EDWARD JOSE VERA DOUGLAS CV 2016 R

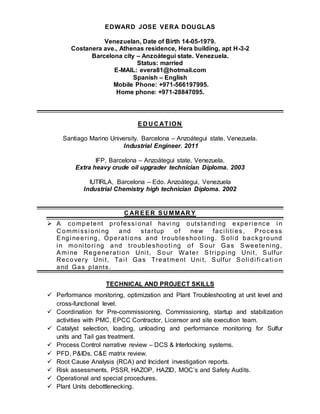

- 1. EDWARD JOSE VERA DOUGLAS Venezuelan, Date of Birth 14-05-1979. Costanera ave., Athenas residence, Hera building, apt H-3-2 Barcelona city – Anzoátegui state. Venezuela. Status: married E-MAIL: evera81@hotmail.com Spanish – English Mobile Phone: +971-566197995. Home phone: +971-28847095. ED U C ATION Santiago Marino University. Barcelona – Anzoátegui state, Venezuela. Industrial Engineer. 2011 IFP, Barcelona – Anzoátegui state, Venezuela. Extra heavy crude oil upgrader technician Diploma. 2003 IUTIRLA, Barcelona – Edo. Anzoátegui, Venezuela Industrial Chemistry high technician Diploma. 2002 C AR EER SU MMAR Y A competent professi onal havi ng outstandi ng experi ence i n C ommi ssi oni ng and startup of new faci li ti es, Process Engi neeri ng, Operati ons and troubleshooti ng. S oli d background i n moni tori ng and troubleshooti ng of Sour Gas Sweeteni ng, Ami ne Regenerati on Uni t, Sour Water Stri ppi ng Uni t, Sulfur Recovery Uni t, Tai l Gas Treatment Uni t, Sulfur Soli di fi cati on and Gas plants. TECHNICAL AND PROJECT SKILLS Performance monitoring, optimization and Plant Troubleshooting at unit level and cross-functional level. Coordination for Pre-commissioning, Commissioning, startup and stabilization activities with PMC, EPCC Contractor, Licensor and site execution team. Catalyst selection, loading, unloading and performance monitoring for Sulfur units and Tail gas treatment. Process Control narrative review – DCS & Interlocking systems. PFD, P&IDs, C&E matrix review. Root Cause Analysis (RCA) and Incident investigation reports. Risk assessments, PSSR, HAZOP, HAZID, MOC’s and Safety Audits. Operational and special procedures. Plant Units debottlenecking.

- 2. Leadership & Management skills Manpower planning and task allocation as per company targets Area objectives framing and goal setting activities. Training Plan and certification. Annual budgeting (OPEX) and forecast for CAPEX. Achievements Enlarged capacity of Sulphur Recovery Units of Al Hosn Gas by 25% after successfully reducing Fuel Gas co-firing for the Reaction furnaces, which represents a cost saving in OPEX of USD 1,000,000 and reduced significantly the SOW for the expansion project. Successful Start Up, stabilization and performance of GTR of Sulphur Recovery Units (10,000 MTD) in Al Hosn Gas – Abu Dhabi (Largest Ultra Sour Gas producer in the world) within schedule. Coordination of safe and reliable startup of Sulfur complex units (1,300 MTD) in SATORP – Saudi Arabia (7th largest refinery in the world) within schedule. Successful training and certification of Field Operators/Boardman for Sulfur Recovery Units in SATORP (2013) and PDVSA Petropiar (2010) Successful RCA related to High Amine losses in PDVSA Petropiar and Technical recommendation (2009) Successful Shutdown coordination for the first Major T&I at Petrolera Ameriven (2009). Participation as Boardman during startup of Sulfur complex units (600 MTD) in Petrolera Ameriven Upgrader (2nd largest in Venezuela). (2004). PR OFESSION AL EXPER IEN C E Al Hosn Gas. May 2015 - current ADNOC and OXY join venture. Abu Dhabi, UAE. Designation: Sr. Process Engineer. Issuance of daily reports including evaluation and recommendations to operations to keep within the Operating Windows the critical parameters of the Sulphur Recovery Units by using PHD and Lab reports. Prepared plan protocol and delivered technical reports for special activities. Follow up of monthly chemical consumption and provision of comments for the issuance of monthly reports by HQ in order to reduce costs. Provided support to shift superintendents by giving clears guidelines in front of units upsets. Troubleshooting in coordination with other supporting disciplines for the failure of control loop elements (Degassing contactor OVHD control valves plugging, pH analyzer malfunction due to probe choking). MOC responsible for minor projects within the Area of responsibility until the implementation.

