Supply Chain Position Descriptions.pdf

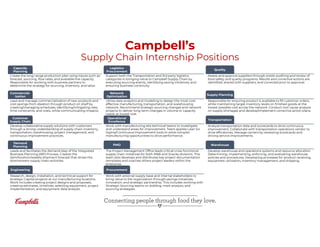

- 1. Campbell’s Supply Chain Internship Positions Capacity Planning Create the long-range production plan using inputs such as forecast, sourcing, flow rates, and available line capacity. Responsible for working with business partners to determine the strategy for sourcing, inventory, and labor. Commercial- ization Lead and manage commercialization of new products and cost savings from ideation through product on shelf by creating/managing schedules, identifying/mitigating risks, time constraints, and costs, while communicating impacts. Customer Supply Chain Develop collaborative supply solutions with customers through a strong understanding of supply chain inventory, transportation, warehousing, project management, and continuous improvement practices. Demand Planning Leads and facilitates the demand step of the Integrated Business Planning (IBP) Process. Creates the item/location/weekly shipment forecast that drives the downstream supply chain activities. Engineering Research, design, installation, and technical support for strategic Capital projects at our manufacturing locations. Work includes creating project designs and proposals, creating estimates, timelines, selecting equipment, project implementation, and equipment data analysis. Quality Assess and approve suppliers through onsite auditing and review of food safety and quality programs. Results and corrective actions are identified, shared with suppliers, and corrected prior to approval. Supply Planning Responsible for ensuring product is available to fill customer orders, while maintaining target inventory levels on finished goods at the lowest possible cost across the network. Conduct root cause analysis on supply shortages and develop/implement corrective action plans. Transportation Analyze transportation data and scorecards to drive continuous improvement. Collaborate with transportation operations vendor to drive efficiencies. Manage carriers by reviewing scorecards and driving service improvements. Warehouse Develop warehouse and operations systems and resource allocation. Determining, implementing, enforcing, and evaluating warehouse policies and procedures. Developing processes for product receiving, equipment utilization, inventory management, and shipping. Logistics Procurement Support both the Transportation and 3rd party logistics categories in bringing value to Campbell Supply Chain by executing sourcing events, identifying saving initiatives, and ensuring business continuity. Network Optimization Utilize data analytics and modeling to design the most cost- effective manufacturing, transportation, and warehousing network. Recommend strategic sourcing changes and network projects to deliver long-term changes in volume or capacity needs at lowest cost. Operational Excellence Work with manufacturing site technical teams to investigate and understand areas for improvement. Team applies Lean Six Sigma/Continuous Improvement tools to solve complex manufacturing opportunities to drive performance. PMO The Project Management Office leads critical cross-functional supply chain initiatives for both M&B and Snacks divisions. This team also develops and distributes key project documentation templates and coaches others project leaders within the enterprise. Procurement Work with external supply base and internal stakeholders to bring value to the organization through savings initiatives, innovation, and strategic partnership. This includes working with Strategic Sourcing teams on bidding, mark analysis, and sourcing strategies.