 #define Z_DIR_PIN 48 #define Z_ENABLE_PIN 62 #define Z_MIN_PIN 18 #define Z_MAX_PIN 19 //Redefining pins #define START_PIN Z_MIN_PIN #define M4_PIN Z_MAX_PIN //MOTOR 3 #define E_STEP_PIN 26 #define E_DIR_PIN 28 #define E_ENABLE_PIN 24 #define LED_PIN 13 #define PS_ON_PIN 12 #define KILL_PIN -1 #define FULL_REVOLUTION 200 #define MOTOR1_DOWN 50 #define MOTOR2_WIGGLE 15 #define MOTOR2_RETRACT 25 #define DELAY_TIME 1500 #define LOOP_STEPS 20 #define DIR_LEVEL(dir) (dir > 0 ? HIGH : LOW) int lastXDir = -LOOP_STEPS; int xDir = 0, yDir = 0, zDir = 0, eDir = 0; int xCount = 0, yCount = 0, zCount = 0, eCount = 0; boolean xMinHit = false, xMaxHit = false, yMinHit = false, yMaxHit = false; enum STATE { PREP, PAINT, PAINT_MOTOR2, RETRACT, DONE

- 16. 16 }; STATE state = PREP; boolean retractSet = false; boolean m4Pressed = false; boolean startPressed = false; void setup() { pinMode(LED_PIN , OUTPUT); pinMode(X_STEP_PIN , OUTPUT); pinMode(X_DIR_PIN , OUTPUT); pinMode(X_ENABLE_PIN , OUTPUT); pinMode(X_MIN_PIN, INPUT_PULLUP); pinMode(X_MAX_PIN, INPUT_PULLUP); pinMode(Y_STEP_PIN , OUTPUT); pinMode(Y_DIR_PIN , OUTPUT); pinMode(Y_ENABLE_PIN , OUTPUT); pinMode(Y_MIN_PIN, INPUT_PULLUP); pinMode(Y_MAX_PIN, INPUT_PULLUP); pinMode(Z_STEP_PIN , OUTPUT); pinMode(Z_DIR_PIN , OUTPUT); pinMode(Z_ENABLE_PIN , OUTPUT); pinMode(E_STEP_PIN , OUTPUT); pinMode(E_DIR_PIN , OUTPUT); pinMode(E_ENABLE_PIN , OUTPUT); pinMode(START_PIN, INPUT_PULLUP); pinMode(M4_PIN, INPUT_PULLUP); digitalWrite(X_ENABLE_PIN , LOW); digitalWrite(Y_ENABLE_PIN , LOW); digitalWrite(Z_ENABLE_PIN , LOW); digitalWrite(E_ENABLE_PIN , LOW); } void loop() { switch(state) { case PREP: prepLoop(); break; case PAINT:

- 17. 17 case PAINT_MOTOR2: paintLoop(); break; case RETRACT: retractLoop(); break; case DONE: return; } stepMotors(); } void prepLoop() { if(yMaxHit) { yDir = 0; } else { yDir = -LOOP_STEPS; } if(digitalRead(M4_PIN)) { if(!m4Pressed) { m4Pressed = true; lastXDir = -lastXDir; } if(xMaxHit) { xMaxHit = false; lastXDir = LOOP_STEPS; } if(xMinHit) { xMinHit = false; lastXDir = -LOOP_STEPS; } xDir = lastXDir; } else { m4Pressed = false; } if(digitalRead(START_PIN)) { state = PAINT; startPressed = true; yMinHit = yMaxHit = false; } } void paintLoop() { eDir = 1; if(digitalRead(START_PIN)) {

- 18. 18 if(!startPressed) { startPressed = true; if(state == PAINT) { state = PAINT_MOTOR2; } else { state = PAINT; zDir = -zCount; } } } else { startPressed = false; } if(state == PAINT_MOTOR2) { if(zDir == 0) { if(zCount < 0) { zDir = MOTOR2_WIGGLE - zCount; } else { zDir = -MOTOR2_WIGGLE - zCount; } } } if((eCount % FULL_REVOLUTION) == 0) { if(yMinHit) { state = RETRACT; eDir = 0; } else { yDir += MOTOR1_DOWN; } } } void retractLoop() { if(!retractSet) { zDir = zCount >= 0 ? MOTOR2_RETRACT - zCount : -(MOTOR2_RETRACT + zCount); retractSet = true; } if(zDir == 0) { state = DONE; } } void stepMotors() { digitalWrite(X_DIR_PIN, DIR_LEVEL(xDir)); digitalWrite(Y_DIR_PIN, DIR_LEVEL(yDir)); digitalWrite(Z_DIR_PIN, DIR_LEVEL(zDir)); digitalWrite(E_DIR_PIN, DIR_LEVEL(eDir));

- 19. 19 if(zDir) { digitalWrite(Z_STEP_PIN, HIGH); } if(eDir) { digitalWrite(E_STEP_PIN, HIGH); } for(int i = 0; i < 10; i++) { checkLimitSwitch(Y_MIN_PIN, false, &yDir, &yMinHit); checkLimitSwitch(Y_MAX_PIN, true, &yDir, &yMaxHit); if(yDir) { digitalWrite(Y_STEP_PIN, HIGH); } for(int j = 0; j < 2; j++) { checkLimitSwitch(X_MIN_PIN, false, &xDir, &xMinHit); checkLimitSwitch(X_MAX_PIN, true, &xDir, &xMaxHit); if(xDir) { digitalWrite(X_STEP_PIN, HIGH); } delayMicroseconds(DELAY_TIME); if(xDir) { digitalWrite(X_STEP_PIN, LOW); updateCounts(&xCount, &xDir); } } if(yDir) { digitalWrite(Y_STEP_PIN, LOW); updateCounts(&yCount, &yDir); } } if(zDir) { digitalWrite(Z_STEP_PIN, LOW); updateCounts(&zCount, &zDir); } if(eDir) { digitalWrite(E_STEP_PIN, LOW); updateCounts(&eCount, &eDir); } } void checkLimitSwitch(int switchPin, boolean isHigh, int* dir, boolean* limitFlag) { if(digitalRead(switchPin)) {

- 20. 20 *limitFlag = true; if(*dir != 0 && ((isHigh && *dir < 0) || (!isHigh && *dir > 0))) { *dir = 0; digitalWrite(LED_PIN, HIGH); } else { digitalWrite(LED_PIN, LOW); } } } void updateCounts(int* count, int* dir) { if(*dir > 0) { (*count)++; (*dir)--; } else { (*count)--; (*dir)++; } } void old_loop () { if (digitalRead(X_MIN_PIN)) { digitalWrite(X_DIR_PIN , HIGH); digitalWrite(Y_DIR_PIN , HIGH); digitalWrite(Z_DIR_PIN , HIGH); digitalWrite(E_DIR_PIN , HIGH); } else { digitalWrite(X_DIR_PIN , LOW); digitalWrite(Y_DIR_PIN , LOW); digitalWrite(Z_DIR_PIN , LOW); digitalWrite(E_DIR_PIN , LOW); } digitalWrite(X_STEP_PIN , HIGH); digitalWrite(Y_STEP_PIN , HIGH); digitalWrite(Z_STEP_PIN , HIGH); digitalWrite(E_STEP_PIN , HIGH); delay(10); digitalWrite(X_STEP_PIN , LOW); digitalWrite(Y_STEP_PIN , LOW); digitalWrite(Z_STEP_PIN , LOW); digitalWrite(E_STEP_PIN , LOW); }