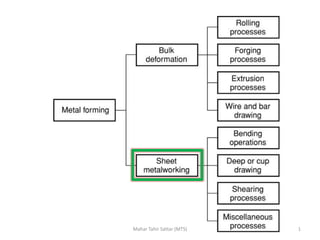

Sheet Metal operation

- 1. 1Mahar Tahir Sattar (MTS)

- 2. 2Mahar Tahir Sattar (MTS)

- 3. Sheet Metal Bending Operations 3Mahar Tahir Sattar (MTS)

- 4. Sheet Metal Bending • It is the operation in which the material in the form of flat sheet or strip is strained perpendicular to the lengthwise direction. • The only movement of the grains in the material takes place at the point where the bend takes place • The outer fibers in the external radius are stretched because they are under tension • The fibers at the inner radius are under compression • At some point within the material the forces are neither compressive nor tensile • This plane of the material is called the neutral bending line (or neutral axis) 4Mahar Tahir Sattar (MTS)

- 5. • Straining sheet metal around a straight axis to take a permanent bend 5(a) Bending of sheet metal Sheet Metal Bending Mahar Tahir Sattar (MTS)

- 6. • Metal on inside of neutral plane is compressed, while metal on outside of neutral plane is stretched 6 (b) both compression and tensile elongation of the metal occur in bending. Sheet Metal Bending Mahar Tahir Sattar (MTS)

- 7. • Bending should take place at right angle to the grain direction • If the bending operation takes place parallel to the grain direction, cracking will develop Sheet Metal Bending Effect of grain direction on sheet metal bending 7Mahar Tahir Sattar (MTS)

- 8. Developed Length • The material before bending is flat stock • The question arises as to how long the flat stock is to be cut so that, once the stock is bent, the finished part will meet the print requirements • The length of the neutral bending line gives the true length of the piece after it has been bent • Its length is the same after bending as before bending 8Mahar Tahir Sattar (MTS)

- 9. Developed Length NOTE: 1. All bending equations that follow are based on the length of the neutral bending line and internal dimensions 9Mahar Tahir Sattar (MTS)

- 10. Bend Lines and Layout Line • The lines where the internal radii are tangent to the legs of a bend are called bend lines A line drawn parallel to, but halfway between, both bend lines is the layout line at which the punch contacts the workpiece • If the internal radius = 0˚, the layout line and bend lines coincide 10Mahar Tahir Sattar (MTS)

- 11. Bend Lines And Layout Line 11Mahar Tahir Sattar (MTS)

- 12. Types of Sheet Metal Bending • V-bending - performed with a V-shaped die, wedge-shaped punch to force the metal into the die • The included angle of the V-bend can be changed by varying the distance the punch forces the sheet-metal into the V-die • Characteristics • Used for low production • Performed on a press brake • V-dies are simple and inexpensive 12Mahar Tahir Sattar (MTS)

- 13. V-bending • When the punch does not ‘bottom out’, the processes are referred to as air bending • In air bending the material being formed contacts only at the point of the punch and two edges of the V-die opening 13 V-bending (air bending) Mahar Tahir Sattar (MTS)

- 14. V-bending • When the punch is allowed to bottom out in the V-bend die, it is called the bottoming die 14 V-bending (bottoming) Mahar Tahir Sattar (MTS)

- 15. • Also called ‘cantilever’ bend dies • The workpiece is clamped to a die block by a spring- loaded pressure pad • The punch wipes the extended material over one edge of the die • For high production • Dies are more complicated and costly 15 Edge Bending Edge bending Mahar Tahir Sattar (MTS)

- 16. TYPES OF BENDING DIES 3. U-dies or Channel Dies: • The workpiece produced resembles the letter ‘U’ or channel Mahar Tahir Sattar (MTS) 16

- 17. V-Bending Dies 17Mahar Tahir Sattar (MTS)

- 18. Bend Allowance • If the bend radius is small relative to stock thickness, the metal tends to stretch during bending. It is important to be able to estimate the amount of stretching that occurs, if any, so that the final part length will match the specified dimension. • The problem is to determine the length of the neutral axis before bending to account for stretching of the final bent section. This length is called the bend allowance, and it can be estimated as follows: 18Mahar Tahir Sattar (MTS)

- 19. Bend Allowance 19Mahar Tahir Sattar (MTS)

- 20. Springback • Increase in included angle of bent part relative to included angle of forming tool after tool is removed • Reason for spring back: – When bending pressure is removed, elastic energy remains in bent part, causing it to recover partially toward its original shape • Over bending is the simplest way of combating spring back problems • The workpiece is bent through a greater angle than required and it springs back to the required angle 20Mahar Tahir Sattar (MTS)

- 21. Springback in bending is seen as a decrease in bend angle and an increase in bend radius: (1) during bending, the work is forced to take radius Rb and included angle b' of the bending tool, (2) after punch is removed, the work springs back to radius R and angle ‘. 21 Springback Mahar Tahir Sattar (MTS)

- 22. Bending Force Maximum bending force is estimated as follows: 22 where F = bending force; TS = tensile strength of sheet metal; w = part width in direction of bend axis; and t = stock thickness, D = die opening dimension. For V- bending, Kbf = 1.33; for edge bending, Kbf = 0.33 D wtTSK F bf 2 )( Mahar Tahir Sattar (MTS)

- 23. Die opening dimension D: (a) V-die, (b) wiping die. 23 Die Opening Dimension Mahar Tahir Sattar (MTS)

- 24. Other Bending Operations • Flanging is a bending operation in which the edge of a sheet metal part is bent at 90°angle • It is often used to strengthen or stiffen sheet metal 24 Flanging: (a) straight flanging, (b) stretch flanging, and (c) shrink flanging Mahar Tahir Sattar (MTS)

- 25. Other Bending Operations • Hemming (also called flattening) involves bending the edge of the sheet over on itself • Usually performed in more than one bending step • Used to eliminate the sharp edge on the workpiece, to increase stiffness, and to improve appearance 25 Hemming Mahar Tahir Sattar (MTS)

- 26. Other Bending Operations • Curling, also called beading, forms the edges of the part into a roll or curl • Done for purposes of safety, strength, and aesthetics 26 Curling Mahar Tahir Sattar (MTS)

- 27. Curling • It rolls a raw edge of sheet metal into a roll or curl • The metal needs to be ductile so that it rolls easily TYPES OF FORMING DIES Mahar Tahir Sattar (MTS) 27

- 28. Other Bending Operations • Seaming is a related operation in which two sheet metal edges are assembled obtained after the hemming. • Staking is a method of fastening sheet metal by squeezing protrusion formed in one part inside a hole in the second part, and then deforming the protrusion 28 Staking Mahar Tahir Sattar (MTS)