Evaporators

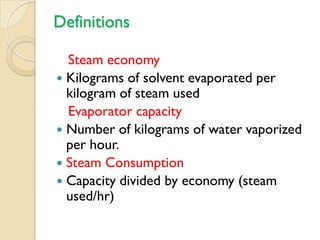

- 1. Definitions Steam economy Kilograms of solvent evaporated per kilogram of steam used Evaporator capacity Number of kilograms of water vaporized per hour. Steam Consumption Capacity divided by economy (steam used/hr)

- 2. Single Effect Evaporators When a single evaporator is used , the vapor from boiling liquid is condensed and discarded. This method is single effect evaporation It is simple, but use steam ineffectively i.e. steam economy is low, so to evaporate one kg of water from solution 11.3 kg steam is required

- 3. Cont… Thick Liquor Condensed vapor

- 4. Where single effect are used Single-effect evaporators are used when the throughput is low when a cheap supply of steam is available when expensive materials of construction must be used as is the case with corrosive feed stocks when the vapor is so contaminated so that it cannot be reused For liquids that boil at high temperatures (high boiling-point elevation liquors)

- 5. Operation of single effect evaporator Single effect units may be operated in batch, semi- batch or continuous batch modes or continuously Batch Operation Batch units require that filling, evaporating and emptying are consecutive steps Such a method of operation is rarely used since it requires that the vessel is large enough to hold the entire charge of feed and that the heating element is low enough to ensure that it is not uncovered when the volume is reduced to that of the product

- 6. Cont… Semi-Batch Operation Semi-batch is the more usual mode of operation in which feed is added continuously in order to maintain a constant level until the entire charge reaches the required product density Continuous-Batch Operation Have a continuous feed and, over at least part of the cycle, a continuous discharge

- 7. Cont… often a feed drawn from a storage tank is returned until the entire contents of the tank reach the desired concentration The final evaporation is then achieved by batch operation Continuous Evaporator continuous evaporators have a continuous feed and discharge and concentrations of both feed and discharge remain constant

- 8. Multiple Effect Evaporators Three methods are available which enable the performance to be improved, either by direct reduction in the steam consumption or by improved energy efficiency of the whole unit Multiple effect operation Recompression of the vapor rising from the evaporator Evaporation at low temperatures using a heat pump cycle

- 9. Multiple Effect Operation If vapor generated from the first effect is used for heating in the 2nd effect, and then vapor from the 2nd effect is sent to a condenser, the operation becomes double effect. Addition effects can be added similarly Method of increasing the evaporation/kg of steam by using a series of evaporators b/w steam supply and condenser is called multiple-effect evaporation.

- 10. Cont…

- 11. Cont… First Effect, in which steam is fed and in which the pressure in the vapor space is the highest (for liquid transfer b/c no pump used) and in last effect it is minimum. Thick liquid out from last effect but it depends on feeding arrangement The boiling point in 2nd effect must be reduced, b/c by concentrating, solution B.P increases, also vapor heat content reduces going from first effect to 2nd. B.P. can be reduced by reducing pressure or applying vacuum.

- 12. Calculations for forward feed system

- 13. Cont… For three evaporators arranged as shown in Figure, in which the temperatures and pressures are T1,T2,T3, and P1, P2, P3, respectively, in each unit, then the heat transmitted per unit time across each effect is Effect 1 Q1 =U1A1∆T1, ∆T1= (T0 − T1) Effect 2 Q2 = U2A2 ∆ T2, ∆ T2=(T1 − T2) Effect 3 Q3 = U3A3∆ T3, ∆ T3 = (T2 − T3) T0 is steam température

- 14. Cont… Neglecting the heat required to heat the feed from Tf to T1, the heat Q1 transferred across where A1 appears as latent heat in the vapor D1 and is used as steam in the second effect, so Q1 = Q2 = Q3 U1A1∆T1 = U2A2∆T2 = U3A3∆T3 If, as is commonly the case, the individual effects are identical, A1 = A2 = A3, Then U1∆T1 = U2∆T2 = U3∆T3

- 15. Cont… The latent heat required to evaporate 1 kg of water in 1, is approximately equal to the heat obtained in condensing 1 kg of steam at T0. Thus 1 kg of steam fed to 1 evaporates 1 kg of water in 1. Again the 1 kg of steam from 1 evaporates about 1 kg of steam in 2. Thus, in a system of N effects,1 kg of steam fed to the first effect will evaporate in all about N kg of liquid, so economy increase with number of effects

- 16. Cont… The water evaporated in each effect is proportional to Q, since the latent heat is approximately constant. Thus the total capacity is: Q = Q1 + Q2 + Q3 = U1A1∆T1 + U1A2∆T2 + U3A3∆T3 If an average value of the coefficients Uav is taken, then: Q = Uav(∆T1 + ∆T2 + ∆T3)A Q = UavA∆T

- 17. Heat Balance on Forward Feed Effect 1: D0λ0 = GFCp(T1 − Tf ) + D1λ1 D0 is steam flow rate to 1st effect, at λ0 latent heat of vaporization Effect 2: D1λ1 + (GF − D1)Cp(T1 − T2) = D2λ2 Effect 3: D2λ2 + (GF − D1 − D2)Cp(T2 − T3)= D3λ3

- 18. Feeding Arrangement Forward Feed Conc. of liquid increase from 1st effect to last effect Pump is required to feed dilute solution to 1st effect & for thick liquid in last effect Transfer b/w effects can be done with out pumps b/c its in decreasing order

- 20. Cont… Backward Feed Dilute feed is fed to last effect and pumped back to 1st effect Additional pumps b/w effects are required b/c flow is from low pressure to high pressure Gives higher capacity for viscous feed Gives low economy for cold feed

- 21. Cont…

- 22. Cont… Mixed Feed Dilute liquid enters in intermediate effect Flow back to first effect, where final conc. Is done at highest temp It eliminate some of the pumps required b/w effects

- 23. Cont…

- 24. Cont… Parallel Feed For crystallization operation, where slurry crystals and mother liquor is drawn, parallel feed arrangement is used. No transfer of liquid b/w effects and no pumps required

- 25. Cont…

- 26. Thank You for Your Attention