- 3. Provided technical support for company claims (WNR) against EPC contractor. Team Leader for Incidents Investigation as requested by Technical Manager for Tier 3 incidents. SATORP. April 2012 – May 2015 Saudi Aramco and Total refining and petrochemical. Jubail, Saudi Arabia Designation: Sr. Operations Engineer. Contact person for references: Tomas Lovera- Operations Superintendent PH#+971-508076436 Successful coordination as technical authority for the completion of the Pre- commissioning and Commissioning activities of the Sulfur Complex process units. (FAT, box up, instrument loop checks, ESD checks, complex loop checks, chemical filling, refractory dry out, degreasing of amine units, boilers soda boil out and passivation, catalyst loading and activation, rotating equipment tests). Acting Operations Superintendent in SATORP for two months as part of career development plan. Participation in HAZIDS for Simultaneous Operation (SIMOPS) Coordinator for the startup, stabilization and PTR of Sulphur Complex Units. Completed troubleshooting for process upsets (HC carryover in Amine units, Sulphur Degassing column fouling, Sulfur rundown line plugging) Completed RCA for SRU Reaction Furnace refractory failure in second zone nozzle. Validation of Process Operating Windows. Provided support for the implementation of the Process Information (PIMS) and Operation Dashboard System. Participation in the training and certification for the new Field Operators and Boardman. Team Leader for the MOC process within the Area. Leader of Incident investigations and risk assessments of unusual operation/ maintenance activities within the Area. PDVSA-PETROPIAR January 2010 – April 2012 Chevron-Texaco/PDVSA Puerto La Cruz, Venezuela Designation: Area Leader of Sulphur complex. Contact person for references: Jose Barrera- Operation Superintendent PH#+584166935827 Provision of technical instructions to operations shift teams in order to achieve production planning goals. Responsible for quality control adjustments as necessary to get products within specifications in coordination with process engineering department. Accountable for the implementation of safety and security policies and operational procedures Coordinator of shift schedule including: work station assignments/rotations, training, vacations, overtime assignment and back up for absent employees

- 4. Responsible for the appraisal of the shift personnel, definition for need of improvement and implementation of career development plant by ensuring progressive training and certifications. Coordination of maintenance activities that are executed in the area in conjunction with the maintenance leader. PDVSA-PETROPIAR/ PETROLERA AMERIVEN September 2003 – December 2009 Chevron-Texaco/Conoco-Phillips/PDVSA. Puerto La Cruz, Venezuela Designation: Sulphur Area Boardman Responsible for the correct and safe operation of plant equipment. Monitoring and control of all process variables such as temperature, pressure, flow and levels of drums, vessels, columns, reactors, considering mass balance and another process protocols to keep the production up according the company production goals. Monitoring, control and operation of chillers, heat exchangers, centrifugal pumps, centrifugal and reciprocating compressors, heater, stripper, amine scrubber, thermal reactors and catalytic reactors from distributed control systems. Report of shift activities during using electronic Log Book. Coordinator and supervisor of commissioning and Start Up activities necessary for the plant start-up (control´ loops and instrumentation tests). Responsible for the correct and safe operation of plant equipment. Carry out the process verification to support the start up procedures Prepare the individual units start up, normal operation an shut down procedures Assist in preparing preservation plans and procedures. Assist in defining the safety requirements of facilities start up. PETROLERA AMERIVEN May 2002 – August 2003 Chevron-Texaco/Conoco-Phillips/PDVSA Puerto La Cruz, Venezuela Designation: Pre-Commissioning and Commissioning Field Supervisor Follow up of pre-commissioning activities necessary for the plant start-up. Activity includes: Tank cleaning, water flushing, air blowing, chemical cleaning, degreasing, dry out, boil out, system drying, tightness test, air freeing of pipelines, preparation of product loading pumps, Steam trace systems. Commissioning of plant systems and equipment such as Amine Unit, Sour Water Stripped Unit, Sulfur Recovery Units, Tail Gas Units, Sulfur Prillers Unit, Oil Water System, Chemical Injection Packages, Loading Pumps, Truck Loading System. Responsible for the correct and safe operation of plant equipment (instrument, stationary, and rotating). Routine monitoring and inspection of running units during operation. Conferences: Contributor of MESPON conference (2015) and attended as delegate for Al Hosn Gas (2016). Attended BRIMSTONE conference (2015, 2016) and nominated as member of Board committee.

- 5. Training ● 2014. Heat Stable Salts Removal. ECO-TECH. ● 2013. TGT heaters. Hamworthy. ● 2012. Sulfur Area licensor´s training. TKT spa. ● 2012. ARU and SWS process. Amine Experts. ● 2012. Work permit. SATORP ● 2012. SAP. SATORP. ● 2011. Sulfur recovery and TGT units´ catalyst training. Axens. ● 2010. Operation of the TDC 3000 LCN network. Honeywell. ● 2010. Train the trainer. PDVSA Petropiar. ● 2009. Turnaround process. PDVSA Petropiar. ● 2008. Amine Treatment. Huntsman. ● 2007. Lube oil and cooling System. (API Plans), John Crane. ● 2004. Motor Control Center Operation (CCM). Baker. ● 2004. Safety in Confined Spaces. Petrolera Ameriven ● 2004. Behaviour Based Safety. Petrolera Ameriven. ● 2004. Centrifugal compressors, operation and maintenance. GE Energy Oil and Gas. ● 2004. Centrifugal Pumps, Operation and maintenance. GE Energy Oil and Gas. ● 2004. Root Cause Advance investigation Team leader course. Iacept. ● 2003. Responsibility, Emotional Intelligence and Achievement of Goals, CAPEFI ● 2003. Basic Radiation Protection. IVIC ● 2003. Radiological Emergencies Workshop. IVIC ● 2003. Reliability Centered Maintenance. Simon Bolivar University.